The Abyssinian well, or (what is) the Abyssinian well, is a simple and inexpensive source of water supply for a country house or cottage. Drilling an Abyssinian well does not require the use of special equipment; it can be done independently, even in limited space. But it is worth knowing that any extraction of water from aquifers following the first near-surface one requires a mandatory license. And in order to obtain such a license, it is necessary to collect a lot of preliminary permitting documents for the well.

Construction of the Abyssinian well and percussion drilling method

Features of the Abyssinian well

You may be interested in information - do-it-yourself well in the country

The Abyssinian well is a sand well; water is drawn from the first sandy aquifer. The main feature is its shallow depth, simple design and low cost.

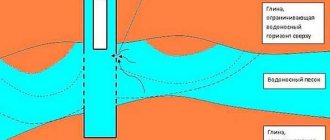

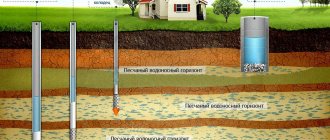

Abstraction of water from various aquifers

Conventional wells are fed from the upper groundwater - the so-called perched water. Groundwater is not separated from the surface by an impermeable layer, so it may contain dissolved organic matter from septic tanks and cesspools, pesticides, and heavy metal salts.

Sources of groundwater pollution

You may be interested in information about

Artesian wells extract water from deep, pressurized sandy or limestone horizons. The water there contains a lot of dissolved mineral salts; there are artesian waters with a high content of dissolved divalent iron. To purify water to potable quality, a complex filtration system is required.

Installation for purification of artesian water with a high content of iron and salts

The water in the Abyssinian well is of high quality. Waterproof clay layers reliably protect the first sandy aquifer from the penetration of contaminants from the upper layers of the soil, while at the same time the water does not contain excess mineral salts.

Construction of the Abyssinian well

The waters of the first sandy horizon are free-flowing, so a pump is needed to pump out the water. For Abyssinian wells, surface manual or electric pumps are used, the operating principle of which is based on the vacuum pumping method. This limits the maximum depth to the surface of the aquifer, not exceeding 8 m. In this case, the depth of the well can reach 14-15 m.

Pump for Abyssinian well

An electric pump or pumping station with a hydraulic accumulator is installed in a caisson directly next to the well or in a warm room at some distance. The permissible distance to the room, as well as the installation diagram of the pumping station, are shown in the figure.

Connecting the pumping station to the Abyssinian well

A hand pump is installed directly above the well. For year-round use, it is placed in an insulated caisson or room. The well can be drilled inside the house, in the underground - in this case, insulation is not needed.

Hand pump for Abyssinian well

The service life of an Abyssinian well is limited by the life of the pipes and pump and averages 10-30 years with regular use. Galvanized, or even better, stainless steel pipes will not only last much longer, but will not degrade the quality of the water.

Note! You can make an Abyssinian well in one day if you have the necessary components and tools for driving.

How it works

Iron pipes about one inch with a pointed tip on one side are driven or drilled into the soil, there is a special device for creating such a well, called an “Abyssinian well drill” , steel pipes should be used because of their durability and environmental friendliness.

Using a manual or electric pump, the water rises to the surface and within a few hours after the well was made, you will receive water; it is best to also use filters for water purification .

In other words, this is a narrow small well in which a pipe with a filter needle is placed at the end, which allows the drill string to pass through the ground and, when it reaches the aquifer, acts as a filter, preventing the pipe from clogging .

Preparing the necessary materials

The design of an Abyssinian well is extremely simple and consists of a set of metal pipes 1-2 m long, connected to each other using couplings, a filter pipe at the bottom for water intake and a pump on the ground surface.

Construction of the Abyssinian well

Step 1. Pipes are preferably galvanized or stainless steel to protect against corrosion, pipe diameter is 1-1½ inches (approximately 2.5-3.8 cm). Copper pipes are not suitable due to the softness of the metal, and copper can release free ions to water, poisoning it. On pipes, except for the lowest one, external threads are cut on both sides.

You may be interested in information on how to connect a pump to a well in your country house

Pipe kit

Step 2. Perforation is performed in the lower pipe, which is a water intake with a filter. The length of the perforated part is 700-1000 mm. The diameter of the holes is 8-10 mm, the center-to-center distance between the holes is 50 mm. The holes are arranged in a checkerboard pattern. Stainless wire is wound over the perforated part according to the diagram.

Wire filter for Abyssinian well

Instead of wire, you can use a fine mesh harpoon or plain mesh made of stainless steel. The mesh is tightly wrapped around the perforated part of the pipe and soldered at all joints.

Note! Soldering is performed with food-grade solder, lead-free or with a minimum lead content. Suitable brands of solders: POSu 95-5, POM-1, POM-3.

Filter on the pipe

A thread is cut at the upper end of the pipe to connect to the coupling.

You may be interested in information - pipe for a pumping station

Step 3. A spear-shaped tip made of hardened steel is welded to the lower end of the pipe, making it easier to drive the well. The diameter of the tip at the junction with the pipe should be 15-20 mm larger than the diameter of the pipe - this makes it easier to pass through the ground when driving.

Welded tip

Step 4. The number of pipes in the set depends on the expected depth of the well. They are connected using a threaded coupling; flax or fluoroplastic thread is wound onto the thread for strength. It is preferable to take thick-walled couplings, with a wall thickness of 5 mm - such products are stronger.

Couplings for connecting pipes

Step 5. To drive the pipes into the ground, a carbide driving tip is made. The tip has an internal thread and is screwed onto the next section of the pipe.

Drive-in tip

Step 6. Hammer the pipes using a sledgehammer or headstock. The headstock is a steel cylinder in which a hole is drilled slightly larger than the diameter of the pipe used. The striking surface inside the cylinder conforms to the cone shape of the striking tip in order to center the impact. A removable ring along the diameter of the pipe is attached to the bottom of the headstock to avoid distortions when driving. The headstock is equipped with handles for lifting on both sides.

You may be interested in information on how to purify water in a well

Grandma

Step 7. Sometimes the headstock is made with a through hole; in this case, instead of an impact tip, a headstock is used, which is attached to the pipe at a convenient height. In this case, the impact does not occur at the end of the pipe, which reduces the chances of bending it when passing through dense layers of soil.

Drawings of devices for driving an Abyssinian well

To make lifting the headstock easier, a clamp with blocks is made. In this case, the headstock is lifted by two people from both sides through blocks, and it lowers under its own weight.

Plugging an Abyssinian well with a headstock and a headstock

Step 8. For the initial pumping of the well and clearing it of sand, it is recommended to use a hand pump. If in the future you plan to install a pumping station, you don’t have to buy a hand pump, but rent it.

Hand pump

Step 9. When placing pumping equipment in a caisson, after installing the well, it is necessary to dig a pit for its (caisson) installation. The depth of the uninsulated caisson must be greater than the freezing level of the soil.

Well caisson

Note! You can make a caisson with your own hands from concrete rings.

Prices for filters for the Abyssinian well

Abyssinian well filter

Making a tip with a filter

Filter for an Abyssinian well with a tip

The filter for an Abyssinian well is made quite simply with your own hands. A piece of pipe (approximately 80 cm) with a cone-shaped tip is perforated - thin cuts are made or round holes are drilled. After this, wire is wound around the perforated area and a braided mesh made of stainless material is applied. The latter is fixed with clamps or soldered using special non-toxic tin solder.

Choosing a site for an Abyssinian well

The operation of an Abyssinian well is only possible if the distance to the aquifer is no more than 8 m. Otherwise, surface pumps will be ineffective, and a submersible pump will require a larger diameter pipe and a different drilling technology.

You might be interested in a do-it-yourself drill for a well

To prepare a set of pipes, you also need to know the approximate depth of the well. Excessive deepening of the suction pipe with a filter can lead to its penetration into dense layers of soil lying below the level of the vein.

How to choose a suitable location for a well and determine its expected depth?

- The surest sign of the possibility of developing an Abyssinian well is the presence of the same wells in the nearest neighbors. You can ask them not only about the depth, but also about the flow rate of the well in order to determine the required performance of the pumping equipment. Measuring the flow rate of a well is quite simple: you need to time 1 minute and determine how much water the well is capable of producing during this time.

Table 1. Required pump performance depending on the well flow rate.

| Well flow rate, l/min. | Maximum pump performance according to the passport, m3/hour | Pump operating capacity, m3/hour |

| 15-20 | 1,8-2,5 | 0,9-1,2 |

| 20-25 | 2,5-3,0 | 1,2-1,5 |

| 25-30 | 3,0-3,6 | 1,5-1,8 |

- If there are wells nearby, you can also find out the depth of the aquifer. Using a rope with a weight, measure the depth of the well to the bottom and to the water surface, and find out the approximate thickness of the aquifer.

- A sign of close occurrence of interstratal aquifers may be the emergence of springs and streams to the surface. If in your area there are springs with good, tasty water, then with a high degree of probability the same water will be in the drilled Abyssinian well, and the depth of the latter will be shallow.

- An indirect sign of the close passage of an aquifer is some plants with a deep root system: coltsfoot, burdock, horse sorrel, celandine and many others. Trees with tap roots also grow better in areas with nearby aquifers.

The presence of various plants depending on the level of underlying waters

- Fog after sunrise, as well as swarming of midges over certain areas, are also clear signs indicating the proximity of an aquifer.

- Well digging experts use metal frames to find the location. It is believed that this requires experience, but you can try to do everything yourself. Take two pieces of copper wire 35 cm long, bend the frames from them at an angle of 90 degrees with an aspect ratio of 10/25 cm. Take the frames in your hands by the short sides and place them parallel to each other, without squeezing too much. Walk slowly through the area. In the place where the aquifer passes, the free ends of the frames should meet.

Folk way to find water on site

Dowser mistakes

Note! Several signs indicating the proximity of water indicate a high probability of finding an aquifer with a high flow rate.

Do-it-yourself Abyssinian well - step-by-step instructions

Equipment for driving an Abyssinian well can be rented from drilling companies, purchased, or made independently according to the ready-made drawings given above.

You may be interested in information - pumping equipment for wells

Step 1. Remove the turf on the well site to a depth of 20-30 cm. When driving a well underground, the turf does not need to be removed. The first 0.5-1.0 m is drilled with a regular garden drill to penetrate the fertile soil layers. Pipes for a well are installed in too dry or frozen ground; this will not affect the water, but will make the drilling process easier.

Drilling the top layers of soil with a garden drill

Step 2. Install a pipe with a punched tip into the drilled well, level it strictly vertically and fix it in this position. This can be done using a tripod or a board with a hole, as shown in the picture.

Fixing the pipe in a vertical position

Step 3. Place the lower ring on the pipe to secure the headstock. Screw a carbide tip onto the upper end of the pipe so as not to damage the thread when driving.

Carbide tip

Step 4. Place the headstock on the tip and screw the fixing ring to it from below. Raise the headstock by the handles until it stops, then release it. The headstock hits the tip, under the influence of a weight of about 25 kg, the pipe goes into the ground to a certain depth. The speed of driving is highly dependent on the density of the soil. A meter-long pipe goes into the sand with 5-8 blows; in clay it moves much more slowly.

Pipe driving head

Step 5. After the pipe has gone to a sufficient depth, the headstock, tip and fixing ring are removed, and the coupling is screwed on with flax or Tangit UNI-LOCK thread. The connection must be as tight as possible, otherwise during operation air or water from the perched water will be sucked through it.

Screwing on the coupling

Step 6. Install the next pipe and repeat steps 3, 4 and 5. Once the expected depth of the well is reached, water begins to be poured into the pipe every half meter. The sandy aquifer is non-pressurized; it is capable of not only releasing, but also absorbing water. If the tip with the filter is located in an aquiferous zone, the water poured into the pipe will drain quickly, almost instantly. If there is no information about the depth of the aquifer, the test is performed starting from 3-4 m.

Checking for water

Step 7. After reaching the aquifer, the pipe is driven another 0.5-0.7 m and a permanent or temporary pump is attached to it. They begin pumping the well. At first the water will be cloudy, with some sand mixed in.

Well pumping

Step 8. After pumping out several hundred liters, the water will become clean; a lens will form around the intake end with the filter - an area of clean water without foreign inclusions.

Clean water from the Abyssinian well

Step 9. A concrete blind area is made around the well: the soil is removed to a depth of 20-30 cm, backfilled with sand 5-10 cm thick, then a reinforcing mesh is laid and filled with concrete. From the center of the blind area to the edges, make a slope of 2-3 degrees to drain water. You can also perform drainage to drain water; in this case, the slope is made towards the drainage hole.

Blind area with drainage hole

Step 10. Install a permanent pump or connect a pumping station according to the diagram.

Connection diagram for pumping station and hand pump

Pumping station connection diagram

Note! The circuit must have a check valve, otherwise before turning on the pump you will have to fill the pumping station with water each time.

Caisson installation

A well is equipped with a caisson when its depth does not allow the pumping equipment to be moved into an insulated room using a horizontally laid and insulated pipe. You can read how to make a filter for a well in our article.

Step 1. When installing a caisson, a pit is dug around the plugged well. To avoid damaging the pipe, it is better to do this manually. Before starting work, wrap the top of the pipe with a bag or thick cloth to prevent soil particles from entering. The depth of the pit is 20-30 cm below the soil freezing level, the diameter is 20-30 cm greater than the outer diameter of the rings. At the same time, they dig a trench for laying pipes. The bottom of the pit and trench is leveled and backfilled with sand (layer thickness - 10 cm).

Pit for installing a caisson

Step 2. Install reinforced concrete rings in the prepared pit. A hole is made in the wall for the water pipe at the level of the trench. Reinforcement mesh is placed on the bottom, the bottom is filled with concrete with a layer of 10-15 cm. Leave to harden and gain minimum strength for 5-7 days.

Filling the bottom with concrete

Step 3. A cover with a hatch is mounted on the well. The hatch must be positioned so that the well pipe is exactly opposite it - in this case, if necessary, you will not have to disassemble the caisson to remove and replace the pipes. All seams are coated with cement mortar.

Cover and hatch

Step 4. Mount the pump and hydraulic accumulator in the caisson. Place the water pipe through the hole in the ring, having previously wrapped it in foamed polyethylene to avoid damage. The hole is covered with cement mortar. Connect the pipe to the pump and check the functionality of the system.

Installation of pumping equipment in a caisson

Step 5. Backfill the pit. A mixture of sand and cement is poured around the walls - gradually gaining moisture from the soil, the latter will set and securely fix the caisson. The cover is insulated with polystyrene from the outside and covered with a 0.3-0.5 m layer of sand. Reinforcement mesh is laid and filled with concrete. After it hardens, install the hatch cover.

Backfilling and concreting

Abyssinian well maintenance

An Abyssinian well will last longer if used regularly. At the same time, the lens around the filter retains its dimensions, the water in it remains clean, and the flow rate of the well does not change. If you plan to use the Abyssinian well seasonally, you need to preserve it: drain the water from the supply pipe so that it does not freeze, cover the pump with waterproof material to protect it from snow and melt water. In the spring, before the start of the season, it is necessary to pump the well, as before the first commissioning.

Using the Abyssinian well

Advantages and disadvantages

In the case of high productivity, a needle well has some pros and cons. Among the disadvantages are:

- Depth restrictions. If the distance is more than 9 m, the pump will have to be deepened, and this is a labor-intensive and complex process.

- If it is not used for a long time, the well or well will need cleaning. Leveling up an Abyssinian is a very labor-intensive task. The reason for this is the small diameter of the pipe.

Positive sides:

- Drilling occurs with minimal labor costs.

- The supplied liquid is 90% potable. You don't have to install a complex filtration system.

- Ease of producing needle wells at home or in the country.

- A minimum set of equipment that does not require special equipment for its transportation.

- Possibility of installation in car washes, since the well flow rate is up to 500 l/hour. Productivity – up to 60 l/hour.

- There is no need to pay for expensive specialist services.

- There is no need to obtain a drilling license.

- Minimum cost for the entire installation.

- Long service life.