The construction of an independent water supply system with water intake from an underground source dictates the need to purchase pumping equipment. Out of habit, we look for products from foreign companies for furnishing. However, the Aquarius well pump is not inferior in reliability and performance to units of foreign brands. It costs much less. And this is a significant plus, don’t you agree?

Do you want to understand the design features of the Aquarius pump? Here you will find answers to all your questions. The information offered for consideration will help you choose the right pump unit correctly and will familiarize you with the specifics of operation and maintenance of the device.

To make your choice easier, we have described in detail the range of deep-well pumps with the Aquarius logo. The rules were given and the sequence of connecting to an autonomous water supply and electrical network was thoroughly discussed. Photos and video attachments accompanying the article will help you better understand the topic.

Aquarius is an excellent choice for a country well

The unit, easy to use and install, is produced (Kharkov, Ukraine). In addition to submersible pumps, the company produces drainage and surface pumping equipment, electric motors, and feed grinders.

The series of pumps for deep use includes products used in wells installed “on sand” and “on limestone”. The range of distances from water intake to its supply to the surface is from 20 to 200 m.

The most powerful models can serve a large cottage or 2-3 country houses, as their productivity reaches 12 m³/h.

The products have been known since 1995 - since the establishment of the enterprise. And since 1996, equipment has been released that has not lost popularity to this day - submersible and surface pumps

Among the advantages of the Aquarius line of devices are:

- economical energy consumption;

- high productivity;

- low noise figure;

- wear resistance of parts made of stainless steel, brass and food-safe plastic;

- possibility of warranty or self-repair;

- light weight and dimensions corresponding to the diameter of the well;

- complete set allowing you to begin installation immediately.

Don’t forget about IEC 335-1 (international safety standard), warranty service for one and a half years and the ability to purchase spare parts from the manufacturer if repairs are necessary.

In terms of technical characteristics, the modifications are comparable to foreign analogues PEDROLLO and GRUNDFOS. Cost depending on the model – from 1800 rubles. up to 27,400 rub.

Image gallery

Photo from

Submersible pump with Aquarius logo

Line of centrifugal equipment

Limitations on the pumped medium

Water supply with centrifugal Aquarius

Briefly about the main thing

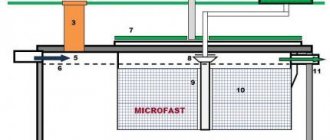

Pump Aquarius 3 is a submersible vibration unit for pumping clean water from wells, wells and other reservoirs.

The equipment is designed for diving to a depth of 1-3 m; water rise is allowed to a height of up to 40 meters.

The working life is limited to approximately 10 years with mandatory use for no more than 2 hours (the break is about 30 minutes).

Preventive inspection is carried out once a month; in the case of swimming pools, it is recommended to check the device after use.

Ratings 0

Features of the deep-well pump device

All downhole submersible models Aquarius have a similar structure.

The main parts are:

- multi-stage pumping sector;

- electric motor separated by a filter;

- capacitor box located outside.

Hidden under the body is a pumping unit - a monolithic box with rotating impellers and a drive.

It is the dimensions of the impeller that are responsible for one of the main characteristics of the unit - productivity. The larger its diameter, the larger the portion of water supplied over a certain period of time.

All parts are securely fastened with a screw-threaded lid. It is also the place where the cable is fixed, one of the pump mounting elements inside the well.

According to the table, you can trace the relationship between the dimensions of the device and two important technical indicators - productivity and the value of the nominal pressure

The motor, using a rotor-stator combination and bearings, drives the apparatus. It is filled with oil. The capacitors and electrical cable are enclosed in a condensation box.

To ensure that the equipment does not fail under force majeure circumstances, for example, during rapid drying, automatic protection made in Germany is provided.

Operation monitoring and control is carried out using a remote device. Knowledge of the structure of the Aquarius pump will help with its repair.

Advantages of the Aquarius pump

Its quality and reliability are determined by several factors. — in its production only high-quality materials are used — ordinary and stainless steel, food-grade plastic. - low noise - thanks to the unique design. - economical - combined with sufficient performance, fairly low power consumption. - long service life and further maintainability - high-quality and reliable electric motor and hydraulic pump mechanism. — high level of efficiency

Operating principle of the submersible apparatus

To supply water upward and move it the required distance, it is necessary to create pressure. The centrifugal type of pump produces the required pressure by rotating a wheel (or several wheels), which is mounted on a working rod (shaft) and connected to the engine.

When the wheel starts, kinetic energy arises and is transferred to the blades, and from them to the liquid. As a result, water is scattered towards the walls, then moves from the receiver to the adjacent (upper) chamber, and in its place, under pressure, another portion of water from the well arrives.

Thanks to a simple but well-thought-out device, water flows smoothly, in a gentle manner, first into the body of the device, then through pipes into the storage tank

A suction pipe is designed to collect liquid, and a filter is provided to protect the internal parts of the device from clogging and rapid wear. The device is simple, but so effective that there is no point in looking for a device with a different operating principle.

All elements of the mechanism are placed in a fairly compact elongated “sleeve”, the design of which is ideal for lowering into a narrow wellbore.

Unlike vibrating analogues, centrifugal ones work evenly and carefully, due to which they do not lift sand from the bottom and do not destroy the walls of the well.

Benefits and Features

According to users who have tested the Aquarius submersible pump, the technical characteristics of which can be called quite worthy and serious, in their country houses and garden plots, its main advantages include:

Deep pump Aquarius

- Significant working life of all units and elements of the unit and excellent quality of its assembly.

- Good maintainability. Any of its parts that fail can be easily replaced, restoring its functionality in the shortest possible time and without unnecessary financial costs.

- Low power consumption.

- Unpretentiousness and low demands on operating conditions.

- Compact and light weight. Thanks to these qualities, the pump is easy and convenient to operate without much effort.

- Reliability of the electrical part of the device. This allows the deep pump for the Aquarius well to operate without failures or shutdowns even with small voltage drops.

- Affordable price.

- The presence of a long cable, as well as a cord for hanging the device in wells and boreholes.

In addition, one can note the increased performance of “Aquarius”, which distinguishes it favorably from other popular brands, such as “Rucheek” or “Malysh”. Unlike the latter, it can be operated without interruptions in operation, while the operating time of the “Kid” should not exceed two hours.

The permissible temperature of the working environment is no more than +35 ⁰С. Work in winter is allowed.

Purpose and characteristics of models

To reach a larger audience, it produces models of various modifications. For convenient orientation, some parameters of the units are included in their names.

For example, let’s take the position of BTsPE 0.5-100U 60/150 and decipher the digital data:

- BCPE – household centrifugal submersible electric pump;

- 0.5 (l/s) – productivity;

- 100 (m) – nominal pressure at nominal volumetric flow;

- 60 (l/m) – maximum productivity;

- 150 (m) – the height of water rise in the well at the highest pressure.

In accordance with individual requirements, you can choose a device belonging to one of four groups: 0.32 l/s, 0.5 l/s, 1.2 l/s, 1.6 l/s.

Let's assume that you are the owner of a well or a small well (diameter 100 mm, 120 mm and above) with a limited flow rate. Most likely, water consumption does not exceed 2 m3/h. Obviously, the choice should fall on the BCPE-0.32 model.

The table shows the technical characteristics of all models of the Aquarius pump with a capacity of 0.32: using data analysis, it is easy to select a device for your own use

Models with a productivity of 0.32 are quite popular, since many people visit the dacha irregularly, and the number of permanent residents rarely exceeds 3-4.

If you decide to purchase a device with minimum performance, please note that other indicators may differ (for example, pressure parameters). This series consists of 9 models.

The next series - BTsPE 0.5 - has a total of 8 models, differing in pressure (from 16 m to 100 m). The pumps can operate with both manual and automatic control. The devices are equipped with a protective function that protects against overheating.

If the diameter of your well is at least 110 mm and the flow rate is from 2 m³/h, you can choose one of the models in this series. The device can also be useful for other purposes, for example, if there is a need to pump out water from a pool, pond or natural body of water.

Pumping equipment with a capacity of 0.5 l/s is perfect for watering lawns, beds, flower beds or garden plantings.

Aquarius BTsPE-1.2 pumps achieve maximum efficiency with a water supply of 1.2 l/s (4 m³/h): the graph shows the dependence of water volume on pressure

The next series - with a capacity of 1.2 l/s - includes a line of 8 products that differ in pressure (from 12 m to 80 m). The manufacturer warns that hot water (with a temperature above +35 ºС) cannot be pumped, as well as overly contaminated liquid.

The most productive are the BTsEP 1.6 models, which are presented in three modifications - with a head of 25 m, 32 m, 40 m. In their line, they also differ in design - they have a different number of pumping stages, from 6 to 8.

Taking into account the technical characteristics of the Aquarius pump, you can choose a unit according to your individual requirements.

What can the Aquarius pump be used for?

The “Aquarius” pump of the BTsPE series is used to provide water to cottages, private houses, and household plots and serves as a borehole pump or a pump for a well. A fairly wide range of models allows you to select this pump with the required performance in a well with a diameter of 100 to 120 mm. Also, any open reservoir or reservoir with the required level and supply of water can serve as a source of water.

It can be used for both drinking and technical water supply for various needs, including watering gardens and personal plots. The pump is designed for pumping clean water, but it can also pump water with minimal impurities of silt and sand, but in this case its service life is significantly reduced.

Selecting a model based on specific characteristics

Let's consider all the stages of choosing a brand pump. These recommendations are general in nature; you can find more detailed information in the technical data sheet and installation instructions.

By clarifying the technical data of the well and comparing the characteristics of different pumps, you can choose the model that is best suited for your site

Before purchasing, it is important to consider all the characteristics necessary to make the right choice.

Namely:

- well diameter;

- well flow rate;

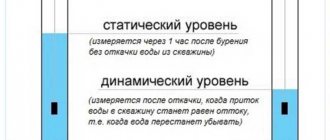

- water levels in the well (static and dynamic);

- estimated water consumption;

- distance from source to home;

- pressure in the hydraulic accumulator (damper tank).

The diameter of the well is very easy to determine - it is indicated in the technical passport, which is issued by the company that drills and installs equipment. Most likely, the diameter is standard, that is, it has dimensions of 100 mm, 133 mm, 152 mm. Aquarius pumps are best installed in wells with a cross-section of more than 100 mm.

The flow rate is also indicated in the passport, thanks to this parameter it is easy to select a pump based on performance. It is important that the pump parameters do not exceed the figures specified in the documents.

Let's assume that the flow rate of the source is 3 m³/h. This is a fairly low figure, which means that there is no need to purchase models from the BTsPE 1.2 series (or higher performance), BTsPE 0.5 is sufficient.

When operating more powerful equipment, the volume of water in the source will not have time to recover, drying will occur and the device will automatically turn off.

The water level must be known in order to correctly determine the installation depth of the pump. Usually the distance to the water surface and from the surface to the bottom is indicated in the passport, but you need to remember a couple of nuances.

The first concerns the installation features of a submersible pump - it is lowered 4-5 m below the surface. The second concerns the variability of the water level.

During the warm period, the level usually decreases, and the difference with the initial value can be up to 4-5 m. It turns out that for installation you need to know the minimum level.

Even at the planning stage of the water supply system, it is necessary to draw up a diagram of the house indicating all possible water collection points - the data will be useful both for installing the wiring and for selecting a pump

To calculate the total water consumption, several factors must be taken into account:

- number of permanent residents;

- number of points of use inside the house (bathroom, kitchen, shower);

- the presence of distribution points outside the house (watering the garden, a tap in the summer kitchen, a tap in the bathhouse), etc.

On average, if you do not take into account additional facilities, the daily consumption per person is 200 liters.

The distance between the water source and the house is necessary to calculate the additional load on the pump. Standard calculation: 10 m of horizontally laid pipes equals 1 m of vertically laid pipes (both – 0.1 atmosphere).

The pressure of the damper tank affects the shutdown threshold. Let’s assume that if you have a volumetric tank of 300 liters installed, then to turn it off you need a pressure of 3.5 atmospheres (converted to vertical meters - 35).

Image gallery

Photo from

Installing a pump in a well

Pump automation

Well caisson with deep pump

Shallow well head

Consumer Reviews

In the user environment, Aquarius pumps are rated quite highly.

Many people have already tried this unit, because it is much more affordable than its imported analogues, and therefore much more popular. At the same time, the Aquarius pump compares favorably with superchargers of other well-known brands produced in the CIS countries.

So, if the Malysh pump is designed for a service life of up to 3 years (Rucheek also has a similar resource), then Aquarius will last from 10 to 15 years.

At the same time, as many users note, it is much more resilient: if the Kid needs a half-hour break every 1.5 - 2 hours of work, then Aquarius can easily withstand the continuous regime.

According to the testimony of many owners, the Aquarius pump is not able to “go astray” either by voltage drops (within reasonable limits, of course), or by sand, which during floods flows into the well in small quantities. If clogging occurs, the pump can be easily cleaned on your own.

More complex repairs also do not cause problems: the pump is completely repairable, spare parts are cheap and delivered quite quickly. In this regard, imported equipment is much inferior to domestic equipment, which includes Aquarius.

Many people greatly regret the absence of pumps for 3-inch wells (76 mm) in the model range. The minimum well diameter of 100 mm significantly limits the scope of application of Aquarius. The automatic safety system, which turns off the pump only in case of overheating, is also considered functionally poor. It should, however, be noted that with full-fledged protective automation, the Aquarius pump would be outside the budget category and would become inaccessible to many users with limited financial resources.

To provide water to a small family and to water a plot of approximately 12 acres, it is enough to purchase an inexpensive Rucheek pump. Brook pump - technical characteristics and operating features, as well as advantages and disadvantages, read carefully.

We will consider the stages of installing a pumping station with our own hands in this block.

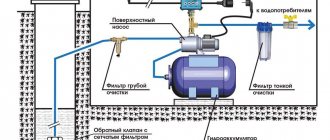

Rules and procedure for connecting the pump

In order for Aquarius brand pumping equipment to work properly, it is important to install and connect it correctly using the appropriate components.

Purchase of components for installation in a well

In addition to purchasing a pump that comes with an electrical cable and a rope for hanging, you may need to purchase the following equipment:

- Hydraulic accumulator with a set of adapters . For a small family (2-3 people), a small hydraulic accumulator with a volume of 100 liters is sufficient: the larger the volume, the less often the device will turn off).

- Header . The purpose of the well head is to cover the shaft from street debris and precipitation and serves as a place for attaching pipes.

- Pipe from pump to tank . Required for outdoor use, 32mm or 40mm diameter.

- Adapter from pipe to submersible pump . For an Aquarius pump and a pipe with a diameter of 32 mm, a product of type 1' with an outer cut of 32 mm is suitable.

- Steel cable with clamps . If for some reason you are not satisfied with the product supplied in the kit.

- Submarine cable . Used for electrical cables.

Together with the hydraulic accumulator and pump, a pressure switch and pressure gauge are purchased. Equipment made in Germany and Italy has proven itself to be excellent.

For example, if the tank volume is more than 300 l (8 atm.), the MDR 5-8 Grundfos relay model is suitable.

One of the options for installing a pressure switch and pressure gauge is using couplings, on the fitting coming out of the hydraulic accumulator (storage tank)

Preparing and installing the pressure pipeline

To reduce problems with delivering water from a well to a house, the pipeline must have certain qualities.

Namely:

- tightness;

- strength;

- minimum length;

- no bends.

Twists and bends can cause air pockets to form, impeding the movement of water. The shorter the pipes, the fewer connecting elements are needed: fittings, couplings, flanges. It is not recommended to use a threaded connection. A possible product option is HDPE-32 pipe.

Layout of the pressure pipe when installing a submersible centrifugal pump: the pipeline is laid below the freezing level of the soil with additional insulation

Check valve installation

The check valve is not included with the pump, but its presence in the water supply system at home is necessary. The main purpose of the valve is to block the movement of water in the opposite direction.

This means that during operation the check valve is open and allows the liquid to move freely towards the disassembly points. However, when the pump is turned off, it shuts off the water, preventing it from moving back.

The valve is installed directly at the outlet of the well pump. It is mounted in a pipe above the pump, in some cases at a short distance from it (no more than 1 m).

When installing the valve, pay attention to the arrow indicating the direction of water movement. This is necessary so as not to embed the part with the back side.

The installation diagram of a check valve in a well is made on the pressure pipe immediately after the submersible pump. When installing a surface pump, the valve is fixed at the end of the pipe lowered into the water

Fastening equipment on a cable

A nylon cable for mounting the pump is included in the kit, but some users note that over time the elastic material loses its elasticity and stretches.

To prevent deformation, you can use a stainless steel cable. It is threaded through special holes in the upper part of the pump housing and firmly tied.

Along with the cable, it is necessary to lower the electrical cable into the well. To prevent mechanical damage and additional load on it, you should make a kind of bundle of safety rope, pipe and electrical cable.

We fasten the cord not in a stretch, but in a loop, with small allowances. It is prohibited to lift the pump from the well by the electric cable.

This is what the pipe should look like after the pump is lowered into the well. The electrical cable is fixed with special staples or adhesive tape

We carefully lower the interconnected communications into the casing to a pre-calculated depth. Under no circumstances should the pump touch the bottom.

Power Connection and Testing

Remember that the operation of the Aquarius pump is possible only if the voltage parameters are observed - 220 V. With other indicators, the normal functioning of the equipment is not guaranteed. If the network characteristics do not meet the manufacturer's requirements, connect a voltage stabilizer.

After immersing the pump in the well, make sure that its body is completely submerged in water. The power cord should not be taut like a string. Only after checking the fulfilled conditions, proceed to connecting the Aquarius pump to the power source.

If the device began pumping water and turned off only when the automation was triggered, everything was done correctly.

To ensure uninterrupted operation of the equipment, preventive disassembly is carried out. If deficiencies are noticed after inspection, they must be eliminated. For example, you can replace the bearings (if the running is tight), change the oil, check the motor winding.

You may also find useful information on how to replace an old pump with a new one, set out in our other article.

How to choose the right pump for a well

To select the correct pump, any user needs to collect some technical data that will guarantee that the pump will be selected correctly by specialists and will provide the required parameters.

- It is necessary to know the flow rate of the well, that is, what part of the water will flow into the well in a certain time. If the flow rate is negative, then the pump will have time to pump out water faster than the well will be filled with water again. And running the pump dry, as mentioned above, is the first way to damage the pump.

- Checking the diameter and quality of the well casing: the diameter must be no less than the recommended: 120 mm for BTsPE pumps and 100 mm for BTsPEU.

- Determine the approximate required pump pressure: • sum up in meters all the differences in height of the pressure pipeline from the pump to the highest water point, • sum up all horizontal sections of pipelines, and the loss of pressure will be 1 m per 5 - 10 meters of pipe; • excess pressure on the spout at the top point of water intake - 25 meters; • losses in local resistance of the pipeline (in corners, tees, turns), excess pressure in the case of installing a hydraulic accumulator, etc. - these parameters can be determined together with specialists when purchasing a pump, having previously drawn up a diagram of the planned water supply station.

- Determine the required water consumption taking into account the number of water points: shower head 0.2 l/s, washbasin 0.12 l/s, sink 0.12 l/s, irrigation tap 0.3 l/s. In residential buildings where all appliances are not used at the same time, a load factor of 0.7 can be used.

The final selection of the pump is made based on the operating point of the pump (flow rate, cubic meters per hour and pressure, m.w.c.) using the hydraulic curve of the model that is closest to the calculated parameters of the network. However, on your own, without experience in precise hydraulic calculations, you can only roughly decide on the model you plan to purchase, but still entrust accurate calculations and more scrupulous selection to specialists. Consumer reviews are varied: powerful, reliable, repairable, easy to install, silent, good water pressure, and they also write that the pump is a bit heavy, a little inconvenient to install alone

Possible malfunctions and methods for eliminating them

Despite prevention, cases of breakdown are possible, so we will consider the most common of them.

Preventative cleaning must be carried out every 1-2 years, but emergency unscheduled repairs are also possible if parts are worn out or the suction pipe is filled with sand ahead of time

If the pump does not turn on, perform the following actions:

- check the presence of contacts in the socket;

- inspect the pump for clogging with sand;

- We measure the voltage, if there is a deficiency, we connect a stabilizer.

If productivity suddenly decreases, we check whether there is a leak in the pipeline. At the same time, we inspect and clean the filters. When the voltage decreases, we use a stabilizer.

The pump will sooner or later become clogged with sand, so we clean it: remove the mesh and protective chute, separate the pump part and the electric motor, check the operation of the shaft, and wash all the elements. We assemble the device in reverse order.

Repair and cleaning

One of the reasons why the pump stops rotating can be damage or clogging of its impellers. A small blockage can be removed on your own. This is done as follows:

- The protective mesh is removed. On new generation models, to do this, you need to open the clip that secures the mesh, hooking it with a screwdriver and pressing it in the middle. In older models, the mesh is held on by two unscrewing screws.

- On wide pumps, it is necessary to additionally remove the cable channel, which looks like a small metal groove.

- We separate the engine from its pumping part. To do this, unscrew the four bolts that secure it and remove the plastic couplings connecting the engine and the pump part.

- We lay out the disassembled structure on a flat surface.

- Using a 12mm socket or socket wrench, rotate the pump shaft, holding its upper part with your hand. When it moves, we rinse the pump part with a stream of water, trying to remove any debris that has clogged the device. If this attempt is successful and the shaft moves again without difficulty, we flush the pump and reassemble it, proceeding in the reverse order.

If the impellers are damaged, it is necessary to disassemble the pumping part of the unit. However, due to the complexity of this operation, it must be performed in specialized services, where worn parts will be replaced professionally and quickly.

In case of self-repair of the device, the following operations are performed:

- The pump housing is compressed with force from the top and bottom sides, with emphasis on the brass element located in its lower part.

- Using narrow-nose pliers, carefully remove the retaining ring installed in a special recess, which should expand after compressing the pump housing.

- The impellers and thrust cover with bearing are removed one by one.

- After the jam is removed, the pump is reassembled. (Sequence of actions: in reverse order).

When starting this work, you need to understand that it will be very difficult to carry out these manipulations yourself due to the need to use special equipment (press).

Thus, we can conclude that Aquarius deep pumps for wells, the technical characteristics and cost of which have made them very popular among consumers, are truly effective and convenient for meeting household needs. Subject to the rules of operation and regular and timely maintenance, they will serve for a long time without requiring the cost of repairs and reinstallation.

How to repair an Aquarius pump with your own hands is shown in the video.

Design features of electric pumps Aquarius

The Aquarius submersible pump for water intake has the following design features:

- The unit consists of modules: a unit with an electric motor in the lower part and a block of impellers in the upper half; a mesh filter is installed in the middle of the housing.

- The body of the electric pump is made of stainless steel; a brass cover with a 1-inch thread inside and two side lugs for attaching a suspension cable is installed at the top.

- The unit has an external capacitor module with a power cable and a plug with a grounding contact (electrical protection class I); to protect against overheating, a German Thermik thermal relay is built into the electric pump winding.

- There is no built-in check valve in the pump body; when connecting the pipeline, it is installed in the adapter coupling at the outlet of the unit.

Rice. 4 Pressure parameters BPCE 0.32, BPCE 0.5