Unlike residents of multi-storey buildings, owners of private households are not provided with a centralized sewerage system and are forced to independently organize wastewater disposal on their property. A filter well plays an important role in the sewer and drainage system of a house.

However, it cannot be installed everywhere; there are certain rules that must be followed when constructing it.

In our material we will understand the types of filter wells, the rules for their installation on the site, and also tell you how to make such a structure yourself.

How many filter wells are needed on the site, how is their size calculated?

The number of structures on a particular site is determined based on the volume of water a family consumes per day. As a rule, for high-quality operation of one septic tank, you need 3 wells. In this case, the volume of the septic tank is at least two times greater than the daily flow rate.

On average, 250 liters of water are allocated per person per day. Accordingly, a family of 3 people requires a septic tank with a volume of 2.5 m³.

When determining the load on a well, take into account the composition of the soil and the distance from the structure to groundwater. If it is more than 2.5 meters, increase the load by 25%.

Advice! Where filtration is required only in the summer months - for example, at dachas, the load on the absorber is also calculated with a margin.

Drainage septic tank

By purchasing products such as a drainage septic tank from Europlast, you receive:

- discounts for wholesale buyers and low prices for everyone else;

- careful and fast delivery of the order in Moscow and the Moscow region or to a transport company;

- a large assortment allowing you to choose only the best products;

- guaranteed quality of every product purchased.

- If you cannot decide which materials you need, just call our consultants. We are ready to help you choose everything you need to implement your project.

Is it possible to make a filter well with a high groundwater level?

In addition to the fact that each specific absorber model is focused on a specific soil composition, the groundwater level plays an important role.

If the ground does not drain water well, the system will not work effectively and the quality of cleaning will be poor. Depth of occurrence can negatively affect filtration processes.

Reference! Experts do not recommend installing wells in places with high groundwater levels precisely because it is impossible to absorb water into the soil. The optimal distance from the filter to the water mains water supply is 1 meter.

Design principles

A septic tank is a sealed container consisting of several sections. The single-section option is used extremely rarely; the most common designs include two or three sections.

Two-section septic tanks are used with a drainage volume of 10 m³/day, and three-chamber septic tanks - over 10 m³/day. As a rule, all sections are combined into one common body (metal, plastic or concrete), but a separate design is also possible.

Each section (chamber) performs specific functions. The first compartment directly enters the sewer drain. This zone provides rough treatment of waste liquid - gravitational sedimentation and mechanical filters. In other words, in section 1, large and heavy sewage precipitates under its own weight and is filtered by a mesh. At the bottom, sludge gradually forms from such components.

The second chamber is considered an anaerobic reactor. It decomposes compounds formed under the influence of detergents, personal hygiene products, and various organic matter of natural origin. Catalysts can be added to speed up the reaction. Section 3 of the septic tank plays the role of final treatment, where the final clarification of wastewater is ensured.

Here, with gravitational settling of suspended particles, a purification degree of over 62% is achieved. All sections are interconnected and have shut-off equipment that does not allow flow back. In the two-section version of the septic tank, the second chamber is eliminated.

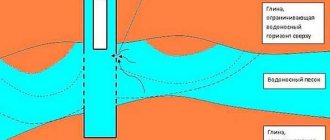

- Filtration well. At the bottom of the last section, a natural filter is formed from layers of sand and crushed stone. The construction of such a system is permitted provided that the depth of groundwater exceeds the depth of the septic tank by at least 1 m, and the lower filter layer must be at a height of at least 50 cm above the water layer. This is the only way to ensure reliable soil post-treatment of runoff.

- Filtration trench. If the groundwater rises high or the soil is clayey, then the well cannot be deepened, and the discharge from the last septic tank occurs in the upper layers of the soil. In order to ensure filtration under such conditions, it is necessary to increase the filter area, which is achieved by forming a closed trench. It can be dug in an open way with a length of up to 10-15 m from the wells. Sand and gravel are laid at the bottom along the entire length, ensuring a gradual release of runoff into the soil.

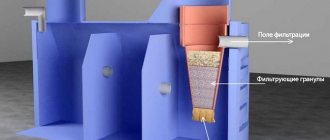

- Filter field or absorption trench. This structure is formed from a system of drainage pipes, i.e. perforated pipes. They cover a significant area to ensure drip discharge. A filter field is being installed to meet increased sanitary requirements.

When designing septic wells, the following basic requirements are put forward:

- The first section must have the required volume and be completely sealed to prevent impurities from entering the soil. The sewer inlet is located at the top of the tank, while the outlet is located at the bottom of the section, but above the sediment. A mesh is installed at the outlet to trap large particles.

- In the second section, gaseous decay products of wastewater accumulate, so in addition to complete sealing from the soil, care should also be taken about insulation in the hatch area. To reduce the dangerous concentration of pathogenic microorganisms, antiseptics and specific compositions with beneficial microorganisms, in particular methanogenic bacteria, are introduced into this chamber.

- The last chamber must ensure the discharge of purified runoff into the soil, that is, it must have a filtration system.

How to choose the right type of filter well

Which design and material to choose for absorber manufacturing depends on a number of factors:

- amount of water consumed;

- soil composition;

- financial opportunities.

Comparison of structures with walls made of different materials and with different filters

Both natural and artificial materials are used as filters. The main condition is that the drainage should not decompose upon contact with water. Toxic and biohazardous components cannot be used as a filter.

Optimal materials:

- quartz;

- pebbles;

- crushed stone;

- river sand.

Advice! It is better not to use the remains of building materials as a drainage layer.

The materials most often chosen for installing wells are:

- brick is a high-quality and durable material. Advantages: reliable design; all work can be done alone. Disadvantages - high cost of installation;

- Concrete rings are quickly installed and last a long time. Helpers will be needed to install the structure;

- plastic - a budget option for water purification. Terms of use are limited. The material is afraid of low temperatures and mechanical influences. Requires enhanced waterproofing;

- old car tires - a well can be made from them quickly; in addition to rubber, you only need plastic brackets for fixing, a sewer pipe and insulation. Suitable only for use in the countryside, as it is afraid of frost.

Comparison of conical and cylindrical well

Let's consider the comparative characteristics of two options for filter wells - conical and cylindrical.

Conical

Used for wastewater disposal that has been pre-filtered in septic tanks and treatment systems. The structures are made from a special corrugated pipe - it performs a cleaning function. Two options are used:

- without perforation;

- with perforation.

The diameter of both pipe options is 6.3 cm.

The advantage of a conical well is the ability to install equipment in soils with different compositions.

Cylindrical

Cylindrical models are made of polypropylene. Their main difference from the conical versions is their limited use. For example, it is better not to install them in soil with a high concentration of clay.

The cylinder tube has a diameter of 100 cm and a height of 300.

Like conical filters, cylinder-shaped filters are inexpensive and easy to install.

Horizontal settling tank

The design of a horizontal settling tank allows for high throughput of the structure. Such devices can be used as treatment stations, which will receive wastewater from several houses located close to each other.

A typical horizontal settling tank is arranged in such a way that the length of the main tank is 10 times greater than its width. When drawing up a drawing of a horizontal sump, it is necessary to correctly calculate the width of the main tank. The bottom is usually flat. A special pit is also required. In its direction, the bottom of the tank slopes at a slight angle.

The entrance to the drains is equipped with a semi-submersible partition. A tray is installed to release clarified water. Its walls will additionally filter wastewater. The internal flow of water through the tank must be uniform. To do this, you need to prepare a project in advance or find a ready-made diagram.

How to make a filtration well with your own hands

You can make a filter absorber yourself. As materials, choose the one that is more convenient.

Brick construction

The shape of a brick well can be made round or square. Moreover, the first option is more convenient to use, and the second is easier to manufacture. The diameter of the structure is 200 x 200 cm. Depth is 200-250 cm.

The hole for the well is made with reserve. A drainage layer is placed between the walls of the structure and the ground. Crushed stone, gravel, broken brick will do.

The thickness of the layer is 400 mm. Height - 100 cm.

To prevent the walls at the location of the filter from allowing water to pass through, the masonry is made with holes. They are made in a checkerboard pattern. Size - 3-4 cm. After construction is completed, they are sprinkled with drainage filler.

The bottom of the well is lined with a layer of filter materials. Its height is 1 meter. They take different fractions - the larger ones are placed on the bottom, the smaller ones are sprinkled on top. Leave a hole for the sewer pipe. A special sheet of plastic is placed in the area where the liquid will flow from - it will prevent the filter from washing out.

A hatch is installed on top. Provide ventilation.

Construction made of concrete rings

A well made from ready-made rings is the simplest filter option.

Step-by-step instruction:

- dig a hole - its diameter is 50 cm wider than the concrete rings;

- lower the perforated block down the structure;

- install the first ring. Remove the soil from inside the workpiece. Over time, the ring will sag a little under its own weight;

- mount the remaining two concrete elements in the same way;

- Place drainage in the space between the walls of the well and the ground, as well as at the bottom of the structure. Next - the hatch and ventilation according to the standard scheme.

Well made from old tires

Car tires are the cheapest option to solve the problem of water filtration. Moreover, the structure will perfectly fulfill its function for a family of 3-4 people.

The disadvantage of such wells is that rubber is not suitable for use in the cold season. Consequently, these absorber models can only be used in the country.

At low temperatures the material freezes completely.

Step-by-step instructions for making a filter:

- dig a pit;

- drop a few tires into it;

- stack one on top of the other. Secure the device with plastic clamps;

- Apply sealant to the joints - it will enhance the grip of the tires and give the structure stability;

- further - according to the scheme described above.

Types of settling tanks

The classification of settling facilities is carried out taking into account such key points as:

- operating mode;

- appointment;

- line of passage of wastewater through the structure.

A settling well can function as a flow-through or contact tank. According to its purpose, the septic tank can be primary. Used water enters it unpurified. The wastewater is transferred to the secondary settling tank after preliminary filtration. The movement of used water inside settling tanks can be horizontal, vertical or circumferential.

How to install a filtration well

Decide what shape the well will be. Carry out calculations - calculate the area of the structure. Make a drawing.

Advice! Look at thematic sites on the Internet - here you can find a ready-made well project that will suit your calculations.

Step-by-step algorithm of actions:

- dig a pit;

- Lay a masonry 100 cm high from concrete rings or bricks. Make uniform holes for the exit of liquid;

- then make even masonry, without holes - the walls should be solid;

- install a sewer pipe. Place it just above the bottom filter. Make a slight incline. Place the open part of the pipe in the center of the pit. Place a container underneath to collect water;

- make a ceiling and install a hatch. Don't forget that there should be two covers - we discussed why in the previous section. The diameter of the hole is 70 cm. Provide waterproofing. Lay insulation on top of the structure and between the covers;

- fill the structure with soil. Leave space for ventilation outlet. Place the pipe to the side of the filter.

What are they?

The design of filtration wells of different types is similar; they differ mainly in the design of the tank and the material from which it is made.

The following types are distinguished:

- Cylindrical - the most common option. Made from plastic, brick or concrete rings. Their advantage is ease of maintenance and installation.

- Rectangular prism - made of concrete or brick. The main characteristics are similar to the previous version, but the rectangular shape cannot always be used;

- Conical - most often such tanks are made of plastic. The conical shape allows you to keep the structure from being squeezed out of the ground.

Maintenance and operation of filter wells

Care and maintenance of a well is a prerequisite for its high-quality operation. In order for the structure to serve for a long time, follow the rules of maintenance and operation:

- Periodically remove dirt from the filter. Do preventive measures - do not use the well for several days - let the water go away;

- loosen the drainage, regularly add a new filter, take away the used one;

- When the filter becomes silted, use industrial cleaning products.

Perform scheduled cleaning as follows:

- drain water from the well using a sewer truck;

- dissolve the pH solution in water and pour it into the well;

- mix hot water and stabilizer, pour inside for several hours;

- Mix Bionet Super with water, pour into the well, stir.

Advice! To prevent filter clogging, pour a bioactivator bag into the pit twice a month in the proportion: 1 dose per 1 m³.

Essence of structures

At its core, a septic tank is a well that is used to collect or treat household wastewater in the absence of a centralized sewer system in private homes and suburban areas. The principle of its operation is based on gravitational settling and additional purification by biological methods using bioenzyme-based products.

In addition, soil filtration is widely used, both natural and forced. On the territory of the Russian Federation, when designing and constructing septic tanks, Code of Rules 32.13330.2012 “Updated edition of SNiP 2.04.03-85 Sewerage. External networks and structures."

When designing your own sewer system, it is very important to correctly determine the place where you can dig a well. There are a number of completely natural requirements for the placement of a septic tank that make it possible to exclude contamination of drinking water, nearby groundwater, contamination of residential areas, i.e.

aimed at ensuring sanitary safety.

First of all, strict standards are established that determine the minimum distance from the septic tank to vital facilities. The following requirements must be observed:

- the distance from the septic tank to a well with drinking water is 50 m;

- to a residential building - 5 m;

- to an open reservoir - 30 m;

- to the garden (fruit trees) - 4 m;

- to the road - 4 m.

The most important characteristic of septic tanks is volume. It is usually set at the rate of 200 liters of wastewater per inhabitant per day. Naturally, the total volume is calculated by multiplying this norm by the number of residents, and if people permanently live in the house, it is recommended to increase the planned volume of wells by 20%. Most of the useful volume should be in the first section of the device (up to 75%). The well for the septic tank should not be placed in a low area, because there is a risk of replenishing the tank due to the influx of sedimentary or melt water.

General procedure for arranging a settling tank

To make your own sump from the selected material, you need to do the following work:

- choose the right place;

- dig a pit;

- place a tank in the hole;

- install sewer pipes;

- connect to a second sump or drainage well;

- seal the joints;

- fill the free space around the tank with earth removed when digging a pit;

- compact and compact the soil;

- decorate the external entrance.

If all work is done correctly, there will be no problems with collecting and purifying used water. Maintenance and cleaning of the sump will not require any special costs.

Preliminary calculations

For domestic sewerage, it is most convenient to equip a vertical sump. You must first draw up a work plan and drawing. This will help avoid mistakes.

When carrying out preliminary calculations, it is necessary to take into account the basic rules for arranging a vertical well. These include:

- placing the inlet 10 cm above the expected filling level of the tank;

- ensuring the passage of water into the adjacent chamber through overflow pipes located in the upper part of the tank;

- placing the inlet above the outlet pipe;

- the presence of a hatch for tank cleaning and repair work;

- At the top of the well, free space is needed to collect gases that will be removed through the ventilation outlet.

When determining the size of the sump, it is necessary to take into account:

- option for using the house (for permanent residence or seasonal recreation);

- house size;

- number of users.

You can choose the option for a summer cottage or a private house in which you live permanently.