In the past, cast iron pipes were usually used for drainage; this material is good, but not eternal. In particular, the sewage system of most of the panel houses built in the 2nd half of the last century is in deplorable condition. Therefore, nowadays it is becoming important to replace the sewer system in a Khrushchev building with your own hands.

Sewer replacement technology

Scope of work when replacing a sewer system

For residents of city apartments, this is usually limited to dismantling old horizontal pipes connecting plumbing fixtures to the riser.

The work is performed in the following sequence:

- during the period of work in the house, a “prohibition” is established;

- Plumbing fixtures are disconnected from the drainage system;

- after this comes the turn of the most labor-intensive operation - removal of horizontal pipes. If they were laid underground or in a special box, then this can be done quickly. But if they were laid in a screed or embedded in a wall, you need to remove the concrete layer using a hammer drill and grinder;

- special attention and care must be taken when removing the area connected to the riser;

The photo shows the result of careless handling of the bell

- a new pipeline is laid, the tightness of the system is checked, then they are hidden in the wall or floor.

If the replacement is carried out in a private house, then in addition to internal work, updating the external sewage system will be required. This is fraught with certain difficulties - the volume of excavation work is significant, and the layout of the site may not allow the use of special equipment for digging trenches. In this regard, the trenchless method of laying a new pipeline is quite popular.

Dismantling external sewerage is quite labor-intensive

Installation of plastic pipes

After dismantling is completed, assembly begins. They start with the riser. Insert a piece of pipe into the tee, then a revision tee. A piece of the required length is inserted into it, onto which the coupling is previously put on. When all the parts are installed, the coupling is moved upward, connecting and sealing the parts of the riser. After this, a horizontal section is assembled according to a pre-drawn diagram. The plumbing is connected, a check is made to see how the new sewer system works in the Khrushchev building. If leaks are detected, all defects are immediately eliminated.

Technology of work execution

If the work will be carried out in a city apartment, then before starting you need to ask your upstairs neighbors to refrain from using the sewer system for a while. It’s better to just turn off the water supply along the riser.

In the future, instructions for performing work look like this:

- after disconnecting the plumbing fixture, cut off the visible part of the pipe;

Note! When working in the bathroom, the siphon must be knocked out carefully. If the bathtub itself is cast iron, then it can be easily split with a careless blow of a hammer.

- It is better to remove the old pipeline in parts, making cuts with a grinder . As a rule, it is not possible to cut through metal to the full depth at once, so you can first make a small cut and use a hammer to bring the wall down inward. After this, the disk will reach the far wall;

To facilitate dismantling, it is better to make a notch

- After removing the pipeline that discharges waste into the riser, you can begin laying a new one.

Features of dismantling old sewerage

The most difficult thing is to dismantle it without damaging the bell. If the slightest crack forms in the riser, you will have to replace it; the cost of updating the sewer system will only increase in this case.

Note! When removing a section of sewerage approaching the riser, it is strictly forbidden to rock it. Cast iron is a very brittle material and this can cause cracks to form on the socket.

Previously, when connecting using the socket method, for additional sealing, the free space at the joint was filled with sulfur or filled with cement mortar. Over the years of operation, the riser has most likely been painted more than once, so first you need to remove a layer of paint and excess sealant.

The first step is to remove excess sealing material. A regular screwdriver or chisel and hammer will do for this. Gently tapping the screwdriver to chip off the excess material.

Excess material around the bell is carefully chipped off

Then you need to remove the sealing material from the space between the pipe walls.

There are several ways to do this:

- using a drill - the frozen sulfur is simply drilled out;

- by heating the joint - in this case the sulfur burns out, absolutely safe for cast iron.

If the connection was filled with sulfur to make it tight, you can simply burn it out

Note! When burning, a lot of harmful gases are formed, so you need to organize good ventilation and equip yourself with personal respiratory protection equipment.

Dismantling the old riser

A rotten riser can cause a lot of headaches, however, you can cope with replacing it yourself.

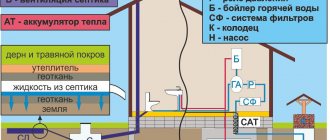

Riser replacement diagram

Instructions for installing a new riser instead of a cast iron one look like this (assuming that the horizontal pipeline has already been removed):

- part of the old riser is removed. You need to step back about 10 cm from the ceiling and make a cut with a grinder; the same cut will be needed in the lower part - above the distribution sewer tee;

- A chisel is carefully driven into the cut; due to the slight bend of the pipe, the cast iron bursts. As a rule, the fault line turns out to be perfectly smooth;

- if the piece of pipe going to the tee looks reliable and does not wobble, then you can leave it, otherwise it is better to cut it along with the tee (the cut should go below the lower socket). The tee socket is cleaned;

The bell needs cleaning

- after this you can proceed to installing the plastic riser.

Installation of a new riser

When connecting a plastic riser to cast iron pipes, a special rubber cuff is used for additional tightness of the connection. Otherwise, the joining process is not much different from a simple socket joint.

In the photo - a rubber cuff in a cast iron pipe

First, a rubber cuff is inserted into the thoroughly cleaned socket and only after that the pipes are connected. Additionally, the connection is generously sealed with sealant.

The joint between plastic and cast iron pipes is carefully sealed

Since only part of the riser is changed, the last pipe connection is made end-to-end, and the tightness of the connection is achieved using an adapter.

The result of replacing a cast iron riser with a plastic one

Replacement of external sewerage

This part applies only to owners of private houses. The price of replacing an external sewer system is not that high, but the process itself is quite labor-intensive, since a large amount of excavation work will have to be performed.

The solution in this situation may be a trenchless method of replacing pipes. If with the open method you need to dig a trench and remove the old pipe, then with the closed method you can do without digging ditches

Gravity sewerage

Most private houses have just such a drainage system. All work is performed by a special mechanism that destroys the old pipe, slightly expands the diameter of the hole and seals its walls.

Scheme for replacing a non-pressure sewer system

Pipe replacement is carried out in areas between wells.

When replacing a drainage system using a trenchless method, the work is performed in the following order:

- a pneumatic punch equipped with an expander and a destroyer moves to the end point along the old pipe;

- the pipe that has served its purpose is destroyed, and at the same time, due to the expander, the walls of the resulting tunnel are compacted;

- Following the punch, a pipeline is immediately sent, the sections of which are connected by a threaded connection.

Pipeline segments are pulled up following the punch

The price, of course, is higher than when replacing pipes using the traditional method. But, given the time savings and quality of work, this method deserves attention.

Features of Khrushchev

Apartments in panel or brick houses are considered one of the most budget-friendly types of real estate. One of the main complaints of consumers about Soviet-era houses is their lack of aesthetics and poor layout. The task of the builders was to quickly erect houses to provide citizens with housing. At the same time, comfort faded into the background.

The standard ceiling height is 2.5 m. The layout in Khrushchev's houses comes in several types. One of the most common is a two-room apartment with narrow adjacent rooms. There are one- and three-room living quarters. The bathroom can be shared or separate. In both cases, a minimum of space is allocated for the premises. Khrushchev houses are characterized by small kitchens, where only a minimum of furniture can fit.

view album in new window

In most cases, owners of such real estate prefer to redevelop. The kitchen is combined with the living room, and the bathroom is expanded due to the hallway. However, all work must be agreed upon with the supervisory authorities.

The main advantage of apartments on the secondary market is their low price. The cost of such real estate will be less than in a new building. However, the disadvantages include the fact that apartment renovation and redevelopment can become quite a costly undertaking.

Pressure sewer

The principle of operation remains the same - the new pipeline is stretched along the route of the old one without digging trenches. The main difference from replacing a gravity sewer is that the old pipeline is not destroyed.

That is, a new pipe of a slightly smaller diameter is simply pulled through the old sewer. Considering that the diameter decreases, this method cannot be used for free-flow sewerage. Due to a decrease in diameter, the throughput will also decrease, which means the likelihood of clogging will increase.

In pressure systems, a decrease in cross-section can be compensated by a slight increase in pressure. Therefore, this method is not used to replace sewerage in private homes.

Replacement of a pipeline operating in pressure mode

Compared to destroying an old pipeline, this method has the advantage that a new pipe can be pulled not only in areas between wells, but also along an inclined line, that is, from the surface. In addition, the old pipeline will serve as additional protection.

↑ Initial data and idea

The bathroom in my Khrushchev apartment is separate. The clear dimensions of the bathroom are 1520*1360 mm, but with certain manipulations they can be increased by 5-6 cm in each dimension, which I will discuss below.

The main idea of the new bathroom was to turn the bathtub 90 degrees and orient it along the far wall (opposite the front door). In my wife’s and my opinion, this position is more rational, although we understood that we would lose ten centimeters in length.

Summarizing

Replacing the drainage system is an integral part of a major overhaul, especially if the house used old cast iron pipes to drain drainage. This task is not as difficult as it seems at first glance, and besides, it can be significantly simplified. For example, when updating the drainage system, trenchless sewer replacement will allow you to quickly cope with work outside the home, but you can handle the internal system yourself.

The video in this article focuses on the internal work of replacing the sewer system.

Did you like the article? Subscribe to our Yandex.Zen channel

↑ Room cladding

Again, in the evening I primed all the walls and the screen under the bathroom with Ceresit ST19 primer-paint. When working with it, I strongly recommend that you carefully cover the bathtub with an old blanket or sheet and immediately wipe off the primer if it gets on the enamel or tiles - it will be too difficult to remove it later, after it has dried.

At the stage of preparatory work, I compiled a layout of tiles from the collections Keramin “Manhattan” and the Italian Alta Ceramica (collection “La Petra di Volta”. The apron in the kitchen was laid with Italian tiles and we are delighted with it.

The tiling of the bathroom took two and a half working days. The most difficult job was in the diagonal laying of Italian tiles, but our tiler successfully completed the task.

Ultimately, the niche was made not dark, as in the layout diagram, but light. The frame already shows a new Wassercraft faucet with a short spout, located not at the end of the bathtub, as usual, but on the side, so that it is convenient to regulate the flow of water without getting up from the bathtub.

And here is the shelf above the front door, already tiled. Made from two sheets of thin plasterboard (6mm) screwed with self-tapping screws to a wooden frame (boards 100x18 mm). Basins and containers with clean towels are now stored on this shelf.

The wiring for the fan and hanging cabinet was pre-installed.

Well, that’s how it happened somehow. Upon completion of the work, even the skeptical uncle of the wife melted - he really liked the result of our idea and his work. On the right under the bathroom there is space for access to communications.