For the installation of wells for any purpose, well rings made of reinforced concrete are often used. However, reinforced concrete products have a number of disadvantages - from heavy weight to insufficient durability. Therefore, they are increasingly being replaced by polymer-sand rings for wells. They are much easier to install, and their performance characteristics are superior to reinforced concrete.

Polymer-sand rings are used for the installation of five types of wells and tanks:

- drainage and inspection wells;

- inspection wells;

- septic tanks-storage systems of sewerage systems;

- storage tanks for process water;

- borehole caissons.

Prefabricated rings made of composite material receive especially high reviews in those areas where it is necessary to ensure increased tightness and durability of the tank.

Material characteristics

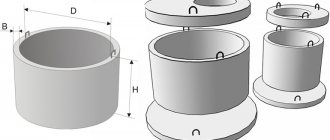

A polymer well is created from several rings with a diameter of no more than 110 cm and a height of 220 cm. The set includes a bottom.

The upper ring tapers on the outside; if necessary, a hatch or cover is installed on it. The material is produced using plastic, polymers, sand, and various additives for moisture resistance of products as ingredients.

Using the hot pressing method, the entire composite material is mixed with sand filler. As it cools, it creates a strong bond, creating a durable product.

The manufacturing process takes place in special molds that give the final appearance of the structure. The strength of the material is ensured by pressing technology, which creates a structure with a minimum number of pores.

Areas of application

Polymer wells can be used for various purposes. The structures are used as traditional wells for the extraction of groundwater, as reservoirs for collecting and storing rainwater.

They are widely used as sewer, drainage and inspection structures. Wells can be used for gas pipeline networks.

The tightness of polymer structures allows for reliable protection of communications from adverse external factors.

The strength of the material prevents chemicals and waste from getting inside the tank. The design maintains the required temperature conditions in hot summer weather, as well as in winter frosts.

Depending on the purpose of application, the necessary material is selected. For water supply, preference is given to classic wide shapes. If communications are laid, the structure should be narrower.

In addition to private use, polymer structures are used on roads, in public places - parks, parking lots, and for business.

Advantages and disadvantages

The emergence and widespread use of polymer rings for wells is explained by the special properties that distinguish this material from reinforced concrete structures.

The main advantages are:

- Small dimensions and dimensions of the structure, which allows transportation by a passenger car with a trailer, without using freight transport.

- Light weight (no more than 65 kg) does not require the use of special equipment for installation; the well can be installed independently, even in hard-to-reach places.

- A tongue-and-groove joint that securely fixes the rings. The joints are additionally fixed with silicone. Groundwater is not capable of destroying an integral structure.

- Resistance to external influences of chemical, natural and weather nature.

- Long service life - up to 100 years.

- the cost is lower than that of reinforced concrete options.

The big advantage is that installation can be carried out by several people

The only drawback that can be identified with polymer wells is the need to carefully select a cover. If the structure is located on the road, near a garage or other places with heavy traffic and activity, then it is necessary to select a stable and strong cover that can withstand the weight of the car.

Installation of the structure

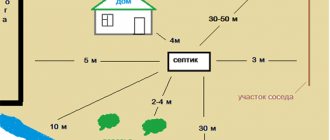

To install the well, a location is initially selected. The correct location determination depends on the goals and purpose of the structure. But in most cases, you should avoid being close to your home, as well as particularly polluted places.

The installation process is shown. Only 2 people work

A shaft of the required size is dug. It should be wider than the polymer structure for easy insertion. The width should be determined by the outer diameter of the tank.

For water supply, a well from 5 to 15 m deep is required.

After completion of the excavation work, a concrete bottom is installed. It is in demand when using a well for sewerage, as well as when conducting communications.

It is imperative to secure the structure to avoid its floating. The structure is assembled before immersion.

The use of polymer structures has recently replaced the use of reinforced concrete. The well's tightness, light weight, compact size, and resistance to external influences allow the tanks to be used for a wide range of applications.

The video below talks about the advantages of such wells and shows installation fragments.

Concrete rings for sewerage: sizes, prices and varieties

In private and suburban construction, sewer systems based on concrete rings are often used. This type of sewage system is considered one of the most economical. After all, the price of concrete rings for sewerage is low, and the process of their installation does not require a lot of time. As a result, the owner of a summer cottage has the opportunity to create comfortable conditions for living outside the city.

Concrete ring with a solid bottom

Along with bricks and polymer rings, concrete elements are also used for the construction of sewage systems in the country without pumping. Each of these materials is characterized by its own advantages and disadvantages, however, concrete structures significantly exceed the parameters of other system options.

Brick is less durable and requires a significant amount of time to make masonry, in contrast to ready-made elements that just need to be placed on the bottom of the pit and fixed. In addition, it is extremely difficult to make deep wells based on brickwork. The turnkey price of a sewer system made of concrete rings is not much higher than the cost of manufacturing a brick system. Taking into account the simplicity of installation work and the minimal time spent, such a small overpayment is completely justified.

Prices for turnkey installation of sewerage from concrete rings:

| Number of rings | Capacity, m³ | Number of consumers | price, rub. |

| 3+2 | 3,5 | 1-3 | 35990 |

| 3+3 | 4,2 | 2-4 | 39990 |

| 4+2 | 4,2 | 3-4 | 39900 |

| 4+3 | 4,9 | 3-5 | 45990 |

| 4+4 | 5,6 | 4-6 | 49900 |

| 3+3+3 | 6,3 | 4-6 | 59990 |

| Installation of a septic tank in areas with high groundwater levels | |||

| 2+2 | 2,8 | 1-2 | 30990 |

| 2+2+2 | 4,2 | 3-4 | 43990 |

Advantages and disadvantages of using concrete wells for sewerage

Many summer residents prefer to buy concrete rings for sewerage for arranging a system on their summer cottage; the prices of these products are far from the only advantage that confirms the benefits of such a purchase.

Advantages of concrete structures:

- the possibility of installation in areas with any type of soil (due to the increased safety factor, concrete rings are able to withstand the natural pressure that is formed during the displacement of groundwater or seasonal movement of soil);

- it is possible to use any materials to perform waterproofing;

Concrete ring for sewerage with stairs

- even if you plan to do the installation work yourself, this process will not take too much time;

- due to the smooth internal surface, the speed and quality of cleaning concrete wells increases;

- the material is more accessible than brick or stone;

- long service life without the need for repair work.

A wide variety of sizes and prices of concrete rings for sewerage allows you to create septic tanks of any capacity and depth. This type of material is highly hygroscopic, so contaminated wastewater can partially seep through the walls into the surrounding soil. However, this problem can be easily solved with waterproofing.

Main types and general sizes of sewer rings

There are two types of concrete products for sale for sewer construction:

- Additional (from 670 rub.).

- Wall (from 990 rub.).

Wall sewer rings

Wall-type elements are used to form the neck of the structure. Additional product options have an expanded range of sizes, and non-standard ones. They are used in cases where the height of storage tanks according to the project cannot be formed from elements with standard dimensions. With the help of additional rings, you can adjust the height of any septic tank structure.

Concrete rings used for the construction of country sewer systems are elements of a regular round shape. The internal diameter of the products ranges from 70 to 200 cm. The standard wall thickness is 70-100 microns. Most often, for the manufacture of drainage pits and country septic tanks, a size of 1-1.5 m is used; the price of concrete rings of this diameter is 1500-2500 rubles. per product.

To make rings, manufacturers use metal reinforcement and grades of concrete with different characteristics. Metal, as a reinforcing component, increases the strength of products and reliability. In addition, the possibility of stretching a structure made of rings is eliminated. In turn, concrete provides corrosion protection to the metal. As a result, the septic tank design is not subject to deformation changes under the influence of compressive loads.

Dimensions of wall concrete rings

Installation work

Polymer floors

The process of installing polymer wells begins with digging a pit for the structure and a trench for the pipeline. When calculating the depth of the pit, you should take into account the need to fill in a layer of sand with a layer of 20 cm and pour concrete with an approximate thickness of 30 cm. The trench for the water supply should be located at a depth below freezing of the soil, so that during the cold season there are no difficulties with supplying water to the house.

The bottom of the polymer well is installed on the prepared concrete base, the joints of which must be coated with bitumen mastic in advance. Next, the rings are installed. Their joints also need to be coated with mastic to improve the sealing properties.

A hole is drilled in the ring located at the level of the pipeline trench, lubricated with bitumen, and sealed with a rubber seal. After connecting the pipes and laying all the rings, install the neck and hatch of the well. At the end, the structure is backfilled and compacted with earth or sand. If the soil on the site is unstable, then for these purposes it is better to use a mixture of sand and cement.

Polymer sand structures can be used not only for the construction of drinking wells, but also for inspection, sewer, and drainage wells. In addition, due to the tightness of the reservoir created by fastening polymer rings, it is often used for telephone communications equipment and electrical networks.

➤

Easy connection to pipeline

When connecting a well to a home water supply system, you have to drill holes or openings in it. This is very difficult to do in reinforced concrete. Often a professional tool is required.

You can cut openings and holes for pipes in polymer sand wells with ordinary household tools, and the edges do not need to be treated with anything.

All openings in the polymer ring are created using household tools. In this case, there is no need to lubricate the edges of the cut piece with any compounds, because the plastic is not afraid of corrosion.

Features of polymer sand rings

Plastic pipes for arranging wells

The desire to build a well that will not need repair or reconstruction for many years is quite understandable. But to implement it, it is necessary to carefully think through and design the structure and not skimp on materials and professional installation work. The price of the described products is higher than that of analogues made of reinforced concrete, but it justifies itself.

Preparation method

In the manufacture of well rings, polymers (plastic with various additives that give the material the required properties) and sand are used. All components enter production in powder form. They are mixed in certain proportions, after which they are pressed under pressure and exposed to high temperatures.

Mixing sand and polymer powder

As a result of hot pressing, sand-polymer rings for wells acquire the desired shape and a durable, low-porosity structure.

Pigments added to the mass allow you to obtain products of different colors

Advantages

The advantages of a particular material are most clearly demonstrated when it is compared with analogues used in the construction of the same structures. For example, it is easy to see the advantages and disadvantages of wooden walls of a house in comparison with brick or stone ones. We will compare polymer-sand well rings with reinforced concrete ones, which are still the leaders in the construction of any types of wells. So:

Weight. Anyone who has ever taken part in the construction of reinforced concrete wells knows that it is impossible to do this work manually, since the concrete rings are very heavy and bulky. Special equipment is required not only for their installation in the mine, but also for delivery to the site, loading, unloading, and moving. The weight of polymer products does not exceed 60 kg, which makes it possible to abandon the use of cargo equipment and manipulators, saving on their rental and payment for the work of loaders.

To center the rings and secure them, they are equipped with locking connections

In addition, ground movement and strong flows of groundwater can cause displacement of concrete rings with rupture of joints, leading to their depressurization and even destruction. Docking of polymer-sand rings is carried out by tightly connecting them to each other using a tongue-and-groove system. Thanks to strictly maintained dimensions, they fit perfectly on top of each other, creating a sealed structure that is not subject to displacement. To be sure, before installation, you can coat the grooves with mastic or silicone sealant:

Easy to install. Light weight and the presence of locking connections greatly simplify the installation of a well made of polymer sand rings. Compared to reinforced concrete products, its connection to the water supply or sewerage system is noticeably easier: holes for pipes are made easily and quickly with ordinary household tools and do not require subsequent treatment with anti-corrosion compounds.

The photo shows that the input is sealed using rubber sealing rings

Moisture resistance. The main disadvantage of concrete is the porosity of the material. Water penetrates into the pores, which when frozen increases in volume and disrupts the structure of the material, causing cracks to appear in it. Over time, they grow, the number increases, and the rings lose their original strength.

Cracks in concrete require sealing, as they violate the tightness of the well

This does not happen with polymer sand products, since they have a dense, low-porosity structure due to the sintering of particles during hot pressing. The minimum degree of water absorption allows the material to withstand up to 500 freezing and thawing cycles without harming the strength of the structure.

Resistance to aggressive environments. The well is likely to be exposed to chemicals dissolved in groundwater, which accelerate the destruction of the concrete structure. If it is sewer or storm, then its inner surface is subject to even more aggressive influence. Due to its composition, the polymer sand ring for a well is not afraid of either chemicals or reactions that occur during the decomposition of biomass.

All of the listed properties clearly indicate that the competitiveness of parts made from a polymer-sand mixture is very high. And primarily due to ease of installation, low maintenance and exceptional durability.

Resistance to aggressive substances

Together with water from the ground, aggressive substances reach the surface of the wells, destroying the structure of concrete, and if the well is a sewer, then the reactions of biomass decomposition will “spoil” it from the inside. To make these processes weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of aggressive environments. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

Which plastic pipes to choose for a well

How to comply with SanPiN for septic tanks

Well pipes are selected based on the manufacturing materials used, the main ones being PVC polyvinyl chloride, unplasticized UPVC polyvinyl chloride, PP polypropylene and HDPE low-density polyethylene.

- When used in open ground, you should immediately discard the polypropylene from which internal sewer lines are made - it is afraid of ultraviolet radiation and is designed for a temperature range from 0 to +95 C, which limits its outdoor use. The exception is Cortis polypropylene products, which have increased frost resistance.

- PVC and uPVC pipes for external sewerage contain unplasticized food resins and are a primary product. The material has high strength characteristics (the highest stiffness coefficient SN8), is designed for a temperature range from -60 to +45 C, and its service life is about 50 years. In addition, the price of external corrugated pipes made of uPVC is acceptable; the total cost of a well 30 meters deep with a diameter of 40 cm with piping will be about 1000 USD.

- HDPE is made from high quality polyethylene. HDPE pipes for water are black with blue longitudinal stripes or completely blue. A special feature of HDPE pipes is that they are produced in coils (coils) of 100 - 200 meters, which is very good when laying water supply systems around the site; the system is obtained without unnecessary joints. Korsis corrugated pipes are made from the same high-quality HDPE as water pipes, so the quality of wells made from these pipes will be high. The inside of the pipe is coated with white plastic, which reduces the effects of ultraviolet radiation and makes it smooth.

Rice. 8 Large diameter sewer pipes Korsis

Warranty period

Manufacturers provide a guarantee of about 50 years for reinforced concrete products, but indicate that these parameters relate only to basic technical characteristics. Those. the ring will definitely not fall apart or become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out incorrectly.

With polymer sand wells such incidents are excluded. Therefore, manufacturers provide a guarantee of up to 100 years, although plastics in nature decompose over 400 years, and the sand included in the raw material is eternal.

Source: aqua-rmnt.com/kanalizaciya/kanal-kolodcy/polimerpeschanyj-kolodec.html

Kinds

Before we talk about the types of wells, let's take a closer look at their structure. As a rule, they consist of the following parts:

- bottom (base);

- set of ring walls;

- transition cone;

- lid.

All polymer wells are primarily distinguished by size. This affects sewage disposal per day. In addition, they differ depending on the purpose:

- prefabricated inspection room - for storm and utility sewerage;

- sedimentary type - used to purify water from precipitation;

- storm drains – used to collect storm water;

- collector - for connecting drainage and sewer systems;

- drainage - used in the drainage system as rotating or connecting elements.

Polymer wells can also differ in their texture; in this case, the following categories can be distinguished:

- single-walled smooth;

- double-walled smooth;

- single-wall corrugated;

- double-wall corrugated;

- combined.

In addition, there is another division - according to the material from which the structure is made.

- Made from polypropylene. They are perhaps the most popular due to the large selection of diameters and the availability of double- and single-layer pipes.

- Made from polyethylene. They are characterized by high tightness and resistance to corrosion. As a rule, they are used for storm and domestic sewer systems.

- Polymer sand. This material appeared relatively recently, but has already gained some popularity due to a number of advantages.

In appearance, two more varieties can be distinguished:

- prefabricated ones, which consist of rings;

- welded - one-piece structures.

There is another type of well that is worth noting - polymer cable. Cable drainage consists of pipes and wells; it is used for laying power and low-current wires underground. Cables can be replaced and repaired without much effort or digging up the soil if the pipeline is built correctly.

Polymers have another function in the field of well installation. During the drilling process, there is a need to strengthen the walls of the wells, especially in cases with loose soils. In these cases, polymer mixtures of several components are used, they are diluted with water in the required proportion and poured into the borehole. Such solutions not only prevent wall shedding and promote stabilization, but also reduce absorption and wear of the drilling tool.

Flaws

When choosing reinforced concrete rings, the dimensions of which make such products universal, you should also consider their disadvantages. There are few of them, but it’s worth familiarizing yourself with them before purchasing.

The presented products are characterized by significant weight. Some rings can weigh around 2500 kg. Therefore, installation will require the use of special equipment (and it is not always convenient to use on site). In addition to special equipment, you will need to resort to the help of several workers. This is also a significant drawback.

Although the cost of concrete rings is small, transporting them is not cheap. After all, such a heavy product must be loaded and removed from the car. To do this you have to hire movers. However, these disadvantages pale in comparison to the numerous advantages.

Tips for selection and self-installation

For a well to last for a long period of time, it is required:

- choose the right device;

- comply with all rules for installation of the structure.

Nuances of choice

To choose the right plastic well, you need to consider the following factors:

- well model;

- overall dimensions of the device;

- manufacturing material.

Polymer wells are manufactured in two types:

monolithic structures have a higher strength under pressure on the walls;

Ready-made polymer well for sewerage

prefabricated structures based on polymer rings for a well of a certain diameter.

Well made of individual polymer sand rings

When choosing a well, it is also recommended to take into account the overall dimensions. This issue is especially relevant when using a monolithic structure.

The overall dimensions of the well are determined depending on the purpose of the device and the parameters of the sewer system.

When constructing a sewer network for a private house, polymer wells can be installed:

to conduct a system audit. They should be located at junctions/branches of individual pipelines, at junctions of pipes of different diameters, as well as at places where large level differences occur. The dimensions of the manhole depend on the number of supply lines and user convenience;

Wells for inspection of pipeline connections

Manholes can be equipped with branch pipes in production. Such designs require careful selection in all respects. Wells are also produced in which the installation of pipes is carried out independently.

drainage, in which pre-treated wastewater is disposed of. A design feature of drainage wells is the absence of a bottom, which is replaced by layers of sand, gravel and other drainage materials;

Well for disposal of treated sewage waste

The storage well is used as a collection tank for sewage. Such a well must be cleaned periodically.

Storage well

When choosing the size of drainage and storage wells, the main parameter is the daily amount of waste.

The type of material from which the well is made is also essential:

- polyvinyl chloride wells are mainly used when there is a large amount of aggressive substances in the wastewater. The products are also characterized by minimal flammability;

- polyethylene structures are installed in cold climates or with constant use during the cold season. Wells are able to compensate for soil pressure at low temperatures;

- polypropylene wells are installed in areas with high buoyancy of the soil. The structures can withstand higher loads on the walls and are distinguished by their ductility and wear resistance.

Installation rules

The instructions for installing a polymer well are practically no different from the instructions for installing wells made from other materials:

- At the preparatory stage, it is necessary to dig a pit and bring trenches to it for laying sewer pipes. The width and length of the pit should be 15–20 cm larger on each side than the well being installed;

- the bottom of the pit and the supplied trenches is leveled and compacted. Sand and, if necessary, gravel cushions are laid on the bottom. When installing a storage tank with your own hands, the bottom of the pit can be concreted. This will give the tank additional stability;

Pit for installing a well

- a well is installed and sewer pipes are connected;

Installation and connection of the well

When installing a collection container, each individual ring is sealed with bitumen mastic or a special sealant.

How to properly install a prefabricated polymer sand well, watch the video.

- soil is backfilled. It is recommended to completely fill the container with water before filling. This will add additional rigidity to the structure and avoid deformation during backfilling;

- the cover is installed. If desired, the well is decorated.

Closing and masking a sewer well

The use of polymer wells significantly reduces the cost of constructing a sewer system. Polymer sand structures require virtually no additional maintenance.

Reviews

1) Excellent material! The well can withstand soil heaving without problems. When we used regular plastic, the inspection wells became deformed. There are no such problems with polymer sand.

2) The internal diameter is too small for maintenance. I screwed the head while I was upside down, otherwise it would be impossible to assemble the structure.

3) It withstands heaving one hundred percent, but you need to think about insulating the storage well in advance. The best option is a caisson. Without it, the contents of the well will freeze.

4) Why go down inside? Everything is mounted on top and lowered into the trench. We used a regular tripod with a winch for lowering; we didn’t need a crane. True, the depth of the well is small - 1.5 meters. All maintenance consists of timely pumping out wastewater - no need to climb inside either! We lowered the pump with the float - everything was pumped out and the hatch was installed in place.

5) Two years ago we installed a wooden inspection well. In one season, everything inside became damp! And the hatch was made of polymer sand. He didn't absorb the water. Therefore, we bought polymer sand rings with the entire set (bottom, neck) and installed them this summer. For now the well is dry. By the way, you won't be able to save money. Concrete rings can be bought for 1,700 rubles (the so-called factory substandard). A well made of polymer sand cost us almost 15,000 rubles.

What it is

Already from the name it is clear that we will talk about products made of composite material: plastic and sand. The product is a prefabricated well consisting of rings, a bottom, a cone-shaped lid and a hatch. The necessary rigidity is ensured by inclusions of sand in a matrix of polymer material. Due to the latter, the best tightness indicators are achieved. The rings, 1 m in diameter and 0.2 m wide, are relatively light, weighing approximately 60 kg. By varying their number, you can obtain the capacity of the calculated volume. All parts of the well are tightly connected into a tongue-and-groove lock.

Benefits of use

In terms of ease of use and performance characteristics, the subject of our article can be compared with concrete rings, from which septic tanks are often made (read about the latter here). Compared to them, polymer-sand wells:

- lighter. Two strong men can handle the installation;

- more compact. If desired, the container can be collected in the basement. The process of self-delivery is simplified;

- more airtight. Composite material does not allow water to pass through. The weak point may be the connection points of the well elements

These are the most significant features that really deserve attention. In terms of product durability and prices, they are approximately the same. But more on that below.

Installation

Polymer sand wells can be used as components of single- or multi-section septic tanks. as an economical option for a caisson, sewer pump station housing, etc. As we said above, the products are durable and airtight. The only weak point is the joints between the individual rings, the bottom, and the lid. Despite the presence of a locking connection, it is impossible to guarantee complete waterproofness of these parts of the well. Therefore, before installation, they are coated with bitumen mastic or special sealants. The future of the structure depends on the quality of this work.

Installation work is carried out in several stages:

- digging trenches for the pipeline (to the freezing depth or in accordance with design data) and a pit for the well (according to the dimensions of the structure, taking into account the information below);

- preparing the base for the container, including filling a 20 cm layer of sand, compacting it and then pouring a concrete slab 20-30 cm thick;

- installing the bottom of the well, coating the joints with bitumen mastic;

- installation of rings, in which the joints must be coated with mastic;

- drilling holes for pipes, sealing with rubber seals mounted on bitumen;

- pipeline connection;

- installation of the cover and hatch;

- backfilling with sand or soil, compaction. Here it is necessary to take into account the nature of the soil on the site. If it is unstable, then it is better to protect the tank with a sarcophagus made of a cement-sand mixture

Prices

Prices for these products may vary depending on the capacity of the manufacturer, the technologies used and a number of other factors. Today, the production of polymer-sand products has been mastered at a number of large factories specializing in the production of plastic containers. Average market prices for well components are presented in the table below.

Cost of well components

Judging by people's reviews, such wells can be used as an alternative to reinforced concrete rings in the manufacture of simple settling tanks. But they are not suitable as containers for storing drinking water, because... The polymer composition is obtained from recycled materials.

As we said above, the only problem area of the finished container is the joints between its components. Despite the fact that the existing fastening prevents lateral displacement of the rings, it does not in any way prevent displacement in the vertical plane. This results in the formation of cracks and a violation of the tightness of the product. For this reason, polymer-sand containers are not recommended for use in conditions of high groundwater levels. In such cases, it is more reliable to use solid tanks made of fiberglass, HDPE, stainless steel, etc.

Finally

Despite the above, polymer sand wells are already an excellent alternative to the use of reinforced concrete rings. Perhaps in the future their cost will drop to levels that will allow them to conquer the market. In the meantime, many prefer to trust traditional solutions.

https://oseptike.ru

Prices

The price for a complete set of wells consists of the cost of segments to achieve a given depth, a hatch and a ring. The overall cost is significantly influenced by the version of the ground part. Therefore, to present the overall picture, let’s consider the prices for segments of the underground part of the well:

| City | Company | Price, rub/piece |

| Stupino | Titanium | 1550 |

| Ulyanovsk | Incom | 880 |

| Cheboksary | Gaztrubkomplekt | 780 |

| Naberezhnye Chelny | Niguez | 1200 |

| Moscow | IP Nikishkin | 940 |

As can be seen from the table, prices in different cities of our country differ. Another factor influencing the cost of the product is the use of recycled plastic, which helps to significantly save on raw materials.

Cost of a caisson for a well

Below we give the estimated cost of caisson components for a well made of concrete and polymer-sand rings.

| Name | Caisson made of reinforced concrete rings | Caisson made of polymer-sand rings |

| Bottom | from 1700 to 5000 rub. | from 2000 rub. |

| Wall ring | from 1600 to 5000 rub. | from 2000 rub. |

| Transition cone under the hatch (or reinforced concrete cover) | from 1700 to 5000 rub. | from 2000 rub. |

| Polymer sewer hatch (cast iron) | from 1000 rub. | from 1000 rub. |

The cost of excavation work to prepare a pit for a caisson is about 20,000 rubles.

We continue the arrangement

The most effective means for insulation is considered to be liquid glass, which can be added to the concrete solution and applied to the joints of the rings.

- on the lower ring, the next one is installed. With a diameter of 1.5 to 2 meters, two rings will be quite enough;

- If you want the drainage pit to function as a septic tank, then for this you need to equip another pit of greater depth nearby. There is no need to fill the bottom of the second drain hole, just lower the rings. Holes are made in the upper ring and pipes are laid to allow liquid to flow from one drain pit to another.

To improve the functionality of the cesspool, special biological preparations can be used. They help to perform wastewater treatment quite well. After purification with drugs, water will be poured into the adjacent hole and then absorbed into the soil. This water is approximately 98% purified and does not pose a threat to the environment.

Once the installation of the rings is complete, you can begin to remove the drain pipes. Do not forget to maintain the slope; its angle should be approximately 15 degrees. The diameter of the drainage pipes is 15 cm. After the pipes are removed, a control drain of water is performed. After checking, you can fill the trenches with earth.

Do not forget that ventilation in the cesspool is required. Ready-made pit rings usually already have them.

It will be a good idea if you carry out additional waterproofing before filling the hole. The earth is filled first, along the outside of the rings. Only a hatch should remain on the soil surface.

Now you can use the drainage pit, but do not forget about periodically pumping out the contents, or using biological agents to clean cesspools.

How to clean a cesspool

The most effective and fastest option is a sewage truck. True, it does not reach all dachas, so the owners of suburban real estate organize pumping themselves. There are two options here:

- By hand, using a bucket and rope. The method is unpleasant, dirty and time-consuming.

- With the help of a fecal pump, fortunately such equipment is sold today in all construction stores. Plus, the range of pumping equipment is very wide both in terms of price and performance.

Both options for cleaning cesspools require the presence of one more element, namely a barrel or any other container into which sewage waste will be drained. After which they are taken outside the village to places for special disposal. That is, you can’t just take dirt into the forest and bury it there.

Cleaning the cesspool manually with bucketsSource kolodes-kopka.ru

How to properly prepare concrete mortar?

Strip foundations are always poured in one sitting. First, you assemble traditional timber formwork, strengthening and reinforcement. For better adhesion, metal rods can be tied together with wire.

- We lay it on broken pieces of brick or stones. It is highly not recommended to lay reinforcement on the ground. Only sand-cement mixture.

- To mix the solution, take cement, sand and crushed stone in a ratio of 1:2:3. We take the required volume of water by eye. The output should be a mass that is not too liquid, but not too thick. A pebble thrown into it should be completely immersed.

- When pouring, the solution is bayoneted to avoid the appearance of bubbles. Any remaining air is unacceptable, as it negatively affects the strength of the monolith. You will have to wait approximately 7-9 days until the site is completely dry.

- If work is carried out in hot weather, the concrete surface is moistened with water. This will help prevent it from cracking and make it more durable. Of course, if a ready-made reinforced concrete ring is used during installation, there is no need to arrange the site.

PHOTO GALLERY

We also offer you: Polymer-sand paving slabs - Polymer-sand tiles - Polymer-sand hatches - Polymer-sand rings: well, caisson, septic tank - Drainage trays with drainage grates - Facade panel and tiles - Basement panel and siding - Caps on the fence post - Lawn grid, eco-parking - Garden decorative fencing for beds, flower beds, flower beds - Flower beds, flowerpots, trash cans - Speed bump - PZK slab - Tactile tiles - Installation, laying, construction - Delivery of polymer-sand products and components

You can buy polymer sand wells, caissons, Tetto septic tanks in cities such as:

Belgorod region, Belgorod, Stary Oskol, Bryansk region, Bryansk, Klintsy, Vladimir region, Vladimir, Kovrov, Murom, Alexandrov, Gus-Khrustalny, Voronezh region, Voronezh, Borisoglebsk, Liski, Rossosh, Ivanovo region, Ivanovo, Kineshma, Shuya, Kaluga region, Kaluga, Obninsk, Kostroma region, Kostroma, Kursk region, Kursk, Zheleznogorsk, Lipetsk region, Lipetsk, Yelets, Moscow, Moscow region, Voskresensk, Chekhov, Stupino, Domodedovo, Vidnoye, Serebryanye Prudy, Moscow region, Balashikha, Zheleznodorozhny , Zhukovsky, Kolomna, Korolev, Krasnogorsk, Lyubertsy, Mytishchi, Odintsovo, Orekhovo-Zuevo, Podolsk, Pushkino, Sergiev Posad, Serpukhov, Khimki, Shchelkovo, Elektrostal, Aprelevka, Bronnitsy, Volokolamsk, Golitsyno, Dzerzhinsky, Zaraysk, Zvenigorod, Istra, Kashira, Kotelniki, Kubinka, Kurovskoye, Lukhovitsy, Mozhaisk, Necklace, Lakes, Protvino, Pushchino, Ruza, Staraya Kupavna, Taldom, Troitsk, Chernogolovka, Shatura, Shcherbinka, Elektrogorsk, Elektrougli, Oryol region, Orel, Livny, Ryazan region, Ryazan , Kasimov, Mikhailov, Smolensk region, Smolensk, Vyazma, Roslavl, Tambov region, Tambov, Michurinsk, Tver region, Tver, Vyshy Volochek, Rzhev, Kimry, Tula region, Tula, Yasnogorsk, Venev, Mordves, Ivankovo, Novomoskovsk, Aleksin, Donskoy, Uzlovaya, Shchekino, Yaroslavl region, Yaroslavl, Rybinsk, Arkhangelsk region, Arkhangelsk, Severodvinsk, Nenets Autonomous Okrug, Naryan-Mar, Vologda region, Vologda, Cherepovets, Kaliningrad region, Kaliningrad, Karelia, Petrozavodsk, Komi Republic, Syktyvkar, Vorkuta , Ukhta, Leningrad region, Vsevolozhsk, Vyborg, Gatchina, Kirishi, Sosnovy Bor, Tikhvin, Murmansk region, Murmansk, Apatity, Severomorsk, Novgorod region, Veliky Novgorod, Borovichi, Pskov region, Pskov, Velikiye Luki, St. Petersburg, Kolpino, Peterhof, Pushkin, Krasnoe Selo, Kronstadt, Zelenogorsk, Sestroretsk, Lomonosov, Pavlovsk, Adygea, Maykop, Astrakhan region, Astrakhan, Volgograd region, Volgograd, Volzhsky, Kamyshin, Kalmykia, Elista, Krasnodar region, Krasnodar, Sochi, Armavir, Novorossiysk, Anapa, Belorechensk, Gelendzhik, Yeisk, Kropotkin, Krymsk, Labinsk, Slavyansk-on-Kuban, Timashevsk, Tikhoretsk, Tuapse, Rostov region, Rostov-on-Don, Taganrog, Bataysk, Volgodonsk, Novocherkassk, Novoshakhtinsk, Shakhty, Azov, Gukovo , Kamensk-Shakhtinsky, Salsk, Republic of Crimea, Alupka, Alushta, Armyansk, Bakhchisaray, Belogorsk, Dzhankoy, Evpatoria, Kerch, Krasnoperekopsk, Saki, Simferopol, Old Crimea, Sudak, Feodosia, Shchelkino, Yalta, Bashkortostan, Ufa, Sterlitamak, Neftekamsk , Oktyabrsky, Salavat, Belebey, Beloretsk, Ishimbay, Kumertau, Meleuz, Sibay, Tuymazy, Kirov region, Kirov, Mari El, Yoshkar-Ola, Volzhsk, Mordovia, Saransk Nizhny Novgorod region, Nizhny Novgorod, Arzamas, Dzerzhinsk, Balakhna, Bor, Vyksa, Kstovo, Pavlovo, Sarov, Orenburg region, Orenburg, Orsk, Buzuluk, Novotroitsk, Penza region, Penza, Zarechny, Kuznetsk, Perm region, Perm, Berezniki, Krasnokamsk, Kungur, Lysva, Solikamsk, Tchaikovsky, Samara region, Samara, Togliatti, Novokuibyshevsk, Syzran, Zhigulevsk, Chapaevsk, Saratov region Saratov, Balakovo, Engels, Balashov, Volsk, Tatarstan, Kazan, Naberezhnye Chelny, Almetyevsk, Nizhnekamsk, Bugulma, Elabuga, Chistopol, Leninogorsk, Udmurt Republic, Izhevsk, Votkinsk, Sarapul, Glazov, Ulyanovsk region, Ulyanovsk, Dimitrovgrad, Chuvashia, Cheboksary, Novocheboksarsk, Dagestan, Makhachkala, Derbent, Kaspiysk, Khasavyurt, Buynaksk, Izberbash, Ingushetia, Nazran, Kabardino-Balkarian Republic, Nalchik, Prokhladny, Karachay-Cherkess Republic, Cherkessk, Stavropol skiy region, Stavropol, Essentuki, Kislovodsk, Nevinnomyssk, Pyatigorsk, Budennovsk, Georgievsk, Mineralnye Vody, Mikhailovsk, Chechen Republic, Grozny, Kurgan region, Kurgan, Shadrinsk, Sverdlovsk region, Yekaterinburg, Nizhny Tagil, Kamensk-Uralsky, Pervouralsk, Asbest, Berezovsky , Verkhnyaya Pyshma, Krasnoturinsk, Lesnoy, Novouralsk, Polevskoy, Revda, Serov, Tyumen region, Tyumen, Ishim, Tobolsk, Khanty-Mansi Autonomous Okrug - Yugra, Nizhnevartovsk, Surgut, Nefteyugansk, Kogalym, Nyagan, Khanty-Mansiysk, Yamalo-Nenets Autonomous Okrug, Novy Urengoy, Noyabrsk, Chelyabinsk region, Chelyabinsk, Magnitogorsk, Zlatoust, Kopeisk, Miass, Ozersk, Troitsk.