Here you will learn:

- What is a hand water pump

- Purpose of manual models

- Advantages and types of hand pumps

- Types of hydraulic pumps

- Pump classification

- Other types of mechanical pumps

- What to look for when choosing

- Assembling a homemade hand pump

- Washing machine pump

- Water pump from compressor

A manual water pump is a simple and practical device that will help out in the event of a lack or instability of power supply. You can buy such a device or make it yourself.

What is a hand water pump

Having a source of water in your garden plot is the key to an excellent harvest. You also cannot do without it at home. However, water supply may be intermittent, and electricity supply in remote areas is unstable. In such conditions, it is necessary to purchase hand pumps for water at the dacha.

If you have shallow aquifers, you can drill a well yourself and become completely independent of the presence of an external water supply and poor-quality service from energy companies. The main thing is to choose the right hand pump for pumping water so that it gives maximum results with minimal investment and downtime for repairs and maintenance.

Purpose of manual models

The main purpose of using pump-type equipment is to pump water from a source to certain points: to a residential building, bathhouse, garage, garden. In suburban areas, the source most often is wells and wells, less often - ponds and other bodies of water.

All residential or country houses can be divided into three categories: permanent, seasonal and periodic residence. Not all of them have electricity, and some are supplied irregularly.

If we summarize all these factors, we can draw the following conclusions:

- in permanent residences, electricity is used by default, so the main equipment for pumping water is an electric pump, and the manual model is a spare backup unit;

- if the cottage is used only in the summer and power lines are connected, then the energy-dependent option is also ideal, and the manual device plays a secondary role;

- a summer cottage without electricity most of all needs manual equipment.

To irrigate 2-3 flower beds, you can still draw water with buckets, but to ensure complete and daily watering of beds, greenhouses and lawns, a pump is needed. This is where a model that requires a pair of hands to operate comes in handy.

You can make a simple speaker yourself by using the skills of welding and assembling metal or plastic parts.

An example for making your own model can be a factory product assembled from durable cast iron or steel parts, with a comfortable handle for use

Some craftsmen build reliable equipment for wells and wells that serves well for years. We present an overview of homemade products, for the manufacture of which scrap materials were used.

Advantages and types of hand pumps

The speed of pumping water mechanically and the resulting volume are significantly inferior to electrical analogues, however, the technique has a right to exist, as it has its advantages. The main advantage is autonomy, which minimizes risks. It is appropriate to use the technique if any condition exists:

- relatively low need for daily water volume;

- for a homemade shallow well or a well located on your own personal plot;

- a hand pump for pumping out water is used as an emergency source in case of a power outage at the main water intake device;

- for public use when there is no desire to use a traditional chain, crankshaft and bucket;

- if there is no electricity connection at the site.

In some cases, a mechanical piston unit in working form is used as a decorative element, complementing the created exotic surroundings of the site.

Such a unit can also become a decoration for the site.

Separately, the sites require fecal pumping units, which are used for pumping contaminated media, including for cleaning sewer pits, cellars and lower floors during flooding. The design includes a grinder designed for a certain particle size, which crushes foreign impurities during operation.

Operating the device has its advantages:

- quick installation;

- repairable units;

- low maintenance;

- unified components;

- long uninterrupted service life;

- minimum cost of the finished product.

The disadvantage in some situations is the need to apply physical force to pump. This makes the device inconvenient for use by elderly, weak people and children. The result will also be low productivity.

Types of hydraulic pumps

Manufacturers offer several types of devices for collecting water from aquifers:

Piston hand pump

Traditionally, this particular device is found in the areas. It effectively copes with the task of collecting liquid from shallow depths of up to 7-8 m. It is based on a working piston moving along a cylinder.

The exit of liquid is blocked through the use of check valves.

It is installed 1 m above ground level. Due to the mechanical control of the lever, the manual pump pump drives the piston. When moving in one direction, liquid is taken into the cavity; when moving in the opposite direction, a portion of water is sent upward. This is how pumping occurs.

Rod hand pump

A hand pump for water is used in areas for sampling from lower horizons of 7-30 m. The principle is similar to the operation of a piston pump, but the length of the “piston” (plunger) is much longer and resembles a drill rod.

Due to its significant dimensions, the plunger apparatus creates a vacuum at a low depth and supplies liquid upward through the inlet pipe.

Gate (rotary-plate)

It has low power and is often used for pumping liquids from barrels or open reservoirs. Outwardly they resemble a tube, at the end of which a pump with a rotor is mounted. It has high mobility unlike other varieties.

If necessary, it can be used in various operations, since it is light in weight, and a regular hose is used for sampling.

Membrane

The device is capable of pumping out even contaminated liquid. The design uses self-cleaning ball valves. This solution allows us to minimize the possibility of jamming of the mechanism. A special feature of such models is the absence of quickly wearing or rubbing parts. The body is made of cast gray cast iron.

When choosing a specific instance, you need to pay attention to the following models:

Hand pump for water at the dacha BSK

It is used without modernization at a horizon not lower than 6 m. When installing an additional check valve, it is capable of sampling from a 9-meter level. Aesthetic appearance allows you to decorate any area. For fastening, the structure has a flange that allows you to fix the device on a pipe or platform. Possibility of installation to a vertical surface is provided. The estimated cost is 4800 rubles.

Hand pump for water at the dacha D-40

D40, Membrane (diaphragm)

Membrane type device. Capable of self-cleaning from possible contamination. Effectively copes with pumping liquids of any type. The cost is 6300 rubles.

Hand pump for water at the dacha RNP 1.3/30

Used in liquid media, including contaminated liquid. Capable of passing contaminants up to 1 mm in diameter. The maximum maximum concentration of pollution should not exceed 30 g/m3. Operates at a horizon of up to 5 m. The body is made of cast iron. The stroke type is double-sided, which increases the performance of the device. The cost is 16,200 rubles.

Hand pump for water at the dacha “K” (impeller)

Used for depths up to 9 m. The design includes 4 valves and a wing. Working with the handle, the operator alternately opens and closes the valves through which the liquid is supplied. The cost of the product in a steel case is 3,100 rubles.

A manual pump for pumping should be in any household. This small alternative device will successfully replace the pumping station in the event of an unauthorized power outage. It will also be useful in case of failure of pumping equipment. This will make it possible to pump up the volume, albeit in a limited quantity, but not be left without it at all.

For automated pumps, the rapid change of on/off cycles is critical - they fail within a short time. When you need a small amount, it is better to use hand pumps.

Pump classification

Hand pumps take on a different and even unexpected appearance.

Today you can often find water standpipes in courtyards or in the private sector. Such speakers have nothing in common with manual mechanical pumps. Why? In conventional water pumps, water pressure is created by pressure in the city water supply. In a mechanical pump, pressure is created through pressure, which must be constantly pumped up using physical effort.

All mechanical pumps are classified into 4 main groups:

- Piston.

- Rod

- Membrane.

- Winged.

Piston devices are used for sources up to 10 m deep. If the well depth is 30 m, then rod devices are ideal. Membrane ones are mainly used for pumping water in water supply systems.

As for vane hand pumps, this is the most expensive device. It is a rotary mechanism in a housing with a suction pipe.

Also, hand pumps differ in operating mode and materials of manufacture. For example, some models can only be used in the summer. The housings of such pumps can be made of plastic. There are also metal models of devices that should be insulated for use in the winter.

Now we invite you to familiarize yourself in more detail with all types of similar devices used to lift water from a well.

Piston type device

Piston pump design in every detail

The unit is based on a special piston, which is the main working unit. The piston itself is placed in the pipe and connected to the bottom of the device. Under the influence of forces on a special lever, the piston moves up and down. As soon as the piston is in water, it flows through the valve into the space above the piston. When the piston rises, it is pushed out through the outlet pipe.

The following nodes are visible from the outside:

- cylindrical body;

- drain pipe;

- lever arm;

- a rod extending into the cylinder.

The internal part consists of the following nodes:

- The piston is located inside the sleeve and comes into action under the influence of a lever mechanism.

- The stem is partially visible from the outside.

- Hole for water outlet.

- A pipe is connected to the pump from below through a fitting.

- Valves located on the piston itself.

In the diagram you can see all these components, as well as familiarize yourself with the operating principle of this pump:

The operating principle of a piston pump is shown in this diagram.

It can be seen that the pump has 2 valves: one on the movable piston, the second on the stationary part, which opens under the influence of pressure and releases water. If it is not there, then pumping out water will be problematic. Typically, after using the pump, a small amount of liquid remains inside, as can be seen in the picture on the left side. When the piston rises, the valve opens, filling the inner cylinder.

In the figure in the center you can see that when the rod with the movable piston is lowered, the lower valve closes. At the same time, the valve on the piston opens and draws in liquid for its subsequent lifting up. When the piston moves completely down the cylinder, water flows completely from the lower chamber into the second.

Now in the diagram on the right side we see that the valve on the piston is closed and water comes out through the pipe. As you can see, the operation scheme is very simple. The only nuance of the operation of this pump is that with intensive use, the rubber seals on the piston quickly wear out. Sometimes valves fail. If the fluid contains small impurities, wear increases.

As for productivity, measured in liters of liquid lifted at one time, it varies depending on the model. Performance is mainly affected by the internal diameter of the cylinder, that is, the volume of water that is located between the first and second valve.

Rod hand pump

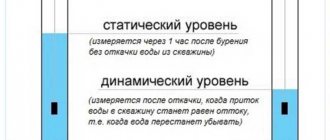

This type of pump is also known as a rod pump. It is used in cases where the water surface lies deeper than 12 meters. With such parameters, the piston type cannot cope. They are somewhat similar in design. The main working unit is the cylinder and piston. The pumping process is carried out practically according to the same scheme as in the case of the piston analogue. However, they differ in that the pump part itself is located directly in the aquifer. You can see its feature in the diagram:

The diagram shows the design of a sucker rod pump in all its details.

The working cylinder is located directly in the water column. To install such a pump, you need a well with a casing pipe. The working cylinder is connected to the main part by a pressure pipeline, inside of which there is a rod or rod. It is he who sets the piston in motion. As for the presence of valves, there are also 2 of them, the first is located on the intake pipe of the cylinder, and the second on the piston.

Based on this diagram, it becomes clear that the supply to the top does not simply occur by suction. The working cylinder located in the aquifer creates a column. Each up and down movement of the piston creates pressure, replenishing the existing column with a new volume of liquid. Using this scheme, water can be raised even from a depth of 30 meters.

If we compare piston and rod units, then when using the latter, more effort is required to raise water to the surface. For this reason, the pump lever is often made longer. This allows you to achieve maximum piston stroke with less labor.

Such installations are more complex. This applies to both installation work and subsequent maintenance. However, if there is no electricity at your summer cottage, and the aquifer is located at a depth of 25–30 meters, then a rod pump is simply irreplaceable.

Diaphragm pump

The small diaphragm pump is convenient to use as it can be carried as needed

Such a pump means a special chamber, which is divided by an elastic membrane. Hence its name - membrane. It can be used to lift water from a depth of up to 6 meters. This device has a round body with handles located above it.

The internal movable partition is connected to the handle. The pump design has an air chamber; it does not participate in any way in the transfer of water. There are 2 pipes at the bottom of the device. One of them is connected to the suction through a valve. The other acts as a supercharger.

When the membrane is pressed down, pressure increases in the chamber containing the liquid. As a result, the valve opens. When the rod is raised up, the membrane also rises up. Under pressure, water is released through the check valve. So, one valve is on the suction pipe, and the second is on the outlet pipe.

Metal or cast iron is used for their manufacture. One of the weak points of this pump is the membrane. With frequent use, it quickly breaks through. Moreover, over time, the membrane stretches and becomes elastic. Because of this, productivity drops to zero. Water may leak through the housing, this is if the membrane has broken. Replacing the membrane will not be much of a problem. But even despite this, diaphragm hand pumps have not gained widespread acceptance.

Vane pump

A vane pump can be used to pump water from a well

Another type that we will describe is winged. Such a pump is used not only for pumping clean water, but also petroleum products, sea water and other liquids. In the diagram, you can familiarize yourself with the vane pump in all details:

Design diagram of a vane pump

The device consists of the following components:

- Inlet valve.

- Valve seat.

- Screw.

- Frame.

- Screw.

- Impeller.

- Exhaust valve.

- Lever.

- Lid.

- Ring.

- Shaft.

- Sleeve.

- Oil seal packing.

- Cork.

To set the impeller in motion, a handle is fixed and rigidly mounted on the shaft. If the pump will not be used in winter, there is a plug on the body, which can be unscrewed to drain the water.

Procedure for commissioning a vane pump:

- The inside should be thoroughly rinsed with hot water. This is necessary, because a conservation lubricant is applied there. During the flushing process, the plugs from the suction and discharge pipes should be removed.

- Next you need to install the handle.

- Using 2 bolts, the pump should be fixed vertically.

- Then the pipeline is connected to the suction pipe. The pipeline must not be deformed under the influence of vacuum. Therefore, the ideal solution would be to use a metal pipe.

- The pressure pipeline is attached to the pump using the same principle. Please note that there is a hole in the pressure pipe through which liquid is poured into the device.

- If the depth of water intake is more than 1 meter, then a check valve must be attached to the suction pipeline. This will ensure normal operation of the pump.

- It is equally important to ensure complete tightness of the suction pipeline. Otherwise, the device will not work normally.

The vane water pump is small in size and has low performance

The main disadvantage of a vane pump is its low performance. That is why it is rarely used in the household. It works great with small amounts of water.

Pumps with different drives

One of the simplest and most popular designs is a pump made of a pump with a handle. To make such a design, you will need an old housing from a deep-well pump or metal pipes of various diameters. You will also need a drive that will allow you to make rotational movements.

There are vibration type pumps. These can often be found on sale. They are inexpensive, but to make them yourself you need to have at least basic knowledge of electrical engineering. The bottom line is that a coil is wound on a core of metal plates, which is supplied with power - 220 V/50 Hz. A metal plate connected to the membrane is attracted to the core. The oscillation frequency is the same as that of alternating current - 50 Hz. In other words, the membrane makes 50 movements per second.

Other types of mechanical pumps

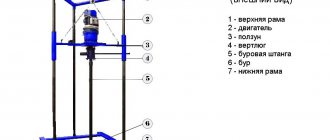

Manual mechanical water supply devices have been used since ancient times and have now been replaced by industrially produced models. In some cases, in the absence of electricity, the use of mechanical factory units is ineffective, and craftsmen come up with their own diagrams and drawings on how to make a hand pump for a well with their own hands.

If in the above case (water intake from a well) the principle of operation of industrial units can be used, then for water intake from open reservoirs they use their own developments based on ancient technologies.

Archimedes screw

Archimedes screw and its uses

The design was invented by a Greek thinker in 250 BC and consists of a cylindrical pipe, inside of which there is a screw; the system is lowered into an open body of water at a slight angle. During operation, the rotating blades capture water and move it up the pipe, at the end of which it is poured into the prepared container.

An analogue of this installation is an electric screw pump designed for constant water intake from deep water sources.

Hydraulic ram

Hydraulic ram

Mechanic Montgolfier is the creator of a hydraulic pump that raises water using its kinetic energy. Its principle of operation is to shut off the fast flow with a valve, after which water under pressure enters the hydraulic tank located above and is then delivered to the consumer through a floor hose. The device operates in repeating cycles; some manufacturers produce hydraulic pumps using artisanal methods.

Airlift

Aerolift - operating principle

The German engineer Karl Loscher developed this method in 1797; its essence consists of pushing out liquid from a hollow pipe lowered into a source with air. To operate the airlift, air is pumped into the lower part of the pipe through the inlet pipe using a hand pump; its bubbles dissolve in water and, due to their light weight, rise to the surface along with the liquid.

To prevent liquid from entering the pressure air hose, inflation is carried out through the nipple.

This design can be used in the presence of electricity by connecting a compressor instead of a mechanical pump.

Homemade piston pump

Some craftsmen make piston pumps themselves. The usual design consists of a working chamber made of a welded pipe; a metal or plastic disk with a rubber sealing ring along the diameter is used as a piston. To ensure water supply using a homemade design, holes are drilled in plastic or metal piston discs to install a check valve system.

Homemade piston pump design

Most modern mechanical units, like surface electric pumps, are capable of lifting liquid from wells up to 10 meters deep. The highest delivery height is provided by a rod pump, which operates in a similar way to electric submersible types. Its body and operating valve can be lowered into a source up to 30 meters deep, providing intake at a similar distance to the water surface.

Among all types in everyday life, the most common are piston hand pumps, which are mounted directly above the outlet of the casing well pipe, with suction occurring through a pipe lowered into the hole with a check valve.

American or spiral type

The use of river flow energy is the basis of the principle of operation of a spiral pump. For normal operation, the water flow must move at a speed exceeding 15 m/s at a depth of at least 0.3 m.

For manufacturing it is necessary to prepare materials according to the following list:

- rubber hose d 50 mm;

- clamps of the appropriate size;

- a piece of plastic pipe with a cross section of 150 mm;

- pipe reducer from a recycled sewer truck;

- wheel, supplemented with blades for efficiency.

The water intake, made of a polyvinyl chloride product with a diameter of 150 mm, is connected to 1 end of the flexible hose. The opposite edge is put on the gearbox. It is allowed to use industrial equipment.

The hose pipeline is fixed to the wheel with clamps. It is recommended to fasten in a spiral manner.

The liquid enters the intake and moves along a spiral path, providing the required pressure. The lifting height is determined by the speed of the water flow and the immersion depth of the water intake pipe.

What to look for when choosing

If there is an urgent need for a hand pump, then you should know how to correctly choose the optimal model.

- First of all, the parameters of the well (depth of the aquifer) and the parameters of the pumps offered for sale are compared. As already mentioned, most hand-held models are capable of working with sources located on the forehead at least 6 ÷ 8, rarely 10 meters. If the burial is deeper, then there is no alternative: you will have to install only a sucker rod pump.

- It is important to know the performance of the pump - how much water it is capable of pumping per cycle (or per unit of time - a minute, under intense load))

- The next parameter of the planned (or existing) well - the diameter of the casing pipe, also affects the choice of pump. If the pipe has a nominal bore of 4 inches (100 mm) or more, there are no problems, and you can purchase any pump. But in the case when the casing is narrower, the rod pump may no longer be suitable - it will simply be impossible to lower its working pump assembly into the water column.

- It is necessary to know the degree of contamination of the water from the well - usually the pump's specifications indicate the permissible level with which the equipment is capable of operating.

- It would probably be worthwhile to evaluate the ease of working with the pump. It is necessary to keep in mind that among the users there may be people of advanced age or children - will their efforts be enough to collect at least a small volume of water.

- It is necessary to think about how the pump will be installed - what mounting platforms or mounting holes, brackets or lugs, etc., are available for a particular model. It is also important to know the weight of the purchased device in order to foresee possible ways of installing it in advance - whether it will be a metal welded frame, a concreted platform, a flange connection to a casing pipe coming out of the ground, a wall mount, or just some lightweight option for seasonal use.

- Based on the expected operating conditions, you can determine the design features of the product. So, for installation only in the summer, you can purchase a lightweight plastic version. If a permanent installation is intended, then the choice is made in favor of cast iron or stainless steel. In addition, for temporary use you should purchase a model that is easy to quickly install and dismantle on your own.

- Finally, for many owners, the determining factor is also the external decorativeness of the pump - this has already been mentioned in the article. Of course, purchasing a pump that can decorate a site will entail much more serious financial costs.

The value of the pressure created by the pump is very often not assessed - such devices, as a rule, are not designed for pumping water through external pipelines. Water from them is most often collected into placed containers.

Assembling a homemade hand pump

Any man or woman can assemble a hand pump for water with their own hands. Follow the instructions and everything will work out:

All dimensions are in hand pump details centimeters

- Frame. As a housing, you can use a sleeve from a diesel engine or take a metal pipe. The required length is from 60 to 85 cm, and the diameter is at least 8 cm. The inner part of the workpiece should be turned on a lathe. The smooth surface of the inside of the cylinder will increase the efficiency of a homemade hand pump.

- The lid can be made of metal or plastic. You will need to make two pancakes according to the dimensions of the outer diameter of the cylinder. The top cover must have a hole for the rod, and the bottom for the valve.

- The piston can be made of plastic, wood or metal. The main thing is that the piston is equipped with a rubber seal, otherwise the water supply will be weak.

- The rod is made of metal or plastic. Often a polypropylene pipe is used.

- A valve is mounted on the bottom cover.

- The inlet pipe should be made of steel pipe, and it should be attached to the bottom cover.

- We carry out welding work, and then painting and decoration.

Using solar energy

This homemade water pump is very easy and simple to make. To make such a design you will need a regular hose made of plastic. The best option is to use a 2-inch plastic hose.

The hose can be installed in two ways:

- spread in the form of rings on the surface;

- hang the hose with a wire using several vertical posts.

The operating principle of this design is based on heating the water in the device by the sun. As the hose fills, the water in it will gradually begin to heat up from the sun's rays and rise.

The connection between the hose and the tank or any other container must be covered with a special material to provide reliable protection from various negative influences. Any material with a reflective surface is suitable for this.

Solar pump: always running (optional)

The design of this pump consists of a special grid containing propane-butane in the tubes. The grid is connected to a rubber bulb lowered into the container. There are two special valves in the lid of the container: the first is designed to allow air into the structure, the second releases it under a certain pressure into the air pipe.

To set the pump in motion, in the warm season you just need to pour cool water over the grill. In this case, the liquefied propane-butane cools, and its vapor pressure decreases. This helps compress the rubber bulb, and the container is filled with air. After a certain period of time, the sun's rays will dry out the grate and it will heat up again.

The resulting liquid vapors will inflate the rubber bulb, as a result of which the pressure in the container increases, and the air will escape through a special valve into the pipe. The resulting plug of air will act as a piston and drive the water in front of it towards the shower head. The liquid then falls back onto the grate and cools it.

Such a system works not only in summer, but also in the cold season. In this case, the cyclicity changes slightly. Cold frosty air cools the lattice of the structure, and its heating occurs due to the influence of underground waters. Therefore, if your garden or summer cottage is located on the shore of a body of water, it is not at all necessary to carry water to water the garden using buckets. You need to make a pump for pumping water with your own hands from scrap materials. In this case, the sun's rays and the flow of the river will do the main work themselves.

A more complex and time-consuming process is the manufacture of wind pump structures for pumping out water. Here you need to show maximum ingenuity and imagination. Such devices often contain complex elements such as flexible drives, various forms of wind deflectors, and so on.

Washing machine pump

Often, parts or even entire units from old things remain on the farm. You can remove a centrifugal pump from a washing machine that is no longer needed. This pump is perfect for pumping water from a depth of up to 2 meters.

- centrifugal pump from a washing machine;

- petal valve from a washing machine or homemade one;

- plug, bottle stopper;

- hose;

- preferably an isolation transformer.

If you use a ready-made valve from a washing machine, it needs to be modified. One hole needs to be plugged, for example using a bottle cap.

We connect the petal valve to the hose and lower it into a pit or well. Connect the second end of the hose to the pump.

For the system to start working, it is necessary to fill the hose with the valve and the pump itself with water. All that remains is to connect the transformer, and the pump is ready for use.

Using wave energy

This option is most optimal for areas that overlook the shore of a body of water. To construct the pump structure, you will need a log about 3 meters long and two stakes, a small piece of corrugated plastic pipe and two valves.

It is necessary to attach several loops of wire to the log, the diameter of which should be 6 mm at the ends. You need to attach a prepared piece of corrugated pipe to it from below. Valves are pre-attached to the pipe at the end holes.

The operating principle of such a pump is based on the action of waves. The wave of water lifts the log, the length of the pipe increases, and the liquid is sucked through the lower inlet. Accordingly, when a wave lowers a log, the size of the corrugated tube decreases, and water is squeezed out through a special upper valve. This process is repeated periodically depending on the fluctuations of the waves.

This design allows you to lift water from a depth of about 25 meters

When producing this design, it is important to properly treat the float using special means to protect the wood from constant exposure to moisture. The best option would be to use regular drying oil for these purposes.

Wave water pump (option)

This design will help to significantly simplify and facilitate the process of pumping water from any reservoir. Managing it is not very difficult.

The production of this device can be divided into several stages.

At the first stage, it is necessary to prepare the main pumping element of the structure. This element is a hollow cylinder in the form of an accordion. During the process of compression and stretching, the volume of this part will change significantly, while creating the pressure necessary for pumping out water. As a material for the manufacture of this element, you can use a regular car tire of the required diameter.

- The second stage in the manufacture of the pump will be the creation of a special “floating” platform. To do this, you can use wooden material, the dimensions of which must correspond to the size of the chamber, or ordinary plastic bottles with lids. The selected material should be carefully secured with electrical tape or construction tape on the bottom of the chamber.

- Next, fix a small wooden board on the top of the chamber. It will help the camera always stay afloat.

- After this, you need to secure the wave pump. Two pillars need to be driven into the bottom of the reservoir; the upper platform of the structure is rigidly attached to them. For the lower platform of the device, it is necessary to provide special wire loops. This is necessary for the free movement of water.

Water pump from compressor

If you already have an air compressor, don't rush into purchasing a water pump.

The operating principle of the pump is very simple. It is necessary to drill a hole in the spout pipe and place them closer to the bottom. The hole should be 2-2.5 times larger in diameter than the air pipe. All that remains is to insert the air pipe and apply air pressure.

The efficiency of such a pump depends on the height of the water, the depth of the reservoir, and the compressor power (performance). The efficiency is about 70%.

Manufacturing instructions

The simplest wave pump can be assembled from a set that at first glance seems ridiculous:

- brass or stainless steel tube;

- two necks from plastic bottles (with caps);

- a piece of thin technical rubber;

- hose.

Instructions for making the device are as follows:

- A hole with a diameter of 10 mm must be drilled in the center of each cap.

- We cut out two valves from rubber, shaped like petals.

- We place the petals in the lids so that they cover the hole, and the narrow part is pressed against the wall of the lid. Thus, after screwing in the neck, the narrow side of the rubber petal will be clamped, and the opposite side will be free. This design will allow water to flow in only one direction.

- We insert the caps into the tube so that one of them lets water in, and the other lets it out.

- All that remains is to secure the hose from the outlet side.

If such a device is tied to a float swaying on the waves, then with each downward movement it will absorb a certain portion of water, which will gradually move along the hose.