The drainage network is divided into pressure and non-pressure. The second type is the most common and involves the organization of natural movement downhill. Pressure sewerage is a system of sealed channels through which wastewater is transported under pressure to the place of its disposal or treatment. To maintain the required pressure, a powerful sewage pump is used.

A pressure sewer is a wastewater disposal system that can be easily installed on your own property

Drainage of wastewater in the life support system of the house

The main life support systems of a home include:

- heating;

- water supply and sanitation;

- electricity supply;

- ventilation, etc.

The laying of almost all utilities is carried out in stages during the construction of the structure. Planning is carried out when creating a project.

Note! If it is not possible to connect to centralized water supply/discharge systems, then individual autonomous wastewater disposal will be required.

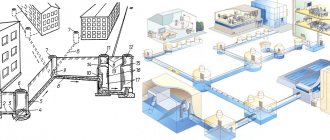

The internal and external parts of the house's drainage network are distinguished. The first consists of many pipelines into which wastewater from connected sanitary devices flows: bathtubs, washbasins, showers, sinks and toilets.

Horizontally located channels are laid at a slope to ensure gravity flow of wastewater into the sewer riser. The latter, installed vertically, rises above the roof and ends in a vent pipe. At the level of the basement or foundation, the riser enters an inclined pipe, which, going beyond the boundaries of the building, becomes the beginning of the external sewage system. The external part of the drainage system can be a gravity pipeline system, treatment facilities, wells or pressure sewerage.

If a sewer pump is not intended to be installed in a private house, then the pipes should be laid with a slope to create a gravity-flow system

Installation

If you comply with all building codes, this allows you to accurately install the external sewer system, as well as the service life of all parts. It is necessary that the pipeline has the correct slope. This slope allows wastewater to drain naturally. According to SNiP, the slope of the pipeline should be towards the well.

The slope of the pipeline is determined by the diameter of the communication installation and ranges from two to three centimeters per meter of structure.

Important! It is necessary, of course, to produce the diameter of the pipes that will be supplied to serve the house or area. There are diameter standards for sewers that serve different numbers of houses

There are diameter standards for sewers that serve different numbers of houses.

If wastewater is discharged from several private properties, then the diameter of the pipe must be at least two hundred millimeters. And if wastewater is discharged from one house, then the diameter of the pipes should be one hundred or one hundred and ten millimeters. If pipes are installed between wells, they must be placed level, without any slope. When designing, you need to draw up a plan for the movement of communications, not forgetting to mark the pipeline and nearby buildings on it.

It is also better to place the water collector close to the roadway, but only if you plan to equip a cesspool (it is usually pumped out by a sewer truck). If an external sewer system is installed at bends or at differences in depth, then an inspection well must be constructed. Also, inspection wells are installed in cases where the straight section of the pipeline is more than 25 meters. And such a well is called an intermediate well.

The pipeline along its entire length must consist of pipes of the same material. Because different materials have different thermal expansion and for this reason a pipeline with pipes made of different materials quickly collapses.

So we have described the basic rules for the arrangement of external sewerage. When arranging external sewerage and, indeed, installing all types of sewerage systems, it is recommended to follow these norms and rules. Because if there are deviations during installation, this can subsequently lead to accidents on the routes and equipment failure. And this is very bad.

Pros and cons of pressure drainage

Pressure sewerage, constructed, for example, from PVC pipes, has the following advantages:

- shallow channel laying depth, which significantly reduces the labor costs of excavation work;

- no need to maintain the pipeline slope;

- ensuring self-cleaning of channels from the inside;

- the possibility of using pipes with a smaller diameter than that of a gravity system, but commensurate with the pump pipe.

External sewage and storm sewers are laid taking into account the depth of soil freezing in the region. Since the wastewater moves under pressure, the internal cavity of the pipeline is simultaneously cleaned and various debris is prevented from sticking to the channel walls.

Pressure sewerage has a significant disadvantage - it is more expensive. The installation of a pumping station, waste storage and a larger number of inspection wells significantly increase the overall cost of the project. In addition, the system is volatile. A power outage leads to the cessation of pumping masses from the storage tank.

Which pipes are best to make NK from?

Since a running pump creates pressure drops in the system, the pipes and fittings involved in it must have:

- sufficient flexibility;

- strength in places of fastenings and joints;

- resistance to frequent changes in pressure.

Cast iron socket and plastic pipes meet these conditions. The former have sufficient strength and performance characteristics, as well as a fairly long service life (25-30 years). But cast iron products have a number of significant disadvantages:

- heavy weight (complicates installation and repair work);

- the material becomes brittle in the cold, which requires mandatory insulation of the pipe if the laying depth is above the soil freezing horizon;

- labor-intensive connection technology.

The listed disadvantages have led to the fact that pipes made of this material are practically not used when laying sewer systems.

Plastic (PVC) and polyethylene pipes (HDPE) are the best option for organizing external and internal drains. Their main advantages:

- light weight;

- the pipe material is not exposed to aggressive environments;

- simple connection technology;

- no deposits form on the inner surface, which reduces the likelihood of blockages and the need to use a plunger for cleaning.

As an example of such products, we can cite the products of Ostendorf, Hemkor, Geberit; these pipes fully comply with GOST standards.

Pipes for internal and external pressure sewerage

Please note that non-pressure sewer pipes designed for gravity flow systems inside and outside the building are not suitable for NK. The joints of such products will not be able to withstand pressure changes within the system, which will lead to the formation of leaks.

The connection of plastic pipes in the NDT system is made using a special soldering station. A description of the soldering technology can be found on our website. Note that there is an alternative connection option using glue; it can only be applied to special glued pipes.

Nuances of using the network

There are several cases when the use of pressure sewerage is necessary. These include:

- the location of the house is below the level of the central sewerage system (for example, in a beam);

- uneven terrain along the route of wastewater to the disposal site;

- the need for open laying of sewer pipes (for example, over the road);

- the inability to dig a trench at an angle to ensure gravity flow of water;

- the need to use channels of small diameter.

A system assembled from small-diameter pipes and not having a sufficient slope must be pressure only, otherwise there will be problems with drainage

The laying of pressure sewers (PVC and other materials) requires coordination of the project with the engineering services of a particular area regarding the intersection with other networks.

Note! It is important in organizing forced drainage to ensure a security zone: no closer than 250 meters from the river bank, 100 meters from the lake and 50 meters from the underground water intake source.

To save money, you can install one system on several farms. This combination is real, since pumps of various capacities are available for sale.

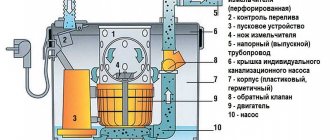

Main components of pressure sewerage

The main node of the sewer pressure network is the pumping station, which receives all wastewater from plumbing fixtures. A powerful pump ensures the movement of sewage to the place of disposal.

Structurally, the station is a storage tank that collects wastewater to a certain level. At a certain moment, the pump turns on and transports it to the pressure collector - a line of sealed pipelines that transport wastewater to a drainage pit, central sewer or septic tank. Modern sewage pumping stations operate automatically and do not require human intervention, except in cases of equipment breakdowns.

Pressure channels made of steel, cast iron or polyvinyl chloride can be used to lay a pipeline network. If the sewerage system is installed using a combined method, then pressure pipes are used after the pumping station, and standard products are used before it. An exception may be areas where water rises from the basement.

Modern sewer networks are installed from pressure polymer pipes, for example, PVC

To transport wastewater from the lower floors, a mini sewer station is used, mounted at the outlet of the toilet. Often in such combination systems, a reverse-acting pressure valve is used, which blocks the possible return of sewage downwards after the pump is turned off.

How to dampen the speed of water movement

The damping of the flow force is achieved due to the difference in the wastewater level. The design of a standard damper well allows reducing the pressure by 17-20%. The deeper it is, the more the waste flow will slow down.

In multi-stage wells, water moves along planes located at different levels. In this case, the next plane is lower than the previous one, like steps. The flow rate decreases repeatedly as the water moves through the cascade.

The flow rate is slowed down by the thickness of the water in the reservoir (the pool) into which it hits. Installing an additional partition (water trap) further reduces the flow rate. Instead of a partition, a special grill can be fixed.

The pressure is reduced by a 90º swivel elbow installed on the incoming pipe.

If large debris is found in wastewater, the well is equipped with a trash basket (grid). It will trap floating objects and prevent pipes from clogging. The trash basket also reduces the speed of wastewater.

Types of holding containers

Among the main types of prefabricated containers are cesspools and septic tanks. The first is a type of cesspool, which is dug into the ground and lined with a thick layer of clay. A modern well is a sealed structure into which sewage is drained and then removed using various devices (pumping pump, sewer truck) beyond the boundaries of the site.

Note! To build a cesspool, you can use a variety of materials: brick, concrete, stone or blocks. One of the options is to install reinforced concrete rings, metal or plastic tanks.

A septic tank is an improved cesspool, with the help of which it is possible to dispose of part of the wastewater on site. It can consist of two containers, one of which (prefabricated or cesspool) has a bottom and is sealed, the second - without a bottom, installed on a filter base (gravel, crushed stone, coarse sand), through which clean water enters the groundwater layer.

The best, albeit expensive, option is to install septic tanks in the form of local sewer systems. Such equipment collects waste and almost completely recycles it. Clean water comes out of it (96-100 percent), which can be used to water the area.

Autonomous sewerage must include a septic tank or cesspool

What to look for when choosing elements

Pressure sewer channels must be protected and highly reliable. Such requirements are explained by the characteristics of the network:

- transfer of liquid under pressure;

- water hammer when starting pumps;

- sudden changes in pressure.

Ideally, products for pressure sewerage will withstand pressure values of up to 1600 kPa. Currently, the most popular are pipes made of polymers (most often unplasticized polyvinyl chloride). They are durable, relatively lightweight and affordable.

PVC-U pressure channels are chosen with a smaller cross-section than for the construction of non-pressure analogues. The connection can be achieved by cold welding or special fittings. It is important to consider that pipes for such systems should not have sockets.

The intermediate tank must have a sufficient volume to accommodate three days' worth of wastewater. This is important for situations where the pump breaks down or there is a power outage, when the sewage system does not function for some time. To carry out the necessary calculations, it is better to use current standards.

The pump power is selected based on the depth of the intermediate tank and the distance to the central sewerage system. For example, 0.4 kW is enough to lift wastewater 2 meters and transport it 200 meters.

Pumps and their features

The type of pump is selected depending on the composition of the wastewater. If this is wastewater of household origin, for example, from a sink, sink, shower, then a regular pump will do. However, the sewer system must be designed to handle waste from the toilet, which can even contain solid objects, so a pump with a grinder is necessary.

If there is a large volume of wastewater and the presence of solid particles in it, a powerful pump equipped with a grinder should be installed

Note! The presence of such equipment makes it possible to reduce the cross-section of the pressure pipeline to 4 centimeters.

Since large volumes of liquid are removed from pools or bathtubs, they must use high-performance pumps that can provide uninterrupted operation for a long time. When choosing equipment, it is necessary to take into account the possibility of its functioning with water at temperatures up to 70 degrees, which comes from washing machines and dishwashers.

Pump installation rules

There are a number of rules that must be taken into account when installing pumps for pressure sewer networks:

- in the place where the pump is installed, it is necessary to constantly maintain the temperature above zero;

- the site for installing a sewage pumping station must have access and be cleared;

- a support elbow with a special flange must be placed at the bottom of the structure;

- the pressure pipeline rests on the elbow;

- in the upper part of the well, the pipe is secured with a bracket fixed to the wall of the structure;

- the channel must be installed without stress or distortion;

- to prevent reverse flow, a valve and a check valve are provided in the pipeline;

- a guide structure and a chain fixed on it are used to raise and lower the pump;

- a tight connection occurs automatically when the pump reaches the lower elbow.

Pumping stations are divided into indoor and outdoor. The first are designed to drain wastewater from one building and consist of a pump with a grinder and a plastic housing. Such a structure is usually installed in the basement. Outdoor stations facilitate the transfer of wastewater from several houses. They pump liquid from a container where sewage flows by gravity, and then into an existing sewer or treatment plant.

To lower and raise the pump, you need to attach a reliable rope or chain to it.

Surface devices

Surface-type devices intended for pumping out sewage are placed close to the collector that collects and moves waste liquid, or in any inspection well that is most convenient for installation. The last installation option is called dry.

Surface models are also considered to be pumping stations for forced sewerage due to the presence of separate parts assembled into one structure. In this case, the contaminated liquid is sucked through a hose connected to the pump and lowered to the bottom of the storage tank.

When choosing a surface unit, special attention should be paid to such an indicator as the suction depth - the manufacturer indicates it in the instructions supplied with the equipment. Most often this is 8 - 10 meters, but from a greater distance it will not lift wastewater from the storage tank

It is necessary to take into account both the height of the tank and the distance from it to the pump.

A surface low-power device for a forced sewer system is a compact device that is located next to the storage tank. To install more powerful equipment for pumping out wastewater, it is necessary to prepare a special place for it with reliable fixation to the floor.

When installing an outdoor unit, care should be taken to ensure its reliable protection from moisture. Unlike a submersible sewage pump, it is not intended for use in wet environments. Its body has minimal protection from water. If liquid gets inside the surface device, there is a high probability of a short circuit.

This pump is inexpensive, easy to operate, but very noisy. It is better to place it in a basement or other heated room. But, if the pump will be used from time to time to pump out the septic tank, then submersible installations are preferable.