One of the common problems that plagues summer residents is the high groundwater level. And coupled with high water, which inevitably appears after heavy rains or melting snow, this brings a lot of trouble.

Prolonged drying of the soil, dampness and fungus on the walls, increased heaving of the soil, destroyed foundations - this is not a complete list of problems. A drainage well is one of the simplest ways to solve these problems. Moreover, you can drill it with your own hands without any problems.

- Why does the site need drainage?

- How drainage works

- Well placement diagram

- Well drilling Percussion drilling

Why does the site need drainage?

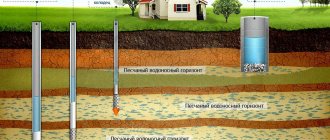

In simple terms, water that falls on the ground in the form of precipitation seeps through the soil and goes into aquifers.

The speed of this process is influenced by two factors:

- groundwater level (GWL);

- soil type.

If the soil is sandy or loose, the water will drain quickly. And if it’s clayey, then slowly. At the same time, it accumulates in the so-called lenses, increasing the ground level. In this case, problems cannot be avoided.

If the soil is not clayey, the water drains quickly. And there may not be any problems with high water. However, often the waterproof layer is located close to the surface. In this case, although not constantly, the water will also stagnate on the surface.

In addition to problems with dampness and flooded basements, high water poses another danger. This is an increase in the heaving of the earth. As you know, in winter liquid freezes and expands. Moreover, such pressure is created inside the soil that it can destroy the foundation of the house. Therefore, the sooner the issue of drainage of perched water from the site is resolved, the better. It is for this purpose that drainage wells are drilled on it.

Groundwater

Installation of plastic inspection and storage tanks

If you purchased a plastic container for a drainage well, you only need to install it correctly on a pre-made base. The installation of these two types of structures is almost similar. The difference may lie in the number of outlet pipes, the parameters of the wells and their different locations, which can be vertical or horizontal.

Inspection structures, as a rule, are created in a vertical position, and storage structures can be equipped in both vertical and horizontal versions. In addition, collector wells are equipped with drainage pumping equipment, and pipes are discharged into a drainage basin.

Before you begin constructing a well intended for collecting and further discharging drainage waste, you need to dig a ditch, perform a series of preparatory steps described earlier, and lay pipes, but do not fill them up.

The installation of the well is carried out in stages:

- On a personal plot, in the area allocated for the installation of the structure, the soil is deepened to about 40 centimeters from the level of laying the pipes.

- Layers of sand and crushed stone are poured and compacted.

- Prepare a concrete solution at the rate of 3 parts sand and 1 part cement and fill the bottom with it.

- After the base has hardened, when it is completely prepared, which takes about two days, a layer of geotextile is laid.

- The container is placed on a concrete base and the pipes are connected to the outlets.

At the final stage, a hatch is installed on top and the structure is covered on all sides with crushed stone and soil.

How drainage works

The main task in the fight against perched water is to help it pass the waterproof layer as quickly as possible. This is exactly what drainage wells do. The operating principle is very simple. A hole is made in the ground to a depth of several meters and through it moisture leaves the soil.

The well must meet two conditions:

- It must completely pass through the first waterproof layer of soil;

- You cannot reach the aquifer.

Those. When the clay layer is passed through, the drilling work ends. If you reach the aquifer, moisture from the site will flow into it. And in a place with it, all the dirt washed away from the top layer of soil will fall into clean water. Which will not be very good, because... Wells and drinking wells are fed from these layers.

Well placement diagram

Naturally, one drainage well per site is not enough. Moreover, they can be divided into several types:

- to lower the groundwater level;

- to protect foundations;

- to protect the root system of trees from excessive moisture.

To protect buildings, drainage is located near the foundations, throughout the rest of the site - in places of greatest accumulation of moisture. To avoid excessive drying of the soil, holes located in gardens and vegetable gardens are made smaller in depth.

Typically, the number of points required for a site is calculated based on the depth of the wells. It is assumed that the area effectively covered by one point is equal to the area of a circle whose radius is equal to the depth of that point.

For example, if there is a drainage with a depth of 6 m, then its working area is calculated using the formula for the area of a circle. Those. it is equal to 38m2.

Well layout

Stages of work

It is recommended to equip drainage before laying the house foundation, distributing the system evenly throughout the area. The procedure is carried out in several stages:

- Creation of a diagram, preparation of tools and materials.

- Drilling a well 10-15 cm in diameter, 2-4 meters deep.

- Inserting a specialized pipe with pre-drilled holes.

- Filling the pipe with washed crushed stone and expanded clay.

- Install a cover or cover with waterproof material and fill with soil.

Drainage of the site using drainage wells is carried out constantly, but for this the technology must be followed.

Well drilling

There is no specific figure that would be suitable for any site and determine to what depth it is necessary to drill. Therefore, for each specific case, it is determined by location, usually 4-10 meters. Although there may be more.

Ideally, exploratory drilling is carried out first, on the basis of which a soil map is drawn up and drainage points are calculated.

For drilling, you can use special equipment. This option will be the fastest, but not the cheapest. Therefore, for self-drilling, the following methods are most often used:

- Rope-percussion.

- Hand drill.

If the point is made close to buildings, it is not recommended to use the rope-impact method. Vibration from impacts can damage the foundation.

Percussion drilling

In this case, a drainage well with high groundwater is made using a bailer. The bailer is a piece of thick-walled pipe 1-2 meters high. At the bottom there is a valve for collecting soil, at the top there is a fastener for the cable, and on the sides there are windows for removing soil.

To drill wells, the bailer is suspended on a cable and dropped into a hole in the ground. As a result of the impact, soil is forced into the pipe, after which it is removed and cleaned.

It is most convenient to use a lifting mechanism so as not to remove the bailer from the pit manually. Because You need to make a lot of effort to get the difficult pipe, the weight of which is added to the mass of the earth being removed. As a lift, you can use a high tripod, to which a rotating mechanism is connected through a system of blocks.

Sequencing:

- It is most convenient to do the initial deepening with a hand drill;

- when the hole is deep enough, a lift is installed above it, and a bailer is connected with a strong cable;

- it is inserted into the edge of the well and released into free fall;

- then it needs to be raised 1-2 meters and released again. Repeat this several times;

- after this, the bailer is taken to the surface and cleaned.

Thus, you drill a drainage well with your own hands. But this method has its limitations. For example, drilling a well in sandy soil can only be done with a casing pipe.

Bailer with lifting mechanism

Drainage well in the garage. Step-by-step instructions for making drainage in your garage with your own hands

The main problem in garages equipped with an inspection pit or cellar is considered to be high humidity. In some cases, the situation reaches the point where puddles accumulate on the floor and the garage begins to flood. An effective way out of this situation is to equip a drainage system that removes excess moisture, helping to keep the room dry. We'll look at how to make drainage in a flooded garage below.

Why do you need to drain water from the garage?

Draining excess water from the garage helps keep the garage dry and prevents problems such as:

- mold formation on the walls of the room;

- corrosion of metal parts.

Moisture in the garage appears due to:

- close proximity of groundwater to the surface;

- large amounts of precipitation;

- the fact that the owner often washes the car right in the garage or next to it.

If the garage is equipped with drainage, the interior will always be dry.

Note! It is advisable to build a drainage system in conjunction with the garage. If you forgot about it, don’t despair. There are ways to equip a garage or basement with drainage after construction.

Drainage options

There are several options for drainage systems to cope with excess moisture:

- surface drainage;

- trench;

- drainage using a storage tank;

- borehole

Each of them has advantages and disadvantages that are worth considering separately.

Surface

Suitable for those buildings that were not initially equipped with drainage, and already during operation there is a need to remove excess moisture entering the building.

Surface drainage is a system of trenches that are installed in the most vulnerable place of the garage - at the junction of the wall and the ground. It is better to concrete the trench or pave the bottom with metal drains, which will prevent moisture from penetrating into the soil.

Advantages of the option:

- does not require serious expenses;

- quickly constructed;

- prevents moisture from accumulating in front of the gate.

Minuses:

- is not suitable as the main method, since it does not solve the problem of moisture formation due to groundwater.

Trench

Another way to remove excess moisture, which is implemented as follows:

- at a distance of one to three meters from the garage, a trench with a depth of at least 0.5 meters is dug;

- the bottom of the trench is covered with a layer of sand;

- a layer of geotextile is laid on top of the sand;

- plastic pipes connected to each other are laid in the trench;

- holes are drilled in the upper part of the pipes into which moisture will drain from the soil;

- the pipes are covered with a layer of geotextile. This will protect the holes from clogging with earth;

- The pipes are filled with soil, after which it is compacted.

Advantages of the method:

- helps combat groundwater.

Minuses:

- It is necessary to have a place where water will flow from the pipes - a ravine, well or pond.

Using a storage tank

This method is suitable for rooms that are often flooded. Construction algorithm:

- A hole is dug in a garage or cellar into which a plastic barrel is placed.

- The floor of the room must be poured with a slope towards the barrel.

- Cover the surface with expanded clay chips.

- Cover with geotextile.

- The top layer of the floor is covered with a board.

- A pump is lowered into the barrel, which will turn on automatically when it is filled to a certain level.

Pros:

- the room is not afraid of even strong floods.

Minuses:

- If the power goes out, the barrel will overflow and water will start pouring out onto the floor.

Note! Trench and borehole methods are considered modified versions of the surface method. They work best in combination with other options.

Borehole

The well method is similar to the use of a storage tank. Only, instead of a barrel, a well at least 2 meters deep is drilled in the ground. A pipe of suitable diameter is lowered into it, in the walls of which holes are drilled. The floor around the well is covered with a layer of crushed stone, after which it is covered with waterproofing.

Drainage arrangement

First of all, a site plan is made with the approximate location of drainage points. After this, you need to calculate the amount of materials needed. To construct a well you need:

- crushed stone or expanded clay with which the hole will be filled;

- casing plastic or asbestos pipes or polypropylene fabric with wooden slats.

The walls of the well must be protected from silting. Therefore, you need to decide in advance on the arrangement method. Because The cost and timing of the work depends on this.

Options:

- use of casing pipes;

- hand-made protective bag made of polypropylene fabric.

Both options have their place and do their job well. The principle of operation is the same. A well is drilled to the required depth, its walls are protected with water-conducting material, and crushed stone or expanded clay is poured inside. In this case, the diameter of the point does not matter much.

Arrangement sequence:

- Using a hand drill or bailer, a hole of the required depth is made. Usually it is no more than 10 meters. As drilling progresses, you need to control the composition of the soil reached by the drill. After the first waterproof layer has been passed, you need to go down another 1-2 meters. It is important not to miss the moment and not reach the aquifer.

- When the hole is made, you need to arrange the walls. If the option with a pipe is chosen, it is simply lowered into the well 15-20 cm below ground level. First, holes are drilled in it along the entire plane.

- If you choose the fabric option, it will be a little more complicated. You will need wooden slats along the length of the well. Fabric is nailed to them so as to form an improvised pipe. To make your work easier, you can make several rings from thick wire to use as guides.

- The resulting structure is lowered into the ground and covered with crushed stone. It performs two functions. Firstly, it prevents the walls from collapsing, and secondly, it filters all the water passing through it.

- After this, the well is covered with any waterproof material. You can use a piece of polyethylene or something else - it makes no difference. It is important that the top is sealed.

- The structure is covered with earth.

This completes the construction of the drainage well. Depending on the depth and complexity of the soil, all work takes 1-2 days.

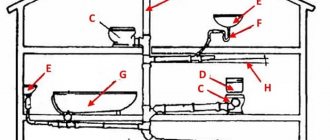

Purpose of viewing structures

An inspection or inspection drainage well is intended for the following work:

- performing routine inspections of the sewerage system;

- monitoring the condition of the pipeline;

- periodic cleaning of pipes;

- carrying out repairs.

An inspection well for sewerage is installed in places where there is a high probability that siltation or contamination of the pipes will occur. Its dimensions are selected taking into account the features of sewerage drainage communications. For small pipelines, inspection wells are created with a diameter of 34 to 46 centimeters.

Where large drainage systems are installed, they are equipped with inspection wells for drainage with an internal diameter of up to 150 centimeters. Some of these containers are equipped with steps for ease of descent into them. A large well can easily accommodate an adult who needs to perform work related to cleaning or repairing pipes.

Cleaning is carried out by washing with a water jet under pressure. One of the types of inspection wells is considered to be rotary devices - they are created at corner joints of pipes for quick sewer cleaning. There is no need to install them at every turn of the pipelines; usually this is done through one corner.

When arranging rotary inspection objects, one should take into account the peculiarities of the drainage system and place them so that all cross or corner sections of the highway can be brought to them.

Other drainage systems

Considering the time it takes to make one point and the physical costs, we can conclude that this option is suitable for small areas. If the area to be drained is large, other methods are used.

Drainage systems are made, which include channels with special pipes, and collectors for water collection. The drainage network is laid throughout the entire territory. In this case, it makes sense to involve specialists who can make a soil map and correctly calculate drainage.

Making complex systems on your own is not entirely advisable. Because it is required to carry out exploration drilling work, as well as make calculations that require at least special knowledge. In addition, it is advisable to use special equipment - making such systems manually is too time-consuming and expensive.

Drainage system on site

Thus, making a drainage well system in a small area is not so difficult. The main thing is to do this on time and not let the water run high. In general, experts recommend making a drainage system before the start of construction work. Otherwise, the foundations of buildings may cause deep subsidence. If you close your eyes to this problem, flooded basements, dampness on the walls and rotting of garden crops are guaranteed.

Previous articles Next articles

Related Posts

- 05.03.2017.

Do-it-yourself water supply at home from a well

- 05.03.2017.

Self-repair of drinking wells

- 05.03.2017.

How to drive a water well yourself: work order

- 22.02.2017.

Making a tank from plastic pipes

If you decide to make a well out of a plastic container, but it is missing, you can make it yourself. To do this, you should buy a plastic pipe with a diameter of 35-45 centimeters if you plan to construct inspection and turning objects, and a product with a cross-section of 63-95 centimeters for absorption and collector structures.

In addition, you will need a round bottom and a plastic hatch, the dimensions of which must match the pipes. You will also need rubber gaskets.

Sequence of making a plastic container:

- Cut off a piece of plastic pipe of the required size, which is determined taking into account the depth of the well.

- At a distance of 40-50 centimeters from the bottom, a hole is made for connecting pipelines and equipped with gaskets.

- Attach the bottom to the plastic tank and seal the resulting seams with sealant or bitumen mastic. The process of installing a self-made drainage tank is carried out as described above.