During the construction or major renovation of a residential premises, the question of choosing a material for creating water supply and heating systems always arises. In old apartment buildings, metal communications are mainly used to this day. But under the influence of time, the corrosive properties of water, as well as the appearance on the market of new materials for constructing hydraulic systems, it is necessary to replace the old with the new. Sometimes it is simply impossible to create a communication using only one type of material, so you have to combine different types of pipes in one system. To accomplish this task, special connecting parts have been developed. In this material I would like to pay attention to how to connect metal-plastic and polypropylene pipes together.

Dissimilar connection

This need arises when a new system needs to be connected to an existing network or when replacing a defective section.

It is still necessary to connect dissimilar pipelines when installing a heated floor, if the communications in the screed have to be connected to the existing heating circuit made of polypropylene.

Heating system fragment

In addition, if you know how to connect a metal-plastic pipe with polypropylene pipe, you will be able to reduce the cost of materials when installing a mixed system.

Properties and places of application of polypropylene

Two filters for cleaning. Self-washing and polypropylene thread

An important positive property of such a material is that corrosion processes have virtually no effect on the material. Low cost allows the use of polypropylene structures everywhere, and the ability to maintain tightness and integrity at a pressure of more than 20 bar makes it possible to use the material for water supply and heating in multi-story buildings. It is also worth noting the light weight and ease of installation. However, to solder homogeneous pipes you will have to acquire a special soldering iron. Thanks to the properties of the PPR material, the pipes are absolutely safe for health, hygienic and can last up to 100 years.

Pipes are available in a variety of colors, but the most common color is white. Of the entire color range, only black pipes have a special layer of protection against ultraviolet rays, which allows them to be used for a long time in the open sun.

To create a water supply system for an apartment building, material with a diameter of 16 mm or more is used. For the use of cold water communications, one-piece pipes work well. For hot water, it is recommended to use PPR material with a foil insert. Foil-lined pipes compensate for expansion due to heating and are marked with the designation PPR. But foil pipes are already considered metal-polymer.

Types of connection

The method of connecting metal-plastic pipes with polymer pipes is selected depending on the parameters of the fluid being moved. There are several options for joining dissimilar pipelines. Each of them has specific features.

It will not be possible to solder PP pipe to a MP pipeline due to the different structure of the products.

coupling

This fitting is used to connect a PP pipe with a MP pipeline if the diameter of the utility pipe does not exceed 40 mm. When joining, an American thread is used, which is a detachable element.

Threaded fitting

To qualitatively connect two pipes made of different materials, you need to perform the following steps:

- disassemble the detachable connecting element - American;

- screw flax onto a part with an external thread and spread silicone sealant on top of the tow;

- screw the prepared American element into the coupling with internal thread;

- screw the flax tow with silicone sealant onto the second coupling with external thread and connect it to the other part of the American one;

- twist the two halves of the American fitting manually;

- Tighten the joint with a wrench, but without unnecessary force, so as not to damage the rubber seal in the American one.

It is not recommended to embed the coupling connection in the building structures of the facility. When laying hidden, it is necessary to provide a technical hatch at the junction.

Compression fitting

The simplest option for connecting metal-plastic pipes with polypropylene pipes is to use a double-sided polyethylene compression fitting.

Compression coupling

This method is only applicable to plumbing systems that move liquid with a temperature of no more than 50˚C. Polyethylene couplings are not used in heating circuits.

Using a compression fitting, you can install pipes of various diameters. There is no need to use additional parts.

A compression coupling is a special element for connecting individual parts of a pipeline system. It consists of a plastic cylinder. This part has a thread on each side. The fitting design also includes 2 union nuts equipped with O-rings.

Docking is done by inserting pipes into a compression coupling. Then the nuts are tightened. Installation work when using a compression fitting is not carried out in cramped conditions.

The process may be hampered by the increased dimensions of the coupling. The fitting also has a limited fitting length.

Flange

These pipeline elements are used to connect pipes with a diameter of more than 40 mm. They are also used when it is necessary to install flanged fittings.

There are no special flanges for MP pipes. Therefore, it is necessary to additionally use an end element with an external thread. A flange piece of suitable diameter with an internal thread is screwed onto it using tow and plumbing paste or silicone sealant.

Threaded flange

After this, the end fitting is mounted on the MP pipeline. Flanges for soldering are available for PP pipes. All elements for connection are inexpensive. Their price increases with increasing diameter.

Connecting elements

The connection of structures made of metal-plastic or polypropylene is made using special fittings. These are connecting elements that allow you to install a water supply network of any design. There are different types of fittings. Among them there are dismountable threaded, press fittings and compression connectors. These two types of fittings are dismountable, so if a leak occurs at the connection point, you can replace the faulty element without any problems.

Press fittings are considered the most durable. However, if a leak occurs, replacing such a unit will cause some inconvenience. Installation of such parts is carried out using a special crimping coupling or press pliers.

Threaded fittings are mainly used for attaching a metal pipe to a metal-plastic one.

Basic mistakes

When connecting pipelines made of polypropylene and metal-plastic, the following mistakes are often made:

- apply great force, which leads to a decrease in the internal diameter;

- they make a loose connection, so a leak occurs;

- do not use sealing materials - flax tow, plumbing paste, silicone sealant.

One of the mistakes is also non-compliance with the temperature conditions and heating time of PP parts, when it is necessary to solder polypropylene fittings elements with PP pipes. As a result, it is not possible to create a monolithic joint if the polymer has not been heated sufficiently.

When the plastic overheats, the products become deformed and the internal diameter decreases. Therefore, the system throughput is reduced.

Connection of metal-plastic and PP pipes

Metal-plastic pipes differ from polypropylene pipes in the structure of the material and installation technology. Therefore, beginners may have difficulties with docking. To avoid problems such as leaks, we recommend that you carefully read the materials.

Tools and materials

To make the transition from metal-plastic to polypropylene, you will need the following tools:

- adjustable wrench;

- gas key;

- tow (combed flax);

- silicone sealant;

- mounting paste.

The list depends on the type of joining of parts.

Docking with couplings

The coupling connection of a metal-plastic pipe with PP is suitable for pipelines with a diameter of less than 40 mm. In addition to the threaded fitting, you will need an American (detachable element). Installation must be carried out according to the following plan:

- Take the American woman apart into two parts.

- Wrap the tow around the part with the external thread, then coat it with silicone sealant.

- Screw this part into the female threaded part of the fitting.

- Do similar work with the second fitting with external thread, which then needs to be screwed into the other half of the American woman.

- Connect the two parts of the detachable part using an adjustable or gas wrench.

When using this type of joining MP and PP products located in the wall, you additionally need to equip an opening niche.

Docking with compression fittings

Connecting pipes with compression fittings is the easiest and cheapest way. But it is worth considering the restrictions on the temperature of the water that will flow through the pipeline - it should not exceed 50°C. The disadvantage is the inability to carry out work in cramped conditions.

Double-sided compression elements are a plastic cylinder with threads on both sides and two union nuts with O-rings. These parts can be used to connect system elements of different diameters.

The process looks like this:

- Insert the pipes into the holes of the fitting fasteners on both sides.

- Tighten the nuts.

Flange connection

Flange joints can also be used to join two pipes made of different materials. This method is suitable for pipelines with a diameter of more than 40 mm. This connection involves the installation of flanged shut-off valves.

For metal-plastic systems, such components are not available, so you will have to use an end fitting with an external thread and a flange with an internal thread. The installation process itself must be performed as follows:

- The flange is screwed onto the fitting using tow.

- The fitting fastener is mounted on the water supply.

For polypropylene products, special flanges are used that are soldered onto them.

How to properly connect plastic pipes

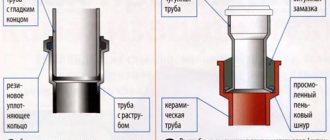

There are several types of plastic pipes, it all depends on the production technology. Choosing the right option will ensure stable and reliable operation of the entire water supply system. Plastic materials include polyethylene, polypropylene, polyvinyl chloride and metal-plastic. Plastic pipes can be connected using several technologies. The most common are the following:

- In the bell. It is mainly used for sewerage systems where water flows by gravity or systems not under pressure.

- Using an adhesive composition. There are several options available here - conventional joining using glue and “cold welding”.

- Threaded. Most often used to connect plastic water pipes with metal ones.

- High temperature welding. Parts of parts that must be connected are heated using a special installation, and then connected.

- Flange connections. Sleeves are created for flanges or overhead flanges made of metal.

- Collets. Ideal for small diameter products.

- Welding with an electric coupling. The parts are cleaned and degreased, then an electric coupling is put on them. Current is connected to them and the parts are heated, so they are connected to each other.

Tools

Ease of installation is a key advantage of polypropylene. You will need certain materials and special tools:

- polypropylene pipes;

- pencil;

- clips to fix the line;

- roulette;

- couplings for connection;

- corners;

- Ushastik-MRV. It is used to secure the mixer;

- MVR outlets with metal threads;

- soldering device;

- scissors for plastic items.

Non-standard connections: with metal pipes, transition to a different diameter

When replacing plumbing or heating, it is often necessary to combine metal and metal-plastic. Most often this happens at the outlet from the riser. In this case, the metal pipe is cut at a certain distance - 3-5 cm, and a thread is cut on it. Next, a fitting with a union nut (collet) or internal thread is screwed onto the thread. Further installation of metal-plastic pipes proceeds according to conventional technology.

Some types of fittings that can be used when switching from metal to metal-plastic

The fitting is selected according to the diameter of the metal pipe, and the thread on the adapter must be internal - the external thread is cut on the pipe. This connection requires sealing. Wrap with flax and coat with packaging paste or simply use fum tape.

The connection of two pipes of different diameters occurs in exactly the same way. All you need is an appropriate adapter fitting with nuts/nipples of the appropriate diameter.

Types of fittings

It is possible to connect 2 pieces of different materials using special fittings. They are also used when you need to connect plumbing fixtures to steel fittings. Inserts on fittings are necessary for a strong connection. They can be made of brass or chrome. Today the most common options are:

- crosses;

- combined tees;

- coupling;

- Ball Valves;

- adapters (have an external plastic thread).

Types of polypropylene products

There are four types of polypropylene products:

- PN 25. Maximum permissible pressure – 2.5 MPa. Used in heating systems, hot water pipes;

- PN 20. A universal product that can cope with loads up to 2 MPa. It is used in cold/hot water supply systems (if the water temperature is not more than eighty degrees Celsius). It is highly durable because there is foil reinforcement inside;

- PN 16. Designed for heating systems with low pressure and cold water supply systems;

- PN 10. A product with thin walls that can withstand loads of up to 1 MPa. It is often used when installing heated floors (temperature no higher than forty-five degrees), cold water supply (up to plus twenty).

To find products that suit your needs, consult with a specialist . You can also watch a video that explains which pipes to use in different situations.

Conclusion

The choice of material for the pipeline, as well as the methods of connecting pipes, are many. All work can be done with your own hands without any problems; you just need to follow the technology. Although it can be difficult to choose, such an abundance of materials helps to find optimal solutions for practicality, long and reliable operation and harmonious fit into the interior.

(

1 ratings, average: 5.00 out of 5)

Previous entry Types and classification of pipes for water supply systems

Next entry How to connect an instantaneous water heater

PVC pipes

They are equipped with a special socket, which is very helpful in installation.

PVC pipes are usually connected using gluing.

Briefly, the installation of PVC pipes looks like this:

Installing a PVC piping system using adhesive

- The outer end of one pipe and the inner surface of the socket of the other are ground with sandpaper to give them roughness and, as a result, better adhesion.

- The treated edges are degreased with methylene chloride.

- Apply glue to the entire length of the calibrated end of the pipe and 2/3 of the length of the socket. The most commonly used glue is GIPC-127; it is applied by very quickly spreading it in an even layer over the surface with soft brushes three to four centimeters wide.

- On both elements to be connected, quickly insert the pipe into the coupling (socket) until it stops, then turn it a quarter turn. Degreasing, applying glue and joining the pipe should take no more than three minutes.

- The connected elements are pressed and held in this state for at least a minute. If everything is done correctly, when gluing, a thin squeezed bead of glue appears.

It will take several hours for complete and uniform gluing.

Advice! If an error is made during the installation process, the connection should be disassembled only in the first 5-10 seconds. After this, all surfaces must be cleaned immediately with a degreaser.

Example of water supply system layout

First, we draw a water supply layout plan. This can be done on a piece of paper, marking the necessary fittings. Please note that installation of taps requires installation of a fitting with a thread at the end. Taps are needed on taps to household appliances and plumbing fixtures, to heating radiators. This makes it possible to turn off devices without shutting down the entire system. The type of thread and its size are selected depending on the type of tap used.

An example of a water supply system using metal-plastic pipes

Also, transition fittings are needed before and after the meter (water or heating depends on the type of system). Having drawn a detailed plan, put down dimensions on all areas. Using this drawing, you calculate how much and what you need. Fittings can be purchased strictly according to the list, and it is advisable to take pipes with some reserve. Firstly, you could make a mistake when measuring, and secondly, in the absence of experience, you can spoil some piece - cut off less than required or crimp incorrectly, etc.

Agree on the possibility of an exchange

When purchasing everything you need, agree with the seller that you can exchange/return some fittings if necessary. Even professionals often make mistakes with them, and even more so those who decide to do the wiring of a plumbing or heating system from metal-plastic with their own hands. No one will take the rest of the pipe back from you, but fittings will easily be taken back. But to be sure, keep the receipt.

Sometimes it is more convenient to use collectors. They allow you to connect several consumers in parallel. There are collectors for plumbing and for heating (when installing heated floors)

When and how to start work

When you get home, lay out the fittings and proceed: installation of metal-plastic pipes in the summer can be done immediately, in the winter you need to wait some time (12 hours) until all the elements warm up to room temperature. It is advisable to cut one piece of pipe of the required length at a time. It's a little longer, but you definitely won't get confused. Further actions depending on the selected type of fittings.

Heating installation with metal-plastic pipes is done only with press fittings

After completing the installation of metal-plastic pipes, the pipeline is checked. If it is a water supply, just open the tap at the inlet. This must be done gradually and smoothly. The system will immediately begin to fill with water. If nothing leaks anywhere, you did everything right. If any connections are leaking, they must either be redone if press fittings were used, or tightened if the assembly was based on crimp connectors.

If a heating system was assembled from metal-plastic pipes, before starting it must be pressurized - tested with high pressure by pumping cold water into the system. If the test was successful, you can do a test run of the heating.

Installation of metal-plastic pipes using compression fittings

Compression fittings consist of several parts. The base is a cast body with threads. There is also a ferrule that secures the piece of pipe to the fitting and a union nut that clamps the connection. An important part is the O-ring, which ensures tightness.

This installation method is good because it does not require any special equipment. The second advantage is that the connection is detachable and, if necessary, the fitting can be replaced. If it fails or there is a need to change the pipeline configuration. And it's very convenient.

But there is also a drawback: from time to time, a leak occurs on the threads. It can be fixed simply by tightening it half a turn. But because of this, all connections must be accessible and cannot be bricked up. Also annoying is the need to check whether it leaked or not. Not everyone likes it.

This is what compression fittings look like

The range of fittings is wide: angles, tees, crosses, adapters (from one diameter to another). And all this with different angles, in different diameters.

Installation of metal-plastic pipes on compression fittings begins with removing the union nut and ferrule ring and checking for the presence of a rubber seal. After this, the assembly actually begins:

- The nut and ring are put on the pipe.

- The section is pulled onto the fitting until it stops. The stop is indicated by a special small protrusion-shoulder.

- The ring is also stretched until it stops on the fitting.

Before tightening the nut - The union nut is tightened. First, by hand, the connection of the metal-plastic tubes is tightened using two keys. One holds the fitting body, the second turns the union nut.

That's all, the installation process of the compression (screw, threaded) fitting is completed. There is only one caveat: if you fill the system with antifreeze, change the gaskets immediately. The ones that come with the kit will leak with anti-freeze very quickly. Use paronite or teflon ones. Only they can ensure tightness. In general, for systems with antifreeze it is better to use press fittings. They definitely don't leak (if crimped correctly).

How to attach to walls

When the pipeline is laid open, it must be fixed to the walls in some way. Usually special plastic clips are used for this. They are single - for laying one pipeline thread. Typically used for plumbing installations. There are dual ones - most often they are installed for heating - supply and return in two-pipe systems run in parallel.

Clips for mounting metal-plastic pipes on the wall

These clips are installed every meter (as often as possible). A hole is drilled in the wall for each, and a dowel of the required type is inserted (selected depending on the type of material from which the walls are made). A large load is not expected, but plumbing and heating look much more attractive if everything is laid out evenly, as if on a ruler.

When it is necessary to connect pipes of different structures

Connections of pipeline systems made of different materials may be necessary in the following cases:

- connecting a new pipeline to an existing line or riser;

- replacing a worn-out area;

- laying and connecting water heated floors to the existing heating system made of polypropylene;

- installation of a mixed system in order to reduce the cost of purchasing materials.

In each case, you will need parts with the same type of connection on one side (fittings).