The operation of traditional sewerage systems involves the gravity movement of water along a pipeline with a slope, which is not always possible to implement in full. Sololift for sewerage is pumping equipment that is small in size, has a self-cleaning system, quiet operation and ease of installation, as well as a high degree of reliability.

- 2 Design and principle of operation

- 3 Choosing a sololift for sewerage

- 4 Installation and connection

4.1 Video: sololift installation

Connecting Sololift to the sewer

In terms of connection to sewer pipes, this is a classic plumbing device. No special knowledge of the installation process is required here, so many people do the installation themselves.

An important rule for installing Sololift for sewerage is free access to the sewer pipe.

Conditions that must be met when installing a plumbing fixture:

- Mandatory small gap within 1 cm between the wall or other plumbing element.

- Installation location: no more than 40 cm from the outlet pipe.

- The distance to the gravity section or to the septic tank is 50 m.

- A slight slope of the pressure pipe is still necessary. This parameter is 1 mm.

- The socket for the sololift must be at an accessible distance from the installation site of the device.

Connection to pipes is carried out using standard adapters, which are included in the package. Vibration-isolating material is placed under the device. Fastening is done with screws, dowels, supports and other fasteners. It can be attached to the floor, wall or other supporting structure of the building. All connections are coated with sealant.

After installation, the Sololift for sewerage is checked to ensure correct operation.

In the video, an example of installing a sololift for sewerage.

SOLOLIFT line

This is a general name for a whole group of pumping stations, varying in their capabilities. The purpose is determined by the marking:

- The Sololift system for sewerage with the letters WC and numbers from one to three is intended primarily for connection to toilets and washbasins. The letters CWC mean that a wall-mounted toilet can be connected to the station.

- Models marked D-3 are for sinks, bathtubs and showers. Models of this modification can be used with cold and relatively hot wastewater.

- Thermally resistant Sololifts are marked C-3. Stations of this type “tolerate” drains with a temperature of 90 degrees, so they are connected to dishwashers and/or washing machines.

Knowledge about the models of pumping stations is necessary for the correct selection of the unit. This is extremely important, since an already working system cannot be expanded (modified). The sewer sololift has a simple operating principle. Here are its stages: the flow of wastewater into the tank - the relay is activated - the pump is started and the liquids are pumped into the building's sewer system.

How does Sololift work for sewerage?

Sololift is a regular pump. Although you can't tell by appearance. A submersible pump is installed inside the plastic case, and a chopper is added to some models. The latter is necessary for grinding household waste and sewage that the sewer pumps.

In addition, the design includes an inlet filter, a carbon filter, and a check valve. That is, this is a serious device that should provide a private home with efficient operation of the sewer system.

Operating principle of Sololift:

- sewage is drawn through the receiving filter;

- enter the pump storage tank;

- here the shredder, which is an impeller, cuts the waste into small pieces;

- then this entire mass is fed into the sewer pipe, on which a check valve is installed, the purpose of which is to prevent backflow into the sololift.

The carbon filter is installed on the lid of the device. Its task is to trap unpleasant odors. The hole itself on the cover is intended to create a vacuum inside the pump housing.

The sololift in a pressure sewer system must operate when the tank is filled and stop when it is empty. This process is controlled by a control unit, which includes:

- hydrodynamic thermal relay;

- pressure tubes that regulate the filling volume;

- float sensor.

The latter is the main element that sends signals to turn the pump on and off. It is programmed at the factory. You should not change parameters without permission. You can mess up the setting, causing the sololift to start working incorrectly.

Principle of operation

What is the Sololift system

The Sololift system is a small sewer pumping unit that makes it easy to drain wastewater from any plumbing fixture, no matter where it is located. The modern design and compactness of the device make it possible to use Sololift in an apartment without disturbing the harmony and beauty of the interior.

Such installations are necessary for collecting wastewater through a discharge pipeline in automatic mode, followed by grinding of all large entries. Next, the resulting mixture is pumped into an overflow pipe leading to the sewer (to a height of up to 7 meters if the pipe is vertical or to a distance of up to 100 meters when the pipe is horizontal).

Characteristics

Characteristics that you need to pay attention to when choosing Sololift:

- Power. Unit of measurement – m³/h or l/min. Here is a small model range designed for domestic use: 10, 12 and 25 m³/h. It is usually selected according to the number of plumbing fixtures that are connected to the forced sewage pump. The more there are, the higher the productivity should be.

- Temperature of pumped sewage. There are two options here - either up to +50 ℃, or up to +90 ℃. The first is used when connecting the Sololift to a toilet, sink or sink. The second, if the connection is made to a dishwasher, washing machine, or bathtub.

- How long can Sololift work for sewerage? There are models that work short-term. They are installed on one plumbing fixture, for example, a toilet. There are durable models. For example, they can drain sewage from an entire private house. It is necessary to pay attention to some instructions from the manufacturer. In the work duration column there can be a percentage, for example, 50%. This means that the device will work for half a minute, then turn off and rest for the same half a minute.

- Presence of a chopper. Not all models have this element.

Manufacturers stipulate the moment of installation of Sololift in the sewer under the bathtub. If you only take a shower, then there are no problems with its operation. If water procedures are carried out in a large volume of water, that is, with the bathtub completely filled, then the sololift, when discharging it into the sewer, simply cannot cope with such an amount of liquid.

Some companies offer devices that can be installed near the bathtub. They are powerful, large in size and have a high price. There is an option to install a conventional unit, but with the formation of an additional pit into which water flows from the bathtub, and from there the pump pumps the wastewater into the sewer.

Another design feature of some Sololift models for sewers is an alarm system. More often it is sound. Triggers when there is an overflow of liquid. Some manufacturers connect an alarm to the control unit of, for example, a dishwasher. The first one simply turns off the power supply to the last one.

Specifications

Advantages and disadvantages

The main advantage of compact individual sewerage installations is that they allow you to equip a sewerage system without carrying out large-scale construction or repair work. With their help, complex problems are solved:

- Drainage arrangement when plumbing fixtures are located below the entry point into the sewer system.

- Equipping a bathroom without carrying out large-scale civil works.

Another positive point is the use of small diameter pipes. Most toilet pumps are connected to the sewer using plastic pipes with a diameter of 28 mm - 32 mm - 40 mm. Only high-capacity installations require the installation of 50 mm pipes. Such plumbing networks are easier to hide. Even if it was not possible to hide them, they do not attract as much attention as the standard one hundred millimeter ones.

Examples of sewage pumps for toilets and bathrooms

However, there are also disadvantages:

- Dependence on electricity. No power - sewerage doesn't work. A redundant source is required for uninterrupted operation.

- The pumps are noisy. Manufacturers are improving their products, installing pumps with lower noise levels, but they are still present.

- Compliance with certain operating rules is required. For example, it is undesirable for fibrous materials to enter the shredder. Modern shredders cope well with toilet paper, but with fibrous components and hair they are a problem. They wrap around the screw, reducing the quality of chopping. Sooner or later the screw gets blocked. An installed overheat sensor will not allow the equipment to burn out - it will turn it off earlier. But the installation will have to be disassembled and cleaned, and this is not the most pleasant task.

There are compact models for installation in niches

Well, the main drawback is that the pumps burn out. If the power and performance are selected correctly, unsuitable objects do not fall into the sewer, and they can work for years. But if there is a selection error, when the equipment is operated to the limit, the pumps often fail. Therefore, when choosing a sewer pump for a toilet, it is better to choose one with a margin of performance. It will cost more, but this installation will last longer.

Model range of Sololift pumping units

Today, many companies produce pumps for pressure sewerage (domestic and foreign). Grundfos was the first. It produces pumping equipment for pressure sewerage under the Sololift brand. Here are several models for private housing construction.

WC-1

Designed for installation after the toilet. You can additionally connect a sink mounted in the toilet.

Specifications:

- productivity – 149 l/min;

- three positions according to the amount of pumped liquid: 4, 6 and 9 l;

- rise in height – up to 8.5 m;

- consumes electricity – 0.62 kW;

- the electric motor is dry, located in a sealed chamber;

- the housing can withstand pressure - 2.5 m in. Art.;

- weight – 7.3 kg;

- body volume – 9 l;

- temperature of drained waste – up to +50 ℃;

- operating mode – 50%;

- horizontal connection;

- the outlet pipe is strictly vertical;

- Installation location: behind the toilet. If a sink is connected, then the distance between the Sololift and the toilet is no more than 15 cm.

Sololift WC-1

WC-3

Designed for pumping sewage simultaneously from a large number of plumbing fixtures: toilet, sink, shower stall, bidet and urinal.

Characteristics:

- productivity – 149 l/min;

- maximum lift height – 8.5 m;

- electric motor power – 0.62 kW.

All other characteristics are identical to the previous model. But the WC-3 design has distinctive features. If WC-1 has only one additional entrance on the side, then WC-3 has two, one on each side and one on top (in the lid).

CWC-3

In appearance, this type of Sololift for sewerage differs from the two previous types. The model is narrow, and the main inlet pipe is located at the end of the body.

Typically, devices of this type are installed on wall-hung toilets with the additional connection of several more plumbing fixtures.

In all technical and installation characteristics, this Sololift is identical to the WC-3 brand.

S-3

Intended for pumping sewage containing insoluble solid particles larger than 20 mm in size. Therefore, installation is carried out under toilets, washing machines and dishwashers.

Characteristics:

- productivity – 185 l/min;

- maximum pressure – 8.8 m;

- electric motor power consumption – 0.64 kW;

- three additional connection pipes: one on top, two on opposite sides of the body;

- temperature of the pumped liquid – up to +90 ℃;

- weight – 6.6 kg;

- volume of the receiving container – 5.7 l.

D-2

Compact model with front mounting method. Can serve bathroom sink, shower and bidet.

Characteristics:

- productivity – 105 l/min;

- head – 5.5 m;

- motor power – 0.22 kW;

- two additional inlets;

- attached to the wall;

- container volume – 2 l;

- device weight – 4.3 kg;

- temperature of the pumped liquid – up to +50 ℃.

Sololift D-2

Installation and connection rules

The installation and connection of toilet pumps and forced drainage from different manufacturers follows very similar rules. But before installation, you should read the instructions for a specific product - there may be special features.

Sewage pump for shower - with installation under the tray

Connection

The installation location must be chosen in such a way that the pump can be reached. It does not require special maintenance, but there is a need for cleaning from time to time. If a dishwasher and washing machine are connected to the pump, it is better to regularly check whether the sewage system is clogged with grease, dirt, and salt deposits. If necessary, cleaning with mild detergents is possible. It is better not to use aggressive chemical compounds, as they can damage the plastic and rubber parts of the installation.

If the sewer inlet is higher than necessary

General rules:

- An individual sewer installation must be grounded. Therefore, the outlet must be three-wire with a working ground.

- For safety, there must be a circuit breaker and an RCD on the power supply line.

- During installation, the block is fixed to the floor. To reduce the noise level, it is advisable to install it on a vibration-damping base (rubber gasket). It is not advisable to press the housing against the wall so as not to transmit vibration from the pump. These measures are needed to reduce noise levels. A sewer pump can be installed in the kitchen to remove waste from the sink or dishwasher.

- The exhaust pipeline is made of rigid plumbing pipes. There are two recommended options - plastic sewer pipes and copper pipes. Fittings are recommended to be rigid and one-piece.

- Pipelines must be fixedly fixed (to walls, floor, etc.).

In general, installing and connecting a sewer pump for a kitchen or toilet is not a very difficult undertaking. But provided that you already have some idea about working with plumbing. In this case, you can do everything yourself.

Features of the outlet pipeline

Compact plumbing pumps for the toilet can pump wastewater not only vertically, but can also lift it upward. If there is a vertical section in its lower part, it is advisable to provide for the possibility of draining - if you have to clear the pipeline from a blockage, it is better if the drains are drained in a certain place and do not start pouring out during work.

The height of the vertical section of the outlet pipeline is determined taking into account the minimum slope of the horizontal section. Each manufacturer (sometimes each model) has its own minimum slope, but in most cases it is 1-4% (1-4 cm per 1 meter).

Rules for installing a sewage pump

Be careful. The description of sewage pumps indicates the maximum lifting height of wastewater and the maximum horizontal transportation distance. For example: 8 m up, and 80 m horizontally. But this does not mean that by lifting the pipe 4 meters up, it will be possible to transport another 80 meters horizontally. In this case - after a four-meter rise - the length of the horizontal section will be no more than 40 meters. Simply lifting 1 meter upward “takes away” about 10 meters of horizontal transportation. This is important and worth remembering.

Sololift maintenance during operation

Periodic maintenance of plumbing fixtures is a guarantee of their long-term and trouble-free operation. Sololifts for sewerage also need to be serviced. Moreover, you only need to spend 3-4 minutes on this process. This is done like this:

- the device is disconnected from the power supply;

- the water supply is cut off, for example, to the toilet;

- the cover is removed from the Sololift, which is held in place by one screw - you need to unscrew it with a screwdriver;

- Unscrew the four screws holding the pump. The latter is removed;

- the storage tank is cleared of debris;

- assembly of parts and assemblies in reverse order.

Operation and Maintenance

The Sololift system can be fully used only after proper installation without any defects. A correctly installed station will serve its full life without failures or breakdowns. But even if some checks and adjustments are required, they can be done quite easily.

In the second generation SOLOLIFT line, the key components are located in the tank above the wastewater level, and the relay, which is activated when the liquid pressure increases, is located outside. Grundfos calls this hand cleanliness.

With proper preparation, connecting the Sololift system to the sewer system will be simple and without “surprises”.

Sololift breakdowns and their repair

Sololift pressure sewer pumps are reliable equipment. But they also cannot withstand improper use. Mainly the electric motor suffers. Reasons for a motor failure that simply burns out and must be replaced:

- An object that could not be crushed got inside the pump: glass, a plastic bag, personal hygiene products, etc. The engine jams, which leads to overheating and burnout.

- The temperature regime of the drained liquid was not maintained. The consequence is overheating of the electric motor and its burnout. There is only one way out - change the Sololift model.

- Thick and sticky liquids were poured into the sewer, which the pump could only pump under heavy load, which led to its combustion.

- Freezing Sololift and sewerage. This happens in winter in unheated dachas.

- Depressurization of the pump and motor. As a result, water gets inside.

Sololift repair

Device and purpose

A pump with a grinder is a surface sewer pumping installation that allows you to organize the removal of wastewater where it is not possible to do this using a gravity system. This is a small plastic container with a powerful built-in pump that pumps waste into the sewer. The movement of drains can be both vertical and horizontal. There are installations with a grinder that can be connected to toilets, and there are those without a grinder - for “gray” waste from sinks, showers, bidets, etc.

The sewer pump for toilets and other plumbing fixtures is small in size

Application area

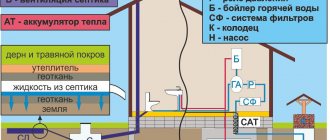

A sewer pump is used in cases where it is impossible to create a gravity sewer system. In most cases, when a plumbing fixture, washing machine or dishwasher is installed below the entrance to the sewer. This is why forced sewage pumps were invented. This solution allows you to move bathrooms and technical rooms to basements or semi-basements.

You can connect sanitary pumps in the bathroom, toilet, kitchen, and laundry room. In any room where water drainage is required and the sewer drain is far away

A pump with a grinder is also installed if it is decided to build a bathroom after the renovation is completed and the sewerage system is not connected to the place where the plumbing is supposed to be installed. In this case, the installed equipment is connected to a compact sewage pump, and it is connected to the sewer. What is the difference? In the following:

- the diameter of the outlet pipes for the sewer pump is much smaller than for the gravity system (28-40 mm);

- drains can rise up to a height of up to 9 meters;

- horizontal wastewater disposal is possible up to 100 meters (requires a minimum slope of 1-4%).

All this allows you to organize a connection to an existing sewer system almost anywhere at minimal cost.

Design and principle of operation

The sewage pump consists of a plastic storage container and a pump. Some models that can be connected to a toilet have a grinder. The filling level is controlled by a sensor. When it is triggered, the grinder and pump are turned on, and wastewater is pumped into the sewer system. The shutdown is controlled by a second sensor - it turns off the power when the wastewater level drops below a certain level. This is a simplified algorithm for the operation of pressure sewerage.

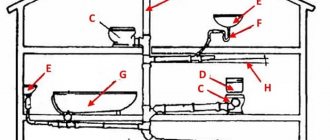

Sewage pump with grinder: device

There are sewage pumping stations designed to connect devices of various types and quantities. The simplest one is designed to connect one or two devices, the most productive one has three additional pipes (and one main one). Accordingly, the container has one or more inlet holes (depending on the model) and one outlet hole. Pipes coming from the plumbing are connected to the inlets, and the outlet is connected to the sewer.

For pumping out high-temperature wastewater from washing machines, dishwashers, and bathtubs, there are special models made of heat-resistant materials. A conventional sewage pump cannot cope with such a load. Therefore, to connect such equipment you need to look for certain models.

Technical characteristics and markings of the device

Today, a number of Sololift models are represented by a line of products of various modifications. All products are produced in white plastic cases with a certain differentiation according to purpose and configuration. Pumping units of this kind are intended for residential premises, offices, and industrial buildings.

Devices of this type are equipped with shredders, but can only process toilet paper; waste must be prevented from entering drains.

If this is not possible, you need to select other similar equipment. Some models are capable of processing more complex contaminants in the form of sanitary pads. This feature is reflected in the device passport.

Watch the video

Sololift Grundfos C3 repair and maintenance. How to disassemble and clean.

The Sololift product line includes the following types of pumping equipment:

- C-3, where the index “C” indicates the size of the product, equal to 125 millimeters;

- D-3, the marking indicates the applicability of the device only for sinks and shower stalls; using it with a toilet leads to sewer blockages;

- WC – designation indicating the presence of a cutting device for grinding inclusions in the kit, allowing it to be used with a toilet;

- WC-1 – the pump is equipped with one inlet;

- WC-3 – the device has 3 inputs.

Such systems can be installed with toilets, bidets, and washing machines.

Equipment of this class can operate with substances with temperatures up to + 45 degrees. If it is necessary to process streams with hot water, you need to use a device model C-3.

Devices of this class provide a power of up to 10 meters with a productivity of about 4.3 cubic meters per hour of operation.

The design features and complete set of devices of this class give them the following capabilities:

- there is an overheating protection function;

- the use of a carbon filter is provided to eliminate sewer odor;

- The cable length of 1.2 meters allows you to choose where to place the pump.

Units of this type operate on a 220 volt network. The use of hydrodynamic thermal relays is provided to prevent the container from overflowing. Non-return valves are installed on the pressure pipes, protecting the device from overflow and liquid leakage to the outside.

Metal parts can work in aggressive environments because they are made of anti-corrosion steel.

Manufacturers and models

Not many companies produce individual sewerage installations. However, the price range is quite wide. Traditionally, European manufacturers are distinguished by good quality, but high prices. No one will be surprised if we say that Chinese sewage pumps cost less, but their quality is worse. In general, the choice, as usual, is expensive and high quality, or cheaper and...

Forced sewerage installations Grundfos (Grundfos) - Sololift (Sololift)

The well-known manufacturer of plumbing fixtures Grundfos produces Sololift pumps for forced sewerage. At the moment, a modified Sololift2 line has been launched. There are no moving parts in contact with drains. The exception is the chopper, but its drive is also “dry”. This makes repairs less of a hassle. There are several Sololift models for different cases:

Sololift sewer pumps are not the cheapest equipment, but they work reliably and meet the stated characteristics. The company also supports warranty repairs.

Pumps for toilets, bathrooms, kitchens and technical rooms SFA

This company specializes in the production of sanitary pumps. There are several lines to solve different problems and connect various devices:

SFA products work reliably and cost slightly less than Grundfus. You can choose a model for any combination of plumbing fixtures. Overall, the SFA sewage pump is a good option. Equipment installation is standard - place it in any convenient place. There is only one limitation - it is better for the outlet pipeline to start from a vertical section, if there is one on your route. If this is not possible, the length of the horizontal section should be no more than 30 cm.

The height of the vertical section is calculated taking into account that the horizontal section must have a slope towards the inlet of at least 1% (1 cm per 1 meter of pipe).

CompactLift fecal pumps from Aquatik

Toilet pumps Compact Lift are produced by the Chinese company Aquatic. This is a more budget-friendly option for individual sewer installations. They have a low noise level.

At the moment there are only three modifications:

Aquatik provides a warranty on its pumps for bathrooms and toilets for 1 year from the date of sale. Failure to operate (presence of fibrous inclusions in drains) may result in refusal of warranty repair.

Willo sewage pumps

The German company Willo is known for producing reliable devices. Toilet pumps are no exception. Good quality plastic, thick tank walls, reliable pump. The following models are available:

The Willo range of sewer pumping units allows you to solve any problem when it comes to equipping bathrooms and toilet rooms in private homes. For commercial or more intensive use, Willo has other solutions.

Pressure sewage pumps STP (Jemix)

These custom sewer installations are manufactured in China. The price category is average. Reviews, as usual, are different - some are completely satisfied, others categorically dislike it.

So, here are the sewerage pumps Jemix offers:

It differs from those described above in its increased power - some models raise drains by 9 meters. Most of the sewerage pressure pumps described above can lift wastewater up to 4-5 meters. So this is where the Jamicks win. In this parameter they have only one competitor - Sololift Grundfos with its lifting height of 8 meters. But its price category is completely different (as is its quality, for that matter).

Sololift cleaning

In many cases, it is impossible to do without a forced wastewater drainage system, for which compact sewage pumping stations are best suited.

Cleaning the Sololift, at the same time, is not only the key to flawless and long service life of the equipment, but also to the correct functioning of the entire system, which ultimately has a positive effect on the comfort of the owner.

In most cases, cleaning the Sololift involves inviting a specialist who will correctly, quickly and accurately perform maintenance, remove plaque and deposits from the knife, system valves and float chamber. If preventive measures are not taken, then over time the plaque will first disable its individual components, and then the entire system.

If for some reason it is difficult to call a specialist, you can try to carry out preventive maintenance of the pumping station yourself. However, it should be borne in mind that incorrect actions may damage the equipment, which will require repair and replacement of some parts.

Therefore, all work should be carried out carefully, without resorting to brute physical force. Also, you should not bring the equipment to a state where the plaque hardens to such an extent that it is impossible to remove it without special means.

- To clean the Sololift, you first need to know the most vulnerable and most deposit-prone components of the unit. These include:

- knife and the space around it. Over time, deposits and plaque can complicate the operation of the knife system, even completely blocking it;

- valves There are quite a lot of deposits on the valve, which deprive it of mobility, which leads to sticking, which will lead to significant damage;

- float system. The plaque blocks the float in one position, which leads to either the pump being constantly turned on or its activation being blocked, depending on the position of the float at the time of sticking.

To ensure proper and safe cleaning of the installation, a certain sequence of actions must be followed.

If the system is operational, you should resort to special means that corrode and remove blockages, then flush clean water several times. This will get rid of most organic residues in the system, which will increase the comfort of further manipulations.

- The installation is de-energized. Under no circumstances should you carry out maintenance work if the unit is connected to the power supply, as this is unsafe and can lead to electric shock.

- The receiving filter is removed and cleaned using any available method that will not damage it. Typically, running water, compressed air, and detergents are used.

- The submersible pump is removed from the storage tank. The tank is cleaned of waste residues, detergent is poured into it in a concentration according to the instructions for the selected drug.

- The space around the knife is cleaned. If you have the necessary tools at hand and the design is more or less clear, you can remove the cutting device, which will make cleaning easier.

- The check valve is washed.

- If necessary, replace the carbon filter. This is required in cases of an unpleasant odor spreading around the installation, or in case of malfunctions of the cleaned equipment.

Design features

The operating principle of Sololift sewerage installations is quite simple. The model is used as the main receiver for wastewater; secondary outlets are connected using auxiliary pipes with a diameter of 5 cm, which are located in the lower sector. Input lines for drains can be implemented using equipment for a standard sewer network, and the outlet elements used to drain liquid must be reliably sealed, since pumping is performed under pressure. That is why during installation it is important to purchase branded components, including a check valve and other elements of plumbing fittings.

The housing contains the pump itself with a separator element and knives that grind large waste. The principle of operation is the operation of an automatic unit, which turns on when the tank is filled and activates the pump; the device is connected to a standard electrical outlet. Energy consumption even for younger models is small, so installing pumping equipment allows you to install an efficient sewer network in a private house or apartment.

Use of forced sewerage

Features of drainage of dishwashers and washing machines

Everyone knows that modern automatic machines (washing or dishwashing) must be connected to the sewer system in order to remove contaminated used water. But in small city apartments there is hardly room to install these assistants in the sewerage area; this is typical for both the bathroom and the kitchen.

And in large cottages, you want to hide the units in the basement rooms, which often serve as the utility floor. In both cases, there is a solution if forced sewage pumps are used. The essence of the solution is as follows:

- Here you will need to place a special sewerage installation equipped with a water collection tank and a built-in pump.

- The drains gradually fill the container in which the float switch operates. When their volume reaches a certain value, a pump is turned on, pumping contaminated water into the sewer.

- Such forced sewerage is small in size and is installed in an apartment or house in close proximity to the equipment that produces wastewater.

- It is equipped with a carbon filter that prevents unpleasant sewage odors from entering the room.

A reliable and efficient system does not require specific maintenance measures; you only need to periodically clean and rinse the tank.

Reconstruction or relocation of a bathroom

As mentioned above, moving a bathroom to another, more convenient place can be done in two ways:

- carry out redevelopment of the apartment, carrying out a major overhaul of the premises;

- install forced pumps for pressure sewerage.

The second option is more affordable and faster. But at the same time, you need to purchase a sanitary pump that meets special requirements. After all, he will have to work with aggressive environments.

Repair

Troubleshooting should be carried out only in service centers, where specialists will accurately diagnose the broken device and select the necessary spare parts. However, sololift maintenance can be carried out independently. To extend the life of the device and prevent the appearance of unpleasant odors, it is necessary to regularly clean the tank with detergent.

To do this, you need to disconnect the device from the power supply and remove the cover. Then the composition should be poured into the storage tank and left in this state for 10-15 minutes. Next, without replacing the lid, you need to connect the device to the network and press the drain. After flushing the tank is completed, you need to turn off the device again and put the lid back in place.

In the next video you will find the selection, connection and operating principle of the Grundfos Sololift 2 WC-3 compact sewage pumping station.