Pumping equipment servicing pipeline systems through which liquid media are transported especially needs protection at the moment when the liquid pressure drops or it stops flowing altogether. To provide such protection in situations where the pump is not supplied with the liquid it pumps, it is equipped with automatic sensors - dry-running relays. Various types of such devices can be used for a pumping station.

Well pump control system: dry running relay on the left, pump on/off sensor on the right

Causes of dry running and its harm to a well pump

Two out of three well pumps fail for one reason - dry running. Warranty repairs do not cover such damage. A similar problem occurs in the following cases:

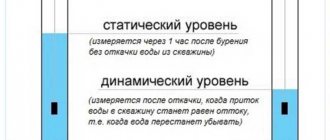

- the height at which the pump hangs in the well is chosen incorrectly. To prevent this from happening, find out the depth of the tank in advance - after the pump pumps liquid to the height of its location, air will enter the pump. As a result, the engine will overheat;

- There is less water in the container. This often happens spontaneously;

- The tightness of the suction pipe is broken. This is typical for surface aggregates. Since water is sucked in along with air, the engine does not have time to cool down to the desired temperature.

From the reasons listed above, we can conclude that if there are no safety measures or their action is impaired, the pump first overheats, after which it burns out.

How can you protect the pump from dry running using relays (sensors)

There are several options for getting out of the situation. These devices function differently and their areas of use are also different. But they have one goal - to turn off the power to the pump as soon as the tank is empty.

The principle of protecting the pump from dry running

The following devices save equipment:

- relay;

- control devices;

- liquid level sensors.

Let's consider how effective they are and what the specifics of their action are.

When will the relay be effective?

A relay is the simplest mechanical device. When it reaches the lower limit, the electrical circuit is interrupted and the pump stops spontaneously.

The device is equipped with a membrane - normally it is extended. There is a reaction to pressure, closing the contacts that are responsible for power supply.

Installation of the device is advisable in the following situations:

- when there is little water;

- for blockages;

- the collecting element of the pump is fixed above the norm.

Fasten the protection product inside the container, if the device body is sealed, or on the surface. The best effect is observed with surface types of pumps.

Briefly about the main thing

A relay that prevents the pump from running dry is an extremely important device. It does not allow idling, which is dangerous due to the failure of the main components of the water supply system.

When choosing a relay, the characteristics of the pump and the level of pressure it creates are taken into account

The installation location of the protection is taken into account, which affects the requirements for its operating parameters. The connection diagram for the relay and related units is selected taking into account the manufacturers’ recommendations

The device is also connected to the electrical network and the protection response limits are set. The relay is adjusted using screws (by turning them in one direction or the other).

The connection diagram for the relay and related units is selected taking into account the manufacturers’ recommendations. The device is also connected to the electrical network and the protection response limits are set. The relay is adjusted using screws (by turning them in one direction or the other).

What are the types of protection relays?

There are three types of protection products:

- switches;

- electromechanical;

- electronic.

Based on their operating principle and functional purpose, sensors are classified into several types of devices. Let's look at them in more detail.

Flow devices

The device is a petal-type valve, which is mounted in the flow part of the pump. Its purpose is to respond to water flows of varying strength.

The spring petal of the relay, under the pressure of passing water flows, brings the spring into a compressed state. The magnet that is installed at the top of the product is in contact with the reed relay. The contacts from which the pump is powered are connected. With a powerful pressure, the petal is constantly in a deflected position, and the pump motor is functioning.

If there is no water in the pipeline or its flow is weakened, the petal and magnet return to their original position. The contacts open and the pump stops.

The advantages of flow relays are low weight and compact size.

Float models

The water threshold control sensors of the float model are designed for both filling the tank and emptying it.

The operating principle is as follows. The float of the device points up - the pump can operate safely. When the liquid filling level decreases, the float lowers. This opens the contactor. Until the filling threshold becomes normal, the station will not start.

Single chamber models

They are made with 1-4 pins. Almost all models operate at minimum pressure. In simple modifications, a wire contactor powered from a regular network is used.

The first nut is placed on the pin. To increase the pressure, the screw is rotated in a clockwise direction.

Scheme:

Dual chamber devices

Double-chamber modifications are equipped with low-conductivity contacts. They are equipped with 3-5 pins. The nuts are located at the top of the device - on the body. The size of the outlet pipe is at least 44 mm. These versions are ideal for protecting powerful equipment.

Installation of the protection sensor

Work algorithm:

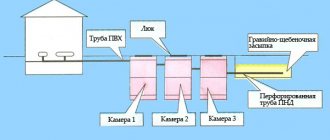

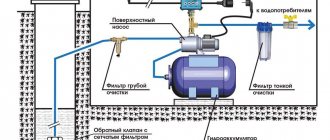

- mount the device together with a device that measures pressure level. Connection rules - according to the manufacturer's instructions;

- find the fragment where the product will be located. Professionals advise mounting the relay on the pipeline - at the exit from the pump. First, a pressure sensor is installed, then a control sensor;

- Place a tee fitting in the device installation area;

- drain off any remaining liquid. Disconnect the liner and secure it to the fitting. Strengthen the fixation with plumbing tape;

- Make a gap at the pump feed point. A relay needs to be installed here. When the contacts open, power is not supplied to the pump and the equipment turns off spontaneously.

Installation diagram:

Overfill protection:

Connecting several sensors at once:

How to choose a device?

When purchasing equipment, pay attention to the design, material of manufacture, and technical parameters. The controller is selected according to the following characteristics:

- power;

- pressure;

- IP protection class;

- inlet/outlet diameter;

- product manufacturer;

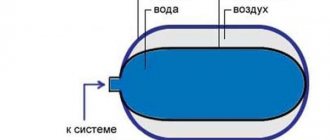

- presence of an expansion tank;

- restart function;

- price.

The IP class in the electronic regulator indicates protection against dust and moisture.

Example of decoding IP 65 on the device:

- IP - Ingress Protection;

- 6 - from dust;

- 5 - from moisture.

IP 65 - high protection class.

The pressure regulator is selected depending on the functionality of the pump.

The following parameters of the hydraulic machine are taken into account:

- operating principle;

- power consumption;

- performance;

- water pressure.

When choosing automation, the plumbing equipment in the house is taken into account. Household appliances are designed for pressure up to 3 atm. If the pressure is greater, the equipment is subject to stress and fails.

Reference! Pumping stations are sold complete with pressure regulators. There is a wide range of automatic water switches on sale.

Configuring the connected protective relay

The device is designed in such a way that the relay regulates the level of communication between the triggered contact group and the surface that responds to pressure force. This function is performed by special screws - they loosen and tighten the spring. The manufacturer sets the lower and upper thresholds. Most often these are indicators:

- 1.4 atmospheres - minimum;

- 2.8 - maximum.

The user can independently adjust the boundaries - the screw is turned left or right.

Note! A mandatory requirement for correct protection settings is to fix the device shutdown threshold below the pump pressure. If this rule is ignored, the pump will not respond - the equipment will quickly break down.

The second adjustment screw is designed to determine the difference in the sensitivity limits of the device. During the setup process, keep in mind that the upper shutdown threshold also changes. Your task is to prevent exceeding the maximum pressure that the equipment produces directly.

Reduce the lower level and the spread of the boundaries by unscrewing the nuts.

Problems with the operation of the dry-running relay of the deep-well pump

Possible errors in the operation of the deep installation relay:

- The minimum setting threshold has been reduced - even a small deviation prevents the device from triggering in a timely manner. This means that the pump will continue to work;

- a similar error of an inflated limit will create protection. This will turn off the pump for no reason;

- too low pressure increases the time required to start the system. The only way out is to drain the fluid from the accumulator;

- even a small error can trigger a pressure release mechanism. As a result, against the background of high consumption, pressure begins to drop sharply. To eliminate idle shutdowns, reduce the pressure force.

The installed relay does not help, the pump continues to work without water (reasons and methods for solving the problem)

As practice shows, often even with protection, the device does not work, but the equipment continues to work. Causes of the problem:

- sticking of contacts - even worse - their melting. The contacts of the breaker are damaged under the influence of the starting current. If the contacts remain intact and are simply stuck, the problem can be easily resolved. Clean the hot spots with fine sandpaper or a regular nail file. If they are severely damaged, you will have to replace them with new ones;

- the interval between the device’s response thresholds is higher than normal - follow the settings recommended by the relay manufacturer, and the problem will be solved.

Supply voltage and overloads must be monitored

The electric motor is the most important structural component of a well pump. Its power supply parameters that meet factory requirements will contribute to long-term and trouble-free operation of all units of the unit.

From the influence of negative factors of the electrical network (current surges, voltage surges), you can reliably protect a submersible pump, namely its motor, using voltage stabilizers or motor protection relays (automatic machines). Currently, models of such protective devices from both foreign and domestic manufacturers are available on the market.

Overload of the pump motor is prevented by inexpensive but important parts of the system - thermal current relays.