Residents of the private sector, deprived of access to a centralized sewer line, have to solve the problem of organic waste disposal on their own by constructing various types of treatment or storage facilities for autonomous sewerage on their site. There is a wide range of ready-made septic tanks of various designs on sale, but many homeowners build treatment wells with their own hands by purchasing sewer rings from the retail chain.

It should be noted that large-diameter ring reinforced concrete products (RCP) are often used in households and for other purposes, using them to assemble engineering structures of various types and purposes. Many homeowners, in addition to certain knowledge about the varieties, auxiliary elements, standard sizes and costs, will benefit from information on how to dig sewer rings from various materials.

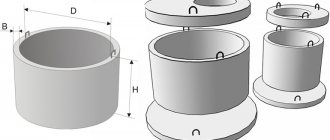

Rice. 1 Concrete sewerage for drainage - device diagram

Description and features

Based on the name, it is clear that the reinforced concrete ring consists of metal and high-quality concrete. This makes it durable and allows it to resist loads from the outside and inside. External loads mean the soil pressure on the ring. As for the internal loads, this is the water that the rings hold back, preventing it from getting into the ground.

The latter is especially important when installing septic tanks and drainage pits. The rings undergo additional waterproofing, which makes them completely sealed. The reinforced concrete rings in the photo have the shape of a cylinder.

Well rings, also known as reinforced concrete products, are available on the market in different diameters. This expands the scope of application of the material, allowing it to be used for the needs of private developers and capital construction. Such rings weigh quite a bit, so you won’t be able to deliver them yourself.

Basically, for their delivery, a manipulator is used, which simultaneously delivers them to the site and independently unloads and performs installation. For installation and unloading, each ring has special hooks. They are part of reinforced concrete structures, so the geometry of the ring itself is not disrupted during unloading.

The rings come complete with a bottom and a top cover. This allows you to achieve maximum tightness, comply with SNiP standards, and install the septic tank correctly.

Practical advice

There are several rules, the implementation of which is considered mandatory. There is no need to invent anything on your own, the technology has been used for many centuries, during which time masters have encountered various situations and, based on their experience, have developed universal recommendations.

- Immediately after dismantling the form, it must be washed and thoroughly cleaned of concrete residues. This should be done not after the work is completely completed, but regularly. The fact is that then the concrete will gain greater strength and will firmly stick to the form. It is very difficult to remove; even strong blows with a sledgehammer do not help. Not to mention that such impacts cause great harm to the form: the walls are deformed, the integrity of welds and other joints is compromised. Uneven walls of the inner ring will make the process of removing them much more difficult.

The mold needs to be cleaned after disassembly. - Lubricate the surfaces of the mold thoroughly, more is better than less. It takes a few minutes to prepare the mold, and the manufacturing process is greatly accelerated. We have already mentioned that the dismantling of the structure is carried out on wet concrete; excessive efforts when removing the form can completely destroy the ring.

- Choose a working place under a canopy, do not expose the form to direct sunlight. The metal gets very hot and quickly transfers heat to the concrete; it does not set due to chemical reactions, but simply dries. As a result, the outer layer crumbles, the thickness of the defect depends on specific conditions.

It is not recommended to make concrete rings outdoors (without a canopy) - If the rings will be mounted at a great distance from the place of manufacture, then it is necessary to insert running brackets for hooks of lifting mechanisms. They are made from wire rod with a diameter of ≈ 6 millimeters. The initial length of the wire is not less than the height of the ring, then it is bent in half, the lower ends are bent again at an angle of 90°. Due to this design, the forces are distributed slightly below the axis of symmetry of the ring, which eliminates the possibility of tipping over during lifting, and a large layer of concrete prevents the hooks from being pulled out.

A well requires up to 10 rings, and with one mold they can be made in about 12 days.

Types of reinforced concrete rings

Speaking about the types, it should be noted that the reinforced concrete ring for a well is represented by several main classes. This is a drainage variety used for sewer systems, for arranging drainage pits and wells. There are wall options. They are convenient to use where it is necessary to equip a well.

Such systems have a number of important hooks, which makes it possible to form a single, powerful block. On sale are a version with a lock, as well as those with a lid and base. The latter allows you to achieve tightness.

There are also additional options available for sale that are relevant for production on individual orders. These options are developed according to the customer's specific dimensions and are always made to order.

Reinforced concrete rings come with holes

Reinforced concrete rings for sewerage always go through the reinforcement stage. Thanks to this, they have a single, powerful design. During installation, the hooks are bent to form grooves. The ring, the second in line, which is lowered onto the previous one, falls together through metal elements. The presence of a groove, even when the rings are in liquid, does not allow them to rise and rotate relative to each other. This property is relevant.

Regarding the species, I would like to note the difference in the diameter of the rings. For the construction of wells and well pits, a ring with a height of 90 centimeters is often used. The internal and external diameters of reinforced concrete rings are individual indicators of the manufacturer.

These should be taken into account at the time of purchase. The wall thickness may also differ, which indicates the strength of the product.

Pipe material

The selection of material for the installation of underground communications is one of the main points in drawing up a project for internal and external water supply and sewerage of residential buildings. It is necessary that they have good resistance to corrosion, the action of solid suspensions and the environment. SNiP considers the possibility of using the following pipes:

Selection of material

- Polyethylene;

- polyvinyl chloride;

- polypropylene;

- steel;

- cast iron;

- reinforced concrete;

- asbestos-cement;

- ceramic

- glass.

The use of the latter is permitted by regulations, but only in exceptional situations.

Reinforced concrete pipes

Used in non-pressure networks. They usually have a large diameter and are resistant to external influences, as well as compressive and tensile loads. They can be used to drain wastewater from industrial buildings, the main area of application is urban sewerage with a large volume of wastewater.

Asbestos cement pipes

Can be used not only in non-pressure networks, but also in pressure networks. The material can withstand loads well and is difficult to impact. As a result of interaction with the aquatic environment, its strength only increases.

Steel pipes, although provided for by SNiP, are rarely used for underground sewers, as they are susceptible to corrosion.

Cast iron pipes

Widely used option. For a long time, only this material was used; its service life reaches 80 years. These are very durable pipes that are not subject to corrosion. They are mainly used for laying urban networks, but are sometimes used in private construction. The disadvantages include internal roughness, which contributes to build-up of solid particles contained in the liquid, large mass of the product and high cost due to the peculiarities of cast iron production according to GOST.

Polymer pipes

They have become widespread recently. They are made of polyethylene, polyvinyl chloride or polypropylene. These products are lightweight and can withstand loads well, so they are used in pressure and non-pressure networks. The advantages also include their lightness and relatively low cost.

The main disadvantage of PVC pipes is the small range within which they retain their performance properties. They do not tolerate high and low temperatures well, so when installing PVC pipelines it is necessary to provide thermal insulation. PVC pipes are rarely used for installing external utility networks, but they perform well when installing internal water supply and sewerage systems.

Characteristics and dimensions

Speaking about the most important characteristics of concrete rings, it is worth noting their resistance to moisture. It is in a humid environment that they will be used most often, since they are used to construct wells, as well as drainage pits, pits for wells, and other places with high humidity.

That is why the rings should not react in any way to water. This is facilitated by the quality of concrete. The higher quality the concrete, the higher its waterproofing properties. For rings that will be used as a pit, that is, in damp conditions, the concrete grade M100 M150 is suitable; for reinforced concrete rings that will stand in a septic tank, it is best not to save money and buy products made of concrete grade M300 no less.

Reinforced concrete rings and their sizes

Pay attention to characteristics such as outer and inner diameter. The outer diameter will allow you to understand the diameter of the recess before installation. The internal diameter will allow you to calculate the volume that the liquid can fill during operation.

The difference between the inner and outer diameter is the wall thickness. The thicker it is, the stronger the purchased products. Internal reinforcement also affects strength. The reinforcement for the ring is a wire with a diameter of at least 4-6 mm. This is enough to ensure that the concrete does not deteriorate from time and moisture.

The dimensions of reinforced concrete rings are important, especially the internal diameter. On sale, reinforced concrete rings used for wells can be supplied with an internal diameter from 60 cm to 2 meters, inclusive. The larger the diameter, the greater the volume of liquid the ring can contain.

This is convenient because you don’t have to often hire equipment to pump out wastewater. In the case of a drinking well, so that the water column is always at the proper level, it is best to choose prefabricated reinforced concrete rings with a diameter of 90 to 160 centimeters, inclusive.

When we look at the label of a product when choosing it in a store, we always see two numbers. The first number indicates the height, the second the internal diameter. Height will also ultimately affect volume.

Concrete rings for sewerage

When manufacturing concrete sewer rings, they are guided by sections of GOST 8020-90, which regulate the technical conditions for this type of product. Its main provisions include the following points useful for specialists and ordinary consumers:

- The structures are made from heavy concrete in accordance with GOST-26633 with a compressive strength of 70% of its grade or class.

- For reinforcement, rod reinforcing wire, thermomechanically hardened or hot-rolled steel are used.

- Well rings must comply with the requirements of GOST 13015-2012, which regulate their parameters according to the following indicators:

- rigidity, strength and crack resistance of structures without load;

- physical strength of concrete in its original finished form, and tempering strength after manufacturing the product;

- waterproof and frost-resistant;

- thickness of the concrete layer to the built-in reinforcement;

- grades of steel for fittings, running and loop fillings.

If the design documentation stipulates the placement of running brackets inside the rings, they are installed along the entire height at a distance of 300 mm from each other with a protrusion of 120 mm.

Rice. 4 Concrete rings for sewerage - dimensions according to GOST 8020-90

Related article:

Sewerage in the country - options, design diagrams and installation. If you need to install a sewer system in your dacha, then in a separate article read about all the possible expensive and cheap options for arranging a sewer system in your dacha. Nuances, types, schemes.

Concrete rings and auxiliary structures have symbols consisting of the following sequence of alphabetic and numeric symbols with the explanation below:

Application area

The scope of application concerns the arrangement of structures characterized by high tightness. That is why reinforced concrete products are used to construct a septic tank. A septic tank is the same drainage pit, but with the ability to treat wastewater. A septic tank of two or three parts can be installed on one site.

The more well rings you use, the cleaner the water will be when it comes out. In the case of three rings, the septic tank can produce almost pure water at the outlet, which can be used to water the garden.

When using rings as a basis for a septic tank, they must be additionally sealed. To do this, the outer diameter of the hole in the ground is dug out larger, a septic tank is installed, and then the outside is coated with bitumen.

Using reinforced concrete rings for cesspools

Using well rings, today you can equip a pit for a well. This is a recess of up to 2 meters, where equipment can be installed in the future. By default, the well head is located on the base of such a pit. It is recommended to install well equipment in homes, since here it will be less exposed to moisture. This way the pressure switch can work longer without failure.

Reinforced concrete rings are also used for constructing wells. In this case, they can be with a base and a lid. This will keep the water used for drinking and irrigation clean. The diameter is not chosen to be the largest so that the water column meets the customer’s wishes.

Otherwise, reinforced concrete rings are used for the needs of sewer systems, for laying communications underground, and for constructing underground drainage holes. They are able to withstand significant external loads from the soil, and not collapse under the influence of moisture for a long time. By performing the necessary sealing of the joints, you can achieve 100% insulation, which is important when installing cables, pipes and other communication systems inside the rings.

Installation Requirements

A septic tank, like any other version of an autonomous sewage system, is subject to strict sanitary requirements. They should be taken into account at the planning stage in order to choose the optimal location and method of execution.

The septic tank should be located at a distance:

- 30-50 meters from a source of drinking water (well, borehole, etc.);

- at least 30 meters to any body of water and at least 10 meters to a river or stream;

- 3-5 meters from trees and other large green spaces;

- over 5 meters from the foundation of the house, taking into account the distance not from the house to the inspection hatch, but to the beginning of the septic tank structure itself and the formwork limiting it.

An important point: distances are taken into account from the boundaries of the entire septic tank system, including the drainage system and the filtration area formed underground.

The location is chosen so that the top of the septic tank with an inspection hatch does not end up in a lowland or depression where rain and melt water can accumulate. Create a straight route from the house to the septic tank.

How to install correctly and what tools are needed

It is difficult to install reinforced concrete rings with your own hands, but sometimes this is done due to the impossibility of special equipment access to the territory. Otherwise, you buy reinforced concrete rings at the construction site, hire a manipulator, and he performs loading, delivery to the customer’s site, and unloading. Unloading can be understood as direct installation.

Before installation, experts recommend going deep to the required depth, compacting the bottom, and adding a cushion of sand. Concrete will draw moisture from the ground, so a pillow is simply necessary. Do not skimp on this layer, and fill up to 10 centimeters of sand, inclusive. To some extent, this will level the base. Place a concrete bottom on the sand, then begin the phased installation of the rings.

Each of them has special hooks. They serve to secure the manipulator slings and to connect the rings together. After the first reinforced concrete product is lowered, the slings are released, the metal hooks are bent, and the second product is installed. Then, all the screams can be linked together using a welding inverter. The work is not difficult and even a novice welder can handle it.

When a well is being constructed and the work is done manually, it is not always possible to use the services of a manipulator. In this case, install the first ring and gradually dig inside it, which allows the rings to fall down.

Next, when the first one is lowered to its own height and stands parallel to the ground at the top, the second reinforced concrete product is installed and work continues in the same way. Experts recommend using a hole drill, with the ability to drill to a depth of 10 meters or more.

This will allow you to drill through the entire internal diameter, install the ring and dig manually only under its walls. You will save the required amount of time and get the job done professionally. To make your work easier manually, you will need a powerful winch. It should be firmly fixed, which will facilitate the process of raising and lowering the products.

Manufacturing technology

The technological process for manufacturing concrete rings consists of three stages:

- Installation of drop-down formwork and frame. A strong cylindrical shape (preferably made of steel) is marked on the outside with two horizontal lines that will divide the entire diameter of the shape in half. The cylinder is cut along one line. Window or door awnings are attached to these lines in two pieces. Special fittings are used to connect the halves. On the second cylindrical form, which is smaller in diameter, markings are made similarly to the large form, and canopies and spindles are also attached. The hinged parts are assembled in such a way that the internal structure is 1 dm higher than the external formwork. Thus, the outer cylinder should open outward, and the inner cylinder inward.

- Filling the mold with concrete and compacting the mass. A reinforcing frame made of steel reinforcement or metal mesh is poured with concrete in portions in a support ring. Each layer is carefully compacted to remove air. Due to this, the finished product becomes more durable. To compact the mixture, it is better to use an area vibrating device or a hammer drill. At the forming stage, four loops of wire are installed on the concrete blank, and its ends are bent and buried into the concrete by 4–5 dm. To prepare the filling, use a high-grade mixture of grade M500 and higher numbered.

- Dismantling. On the outer formwork, first unscrew the bolts. After the wall of the form is tapped with a hammer to better separate it from the concrete workpiece.

Price

Those who need well rings, also known as reinforced concrete products, are interested in the cost of reinforced concrete rings . It cannot be said that by paying for the rings, you will be able to fully cover the costs of the project estimate. This is not true, since you also need to pay for the services of special equipment, order the bottom, lid, hatch, pipes, sealant and other things that may be required when installing and arranging a septic tank or other structure.

As for the rings, depending on the city, as well as on the task for which they are intended, the price can vary from 2000 rubles per unit. The larger the diameter, the more expensive the product costs. Remember that with an increase in diameter you will be able to deliver a much smaller number of pieces on a manipulator, which will require either renting 2 machines or making several trips.

In any case, rental of special equipment is hourly, so be prepared to pay for the amount of time. The cost of a well made of reinforced concrete rings , taking into account delivery, installation and excavation work, can reach 50 thousand rubles.

Waterproofing

In the case of a septic tank made of reinforced concrete slabs, special attention is paid to waterproofing. All containers must be sealed. Even a drainage shaft, which by definition has no bottom and has direct access to the ground, must be built with hermetically joined rings.

Even without taking into account that all the rings were laid with liquid glass, the joints are additionally insulated with bitumen mastic on both sides. Particular attention is paid to the bottom of the tanks; if a slab was initially used and rings without a bottom, then before laying it you should lay an insulating gasket made of roofing felt or use liquid rubber.

All pipe inlets and outlets must be sealed with liquid rubber or tightly fitted gaskets. The wastewater must not be allowed to leak into the ground until cleaned up. This will lead to the accumulation of harmful substances in the soil and subsequently to the destruction of the concrete rings themselves.

Ring waterproofing scheme

Advantages and disadvantages

The material has advantages and disadvantages. They are important at the time of selection. We suggest you first familiarize yourself with the advantages:

- High speed of work performed. For example, you decide to build a drainage pit. Previously, for its construction it was necessary to lay out a rectangular base and red brick walls. This took time, provided you were working alone. Now, you have bought reinforced concrete rings, hired a manipulator, prepared a hole in the ground using an excavator, delivered the contents and carried out installation. This will take no more than 3 hours.

- Moisture resistant. This is what makes reinforced concrete rings most beneficial for individuals and companies. With their help, entire tunnels are built underground, where communications are then laid. Well rings are used for arranging a septic tank, as well as for a pit in a well. Here, the equipment and the general contents of the internal volume will be protected from groundwater, which is important during operation.

- Long service life. Even if your septic tank constantly contains water and you do not pump it out in a short time, worry about it, this will not at all affect the condition of the concrete. With high-quality concrete, the tightness retains its 100% values.

- Affordable price. Despite a number of significant advantages, you can buy this material for little money. Delivery will also be inexpensive, since the rental is based on the number of hours spent.

Among the disadvantages, I would like to highlight the need for additional sealing of the seam. Be that as it may, one ring fits on top of the other, and in order to reduce the level of seam leakage, it must be sealed. Sealing is necessary both from the inside and from the outside, where the latter involves laying and additional excavation of soil in order to gain access.

Bitumen is used for sealing, and each of the seams must be coated with cement or glue. This will allow the rings to better adhere to each other. The latter will not allow them to move during operation under internal water pressure.

Another disadvantage is that the rings are supplied without inlet holes. These holes could be used for laying communication pipes and cables. You will have to do them yourself after installing all the cells of the block. When installing pipes and parts of the drain/overflow system in a septic tank, plastic products must be fixed with foam.

Problems and difficulties in designing external and internal networks

The main difficulties in preparing sections of the project for utility networks are associated with the following points:

- with the restrictions specified in the technical specifications for connection;

- lack of technical capability to connect the facility to general networks, the need for serious additional costs for connecting communications;

- poor condition of current networks and equipment, they need to be replaced and restored;

- the need to strengthen building structures for the installation of internal or external networks.

To avoid difficulties during design and coordination, contact only ]Smart Way.

Ventilation

Ventilation of both mines is mandatory. This is necessary for the removal of gases formed as a result of the activity of anaerobic microorganisms operating in the first storage tank and for the access of oxygen for the life of aerobic microorganisms and the oxidation of some complex chemical compounds.

If there is a ventilation pipe between the shafts, it is enough to install a ventilation outlet in the second tank. To do this, a hole for a 110 mm pipe is punched in the upper inspection ring on the opposite side of the hatch. A pipe is installed that goes inside by 5 cm and protrudes above the ground by 20-30 cm. The head of the ventilation duct is protected by a fungus.

To increase ventilation efficiency, ducts are installed on both tanks. This also increases the efficiency of microorganism reproduction when using special biological additives for wastewater treatment. The use of the latter is mandatory when installing a septic tank yourself. In the absence of automated aeration during the aerobic decomposition stage, the normal maintenance of microorganism colonies is very doubtful, so constant replenishment is required. Especially if water with detergents from a washing machine, bathtub or kitchen sink gets into the drains.

General recommendations for those who make a storage septic tank with their own hands

Following the following 5 aspects will help ensure smooth operation of the system:

- be sure to thoroughly seal the pipes;

- install check valves on the pipes to prevent backflow;

- Be sure to clean the sewer walls several times a year.

Competent calculations and equally competent installation make it possible to obtain an effective and relatively inexpensive sewer system for a private home, which is guaranteed to faithfully serve for at least 50 years.

A permit must be obtained for installing any type of septic tank. Otherwise, the construction will be declared illegal, which will be subject to an administrative fine.

In general, the advantages of sewerage made from concrete rings outweigh its disadvantages, so you can safely choose this type of septic tank for your private home in order to provide comfort for the whole family for many years.