A septic tank is a container into which, if the site does not have a drain to the central sewer system, household and household wastewater is collected. Inside they accumulate, settle, purify or are simply pumped out. Traditional materials are concrete, brick, and recently ready-made factory containers have been used.

A concrete septic tank - prefabricated or monolithic - can be made with your own hands. Even taking into account materials, excavation work, and delivery services, building will cost less than buying and installing a ready-made factory module. But to do this, you need to understand the principles of operation of the structure and correctly carry out calculations and installation.

Rules and regulations

The guide for the design, construction and operation of septic tanks is the Code of Rules 32.13330.2012 “Updated edition of SNiP 2.04.03-85 “Sewerage. External networks and structures."

When drawing up a network laying diagram, you also need to study:

- SNiP 2.04.01-85 Internal sewerage and water supply networks;

- SNiP 2.04.03-85 Sanitary protection zones.

Their rules are focused primarily on preserving the quality of soil and water sources near a private home.

Drain modules are located:

- From wells and wells of drinking water at a distance of at least 30 m (this is minimal, and works provided that the water intake is located higher in the direction of groundwater flow). For areas with highly permeable sandy soils - 50 m.

- From bodies of water (rivers, lakes, streams) - at least 30 m.

- From roads - a distance of at least 4 m.

- From plantings - at least 4 m.

- From the border of the neighboring plot - at least 2 m.

The tank itself is located more than 5 m on the plan from the country house. Sewer pipes should be laid at a distance of at least 3 m from permanent foundations. This will protect both the foundation (from erosion in the event of a breakthrough) and the networks themselves (when the building shrinks, it “pulls” nearby soils with it, damaging communications).

You will have to abandon the septic tank in 2 cases:

- if the soils on the site are too low-permeable (for example, clayey), the drained liquid simply cannot filter through them;

- when the groundwater level is too high.

Typically, the container and filtration field are located at the lower elevations of the site to facilitate gravity flow. It is advisable to place the diagram on the drawing so that the pipe going into the container has as few turns as possible - they are the ones that become clogged in the first place.

It may be impossible to fulfill all these requirements in a real situation. Therefore, it is necessary to carry out the most critical ones and to include additional volumes and strength in the design beyond the calculated ones.

How to make a septic tank on the site

To design a concrete septic tank on a site, you first need to decide on the type of construction itself. A septic tank can be made from ready-made reinforced concrete products, filled in yourself, or purchased completely ready-made.

Each option has certain pros and cons.

Installation of ready-made structures

The finished product is the easiest way to arrange a septic tank. It will not be difficult to select a design at the factory that exactly matches absolutely all the parameters - many manufacturers offer properly designed, reliable septic tanks with overflow holes, hatches, and covers. You can find models that come with sump pumps and not have to worry about where to drain the water from the septic tank.

Having purchased a ready-made reinforced concrete septic tank, it is enough to simply install fittings and pipes. The main advantages of a ready-made septic tank: the sewerage system is installed in the shortest possible time, there is no need to carry out expensive, dirty and heavy concrete work.

It is also worth noting that factory designs guarantee strength, reliability and guarantee protection against errors during the design process.

Disadvantages include the relatively high cost (purchase, delivery, installation on site), the need to use lifting equipment and special vehicles. If the site is small and there is no convenient access, then you will have to consider other options for constructing a septic tank.

Septic tank made of reinforced concrete rings

Water purification using a sewer system created from reinforced concrete rings is carried out according to the same principle as in the case of a ready-made septic tank. It’s just that here you will have to do the bulk of the work yourself.

Stages of constructing a septic tank from reinforced concrete rings:

- Choosing a location on a site, performing calculations, digging a pit - it is better to use machinery, but it can also be done manually. The dimensions of the pit should be slightly larger than the dimensions of the septic tank.

- Concreting the bottom - you can use a reinforced concrete slab or reinforce it with steel rods and pour the solution yourself.

- Installation of rings - they are lowered into the pit using a winch or lifting equipment, and installed one on top of the other. It is advisable to make holes for sewer and ventilation pipes in advance.

- Sealing of joints - treatment with waterproofing materials, sealing with cement.

- Backfilling can be done with the soil that was dug up, or with sand. Fill them with layers of 10 centimeters and compact them carefully so as not to damage the pipes.

Among the disadvantages of this method, mention should be made of the costs of delivery/installation of rings and the entire system, and the need to attract equipment.

Filled septic tank

Self-pouring a concrete septic tank is the cheapest, but labor-intensive and time-consuming option for arranging a sewerage system. But such a design turns out to be reliable, durable, hermetically sealed, and monolithic.

How to fill a septic tank:

- Design, choosing a location, digging a pit in accordance with the volume of the structure, backfilling a layer of sand 20 centimeters thick, tamping.

- Creating a mesh with cells of 20x20 millimeters from steel rods with a cross-section of 10 millimeters and knitting wire. Clamps or stones are laid at the bottom of the pit, and a metal mesh is placed on top.

- Filling the structure with concrete of minimum strength class B15, compacting, waiting for hardening for 2-14 days.

- Pouring walls with preliminary reinforcement and installation of formwork. If the formwork is done carefully, the walls will be smooth; they can be covered with roofing felt or two-layer film (then you can do without backfilling the soil). Before pouring the walls, pipes are installed. The structure must be monolithic, so it is better to fill it at a time.

- Dismantling the formwork, filling cracks with mortar (if any), applying a layer of mastic for waterproofing.

- Laying a welded frame from a metal angle around the perimeter of the walls (for the cover), fastening the slate, pouring concrete with reinforcement. Wait at least 14 days for the concrete to set.

- Installing hatches, backfilling a concrete septic tank with soil or sand.

Such work can be carried out in any area (even where access to special equipment is limited), the design is seamless, monolithic, so groundwater does not get inside and wastewater does not go into the ground.

Calculation of volume for self-production

If only domestic sewage flows into the tank, then its volume is calculated from the minimum established by SNiP - 0.2 m3 per day per person. The minimum settling period (for consumption less than 5 m3 per day) is 3 days. With higher water consumption – 2.5 days. In total, for 4 people the volume of the container will be from 2.4 m3, and taking into account silt sediment - from 2.7 m3. The larger the reserve volume of the septic tank, the less likely it is that sludge will fill the entire working glass. But you need to remember that the capacity of a standard sewer truck tank is no more than 4 cubic meters.

Types of concrete structures and operating principle

Let's consider various options:

- Single-chamber . Suitable for small and irregular volumes of waste discharge - for example, for a summer cottage where people come for the weekend. Wastewater enters, accumulates and settles in a sealed tank. Primary (anaerobic) cleaning is carried out. Mineralized sediment (so-called activated sludge) is pumped out as it accumulates - on average 1-2 times per season. Primary purified water can be used for economic purposes.

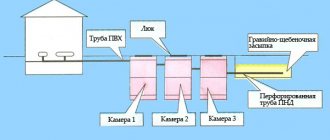

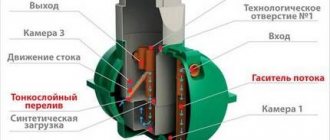

- Two-chamber . From the first purifier, through an overflow, water enters the aerobic filtration chamber, where it undergoes additional purification. The second compartment, unlike the first, requires ventilation - and therefore is equipped with an air intake and often a compressor. From this chamber the liquid goes to the filtration field.

- Three-chamber . In them, work is underway to uniformly drain water into the ground through additionally added layers of sand and crushed stone; a third container is carried out - the purification column.

Attention! When calculating the volume of a septic tank, the “working” size is considered to be the size of the primary treatment tank (with the height from the bottom to the outlet) and the volume of the secondary treatment tank (calculated similarly).

Selection of design scheme

The number of containers is selected based on the task at hand. That is, the cleaner the water should be at the outlet, the more compartments there should be inside the septic tank. Therefore, there may be one, two or three.

One camera

This is not much different from a cesspool because the sewage is collected inside a constructed container. This is where solid particles settle. Partially clarified water forms on top.

Not the best option, because the efficiency of sewage treatment here is low.

Two cameras

As stated above, this is a frequently used design. This is a large septic tank - monolithic reinforced concrete, which is divided by a partition. The height of the latter is 10 cm less than the same size of the container itself. This is done on purpose so that the water accumulated in the first compartment can easily flow into the second. Here it will be purified further due to the precipitation of small particles of sewage. This partition is called overflow.

There is another option when this wall is made the same height as the others. Then holes are made in it to drain the water.

Three cameras

This type is not often used because it is more expensive to construct. But the efficiency of wastewater treatment is maximum here. Purely structurally, this is a two-chamber version, to which another overflow has been added. The photo below shows this option.

Attention! The first chamber for receiving sewage from the house is made twice as large as the others. It is she who takes on the main share of the cleansing process.

Designs without pumping: myth or reality

Even if only water from sinks is drained into the container, the liquid inevitably becomes contaminated with solid particles, grease, and food waste. In the primary treatment drain, it decomposes into methane, liquid waste and mineral sediment that forms at the bottom. Cleaning may be required from 3–4 times a year, to once every 5–7 years. But it will be necessary.

Conventionally, “without pumping” you can make containers that:

- They have sufficient volume.

- They are operated regularly (or properly “started up” at the beginning of each operating season).

- They are not forced to work with complex contaminants (chlorination, soaping, aggressive cleaning agents, accumulated fat - all this harms the bioflora, and active siltation occurs).

Purpose

The name of this device has Greek roots and comes from the word rotten.

In simple terms, these are special underground chambers that consist of one or several compartments through which various organic liquids and waste enter. Concrete septic tanks do not function as independent structures; they are used together with special post-treatment. Post-treatment is carried out underground. It follows from this that it cannot be said that this structure cannot cope with the tasks of treating wastewater and waste. At dachas, concrete septic tanks are used to collect and treat organic waste and wastewater. The resulting sediment, after purification, is mineralized and can be used as fertilizer for plants and trees that grow in the country.

Concrete: pros and cons

Advantages:

- Price. Even taking into account delivery, installation with the work of a crane and earth-moving machines, a self-made concrete drain will still cost 5–7 times more than a finished one of a similar container.

- Massiveness. Freezing soil with a lot of water, expanding, can push the container out. Therefore, light tanks require additional anchoring. Concrete products are held under their own weight.

- Strength. Factory sections or self-made containers that have achieved the design strength can withstand compression, impacts, and heavy weight without cracking.

- Possibility of repair. Even in the event of a leak or corrosion, it is possible to repair the damaged area yourself.

Flaws:

- It is necessary to take into account all operating conditions and site features. Incorrect slopes, clogging, freezing, and uneven shrinkage can make the drain ineffective.

- Large volume of concreting, heavy sections, sometimes problems with the tightness of joints.

Concrete septic tanks can be made independently from start to finish. Wherein:

- no need to deliver and install heavy sections;

- it is possible to produce a product of non-standard diameter;

- fewer sealed joints;

- it is easier to make holes for communications;

- the cost of the product is lower.

Work cycle and material consumption

The sewer pipe leaving the dacha must be thermally insulated and laid to a depth of half a meter (depending on the degree of soil freezing). Its slope is 1.5–2 cm per linear meter (preferably 3 cm), an inspection is installed every 15 m. It is insulated, usually with polystyrene foam; it is also possible to lay a heating electric cable, which is connected in cold weather. The final level of the outlet pipe will be the height of the entry into the first tank.

The bottom of the chamber is at a level of at least 3.5 m - this is the length of the pump of the sewer truck.

We calculate materials

The volume of a reinforced concrete ring with a diameter of 1 m is 0.7 m3;

1.5 m – 1.59 m3;

2 m – 2.83 m3.

For a typical reinforced concrete septic tank with two chambers, two one and a half meter rings or four one-meter rings will be sufficient.

If you make your own casting for a similar structure, you will need about 400 kg of Portland cement, 600 kg of sifted sand, 200 liters of water, as well as reinforcing bars, formwork boards, and plastic film.

Construction technology

In order for the structure to be durable and of high quality, before starting construction, it is necessary to carefully prepare. First, you should familiarize yourself with the list of requirements that the sanitary and epidemiological station imposes on such installations:

- the installation should be no closer than 6 meters to the house;

- be sure to install rubber tanks;

- the pipe through which waste flows must be below the freezing level of the ground;

- the pipe must have a slope for every 2 cm of each meter of pipe.

- the total amount of organic waste and wastewater for 1 day;

- the volume of the installation must be at least 3 times the total amount of incoming wastewater;

- if the water consumption per day is no more than 1 cubic meter, then a single-chamber installation is sufficient.

To install a septic tank, a certain list of materials and tools is required:

- cement mortar for concreting;

- sewerage pipes;

- bitumen;

- tee;

- ventilation pipes;

- crushed stone;

- slate;

- hacksaw for cutting pipes;

- shovel;

- Master OK;

- ladder;

- container for mixing the solution.

To use a concrete septic tank, it is important to follow the construction technology. First you need to dig a pit

To install the structure, it is necessary to equip a special pit. The dimensions of the pit must meet the required data. In such a situation, they dig one hole. Afterwards it is divided in two. Each part will be a specific component in the treatment of organic waste

It is during this process that it is worth taking into account the level of freezing of the ground. To prevent the soil from falling off, you need to use plastic film.

In addition to the pit, it is necessary to dig trenches of a certain size for laying pipes. Drain pipes must be placed at an angle.

The next step is to strengthen the walls of the pit. To save resources, you can do this using sliding formwork.

It is performed for half of the pit, and then, after filling and drying, it is transported to another compartment of the pit. The panels are made of wood, mounted and fastened to each other using timber. They are fixed in the ground about 5-10 centimeters. They make holes to install pipes that are laid from housing. Installation takes place over a length of about 35 centimeters. Before you start filling the hole with mortar, the formwork must be strengthened with reinforcing bars. This is necessary so that the future installation will be more durable. Metal rods for fittings can be replaced with pipes made of different materials or wooden beams.

Next, you need to fill with concrete. Pouring can begin after the pit has been reinforced with reinforcement. To start mixing the solution, you need the following components - plasticizer, cement, water, sand. It is worth waiting a few weeks for the concrete mixture to dry and harden. If cracks appear on the surface, you can cover them with concrete mixture.

Now you can begin installing the partition. This partition is made from existing building materials - stone, brick. A pipe is installed between the compartments. With its help, waste from one compartment will be transferred to another. The first compartment deals with the sedimentation of solid components of wastewater. In the second compartment, organic waste is filtered and discharged into the soil. In order for the drainage pit to work better, it is advisable to install a tee in the overflow.

We must not forget about covering the installation. In order to provide strong support for the ceiling, it is necessary to install metal channels inside.

On top of them is a wooden shield. The shield should have small sides; they mark the limit of the hatch's clearance above the ceiling. Slate is placed on top of the shield. Only after this, pipes for ventilation are installed. How the final work is performed. The quality of the completed septic tank can be determined in a couple of weeks.

Installation of reinforced concrete rings

Concrete rings for the septic tank are placed sequentially (small sections can be laid using a winch, but large ones will require a truck crane), and you need to ensure the verticality of the structure and the alignment of the embedded parts, which are then welded.

The seam is sealed. The outer and inner surfaces of the rings are waterproofed: from the inside - with liquid glass or special mastic, from the outside - with roofing felt or bitumen mastic. Internal waterproofing should not be chemically aggressive - this will disrupt the operation of the system. However, damage to the seal will lead to rapid destruction of the concrete. The upper part of the structure is thermally insulated up to the freezing limit of the soil (usually with polystyrene foam blocks).

Installation Tips

- To prevent the well from freezing, its chambers should be insulated.

- It is advisable to install ventilation pipes on each of the containers.

- To increase the strength of the structure, concrete rings can be connected with metal brackets.

- When building a septic tank, it is best to rent special equipment that will lay rings of concrete in dug holes. For the same reason, excavation work must be carried out first before laying the cameras.

- When blocking each of the wells, it is necessary to take care of creating covers with hatches that allow you to monitor the condition of the septic tanks.

Thus, the construction of a septic structure from concrete rings will solve the problem with the sewerage of private houses. This design will cope with large volumes of waste, preventing soil contamination.

Construction and concreting of a monolithic two-, three-chamber

The simplest septic tank is rectangular, the pit for which (with the most even bottom and wall) will become the outer formwork. When calculating the proportions, remember that the distance from the water level to the bottom should be no less than 1.2 m and no more than 3.5 m. The length and width of the pit is from 750 to 1000 mm (the best ratio is 1:2–1:3).

After laying the pillow in the hole and compacting it, the walls and bottom are lined with film. Next, a reinforcement structure is erected (rods 10 mm thick, cell 20 cm), internal formwork (usually made of boards) and spacers are installed.

The thickness of the external walls is at least 20 cm, the internal walls are from 15 cm, the reinforcement is covered with a layer of at least 3 cm of concrete. The input and output holes are filled using scraps of plastic pipe with a diameter of 15 cm.

Reviews from our clients

Ivan Ivanov

I bought a storage tank and installed it myself with the help of a neighbor in the country.

Now everything I have is modern and stylish. I have established waste removal on a regular basis and am very satisfied. SEPTIC Service

2020-06-18T14:20:49+00:00

I bought a storage tank and installed it myself with the help of a neighbor in the country. Now everything I have is modern and stylish. I have established waste removal on a regular basis and am very satisfied.

https://bioseptik.ru/testimonials/ivan-ivanov/

Igor Chekalin

This company advised, selected and installed a septic tank for high groundwater.

Everything was done efficiently and on time. I think I have the right to recommend this company to you. SEPTIC Service

2020-06-18T14:21:10+00:00

This company advised, selected and installed a septic tank for high groundwater. Everything was done efficiently and on time. I think I have the right to recommend this company to you.

https://bioseptik.ru/testimonials/igor-chekalin/

Evgeny Serdyukov

I am very pleased with the turnkey installation of Favorite 2P.

I carried out the pumping once. I’ve been using it for 4 years now, and overall, I recommend it! SEPTIC Service

2020-06-18T14:21:28+00:00

I am very pleased with the turnkey installation of Favorite 2P. I carried out the pumping once. I’ve been using it for 4 years now, and overall, I recommend it!

https://bioseptik.ru/testimonials/evgenij-serdyukov/

Vladimir Serovsky

We bet Favorite 2P with a neighbor for two.

There were no complaints or claims regarding the work of the Septic Service company specialists. We are satisfied with both the work of the septic tank and its maintenance. SEPTIC Service

2020-06-18T14:21:41+00:00

We bet Favorite 2P with a neighbor for two. There were no complaints or claims regarding the work of the Septic Service company specialists. We are satisfied with both the work of the septic tank and its maintenance.

https://bioseptik.ru/testimonials/vladimir-serovskij/

Stanislav Belik

We installed FAVORITE 2P; there used to be a plastic septic tank (which became deformed after the winter).

We are completely satisfied with the new septic tank. We hope for its longevity. SEPTIC Service

2020-06-18T14:21:58+00:00

We installed FAVORITE 2P; there used to be a plastic septic tank (which became deformed after the winter). We are completely satisfied with the new septic tank. We hope for its longevity.

https://bioseptik.ru/testimonials/stanislav-belik/

Nikolay Perevedtsev

I was often bothered by a problem with the sewer system at my dacha, so I decided to contact them to install a storage tank, now the problem is solved, everything was done efficiently and quickly.

SEPTIC Service

2020-06-18T14:22:14+00:00

I was often bothered by a problem with the sewer system at my dacha, so I decided to contact them to install a storage tank, now the problem is solved, everything was done efficiently and quickly.

https://bioseptik.ru/testimonials/nikolaj-perevedntsev/

0

0

SEPTIC Service

Maintenance and operation

Small amounts of food residue, paper, and detergents are allowed to enter drains. There are a number of parameters that must be observed when operating the sewer:

- Once a year you need to clean the chamber from solid fractions. You can reduce the frequency of cleaning insoluble sludge to pumping every 3–5 years. To do this, a drug with bacteria is added to the system, which liquefies it.

- It is unacceptable for antibacterial materials to enter drains: alcohol, chemicals, medications, antifreeze and similar alkalis or acids.

- Do not allow aggressive bacteria, which may be contained in rotting food or pickles, to enter the sewer system.

- In winter, it is forbidden to keep the inspection hatch open for a long time.

- A break in the operation of the septic tank for more than two weeks is unacceptable. If the house is used only periodically, then the system must be “mothballed”. Clean water is poured into the tank at 50–70% of the total volume to prevent the death of bacteria and the soil pushing the tank out.

Possible problems and their solutions

1. The septic tank gets clogged too quickly.

This is due to disruption of the microorganisms inside. It is necessary to pump out excess sludge from the first tank, leaving 15% sludge, and fill it with clean water, adding a bioactivator. If there is excess fat or lathering, you need to remove it using a special product. Microbes also die from low temperatures (you need to additionally insulate) or water that is too contaminated with detergents (you need to add a bioactivator and limit the aggressiveness of the drain).

2. An overflow has occurred. If the volume of the tank is incorrectly calculated, this is due either to blockages and growths in the pipes, or to siltation of the soil. They need to be cleaned both through inspection and with the help of drugs against growths. Blockages are common in pipes with L- and T-shaped joints, as well as a low slope.

3. Damaged walls of the product with cracks or shifts of 1 cm or more in size are plugged with glass-basalt reinforcement. Then they are filled with a waterproofing quick-setting mixture (special mixture or cement-sand mortar with liquid glass). 7 days after hardening, the damaged area is re-coated with waterproofing.