Currently, there are many gadgets in the kitchen that make the housewife's work easier. However, even when using a dishwasher, grease accumulates and enters the drain, which is the enemy of pipes and one of the causes of blockages.

Based on the name, a special device was invented - a grease trap. Industrial enterprises are required to install such a thing in their production, but this is not necessary in private homes. We will look at which model to prefer and how the work process works below.

Variety of devices

Grease traps are presented in specialized stores in a fairly large assortment, with different capacities and configurations.

First of all, devices are divided into types according to the material from which the case is made. They can be plastic, fiberglass or metal.

Polyethylene and polypropylene are used in the manufacture of industrial and household models. Such products are characterized by low maintenance, light weight, low cost and a fairly long service life.

Fiberglass is characterized by high strength and resistance to aggressive environments. This allows grease traps to be buried in the ground or installed outside the building.

Metal grease traps are made of stainless steel, so they can withstand cleaning with a stiff brush without damaging the surface. They have an aesthetically attractive appearance, but are quite expensive. Sometimes there are models made of galvanized or painted steel, but they are susceptible to rust. In contrast, products made of aluminum and stainless steel are characterized by a fairly long service life.

The second characteristic by which all grease traps can be divided is the design feature of the products.

There are several main types:

- Grease trap under the sink

. Suitable for installation in a private house, apartment or small catering establishment, it requires manual operation. - Industrial model

. Installed in a catering unit designed to serve a large number of people, or in food industry enterprises. In most cases, industrial equipment has a fill sensor. - Automatic equipment

. The presence of an electric mechanism for automatic fat collection makes maintenance simpler and easier. In addition, the possibility of clogging the inlet and outlet pipes is almost completely eliminated. - Models with the possibility of being located below the sewer level

. A distinctive feature of such grease traps is the presence of a built-in electric pump. With its help, purified water rises to the sewer system, which is located at a higher level. This allows equipment to be installed in basements or buried in the ground. - The well model

has the shape of a cylinder and belongs to large industrial devices. They are placed in a special external well and served through a hatch.

For household use, it is recommended to purchase a regular grease trap under the sink, which is suitable for independent maintenance once every 2-3 weeks. The design and arrangement of such products are not particularly difficult.

Classification by installation type

There are varieties:

- Models that are installed directly under the sink;

- Devices installed in separate rooms;

- Devices intended for installation in the basement;

- Devices that require installation outdoors separate fat particles from water.

The first 3 modifications differ from each other only in performance; it all depends on how many pieces of equipment: washing machines, bathtubs, shower cabins are planned to be connected.

Grease trap structure and operating principle

Domestic kitchen sink drains contain large amounts of grease, which can settle on the inside walls of the drain pipes. Over time, the build-up increases and causes pipe clogging and an unpleasant odor from the process of decomposition of organic compounds. In some cases, old fatty deposits cannot be cleaned mechanically, and the only solution in such a situation is to dismantle the sewer. When installing a grease trap in a private home, the problem of clogging with fat deposits loses its relevance.

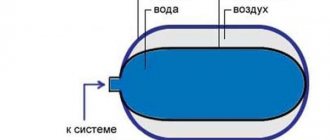

Considering the equipment, we can highlight the following design elements:

- The body is rectangular in shape, having an inlet and outlet on opposite sides.

- Partitions that slow down the movement of water and prevent greasy and solid particles from entering the pipes of the sewer system.

- The lid has a rubberized gasket for tighter closure and prevents unpleasant odors from entering the room.

- Short inlet pipe elbow.

- The exhaust pipe is in the form of a tee with open holes on all sides. The long part of the pipe is lowered to the bottom of the housing, the short part ends under the lid.

- Ventilation hole.

The design determines the operating principle of the grease trap under the sink. From the sink, water enters the receiving chamber, and the inlet can be located on the top or side wall of the grease trap. Next there may be one or two partitions that separate the receiving chamber from the main body. Everyone knows from school that water and fat have different densities, so fat rises upward, where it gradually accumulates.

An additional chamber is formed behind the partitions, in the lower part of which there is an outlet for discharging purified water into the sewer.

To prevent accumulated fats from entering the outlet, they require regular removal. To do this, the upper part of the internal space is cleaned at certain intervals.

Main types

Devices of this type are classified according to the principle of cleaning; it can be performed in three ways:

- Mechanical. This most common option was described above, its main disadvantages are:

- during operation, it is necessary to regularly clean the device from the accumulation of fats;

- low efficiency and level of purification; some impurities still remain in the wastewater.

- Gravitational. The design of such separators and the operating principle are similar to the previous type (see Fig. 3), the only difference is in the cleaning process. The effluent is given time to settle (about a day), which allows almost all impurities to collect near the surface. Often, these devices use special chemical reagents that bind fatty impurities, forming heavy conglomerates from them that precipitate.

The principle of operation of the Evo Stok gravity grease trap.

Such devices have a much higher cleaning percentage, approximately 98%, but they also have characteristic disadvantages:

- manual cleaning and subsequent disposal of fat is required;

- In the precipitated organic matter, the process of decay may begin, which manifests itself in the form of an unpleasant odor.

- Biological. Such separators are called biological destructors. The difference from previous types also lies in the cleaning technology. It is produced by adding biological products (special cultures of microorganisms), which, feeding on fat, convert it into a neutral sediment.

Tablets for the Custom GT grease trap

The advantages of this method are obvious: after the grease decomposes, there is no unpleasant odor and the cleaning process is less difficult.

Concluding the topic about the types of grease traps, we should mention devices for ventilation systems, for example, a kitchen hood, which also has special devices for separating fats.

Grease traps in kitchen hoods: a – grille filters; b – labyrinth type

Passing through the filters, fat vapors settle on them, which reduces contamination of duct ventilation systems.

Rules for calculating equipment performance

To choose the right equipment, you need to understand why you need a grease trap under the sink, and perform several calculations using a simple formula:

P = n*Ps.

Here the letter “P” denotes the performance of the device, “n” is the number of connected sinks, Ps is the speed at which water enters the grease trap (measured in liters per second). The last value can be determined independently, using any container with a known volume. Fill the container with water and set the filling time.

Then calculate how much water flows out of the tap in 1 second using the following formula:

Ps = V/T,

where V is the number of full liters in the container, T is the time to fill the container in seconds.

Having determined the required equipment performance, you can calculate the recommended volume. To do this, use the formula:

V = 60*P*t.

Here the symbol t denotes the rate of fat floating. Most often, this value is determined by the manufacturer; for household equipment, the value is 6.4 minutes.

If only one sink is connected to the grease trap, then its productivity should be 0.5-1 m3/hour. The equipment on the market is characterized by a productivity of 0.145 l/s and has a volume of 50 liters.

Comparison table of characteristics

For convenience and a clearer comparison, let’s enter the parameters of the models presented above into the table.

| Model names | Productivity, m3/hour | Peak discharge, l | Dimensions, mm | Weight, kg |

| Biofor Economy 0.5-40 | 0,5 | 40 | 460x370x400 | 8 |

| Alta-M-In 0.5-25 | 0,5 | 25 | 500x350x400 | 8 |

| Onyx 0.5-15 | 0,5 | 15 | 300x300x300 | 5 |

| Aqua Mini (0.3-20) | 0,3 | 30 | 320x260x320 | 2,7 |

| EVO STOCK 0.5-25 | 0,5 | 25 | 420x320x370 | 8 |

| PU-0.5-0.25 series “Standard” | 0,5 | 25 | 420x320x370 | 7 |

| Termite 0.5-25 | 0,5 | 25 | 450x350x395 | 7 |

Operating rules

When using a grease trap for a home sink, you must follow several specific rules that will allow you to achieve maximum efficiency in the operation of the equipment, prevent flooding and the appearance of an unpleasant odor in the kitchen.

In particular we are talking about the following:

- Mineral and synthetic oils should not be present in water waste.

- It is not recommended to connect the equipment to the toilet.

- It is forbidden to install a pump in front of the grease trap to avoid the formation of an emulsion that does not settle well.

- The inlet pipe should be located at a minimum distance from the sink and at a slope of at least 2 degrees.

- Purified water must immediately go into the sewer system.

- It is recommended to connect the equipment in the ventilation system shaft (if there is a corresponding hole in the wall or ceiling).

Advantages of grease traps

A grease trap for domestic use has a small volume, but the dimensions of the equipment itself require quite a lot of space. Most often, the device occupies the entire cabinet under the sink, so its installation must be justified.

Those who have doubts about the use of such equipment should study the principle of operation of a grease trap under the sink and become familiar with its advantages:

- The design of the grease trap is quite simple, so the possibility of making it yourself from an old plastic container is not ruled out.

- Easy installation. Connecting to a siphon involves connecting two tubes without using any tools.

- Easy maintenance. The cleaning process involves removing grease from the top of the device every few weeks. The entire procedure takes no more than 5 minutes.

- No blockages in sewer pipes. A grease trap for your home allows you to operate the system without additional cleaning.

- Possibility of placing the container in the cabinet under the sink.

- In some cases, a grease fill sensor can be installed.

The main purpose of a grease trap is to separate particles from the main liquid that can cause blockages in the sewer pipe.

Choice for home use

Before you go to the store to purchase equipment, you need to study the place where you plan to install it. The parameters of this section will allow you to reduce the number of options when deciding how to choose a grease trap for a sink directly in a store or on the Internet (read: “How to choose a grease trap for sewerage - types, differences, installation rules”).

In particular, we are talking about the following:

- The size of the internal space under the sink. When analyzing these values, it is necessary to take into account the additional distance to the top panel of the cabinet for free removal of the cover; space is required on both sides of the equipment to connect the inlet and outlet pipes.

- The diameter of the sewer pipe to which the equipment will be directly connected. The grease trap holes should have the same diameter to avoid purchasing additional adapters.

- Number of connected sinks. Need to know to determine equipment performance.

- Characteristics of waste water.

- If large quantities of solid particles are present in the drain, it is recommended to purchase a model with several partitions.

- Sewer riser or drain pipe in close proximity to the equipment installation site. This prevents the water seal on the siphon from breaking.

- Possibility of unhindered maintenance of the device, its individual elements and cleaning of the space after completed activities.

- The material from which the body is made. Most often, this question is relevant for equipment located in plain sight. In this case, it is better to purchase a grease trap for a private home, the body of which is made of stainless steel. If you plan to place the equipment in a cabinet under the sink, then you can get by with a plastic product.

- The volume of the sink bowl is especially important when it becomes necessary to immediately drain a large amount of water from the sink. In the manufacturer's instructions supplied with the device, this value is indicated as one of the characteristics.

Having studied all the selection criteria, you can safely go to the store for suitable equipment.

Plastic models

These are the most popular and in demand models on the market. They are affordable and easy to use.

They are usually placed under the sink at home. The benefits include:

- long period of use subject to operating conditions - up to 25-30 years;

- environmental friendliness of the material and harmlessness to humans;

- possibility of individual selection of the size and shape of the separator;

- ease of maintenance.

With a wide variety of models in terms of power and throughput, plastic products are sensitive to mechanical damage.

Self-installation of equipment in the cabinet under the sink

All work on installing a grease trap under a sink can be done independently; for this you do not need to have special knowledge or special tools. Connecting elements for connection are purchased directly with the equipment. Additional fittings and pipes are required only to connect the unit to the sewer system and siphon.

In most cases, the store presents assembled structures, including grease traps for the sink, which requires the presence of connecting tubes or rubber adapters that are inserted and tested for leaks.

Directly installing equipment under the sink to purify water from grease impurities involves performing the following actions:

- Before installing a grease trap under the sink, you need to prepare a place for it.

- Next, the equipment is assembled if the main unit and additional connecting elements were purchased separately. In particular, the fluid supply elbow and the outlet tee must be connected to the corresponding holes, having previously treated the joint with silicone grease.

- If the design requires adapters, then they must also be screwed to the main body.

- Next, the equipment is installed in its main place.

- Coat the outer part of the pipes and siphon, which are directly adjacent to the grease trap, with a sealing compound.

- After connecting all the elements, the structure is left for some time so that the sealant completely hardens.

- If there is an air duct, connect it to the sewer riser.

- Open the tap and supply water to the equipment. Check the functionality of the structure and the tightness of all connections. If there are no leaks, the work of installing a grease trap under the sink can be considered complete.

When choosing a place to install equipment, it is important to understand that when exposed to high temperatures, its operating efficiency is significantly reduced. For this reason, you need to choose a place away from the oven. In addition, do not allow the temperature to be too low, which will cause the liquid to freeze and cause the tank to rupture.

Service

This is not to say that the procedure for removing fat from the upper part of the equipment body is a pleasant undertaking. However, cleaning sewer pipes is an even more unpleasant task. Depending on the volume of the tank, the nature of the family’s diet and the temperature of the water used, the frequency of cleaning work is determined. In most cases, it takes several weeks to several months between cleanings.

It is very important to check the operation of the equipment the first time after installing a grease trap under the sink. The layer of fat should not be allowed to reach the level of the inlet and clog it. For this reason, you should regularly open the main body cover and check the level of fat deposits.

Cleaning the grease trap is performed after the fat layer reaches a line located 4-5 cm above the outlet pipe. The procedure involves removing the fatty viscous mass with gloves or some other device.

At the end of cleaning activities, be sure to rinse the equipment with a stream of hot water for several minutes. It is worth noting that after determining the approximate period of safe use of the structure, monitoring can be carried out less frequently.