If there is a drilled well on the site of the house, then a self-priming water pump can be used to organize an irrigation or water supply system. Today we will analyze the structure and operating principles of such equipment, learn about its advantages and disadvantages and see how it is installed and connected. The material will be useful to all owners of private houses and suburban areas, where problems with water delivery are especially pressing.

Self-priming water pump

Surface pump - types, structure and principle of operation

Self-priming pumps lift water from wells due to differences in pressure drop. The maximum they are capable of under ideal conditions (when creating a vacuum) is to raise it to a height of 10.3 m, but there are none anywhere, so this parameter is actually 8-9 meters. Blades rotate inside the unit, creating areas of low pressure that immediately tend to fill with liquid.

Compact assistant for watering the garden

Such pumps consist of an electric motor, which performs the main work, and a working chamber through which liquid is pumped due to a pumping mechanism driven by a motor. The active parts are connected by a shaft that passes through a seal that prevents water from entering the electrical part of the device.

Sectional view of the working chamber of a centrifugal vortex pump

There are two types of seals - seals and end seals. The first option is inexpensive, but its quality is not very high. The second is less common due to its high cost - it is equipped with the most reliable units.

Interesting to know! There are pumps without seals at all. They are equipped with magnetic couplings. On the one hand, this solution speaks of reliability, and on the other hand, of the low efficiency of the pump. Very high losses when transmitting torque from shaft to shaft. Such designs are the most expensive today.

Based on the principle of creating suction force, pumps are divided into centrifugal and vortex. Both have an impeller installed, only it differs in shape. Let's talk more about these systems.

Centrifugal pumps

If you look at the working chamber of a centrifugal pump in cross-section, you will notice that it resembles a snail shell. The working blades that make up the wheel are installed in the center. There can be several wheels - a multi-stage design, or one - a single-stage pump. The former can change the suction parameters, while the latter always operate with the same power.

The working chamber of the centrifugal pump is quite large

The blades diverge radially from the shaft and are bent in the direction opposite to rotation - this can be seen in the diagram presented above. When the wheel begins to rotate, the blades seem to push the water away from themselves, pressing it against the walls of the chamber, thereby creating a centrifugal effect. Water passes through the diffuser - the distance from the walls of the chamber to the tips of the blades. Increased pressure is created on the diffuser, due to which the water rises up, twisting along the “snail” and leaving to the sides of the outlet pipe.

Self-priming water pump prices

self-priming water pump

Structure of a centrifugal pump chamber

At the same time, an area of low pressure is created in the area of the center of the working chamber (wheel), which pulls water through the inlet pipe. The main line from it goes either into a reservoir or into a well. This process is not even cyclical, it is simply endless and occurs constantly while the motor is running and the shaft is rotating.

In principle, this is a fairly productive method of pumping water, but it has one significant drawback - if the system is filled with air, then an area of low pressure cannot be created. The unit begins to run idle, which can lead to overheating and failure. Therefore, before the first start, water is poured into it through a special hole to fill the supply line and the working chamber. A check valve, which is usually equipped with a coarse filter and is placed at the end of the inlet line, immersed in the water source, prevents water from flowing in the opposite direction.

Self-priming pump - internal structure

Vortex pumps

Vortex pumps work on a slightly different principle. There is also an impeller inside, but its shape is different - the blades are located on both sides, they are straight and radial. This structure is called an impeller. The working chamber housing is made in such a way that the impeller is tightly enclosed and only has a large gap in the area of the side partitions.

The structure of the working parts of a vortex pump

The rotation of such a wheel makes the water move. Due to the resulting centrifugal force, it begins to press against the walls of the chamber and move along it. Upon contact with the second side of the blades, the liquid receives additional acceleration, which is why it begins to swirl into vortices. As a result, a constant vortex flow is formed, which, in fact, gave the equipment its name.

Such a water pumping system allows you to create a pressure 5-7 times higher than that of centrifugal pumps of the same power. If you need to ensure high pressure in your water supply and you do not consume much water, then using such equipment will be a good solution for you. Such pumps are capable of creating low-pressure zones, even when filled only with air, although much depends on the structure of a particular model and its power, but in any case, it will calmly pump a mixture of water and air without loss of suction power and overheating. Therefore, the chamber can be partially filled with water.

High-quality Italian equipment

Among the disadvantages, it is worth noting low efficiency and increased energy consumption. It is for this reason that it is better to install such pumps where water flow is low.

Vortex and centrifugal - comparison and scope

First the general features:

- maximum suction depth - 8-9 meters;

- installation method: surface;

- there should be a pipe or reinforced hose on the suction pipeline (do not install a regular one, it will be flattened by negative pressure).

Now about the differences between vortex and centrifugal models. Vortex pumps are more compact, cost less, but produce more noise during operation. Centrifugal ones are quieter and create little pressure at the outlet. Vortex engines, with the same impeller size and rotation speed, can create a pressure 3-7 times greater. But we cannot say that this is their advantage - a large output pressure is not always required. For example, it is not needed when watering the garden. Water supplied with high pressure will simply wash away the soil and expose the roots. Therefore, it is better to use a self-priming centrifugal pump as an irrigation pump.

High outlet pressure may be required when organizing a water supply system at home. This is where the characteristics of vortex pumps are required. They only have one drawback: they cannot provide high flow rates. So, more often for these purposes they use the same centrifugal one, but paired with a hydraulic accumulator. True, then it turns out to be a pumping station.

Surface centrifugal pumps must be filled with water before starting

The main disadvantage of surface centrifugal self-priming pumps is the need to fill them with water before starting. Not the most pleasant activity, which adds hassle when using such a pump for watering.

What is an ejector

We have already written that self-priming pumps cannot raise a column of water above 9 meters. As you know, if you need to organize water intake from a well, such a depth will not be enough, since the water at this level will not be of high quality, it contains many impurities and may contain organic inclusions. What to do in a situation when you need to get water from great depths?

For these purposes, a special device is used - an ejector. This is a specially shaped tube with two inlets and one outlet - you can see its structure in the diagram above. The lower, wide inlet is intended for drawing water from the well, and the second, tapering inside, is used to recirculate water supplied from the pump; through the outlet, both flows, mixed, rush back to the pump. What does such a scheme provide, and why is it possible to overcome the pressure drop limit in this way?

A pump with an ejector can lift water from a depth of up to 40 meters

This is where Bernoulli's law comes into force. When water flows through a tapering pipe, a certain turbine effect is created - the water receives additional acceleration, which is why a low-pressure area is created in the ejector. Since our world does not tolerate emptiness, these areas are immediately filled with water entering through the main nozzle from the well. As a result, the pressure of the well increases, the difference between its drop and the area created on the pump wheel also increases, which causes the water to quickly rise upward.

It doesn't take a physicist to understand that the efficiency of such equipment will suffer due to the fact that it has to return part of the water back to the well. Speaking in numbers, it could work 30-35% more efficiently without an ejector, but you always have to put up with something; no one has yet been able to defeat the laws of physics.

Ejectors in pumps are internal and external

Conventional pumps are equipped with a built-in ejector, which forms part of their housing. We described such equipment earlier; it is precisely this equipment that cannot overcome the lifting mark of 9 m. What other features are characteristic of such equipment?

- The productivity of such pumps is 3-5 cubic meters per hour, which is enough even for a large house with a large number of residents.

- The operating pressure in the system is 4-6 bar - this is enough for the normal operation of all types of plumbing fixtures and household appliances. Important! The pump's performance is calculated not only by the depth from which it needs to lift water. The length of the water supply pipe and the number of water points in the house play a very important role.

- These pumps are very noisy, so they are installed outside the room, for example in a well caisson, or in the basement, where it will not be heard.

Caisson for a well Pump

models with a remote ejector operate much quieter, which must be remembered if you choose equipment that will be installed in close proximity to residential premises.

Operating principle + video review of models

The functionality is based on forced mechanical removal of the environment from a limited space. This happens in several ways:

Jet pump

The unit operates by supplying a stream of water or steam molecules from the side pipe, which removes the substance at high speed and creates a vacuum. The advantage of this scheme is the absence of moving elements, which significantly increases the service life of the structure. The downside is the mixing of components and low efficiency.

Mechanical type pump

The operating principle of the vacuum pump includes a rotating or reciprocating design, which inside creates the effect of expanding the space by filling it from the inlet pipe and then pushing it out through the outlet pipe. There are a sufficient number of constructive solutions to this principle. Such designs are characterized by high efficiency.

How to choose the right pump for your home

What other differences can be noted for different types of self-priming pumps?

- Centrifugal units are superior to vortex units in size and weight. At the same time, they operate much quieter and can pump water with fairly large foreign inclusions through them without fear of breakdown. For example, fecal and drainage pumps have exactly this structure. Vortex units are quite sensitive, so filtering units must be installed in front of them to purify the water.

- Centrifugal pumps are considered more reliable equipment. Their service life with regular maintenance can be 20 years or more. They are also quite simple to repair - there are a lot of parts for sale, you can do everything yourself if you want, if you have at least basic knowledge of the structure of electric motors.

- We have already written about electricity consumption and efficiency, we will not repeat it.

Compact and lightweight pump for watering the garden

Before purchasing, be sure to ask for the product data sheet and familiarize yourself with its performance characteristics. We are interested in the following:

- First of all, we look at performance and power. This parameter must be compared with the distance of the well from the house, the depth from which the unit raises water, the volume of the entire water supply system and the maximum possible volume of water consumption at any given moment. Before going to the store, you need to make the appropriate calculations so that you don’t have to guess whether it’s enough or not. The method for carrying out such calculations is not complicated; it can be easily found on the Internet. You can also use convenient online calculators, into which you just need to enter all the necessary data.

- The minimum pressure that should be in the system is 0.3 Bar. It must be constant, otherwise household appliances connected to the water supply may simply fail.

- It is also worth correlating the capabilities of your pump with the diameter of the well casing and its maximum productivity. It is better to obtain such information from the specialists who performed drilling on your site.

Anyone can handle connecting such a pump.

Features of self-priming units

The main feature of a self-priming pump or pumping station is the ability to independently remove air from the pipeline and suck in water. If you use a normal suction unit, then when air appears in the system, it must be filled with liquid again.

Based on the principle of operation, the following types of self-priming water pumps are distinguished:

- centrifugal;

- volumetric;

- vortex;

- ejector

Based on the method of location relative to the level of the pumped liquid, self-priming pumps are distinguished:

- superficial;

- submersible, their repair and operation are more difficult.

Based on power, pumps are divided into household and industrial. The first type of pumps is prohibited from being used in production.

Areas of application for self-priming devices are plumbing, heating and sewerage of private houses, pumping water, fire fighting, lowering the groundwater level before pouring the foundation.

average cost

On the market you can find pumps from different manufacturers with a wide range of prices, and if you take a surface pumping station with a power of 0.75 kW, then the average price can range from 4 to 8 thousand rubles.

Based on your means and needs, you can buy a more expensive item from Western manufacturers (Germany or Denmark), or cheaper (China).

Submersible equipment of the same power will cost more - its cost starts from 10 thousand rubles.

Since a pump for a home is purchased with the expectation of long-term use, you should not choose the one that is cheaper - the quality is always directly proportional to the monetary investment in the product.

Such a pump from the Italian company Pedrollo costs about 10,000 rubles in a steel casing and 22,000 rubles in a cast iron casing.

Characteristics

Main characteristics of self-priming devices depending on the power of the model:

Possible pump characteristics.

- Lifting depth (maximum distance from the pump to the level of the pumped liquid) – from 7 to 30 m.

- Discharge height (the maximum distance from the device to the mark to which it is capable of lifting water vertically upward) – from 10 to 64 m.

Pumps have different maximum temperatures of the working medium, performance, and work with different types of liquids - not all self-priming devices are suitable for water; there are models that can only work with clean water.

TOP 8 best surface pumping stations

| Photo | Name | Rating | Price | |

| #1 | AQUAROBOT JET 100 L | ⭐ 5 / 5 | Find out the price | |

| #2 | UNIPUMP AUTO JET 100 L | ⭐ 4.95 / 5 1 - voice | Find out the price | |

| #3 | Marina CAM 100/25 | ⭐ 4.9 / 5 | Find out the price | |

| #4 | GILEX Jumbo 70/50 N-24 | ⭐ 4.85 / 5 | Find out the price | |

| #5 | DENZEL PSX1300 | ⭐ 4.8 / 5 | Find out the price | |

| #6 | VORTEX ASV-1200/50 | ⭐ 4.75 / 5 | Find out the price | |

| #7 | GARDENA 3000/4 Classic (1770) | ⭐ 4.7 / 5 | Find out the price | |

| #8 | Quattro Elementi Automatico 1000 Inox (19 l.) | ⭐ 4.65 / 5 | Find out the price |

Which pumping station would you choose or recommend?

Take the survey

Pump for dairy farms GNV2 25 30 s

The stainless steel design of the body and internal impeller allows this device to be effectively used for transporting milk and liquid food solutions.

Peculiarities:

- primitiveness of the design, which determines its durability and ease of maintenance;

- easy to clean – the body can be assembled and reassembled after washing, even for an inexperienced user;

- small size;

- horizontal localization of the device.

Technical specifications:

- Maximum t оС – 90;

- Motor – 5500 W;

- Impeller torque – 3 thousand rpm;

- Productivity – 0.42 m3/min;

- Head (m) – 30;

- Weight – 55 kg.

Pumping station structure

If you need a pump only for irrigation, then to put it into operation you will need the pump itself, inlet and outlet lines, a check valve and a system that controls water flow - taps, sprinklers. If the system is intended to organize the water supply of a cottage, then there will be more components. In this chapter we will name the main ones and describe their purpose. A set of such equipment is called a pumping station.

Pumping station before installation

Table 1. Components of the pumping station

| Detail, photo | Description |

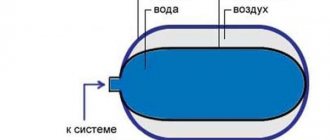

| Hydraulic accumulator | A hydraulic accumulator must be installed in the system, the purpose of which is to control smooth changes in pressure. A separation membrane is installed inside such a tank; on one side of the bark there is compressed air, and on the other, water supplied from the pump. The membrane is elastic, so it helps the air press on the water. When the pump starts, it creates its operating pressure inside the tank, which is usually 2-5 Bar. When it is reached, the unit turns off. If you open the water tap, the membrane will begin to push water into the pipes. As water is consumed, the pressure in the tank will drop until it reaches the lower level. At this moment, the automation starts the pump again. If the tank were not in the chain, the pump would constantly turn on and off, since the maximum pressure in the pipes is reached quickly even with the taps open. This would lead to accelerated failure of the electric motor. |

| Usually this is a flexible line that connects the pump itself to the accumulator. Its analogue can be seen on any kitchen faucets. The product is reinforced with steel wire braiding. It is connected to the equipment through threaded connections. Important! The diameter of this tube should not be less than the diameter of the outlet pipe of the pump and the inlet pipe of the membrane tank. The tank itself is connected to the water supply system directly, directly to the pipes, or with the same flexible connection |

| The supply line is lowered directly into the well. It can be made of a flexible hose or pipes, metal or polymer. At the end of the line, a filter element and a check valve are installed, which prevent water from the system from flowing back into the well. The length of the pipes is calculated so that they do not reach the bottom of the well, but are immersed in water several meters. If the first condition is not met, a lot of sand and other impurities will enter the system. Secondly, with prolonged consumption of water, its level in the well may drop, and air will pass into the pump. Working in “dry” mode is fraught with breakdowns |

| Here is a check valve. In principle, we have already described its purpose; we will not repeat it. |

| Filters and various fittings may not be part of the pumping station, but in the overall water supply system, they are important. This includes various cleaning systems, shut-off valves, and pressure gauges for monitoring the pressure in the system. |

| Float switch | To protect yourself, or rather the pump, from working without water, an automatic float switch is placed in the well, which will stop the pump if the water drops below a critical level. Some stations have a built-in dry-running sensor - they do not need to install additional shutdown devices. |

The pump runs on electricity, so you need to run a separate wire into the caisson and install a socket under it. It must be placed in a place inaccessible to water.

Correct installation of the suction line

The suction line is the pipeline through which the liquid moves towards the surface pump. This pipeline is connected to the inlet pipe. The shorter the length of this line, the better. Before entering the unit, there must be a straight section of at least 2 pipe diameters in length. Most of the line is most often located vertically and ends at the bottom of a well, well, pit, or tank. The pipeline is made without sharp transitions with a minimum number of joints and bends. Connections must be tight. A slope of at least 5 mm per 1000 mm is required.

A bottom check valve is installed at the liquid inlet into the pipe: without it, when pumping is stopped, the working medium flows back down under the influence of gravity, air pockets form in the pipeline, and the pump operates in dry running mode, which leads to its rapid breakdown. In the operating instructions for the device, the manufacturer indicates the minimum distance from the bottom to the entrance to the suction line and the minimum length of the line from the check valve to the level of the liquid surface.

Characteristics

Before purchasing a self-priming pump, you must familiarize yourself with a number of requirements that must be observed when connecting it:

- Depth of the water source.

- Distance from the source to the watering site or to the house.

- Degree of pressure.

- Quality of incoming water.

- Average water consumption.

Expert opinion

Kuznetsov Vasily Stepanovich

These requirements are usually necessary when selecting pump performance, as they affect the quality of its operation.

BCPN 63 30 s

A type of downhole equipment operating on the centrifugal principle. It will be a good helper for household needs that require the supply of fresh and slightly salted water from above-ground and underground sources.

Advantages:

- high-quality motor part with a 2-phase winding, making it possible to start it at voltages below 220 V;

- stainless steel body;

- integrated starting device;

- The starter is equipped with a thermal relay, which provides additional protection in case of power surges.

Technical features:

- Operating speed – 2.3 m3/h;

- Permissible working depth – 15 m;

- Engine – 660 W;

- Pressure – 30-38 m;

- Weight – 13.5 kg.

Tips for choosing

When choosing a specific model, you must remember that the vortex pump must perform 2 main functions - ensure an uninterrupted supply of fluid from the well and at the same time have a reliable design.

Many models on the market meet these parameters. But in order to choose the optimal one, it is recommended to adhere to the following recommendations:

- Optimal power indicator and volume of pumped liquid. Depending on the needs, it is necessary to select a model so that its technical characteristics fully comply with the required ones - the volume of liquid from the well should not be less than the minimum consumption rate.

- Calculation of pressure. It depends on the depth of the source of water intake and horizontal pipelines. The manufacturer indicates this data in the equipment passport.

- Pump operation warranty.

Taking these factors into account and using a systematic approach, you can choose the optimally suitable equipment model that will fully meet the requirements of the water supply system.