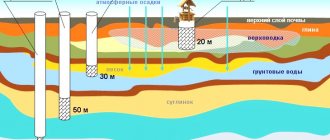

One of the mandatory conditions for the uninterrupted operation of autonomous water supply is the protection of communications from icing in winter. This problem can be solved by diverting the system below the dangerous level of soil freezing, as well as connecting the pipe coming from the well pump through an adapter.

We will tell you what this device is and what advantages it has in comparison with the construction of a caisson. You will learn how to correctly install a well adapter with your own hands, how to connect it to the pipeline and at what depth. Taking into account our advice, you can install it yourself without any problems.

Design features of the device

The downhole adapter is a special device. It ensures a hermetically sealed entry of water supply pipes through the casing when installing a non-freezing water supply system. Essentially, the adapter is an angle connector.

The principle of operation of the adapter is that it redirects the water rising up the well shaft into the pipeline leading to the house, which is located below the freezing level of the ground

Although downhole adapters have a fairly simple design, equipping a well with their use is associated with many features. This specificity largely determines the service life of the hydraulic structure.

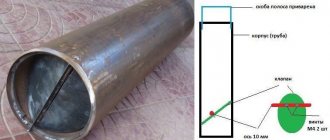

The main elements of the adapter are the outer and inner parts.

Internal flow part

Externally, this part of the device resembles a tee. One of its sides is blank. It is equipped with technical threads required for joining the two parts of the adapter. The other part is connected to the pipe leading to the deep-well pump. The central branch of the tee-like connection is equipped with the second half of the general connection of the dovetail design.

The reverse side of the holder is equipped with an annular groove intended for a rubber gasket, as well as protrusions for pressing the wedge of the mating part

Its installation is carried out in the hole of the casing pipe, securing it with a union nut equipped with a sealing ring.

Rubber seals are designed to seal the well from the ingress of groundwater. The first seal is placed on the inner surface of the holder plane, the second - between the outer wall and the union nut.

External mate

This is a compact threaded pipe. It is connected to the HDPE pipe and to the discharge pipe of the pump, and is connected to the main part by threading a special rod into the wedge slide. In addition to the wedge, it is equipped with an annular groove and two fittings with internal threads.

The main feature of the device is the strong connection of the external and internal elements, called the “dovetail”.

Thanks to this design solution, a hermetically sealed connection is obtained between the vertical and horizontal sections of the water pipeline with their subsequent removal to the outside through the casing

The intermediate element nipple, which is a single structure with a holder, is intended for connecting the water supply to the pump.

Video description

Watch the video to see how to install the downhole adapter:

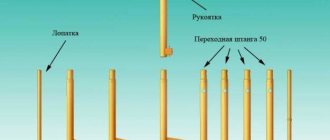

- By pulling the mounting rod up, the adapter tee is removed from the socket and pulled out.

- A pump is assembled, to which a pipe, a safety rope and an electrical cable are connected.

- The upper part of the pipe is inserted into the lower channel of the adapter tee and secured with a coupling.

- Screw the mounting rod onto the adapter again and use it to lower the entire structure into the well, placing the tee in the mating socket until it stops.

Note! Installing a well adapter reduces the internal cross-section of the casing pipe. Its counterpart with a socket may interfere with the installation of the pump, so it is selected taking this nuance into account.

The wellbore is cut off just above ground level and covered with a special sealed lid through which the power cable is led out. The safety rope that holds the pump at the desired level is also fixed in the cover structure.

Internal structure of a well cover Source svayburvod.rf

Advantages and disadvantages of “adapter” technology

The technology of constructing a well using an adapter is a worthy alternative to installing a caisson. And the reason for this is a number of undeniable advantages that the downhole adapter has:

- Affordable price . The price of the adapter is many times cheaper than the caisson, thanks to which a wide range of buyers can afford to purchase and install the device on their site.

- Easy to install. It does not require the use of welding equipment or the welding skills of the performer. Excavation work is carried out to a minimum - only along the connected water supply branch. Even a novice master can handle the installation of a downhole adapter.

- High system tightness . The adapter links are adjacent extremely tightly to each other. The sealing ring of the device is quite capable of withstanding a system pressure of 7-8 atmospheres. The design, which provides for disassembling the flow part of the device inside the casing pipe, will ensure the operation of the device even in the presence of a leak.

- High load-bearing capacity. Depending on the thickness of the walls of the device and the material of manufacture, all sections of the adapter thread are able to withstand connected communications and a submersible pump, the total weight of which reaches from 200 to 800 kg.

- Aesthetic qualities . Thanks to the possibility of hidden installation, a well equipped with an adapter will be practically invisible on the site. This is especially true for owners who are afraid of theft of the pump.

Due to the high tightness of the device, it can be safely used when constructing a system in areas with high water typical for the off-season, as well as those located in close proximity to underground communication lines.

Installing an adapter is a win-win option in case of irregular use of the well and “freezing” of the hydraulic structure for a long period

But, like any device, this very useful device is not without its drawbacks. For example, when installing a downhole adapter, it is impossible to provide quick access in case of need for maintenance and repair work.

The tightness of the joining of parts of the downhole adapter can be guaranteed only if preventive treatment of external and internal gaskets is carried out, as well as their timely replacement.

For example, an external gasket in direct contact with the ground becomes unusable after use for 2-3 years. And to carry out this work, you have to dig a pit, which is not always possible.

Installing an adapter limits the possibility of connecting additional sources of water intake from the well, for example, for watering the site

Brass and other metal alloys used in the manufacture of cheap adapters oxidize during use. As a result, parts are often jammed at the joints, which complicates the process of removing the pump.

For this reason, experts advise purchasing adapters made of bronze, stainless steel and specialized “food” alloys. These oxidation-resistant metals will last from 20 to 50 years.

In European countries today only adapters made of food alloys, such as DZR or Sanitary Brass, are used. But domestic GOSTs allow the use of stainless, bronze and brass devices due to the fact that the area of contact of its elements with water is negligible.

Another vulnerable point is the connection of the adapter with the drainage pipe and hose on which the pump is installed.

The key reason for the possible depressurization of structural connections is that the connecting elements are made of different materials

The connecting elements of the system react differently to the effects of temperature and moisture, and also have different periods of wear and aging. Therefore, experts advise, if possible, the pipe leading from the well to the house should be made of stainless steel.

Briefly about the main thing

Wanting to protect the water supply from freezing, spending a minimum of money on it, it is removed from the well through an adapter installed in the casing pipe underground. This method preserves the tightness of the source, reduces the time to put the well into operation, but excludes free access to the hydraulic unit for inspection and repair. However, if the installation technology is followed, its service life is at least 20 years, and such rare “excavations” should not create problems.

Ratings 0

Relay selection

When choosing a hydraulic relay, you are guided by its range in the water supply; the standard value is 1.5 - 3 bar. When connecting using a pressure gauge, adjust it using the adjusting screws. Do the same with the dry-running relay, setting it to turn off the power when the pressure in the line is less than 1.5 bar. If a private house has a high number of floors, then to supply water with the required pressure to the upper floors, the relay is additionally adjusted, increasing the upper and lower response thresholds.

For example, if the height of the rise to the upper floors is 5 meters (1 bar corresponds to 10 meters of vertical water column), then 0.5 bar is added to the upper and lower response limits and the resulting response range is from 2 to 3.5 bar . The brand chosen for water supply at home must have the appropriate pressure range according to the passport.

Rice. 8 Pumping units with floats and electrolytic sensors

Technological process

Installing the caisson on the top of the casing pipe

A caisson is a tank that can be made of plastic or steel. Its main task is to prevent contamination of the equipped well, as well as its insulation.

Preparing a pit for installing a caisson

Dig a hole for it, usually about 1 m high. Leave an inconspicuous technological hatch at the top, through which it will be convenient to get inside, where there is free access to all equipment.

Plastic version of the caisson

Select pumping and filter systems

Before choosing equipment and a method for piping a water well, you must know the following parameters: the quantity and quality of the water being raised, as well as the depth of the limestone and sand layer.

The pump is selected based on the static and dynamic water levels, which can be determined during the process of drilling a well. The first is the height of the water column at rest, the second is the level that changes during operation of the pumping system.

Later, you can determine the level of the water surface, for example, when replacing a pump after a few years, using a level gauge. It needs to be immersed inside the well and the depth calculated using special marks.

Advice: you can raise water to the surface with a pump only if you know exactly the depth of the aquifer and the flow rate of the well along with all consumers.

You must remember that the choice of pumping system when constructing a well plays a decisive role in the pressure and amount of water from the tap. In this case, you should not skimp on equipment; purchase only what is recommended for your needs.

The photo shows the placement of equipment for supplying water to the house from a well in a caisson

Hydraulic accumulator

Its use makes it possible to increase the service life of the pump and the service life of the entire system. You can install it indoors inside the house, inside a boiler room or a caisson.

Installing a hydraulic accumulator will significantly reduce the load on the pump, reducing its wear to a minimum by adjusting the on-off switch. If the system operates for a long time, the load on it will still increase, so even the most durable such equipment will someday or suddenly become unusable.

Choose a hydraulic tank after consulting with a specialist who can calculate the maximum volume of water consumption. Often you specifically buy more powerful equipment that will never be able to work at full capacity, but its price will be much more expensive than what is needed.

Advice: before going to the store or placing an order, you need to calculate everything correctly so as not to spend extra money.

Pipeline supply and installation of additional equipment

It is possible to supply water to the house year-round, but for this it is necessary to eliminate the slightest possibility of it freezing along the way to the house. The construction of a well involves its insulation. What is a caisson used for?

Preparing the trench from the pit to the house

If you do not have the opportunity to insulate the pipes leading to the house, they should be placed at a level below the freezing depth in the area. Otherwise, it is necessary to prepare foam chips with slag or mineral wool, but with concrete slabs protecting on top. Now no frost will stop the passage of water to the home.

Another option for tying is the use of a pit, which, unlike a caisson, can be made from scrap materials.

It is simpler in design and is often used as an alternative without the involvement of specialists.

Tying the wellhead using a pit

- Dig a hole above the well to a height of 1.5-2 m.

- Insert well rings into it, or you can line the walls with bricks, fill them with concrete, or make wooden formwork.

The advantage of the design is cost, the negative is poor tightness. Also, a pumping station, hydraulic accumulator and other equipment cannot be placed here.

Construction of a well is a responsible matter, on which the quality of drinking water and its service life depend. Do not rush to start work without consulting with specialists. In the video presented in this article you will find additional information on this topic.

More from my site

- Well design: what you need to know

- Proper installation of a water well

- Construction of a water well: basic elements and tips for selecting components

- How to determine a location for a well on a site: criteria for choosing a drilling point

- Construction of a water well with your own hands

- Well for a well: self-arrangement

Which adapter to choose

It is worth immediately noting the main point: the adapters are practically no different from each other in their design features. Their main difference is the material used to create the device. Thus, adapters for wells come in several types:

- Steel (steel alloys). This option is most popular among consumers. Firstly, these alloys are characterized by increased strength and are significantly superior to other adapters in this indicator. Secondly, steel alloys are “not afraid” even of heated acids if they are pumped through a well, so they will be “friendly” with water for a very long time.

- Brass. Most often they are used not in domestic, but in technical plumbing systems, since they cannot be called absolutely inert in relation to water: experts have noted the negative impact of brass oxide on water quality.

Bronze adapter - Bronze. Such devices have been popular for quite some time. They can be a good competitor to steel ones, but are currently presented on the market in small quantities, since they are quite expensive.

Advice. Experts advise that those whose water supply system is practically in “contact” with communication lines must install an adapter on their site.

Some tips

Why do you need a cap (fungus, deflector) on a chimney pipe and how to make it yourself?

Having decided to equip a well with an adapter (in retail chains they are called Pitless adapters), you get a reliable water supply system and save on the timing of the work and the cost of its implementation. However, when purchasing it, you must remember the following:

- In order for the product to maintain its tightness throughout its entire service life and guarantee the possibility of repeated installation and dismantling of the deep-well pump, it must be of high quality. Do not buy adapters from little-known manufacturers that do not have a manufacturer's warranty.

- Having decided to purchase a Pitless adapter, be sure to check with the seller how difficult it is to find spare parts for this product in retail chains, first of all, o-rings and a removable part assembly. What is the probability that in a couple (or better, in five) years this product will still be produced.

- Having settled on this option, you will need to place all the equipment of your water supply system in the house itself and, preferably, in a separate room.

Video with the pros and cons of the adapter and caisson:

If you also have a main water supply, then it is useful to install an avk flanged valve to be able to shut it off. Depending on the situation, you can choose the source of water supply.