Statistics show that while at home, we spend the most time in bed, in the kitchen and... on the toilet. This means that choosing a convenient and reliable “faience friend” is extremely important for our attitude and mental balance. After all, if harmony reigns around, then it comes into the inner world much easier. The plumbing trend of recent decades has been wall-hung toilets, which literally transformed not only the appearance of the bathroom, but also the constructive approach to the placement of sanitary equipment.

Wall-hung toilet and its features

The wall-hung toilet differs from the usual sanitary ware in the absence of a supporting part. The white bowl seems to float above the floor, attached to the wall at the back end. The tank, pipes and other not very aesthetic elements of the system are hidden behind a false wall, leaving only the bowl with a seat and a panel with a water drain button visible. A bathroom equipped with a wall-hung toilet immediately takes on an elegant, stylish look. But to understand how this impression is achieved, you need to look beyond the tile layer and understand the internal structure of the suspension system.

Wall hung toilet AM.PM Awe

Advantages of a built-in toilet installation

The built-in toilet reveals only the toilet seat itself. The tank with the mounting system is hidden in the wall or covered with a special panel. This design looks fashionable and modern, allows you to save space in small bathrooms and create space and an atmosphere of ease of life in large bathrooms. Convenience of cleaning can also be added to the advantages - it’s easy to wash the floor under the installation. But, like everything beautiful and convenient, the toilet installation also has its drawbacks (as people say: “Beauty requires sacrifice”:)

Design of a toilet hanging system

The shining bowl is just the tip of the iceberg, the base of which is hidden inside the wall. The wall hung toilet system includes:

- installation

- a durable steel frame that is attached to the wall or floor and takes on the weight of the plumbing fixtures and the seated person;

a rectangular drain tank- the flush button

is a rather complex device that transmits pressing force from the button to the tank; - a toilet

without a support leg, providing for hanging installation.

These are mandatory elements that you cannot do without if you install a wall-hung toilet in your home. Let's look at them in more detail.

Installation of a suspended model

In any case, such installation work should be performed by professionals, but it won’t hurt you to know how this happens:

- First, they think about the location of the toilet, tank and installation system. Determine the optimal height for all family members. Most often, the height of the device relative to the floor level is 40 cm.

- Install the installation system following the manufacturer's detailed instructions. This type of work depends on the type of system - floor or suspended (built-in).

- Then the toilet is attached to special pins located on the frame.

- A plastic water tank is connected using clamps, which can also be found on the frame.

- The installation is most often sheathed with plasterboard and lined in accordance with the finishing raw materials that are used to renovate the bathroom.

Important! In this difficult task, the most important thing is to correctly select all the components, which must fit perfectly together in order to ensure a simple sewer or water supply connection.

Installation - what is it?

It is impossible to securely fix the toilet directly to the wall for a number of technical reasons. The designers found an elegant and simple solution to this problem, proposing the use of a special load-bearing frame. It is called an installation because all the functional elements of the water closet are installed on it. The frame is made of steel profile coated with anti-corrosion paint. He is not afraid of high humidity. The installation is designed to withstand significant weight loads: products from well-known European companies can withstand weights of up to 400-500 kg, and some even up to 800 kg.

There are two types of installations:

- block

- designed for wall mounting and used only when fixing the toilet to a load-bearing wall made of durable material - concrete or brick; - frame

- which is a vertical frame on two horizontal supports, which is attached to the floor and wall. The height of the frame is chosen based on the characteristics of the bathroom and installation requirements.

Wall-hung toilet KERAMIN Grand R without rims, with microlift seat

The frame installation does not depend on the wall material and can be installed anywhere, even in the center of the bathroom, if such a desire arises. But the block one allows you to gain some free space, since it has a more compact size.

As a rule, the installation is sold complete with a tank, since it is important that these products match each other in size and other design nuances.

Stages of formwork installation

Take a board made of plywood or chipboard measuring 50/30 cm . Markings are made on it where in the future the places where the toilet will be attached to the wall will be located. Usually this is a point at a height of 35-40 cm. Between the points the width is 20 cm. Before fixing the formwork, you need to bring the toilet to the markings and check their accuracy.

Using a hammer drill or a drill, 2 holes according to the markings of the shield, 15 cm deep. They are cleaned of dust. chemical anchor is poured into the holes (it is in the T.M. Moment and Ceresit catalogs under the index CF 850).

The required length of the pins is cut off (taking into account the distance of penetration into the wall of 15 cm + the distance from the wall to the toilet + the thickness of the toilet + the length of the free end where the nut will be screwed). The pin is inserted into the hole filled with a “chemical anchor” .

The front shield with a drain hole is protected at the hole with polyethylene. The location of the outlet of the toilet should coincide with the inlet of the coupling in the toilet. Two holes are also made in the shield, and through them the shield is secured to pins fixed in the wall. Two side shields are installed nearby. Their verticality is checked with a level. To give the formwork stability, nuts are screwed to the pins. On the inside of the front shield, a piece of foam plastic slightly larger than a matchbox is glued to the top. It will become a form for recessing in the concrete.

Wall-hung toilet cistern

Even such a prosaic element of a water closet as a cistern has its own character in a suspended system. As a rule, it is made of durable solid plastic, but some manufacturers offer metal tanks with an anti-corrosion coating. It is shaped like a flat rectangle, the width of which corresponds to the width of the installation frame.

GEBERIT Delta concealed cistern 12cm

Modern tanks are divided in half by a partition, allowing only half the water to be used, thereby saving a valuable natural resource. A reliable drainage system with a float is installed inside, for which the manufacturer provides a guarantee for a period of 5-10 years. All its elements are coated from the inside with a special composition that prevents the settling of limescale, thereby significantly increasing their durability and performance. In addition, the tank must be equipped with a drainage hole in case the float fails. The water entering the tank will flow through the drainage hole into the toilet to prevent overflow and flooding.

Main causes of malfunction and ways to eliminate them

Considering the design features of such a system, we can identify just a few malfunctions that may arise during operation:

- the float does not shut off the water when the level is reached;

- water does not flow when the tank is empty;

- Water constantly flows in the toilet.

As for the first point, the main reason here may be a faulty float. Since it is often made in the form of a hollow container, it most likely began to leak under the influence of water and can no longer float. Also, the reason here may be that either rust or some other debris has gotten under the float valve mechanism itself, causing the system to jam. This will most likely be the cause of the second breakdown, when water does not flow. If the failure is in the float itself, then it simply needs to be replaced. If the whole thing is garbage, then it’s enough to simply clean the entire system.

It should also be noted that if, out of the blue, water starts flowing constantly in the toilet, this could also be what was discussed earlier. Since in this case the float has ceased to fulfill its direct duty and does not shut off the water supply. However, in this case there may also be a problem with the overflow system itself. However, all troubleshooting should start with the float system.

Flush button

In a suspended system, the flush button, for obvious reasons, is mounted separately from the cistern, on a false wall that hides the installation. The consumer sees only a decorative panel with one or two keys. By design, the button can be:

- ordinary

, with a single key, when pressed, all the water in the tank is drained; - economical with a bipartite key

: by pressing one half, you drain all the water from the tank, when you press the other, only half of the water; - economical with the “start-stop” function

: the first press opens the drain, the second closes it, i.e. you regulate the amount of water drained yourself.

The key is connected to the drainage system using a pneumatic drive, a special lever or a cable.

GROHE Sail flush plate, chrome

What are wall-hung toilets made of?

Currently, manufacturers produce plumbing fixtures from various materials that satisfy the widest possible range of consumer needs.

Plumbing faience

For the manufacture of wall-hung toilets in the budget segment, high-quality sanitary faience is used - a porous ceramic material coated with a durable, durable glaze. Modern glazes have a dirt-repellent surface, so they are easy to clean using any disinfectant.

Plumbing porcelain

Plumbing porcelain is recognized as the most successful material for making a wall-hung toilet. This ceramic material has a highly durable and very smooth surface, making it look solid and elegant. Due to the absence of pores, dirt does not accumulate on the surface and plaque does not form. All contaminants can be removed with minimal effort using a wide range of detergents and disinfectants.

Strained glass

A glass toilet is an impressive, but very expensive plumbing fixture. As a rule, such products are produced in very small series or are made individually to order from a design studio. They look at least unusual, but they require constant and rather complex maintenance, because even dried drops of water on the surface of the glass give an untidy appearance to capricious plumbing fixtures.

Stainless steel

A stainless steel toilet looks unusual and brutal, which is why such models are used in interiors of “industrial” style trends: loft, high-tech, industrial, etc. The product is characterized by practicality and unsurpassed durability, and the efforts of technologists make it possible to make it low-noise. The stainless steel toilet is lightweight and easy to clean. With minimal engineering modification, modern high-tech accessories can be easily integrated into its internal cavities.

Polymer concrete, acrylic marble

Various types of artificial stone are used for the manufacture of designer toilets, that is, products produced in single copies or in small series. As a rule, they have an original design and look impressive in the interior, are quite durable and quite reliable, but they are very expensive for their owners.

Acrylic

The wall-hung acrylic toilet is lightweight, excellent in appearance and relatively affordable. The antibacterial coating prevents the appearance of unpleasant odors, the smooth surface is easy to clean and does not accumulate lime deposits. The only drawback of the material is its low durability: after 7-8 years, it usually has to be replaced.

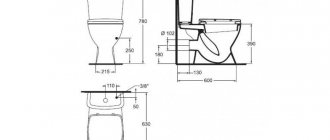

Dimensions of wall-hung toilets

The size of the toilet bowl is especially important for owners of small apartments where the bathroom is not spacious. Depending on the length of the bowl, wall-hung toilets are divided into three groups:

- compact

- no more than 54 cm, ideal for small apartments; - medium

- from 55 to 60 cm, making up the bulk of the assortment; - large

- from 61 to 70 cm, convenient for people with disabilities or designed for spacious bathrooms.

When choosing a model, you should definitely take into account the dimensions of the bowl, correlating them with the dimensions of the bathroom and the design features of the rest of the plumbing.

Wall-hung toilet JACOB DELAFON Presquile with microlift seat

Toilet design

The design decision is an important factor that has a huge impact on the choice of plumbing fixtures. The traditional shape for a bowl is an oval or semi-oval. Among the products in the upper price segment, many models have an almost round shape. Due to the absence of corners, they are considered the most injury-proof. In addition, a round or oval bowl is easier to clean, since it does not have internal corners where dirt can accumulate.

However, consumers gravitate toward variety, so many plumbing manufacturers offer toilets in a variety of shapes: rectangular, teardrop-shaped, etc. It is not difficult to find a wall-hung model of an unusual shape if the embodiment of your design idea requires it. The color palette is also quite wide. Although most models are made in the traditional white color for plumbing fixtures, manufacturers offer products in other shades, from delicate pastel tones to radical black.

general information

Built-in toilets are a design where only the bowl is located on the outside. The entire drainage system, along with the tank and fittings, is located behind the wall. On sale you can find wall-hung and floor-mounted built-in models. The specific choice depends on the characteristics of the bathroom, personal preferences and other factors.

The overall dimensions are much smaller, which makes cleaning much easier. Flooring solutions will always have areas that are difficult to access and where dirt cannot be washed off. A huge amount of it will accumulate in these places.

Even the most ordinary frame can withstand loads of up to 400 kilograms - this is more than enough. There are installations that allow you to mount a built-in toilet (photo in our article) in one of the corners. Manufacturers offer special rail systems - on these frames you can mount not only a toilet, but also other plumbing fixtures. For example, a bidet and a sink.

Structure of the toilet bowl

There are three main types of toilet bowl, depending on its internal structure: plate-shaped, funnel-shaped and visor-shaped. A bowl in the form of a funnel is considered the most hygienic, but due to the high water level, a lot of splashes are formed in it during the discharge of needs, and not everyone likes this. Such toilets are popular in the USA, but in our country the most successful are visor models with a special shelf that protects against splashing.

Flush design

In traditionally designed toilets, the flush water comes from a hole in the back of the bowl, so the flow does not always reach the front wall, which has to be cleaned with a brush. Another disadvantage is the increased formation of splashes. This flushing system is called direct, or horizontal.

Modern models are usually equipped with a reverse, or circular, flush system. In the upper part of the bowl, close to the rim, there is a series of small holes located along the entire circumference and at an angle. The streams of water flowing through them twist in a spiral and wash the entire inner surface of the bowl. In addition to high-quality cleaning, back flushing is characterized by minimal splashing and low noise. In addition, such a system uses water more economically.

Additional accessories

There are a number of additional accessories and devices that will make using a wall-hung toilet even more convenient and safe for you and your family.

- Cover with microlift.

A device for smoothly lowering the lid significantly extends the life of the seat. At the same time, the lid is easy to remove for washing. - Built-in bidet.

The design consists of an additional container with a built-in water heater, a retractable tube with a fountain nozzle and an electronic control unit. When you press a key, the tube extends from under the seat, and the control unit supplies heated water to the nozzle. - Flush aeration.

Thanks to a special device, the water is saturated with air bubbles and washes the walls of the bowl more effectively. For a complete flush, much less water is required than usual. - Heated seat.

During the cold season, it is much more pleasant to sink into a warm seat, the temperature of which is equal to or slightly higher than body temperature. - Air towel.

After using the bidet, the heated fan turns on, delivering a stream of warm air that dries out the moisture.

Installation work - installing the structure

Thanks to the installation, a toilet with a built-in tank can be installed in any part of the room.

Of course, the main factor determining the position of the product is the location of the sewer system to which the device is connected. But, if you contact a competent specialist, this trouble will not become a problem. Regardless of the position of the plumbing, there are only two types of installation. The first type is classic solutions, which look like a metal frame equipped with fasteners and supports. The second type of installation is a device that allows you to mount the toilet in the corner of the bathroom.

The rail installation deserves special attention. The key feature of this product is that in addition to the toilet, it can be used to install a urinal, bidet and washbasin, while combining the entire structure into one.

Installation procedure

Proper installation of a toilet with a built-in tank is established according to the following rules:

- Before starting installation work, it is necessary to check the quality of the floor and walls for strength, and check the good condition of communications (pipes). If the sewer pipe has become unusable over time and is crumbling before our eyes, it is recommended to have it repaired.

- These measures will protect you from accidental collapses, malfunctions and breakdowns, which will subsequently require repair measures;

- The next step is to fix the installation on the floor, screw in all the studs that are included in the structure of the built-in toilet;

- After fixing the installation, it is necessary to insulate it well - for these purposes, most craftsmen choose drywall, but other materials can also be used.

- The main advantage of drywall is its ease of installation and the fact that you can easily stick tiles or mosaics onto it;

- Now, you need to take the toilet and place it on the studs. The next step is to insulate the studs themselves using special washers;

- At the final stage, all that remains is the decorative finishing of the fixed structure, which can be made with any convenient and attractive material.

That's it, the installation work is completed - the built-in toilet cistern is securely hidden in the wall and the device functions perfectly. You will be pleased with the convenient design of this product and the low noise level produced by the tank.

Other design features

Another unshakable advantage of such products is the cost-effectiveness of flush tanks. Standardized tank models installed on simple toilets consume about 7-9 liters of water per flush. Built-in tanks consume about 4-5 liters per flush, which is 1.5-2 times more economical, while the quality of the flush does not suffer at all. If your home has water meters, such a toilet will be an excellent solution for your bathroom.

Having considered all the positive qualities and disadvantages, features of installation work and other characteristics, it becomes clear that toilets with a built-in tank are a smart and rational purchase. Such devices have a long service life and are unpretentious in terms of maintenance. If you have the means and you decide to renovate your bathroom, then purchasing a built-in toilet will be the ideal solution.

Caring for a wall-hung toilet

Methods for maintaining hygiene in a bathroom equipped with a wall-hung toilet are absolutely no different from caring for conventional plumbing fixtures. At least once a week, the bowl and lid, as well as the floor and walls in the bathroom, must be washed using a special disinfectant. For routine maintenance of cleanliness, use a round brush, which is usually located next to the device.

Wall-hung toilet JACOB DELAFON Struktura, used rim, used seats

Photo

Round toilet

Black toilet

Wall-hung toilet with installation

Attached toilet with built-in hidden cistern