Many owners of country and private farms not connected to a centralized water supply are familiar firsthand with the problem of supplying water to their home and garden plot.

The “Malysh” submersible pump will help partially solve this problem; although it is not a powerful device capable of pumping water from artesian wells, it can cope with supplying water from wells, shallow wells and open reservoirs.

It will be useful for those who are just planning to set up an autonomous water supply, as well as users of pumping equipment, to learn about the structure, operating principle and operating rules of the unit. We will describe in detail how to install the “Baby” in a well and ensure its uninterrupted operation.

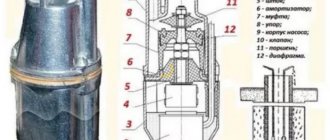

Pump device Baby

In the event of a breakdown, it is impossible to carry out high-quality repairs if the owner does not know what the principle of operation of the device is and what elements it consists of.

Information can be studied in the instructions if it is not lost.

Let's look at the design of the vibration pump Malysh.

- The main and largest element is the metal body. It must be as reliable as possible so that the pump can be immersed in deep water.

- Electromagnet.

- Vibration wire.

- Valve.

- Piston.

- Shock absorbers.

Device diagram Source belamos-expert.ru

The design of the Malysh pump can have several different variations. For example, water intake can be bottom or top.

With top fence

The specificity of the device is that the valve responsible for water suction will be located at the very top of the housing. At the same time, the manufacturer placed the electric drive in the lower part.

This pump has several clear advantages.

- The electrics of the pump are under the water column during operation. This means that it will not get very hot.

- Sediments in the form of silt and debris are too heavy. They will not rise to the top where the suction pipe is located.

With lower fence

The design of the Baby pump with a lower water intake has exactly the same design. However, the elements and mechanisms are located exactly the opposite. The electric drive is located on the top of the housing, and the suction valve is located on the bottom.

For a model with a lower intake, the valve is located at the bottom Source ai911.ru

In this case, the owners of the Baby must constantly monitor the normal water level. If the pump operates “dry”, that is, it is not completely immersed in water, overheating is possible.

How to replace the compound

- Let's disassemble the device.

- We determine the place where the compound has peeled off from the submersible pump housing. This can be done by lightly tapping the body with a small hammer. In normal areas the sound will be dull, in damaged areas it will be ringing.

- We remove the assembly with the compound from the vibration pump housing.

- Using a grinder, we carefully apply a mesh of notches, up to 2 millimeters deep, to the inside of the body. We make the same mesh on the unit with epoxy compound.

- Cover both areas with notches with glue for glass surfaces (any sealant can be used)

- We return the assembly with the compound to its original position - fix it and wait until the sealant hardens.

- Putting the body back together.

Varieties

The manufacturer offers several versions of the “Malysh” pump of different modifications.

- "Baby". This pump is equipped with a bottom liquid intake function. One of the most powerful modifications, suitable for working in thick water. But at the bottom it doesn’t show itself in the best way. Often collects silt and dirt, clogging the interior space.

- "Baby-M" The model is equipped with top fence functions. The power is not as high as the previous version. But on the other hand, it has the function of sifting out dirt and silt from the bottom. Owners of this model often experience overheating, since as a result of a drop in water level, the pump is exposed to air and overheats.

- "Baby-K." Equipped with a bottom fence function. Grounded. It is equipped with a powerful motor, which affects the cost. Not equipped with a dirt filter.

- "Baby 3". The model is suitable for narrow wells and boreholes. Has compact dimensions. Power is low.

Types of pumps Baby Source santprice.ru

Uses and areas of application

Regardless of the type and scope of application, each Malysh pump has similar technical characteristics, design and operating principles. However, in some cases the differences can be extremely radical. Thus, the internal structure and principle of operation may directly depend on the scope of application of the device.

As a rule, pumping equipment can be used in many household areas. For example, a compact device model is often used in various facilities with low water consumption. Such objects include the irrigation system for summer cottages and water supply for private houses.

In most cases, Malysh is used to draw water from a well.

Thanks to the use of such equipment in agriculture, it is possible to solve a number of significant problems, which include:

- pumping out liquid at the time of flooding of basements and ground floors;

- home water supply with drinking water;

- transfer of liquid for a variety of irrigation systems, which equally include irrigation and spraying.

Helpful advice! Before using the baby pump, you should take into account that its technical characteristics do not predispose it to work with excessively contaminated liquids. Thus, the device is most suitable for pumping clean water.

What types of malfunctions are there?

Very often, owners encounter various problems with the operation of pumps. Depending on the specifics, how to repair the Baby pump depends on the nature of the breakdown - it relates to a technical or mechanical part.

Some users themselves provoke a partial malfunction (for example, the filtration system is broken, but the pump is still pumping water). Or the device is rendered completely inoperative. Let's look at the main types of problems.

Electrical breakdowns

The main electrical problem with the Malysh submersible pump is related to the failure of the coil. The result is a breakdown to the housing or complete burnout. The latter is possible when the pump runs dry after the water level has dropped.

Coil location in the Malysh pump circuit Source themechanic.ru

Due to the lack of water, the insulation begins to burn, the materials expand, the yoke falls out of the housing, and the coil fails. Depending on how early it is possible to see that the pump is running idle, this can either partially affect the performance of the device or completely disable it.

In order to avoid such problems, you must carefully follow the operating rules and do not leave the pump running without water.

See also: Catalog of companies that specialize in electrical work of any complexity

Mechanical breakdowns

There are many more reasons for failure and each requires detailed consideration.

Parts are calcified

This happens when the pump operates in hard water. First, a small white coating appears on the “insides,” like scale. Owners of the Malysh pump must clean it in a timely manner. But if you neglect this procedure, then very soon it will affect your work.

The presence of limestone may jam the device. Most often this happens in the cold season, when frost sets in.

Limescale is the main enemy of the Malysh pump Source moikolodets.ru

The integrity of the pump is compromised

This happens when the body is deformed. Most often, the fins of the pump are hit. When examining a deformed device, it seems that someone specially used a saw or a router. But that's not true. The fact is that the pump is in contact with the concrete surface of the well. Due to strong friction, the integrity of the body is compromised.

The cavity is clogged

This most often happens with submersible pumps. Sometimes the device lies on the bottom, where there is an abundance of silt, sand, stones, earth, algae and other debris. The device begins to suck them in. Debris sticks to the valve and disrupts the seal.

Pump Baby, stained with sludge Source lovedacha.ru

As a result, the device can no longer develop good power and work at full capacity.

The thread is loose

This occurs due to excessive strong vibration or friction of the housing against the walls of the well. Usually the nuts that hold the piston in place are affected. Unfortunately, if this problem is not completely eliminated, it can lead to complete destruction of the case, when repair will not help.

Thinning rubber

Rubber gaskets are used to ensure a tight fit of the parts inside the Malysh pump body. Over time, the rubber wears out and wears out, causing the power of the device to rapidly decrease.

Gaskets from the Malysh pump repair kit Source youla.io

Sometimes it even stops working completely.

Pumping station

Today you can often come across the question, is it possible to make a pumping station from the “Baby”? In principle, there are no problems. This is still the same submersible pump, albeit low-power.

To do this, in addition to the pump, you will have to purchase a hydraulic accumulator and a check valve for the supply pipeline. It is clear that the accumulator must be equipped with a pressure switch. All these additional elements of local water supply will pay off, because the dacha will have a full-fledged water supply system that works with a certain water pressure inside the pipework, plus the constant availability of water due to the hydraulic accumulator tank. Such a system will supply water to the dacha even in the event of a power outage. It is clear that for a certain time, depending on the volume of the storage tank.

Pumping station with Baby

Eliminating problems with the Malysh pump

If you notice that the pump has lost power, is working poorly, or has stopped functioning altogether, you must immediately remove it from the water. Next, you need to carry out a step-by-step check, during which you will certainly find the source of the problem.

- Carry out an external inspection.

Before doing this, you need to rid the pump of excess moisture with a towel. Pay attention to the body. There should be no serious damage to it that would lead to leakage or loss of integrity.

If you notice cracks or serious holes, then, unfortunately, there is no way to patch them on your own. Over time, they will still begin to leak. The only way to fix the problem is to completely replace the case.

- If after inspection the device turns out to be intact, it is necessary to find out whether the resistance of the coils is sufficient.

Pump Coils Baby Source googleapis.com

Specifications

All of the above pumps use a standard electrical network with a nominal voltage of 220 Volts, their immersion depth is up to 3 meters, they pump out 430 liters per hour, water pressure is 40 m (maximum -60). “Malysh-3” has a water pressure of 20 m (maximum 25).

The power of the basic models and “Malysh-M” is 240 W, their body length is 25.5 cm, and their weight is 3.4 kg. Models are equipped with cables of various lengths from 10 to 40 meters.

When purchasing a pump, you need to pay special attention to the electrical protection class. Class 1 devices are designated “I” and are equipped with a three-core cable with grounding. If there is no marking, therefore, the unit belongs to class 2 and has a two-core cord.

Video description

Instructions for properly rewinding windings in this video:

- If you find out that the housing is intact and the resistance is at the required level, you need to clean the pump (bleed it out).

To do this, you just need to strongly inhale air into the supply hole, and then into the reverse, intake hole. The air flow should flow freely in both directions and not get stuck anywhere.

If you blow into the hole, the valve should close quickly, thereby blocking the oxygen supply. If this does not happen, it means that the adjustment of the device has been completely disrupted.

- The next step is to simply shake the device well.

There should not be any strange sounds inside it. If you hear a non-characteristic ringing, this means that some kind of detachment has occurred or one of the parts has simply fallen off.

Pump Baby after assembly Source etalon-bt.ru

Experts advise lowering the pump into a container of water. You can also add 100 g of acetic acid 9%. If you don’t have it, then lemon will do. Leave the pump in this solution for 7-8 hours.

Then it is washed under running cold running water. Thanks to this solution, limescale deposits can be removed.

- Now you need to check the valve.

There should be a small gap of up to 1 mm from it to the device. Unscrew the hose and lower the pump into the water. Turn it on. If the pump is working properly, then without a valve a stream of water will rise high. A properly operating pump will have a height of from 50 cm to 1 m. Thanks to this experiment, you will be able to judge the pressure.

Second stage: disassembling the device

Let's find out how to properly disassemble the Baby pump before a thorough inspection.

It is advisable to disassemble the pump according to the instructions. Some people are unable to complete this procedure because the screws included in the structure rust and oxidize so badly that they simply cannot be removed from the body. In this case, of course, you should contact professionals.

Disassembling the Baby pump is carried out according to the following scheme Source vodatyt.ru

If you still manage to disconnect the screws, then you can see for yourself what’s wrong.

After the pump is disassembled into two parts, the electrical part is inspected, and then the mechanical part.

Assembly

Reassembly must be done as carefully as possible.

- It is necessary that all holes in the housing coincide with each other and are installed in the same way as before disassembly. If the assembly is incorrect, and at least one of the devices inside is out of place, the pump will not function.

- The screws need to be pulled crosswise one by one, gradually. The twist should be very tight.

The process of assembling the Baby pump must be carried out in stages Source oboiman.ru

- When the pump body is assembled, the tightness is checked by immersing it in a bucket of water.

- Be sure to measure the resistance.

- If everything is fine, then you can release the pump to depth. You have checked.

Experts recommend performing a preventive inspection and cleaning of the pump once a year. In this case, the device will function for a long time without losing power or breaking down.

Assembled pump Source sm-news.ru

Rewind the reel

If you need to rewind the vibration pump coil, prepare the following consumables and tools:

- wire brand PETV;

- set for replacing epoxy compound (epoxy resin, plasticizer, hardener);

- electric stove;

- winding machine (can also be done manually);

- soldering iron;

- hammer.

While rewinding the coil, you will need to melt the epoxy compound. It is toxic, so carry out the work outside or in the garage. Place the filled electromagnet on the tile and wait until the epoxy heats up to 165 degrees. This will be visible from the toxic haze that appears.

Carefully knock the electromagnet out of the housing on a wooden object, while the electromagnet looks straight down. When the magnet changes its position, remove it. We clean the heated body from epoxy resin, using a screwdriver or a metal brush.

We knock the electromagnet out of the coil with a wooden wedge.

We do not clamp the coils in a vice, we only hold them with our hands.

Once the magnet is removed, unwind the coil, removing all the epoxy.

Using a winding machine, wrap the spool completely. Here you can do without a machine, but it will take longer to wrap it by hand.

Solder the ends of the wire to the main part, now we mount the electromagnetic core into the coil body. We solder the power cable to the beginning of the new winding. It is permissible to “seat” the coils by lightly tapping the core.

After mixing the epoxy with the plasticizer and adding the hardener, we pour it into the vertically fixed body of the device. Fill the compound to the top of the electromagnet, wait 10 minutes and add the compound again (after filling all the cracks, it will settle). After 24 hours, we assemble the pump and check its functionality.

Briefly about the main thing

There are several versions of the Baby pump on the market. All its modifications, like any other devices, are subject to breakdowns. They are observed in the electrical or mechanical part. Another common reason why the Baby pump does not pump is deformation of the housing and its liming.

You can deal with problems on your own. To do this, you need to study the structure of the device and disassemble it sequentially. Electrical and mechanical checks are carried out. Quality assembly completes the process.

It is recommended to check the Baby’s readiness for work in a small container before diving to depth.

Ratings 0

Main types of breakdowns

Vibration pumps of the “Malysh” type were developed more than half a century ago by Soviet designers. But, despite this, they are still very popular among our compatriots. The reason for this is the affordable price and high reliability. But, despite this, submersible pumps “suffer” from a number of characteristic malfunctions that are also characteristic of the “Malysh”. The main types of “Malysh” malfunctions include:

- Detachment of the electromagnet.

- The gap between the piston and magnet coils does not meet the standards.

- When plugged in, the pump hums, but does not supply water.