Some regions experience rainfall, while others experience snowy winters. In such situations, it often becomes necessary to install an entire system for draining rain and melt water. This issue is relevant both for settlements of different levels and for private households.

When it comes to such an important structure as a storm sewer, SNiP, GOST and similar regulatory documents are very important. After all, only a properly constructed storm drainage system will work properly and for a truly long time.

Design Features

Every year, the roof of a dacha building receives a large amount of precipitation, approximately 100 m3. Several times more water falls on the ground around the building, which significantly increases the risk of subsidence of the foundation of the house and deformation of the building.

Storm drainage system - this is how you can answer the question of what is the correct name for a storm drain. is a system that effectively collects and removes water outside the site in the form of precipitation. A similar system should be equipped in large private houses, warehouses and shopping complexes, large factories and places where cars accumulate. If there is a high risk of petrochemical products and other hazardous industries getting into the water, the creation of an industrial storm sewer is required.

The stormwater system works on the following principle: water is collected on the surface of the earth, purified and transported to special tanks. The system consists of the following elements:

- Distribution tank.

- Sand separator.

- Grease separator.

- Adsorbent filter.

- Control well.

To collect water, special closed or open gutters are laid on the surface, through which the liquid is directed into a distribution well. From it, water goes to the sand separator, where large particles and debris are removed. After this, fats and petrochemicals are removed using oil and gasoline separators and an adsorber filter. Purified water flows into a control well and is used to water crops or fill various reservoirs.

The line of all the constituent elements of the storm drainage system, including conductive pipes, is located deep in the ground. This allows you to avoid deformation of the road surface and save space on the site for other more important purposes. If it is impossible to deepen the supply gutters, concrete, plastic or asbestos-cement elements are laid in ditches, making a slope towards the distribution well.

The installation of a rainwater drainage system should be carried out by professional craftsmen, as this requires special knowledge and compliance with sanitary standards and regulations. By following the recommendations specified in the relevant regulatory documents, you can obtain a reliable and durable storm sewer system with correctly calculated tank parameters. In addition, in this case, the pipes are located at a certain depth, which prevents them from freezing during the cold season.

Types of storm drainage systems

Depending on certain factors, different types of storm drainage systems are distinguished.

Based on the type of system, the following types of storm drains are distinguished: point and linear.

A simple point storm drain consists of several storm inlets installed under a drain and connected into a single network. Such systems are designed to collect water falling from the roof of buildings and drain it into a reservoir.

The linear storm drainage system has a more complex design, as it is used to collect water from the building and from the ground surface throughout the entire site. In this case, the system includes rainwater inlets for storm drainage, drainage pipes or trays and the main collector.

In both cases, it is possible to equip inspection wells, with the help of which preventive cleaning measures are carried out and the performance of the entire system is checked.

According to the type of location, the system can be external, internal or mixed.

External storm drainage is the simplest drainage option. The simplest design allows installation work to be completed in a short period of time with minimal material costs. The open-type storm drain includes a linear drainage system in the form of a ground gutter and underground sand traps. Gutters are laid under the drain and along the paths. The collected water is in most cases discharged into a small reservoir on the site.

An internal stormwater system is more complex and expensive, but when used, there are guaranteed to be no puddles on the site. Calculation, assembly and arrangement of this drainage option should be carried out by professional craftsmen.

Internal storm drainage is a drainage system consisting of a large number of elements. When laying gutters, be sure to make a slight slope towards the tank. Stormwater inlets and gutters are covered with special gratings that trap large debris and leaves on the surface, preventing the formation of blockages in underground pipes. Grates can also serve a decorative function. If you install entrance gratings, you can protect the gates and porch from water; installing lawn gratings helps protect plantings located at the lowest points of the site.

The underground storm sewer has a minimum number of bends and is located at a slope towards the collector. It is possible to equip such a system with inspection wells for cleaning and repairing the system. Water from the collector is quite suitable for irrigation or filling artificial reservoirs.

A mixed type system implies something between an open storm drain and a closed drainage system. In this case, water is drained from the roof using closed gutters and channels, and water from the site, from paths and platforms is drained using open gutters. Such a system is characterized by maximum efficiency and lower material costs.

In addition to the main types of storm drains, there are several other options that drain water by using additional resources. This includes gravity-vacuum drainage, which operates on the principle of a siphon. In this case, water from the roof is sucked in due to the difference in the height of the water intake funnel and the drain. Another example is a pressure storm system, in which pumping equipment installed in certain locations is responsible for the movement of water. The pump can be equipped with a grinder, which reduces the risk of clogging the internal storm drain pipes.

What it is

Drainage sewerage is a complex of connected drains and channels, which are often called trenches. Pipes and channels are placed around the perimeter of a private plot to drain excess moisture outside the private house. It is advisable that the installation of the system be carried out by a qualified specialist. After all, only a professional in this field is able to determine the required distance between the pipes, since it differs with different soils.

In clay soils, the system is installed with a smaller distance, and in sandy soil with a larger distance. This is primarily due to the speed at which the soil absorbs water. The better the soil allows liquid to pass through, the smaller the distance between the pipes becomes. Excess liquid is driven through pipes and drained into the general sewer system. In the absence of local sewerage, home owners dig wells, which serve as a place for drainage of liquid.

Gutters and storm water inlets

In most cases, storm drain gutters are made of concrete or polymer materials. The use of metal in this case is undesirable for two reasons. Firstly, as a result of constant contact with water, pockets of corrosion may form on the metal surface. Secondly, the impact of water drops on a metal gutter is accompanied by loud noise. As for concrete structures, they are reliable and durable. However, the regulated dimensions of the elements do not always allow their installation on the site. Plastic gutters are the optimal element in storm drainage; they are easy to cut to combine with other elements and can be located at any depth in the ground.

Surface drainage

Surface drainage is a network of drainage channels and containers - sand traps. Through a system of vertical and horizontal drainage systems, rainwater flows from the surface storm drain into the storm sewer collectors, and then enters the treatment plant. Drainage channels are most often constructed from pre-made trays, which are covered with drainage gratings. But sometimes drainage channels are concreted right on site using formwork. Industrially, trays are made from concrete, plastic, polymer concrete and other materials. Products made from composite materials deserve attention, including trays containing mineral components (crumbs) “poured” into a polymer form.

According to experts, the main advantage of composite trays is that they are quite durable, despite their relatively low weight. Often, in areas lined with paving slabs (on streets, in gardens, squares, in private properties), drainage gutters made of the same material are used. Experts believe that the main criterion when choosing trays (when it comes to building a private house) is often distance. That is, the transportation distance from the place of purchase of building materials to the building under construction.

If a house is being built nearby, the owners often prefer to pave the surface drainage system with concrete trays. But it’s easier to bring relatively light and well-packaged products from afar. Although, of course, the material from which the trays are made must be provided for by the project. As well as the cross-section of the drainage system, the number and volume of sand traps, the type of drainage grid and a number of other elements of the system. In urban planning, other approaches are usually used. On the roadway, and even more so on large highways, high-strength trays made of concrete or reinforced concrete are installed. They are covered on top with cast iron grates that have a special fastening.

Accordingly, the stronger the materials used to lay the drainage channel, the more powerful the grate should be. For a drainage system that does not experience significant external load, you can use plastic, steel (galvanized or stainless), bimetallic or copper gratings. The latter, however, are quite expensive. Grates come in various shapes, including cellular. They not only protect pedestrians and vehicle wheels from accidentally falling into the drainage tray, but also prevent debris from entering the storm drain.

Thus, it is advisable to select the “step width” of the grid and the size of the cells based on the size of potential “clogs”. These include fallen tree leaves, which easily fall into trays covered with large bars. Sand traps are shaped like deeply recessed trays. They are also made from concrete, plastic or other “tray” materials. As a rule, the last channel at the end of the drainage line is connected to the sand trap. Thanks to the special in-depth shape of the sand trap, the flow rate of rainwater is reduced. Substances found in rainwater (mostly sand and small pebbles, which are generously sprinkled on sidewalks during icy winters) settle to the bottom of the sand trap, and rainwater flows into the storm drain.

According to experts, for stable operation of the storm drain, the sand trap must be cleaned several times a season. Silt, sand, dirt can be scooped out “by hand” by removing the protective grille. At the same time, in areas “not loaded” with heavy transport, it is advisable to use plastic sand traps equipped with removable waste baskets. Emptying such containers is much more convenient.

Return to the section “Storm treatment facilities” August 12, 2013

Lattices

The gratings installed during the storm drain installation process protect the systems from heavy contamination and completely eliminate the possibility of a passing person tripping. Cast iron elements are reliable and long-lasting, but require regular painting, approximately once every two to three years. Steel gratings are less practical, as they quickly become covered with rust stains from contact with moisture. Ideally, the grille should be made of aluminum. Such products have a long service life and attractive appearance, but their high cost should be taken into account.

The holes in the grill should not be too large to trap large debris and not too small to allow large amounts of water to pass through.

Storm drain pipes

When installing storm drainage systems, it is recommended to use pipes made of polymer materials. They are not subject to corrosion, like metal products, and have a smooth inner surface, which reduces the risk of pipe silting. As for the diameter, for a small area you can use products with a cross-section of 110 mm; to drain water from a large area, it is better to use pipes with a diameter of 150 mm.

European siphon-vacuum storm drainage system inside the building Quick stream. Particularly effective for wide area roofs, high levels of noise absorption and vibration insulation. It has a significantly higher throughput than traditional sewerage, fewer risers do not require excavation - all this provides a significant economic and technical advantage.

How to calculate the minimum slope for a tray

Using regulatory documents, you can calculate the sewer slope. It is necessary to ensure that wastewater flows away by gravity. Additionally, no attractive forces are used.

The slope is towards the main collector.

Determining the correct slope is not easy to ensure that water is transported smoothly and evenly. The SNiP document will help you perform the calculation. It all depends on the dimensions of the pipes. A special table is used for the calculation.

Using a special table, you can calculate the minimum slope along the tray

Scheme for calculating the slope of pipes:

- If the pipe diameter is less than 110 mm, then the optimal slope will be 2 cm per 1 m;

- If the size is 150 mm, then the slope must be taken within 8-10 cm;

- When the diameter is 200 mm, you can take a slope of 7 cm;

- For 500 mm, the slope per 1 m is 30 mm.

In front of the sand trap, the slope of the pipes is made slightly smaller. This is necessary to evenly distribute debris and sand with liquid. Otherwise, wastewater streams may simply form one whole.

Collector

The collector is equipped with closed and mixed type storm sewer systems. This element is a container for storing the main volume of water. Depending on the further use of water, the collector design can be made of rings mounted on a concrete pad. In this case, the collected water can be used to water plants on the site or fill artificial reservoirs. If you do not plan to use the collected sediment, you can make a well without a bottom. In this case, it is necessary to carefully select the location for installing the collector; if it gets into the aquifer, the bottomless collector will become a regular well.

You can use ready-made forms made of polyvinyl chloride; it is recommended to install such a collector in an area with shallow groundwater.

If the site is dominated by sandy soils, then drainage can be installed to remove water. For this purpose, a special plastic container is buried in the ground, the walls of which have many holes. It is worth noting that using a drainage system on clay soil will not give results, since such soil practically does not absorb water.

There is also the possibility of connecting the collector to the central sewer system, in which case the water will go to special storage facilities and treatment facilities.

Is it possible to discharge stormwater into a domestic sewer: requirements and standards

One of the most controversial and discussed issues is whether it is possible to discharge storm water into a domestic sewer.

There is no consensus of opinion even among specialists. Some argue that such a unification is impossible in principle. Others recall the existence of common sewer systems, where rain and domestic wastewater are transported through one collector. Such networks operate quite successfully, although they require certain operating conditions. Let's look at the issue from different points of view.

Do-it-yourself storm sewer installation

To install storm drainage on a site, it is recommended to invite professional craftsmen. However, if you wish and have free time, you can find the answer to the question, storm or rainwater drainage, what is the correct name for the system, and do all the work yourself.

The installation process is not particularly difficult; the main thing is to be patient and follow a certain algorithm.

In particular, the construction of the storm drain is carried out according to the following plan:

- First of all, you need to draw a diagram of the site with a certain scaling.

- Next, they examine the area and determine the lowest point of the site; this is where the collector needs to be located.

- The next step is to mark the drainage points. This could be a drain on the roof of a building, a concrete platform and paths.

- Then you need to draw the location of the pipes with all the elements, turns and connections. It should be remembered that with a minimum number of turns, more efficient drainage is ensured. As a last resort, you can make turns at right angles.

- Based on the drawing, the amount of materials required is calculated. When going shopping, you should take into account that the system will be located in the ground, so it is not necessary to select elements of the same color. For the same reason, you should not buy materials with a reserve.

- The installation of a storm drainage system itself begins with the installation of the roofing part of the system. Stormwater inlets, gutters and risers are installed, and a place for discharging liquid into a collector or tray is arranged.

- Next, mark the area by pulling a rope or cord along the location of the pipes.

- Following the markings, trenches are dug to the depth of soil freezing to prevent water from freezing in the pipes in winter. If the pipes are laid to a shallower depth, it is recommended to carry out a number of thermal insulation measures. Such a system can work flawlessly from early spring until late autumn.

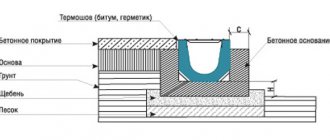

- The bottom of the finished trench is covered with a layer of sand, which is carefully compacted. The sand cushion prevents the soil from subsiding, therefore eliminating the possibility of changing the slope of the pipeline. Crushed stone is poured on top of the sand, which reduces the impact of heaving soil.

- Next, the collector, wells and storm water inlet are installed and concreted. Then the pipe elements are laid and connected.

- The assembled system is checked for leaks and operability.

- If there are no defects, backfill the soil.

Secured territory

To ensure that storm drainage meets sanitary standards and requirements, it is necessary to take measures to arrange a security zone. It is forbidden to dump garbage or erect any buildings in this zone; in addition, the construction of parking lots is prohibited here. Planting is possible only at a distance of 3 meters from the pipe. A security zone in a suburban area is easier to set up due to more lenient requirements. However, to prevent structural collapses, it is not recommended to park vehicles in these places.

Storm drain maintenance

Any communication system requires regular maintenance, and storm drainage is no exception in this regard.

Therefore, in addition to knowledge of how storm drainage works, it is necessary to carry out the following activities:

- After a certain time, the system is inspected, accumulated debris is removed, and blockages are cleared.

- The system is flushed once every 3-4 years.

- During the inspection, the level of sludge at the bottom of the wells is monitored and, if necessary, cleaning measures are carried out. In particular, all the water is pumped out of the well using a pump located a short distance from the bottom. Then the systems are washed using the same pumping equipment.

If major cleaning of storm drains is required, it is recommended to invite specialists with special equipment.

In winter, open-type storm drains freeze; with the arrival of warmer weather, the ice begins to melt, and the system becomes operational again.

In the case of a closed storm sewer located at a shallow depth, the situation is more complicated; it requires preparing the elements for winter. The entire system is cleaned, the remaining water is drained and the inlets are closed. Better and more reliable results can be achieved if the work is performed by professional craftsmen. However, the possibility of independently solving the problem of arranging a drainage system on your site cannot be ruled out. The arrangement of storm drainage in compliance with all norms and requirements, as well as proper and timely maintenance, makes it possible to protect the site from excess water and complement the design of the local area with new decorative elements.

Possibility of combining storm drainage

Often, owners of individual housing install several drainage systems on their plots - storm, domestic and drainage sewers. Usually all these communications are located next to and parallel to each other. Wanting to save money, some site owners are considering the option of combining stormwater and drainage. But, as we found out, it is not worth using an existing well to connect a storm sewer to it. At the first heavy rain, it can overflow quite quickly, because the average flow rate will be 10 cubic meters per hour.

If a home sewer is connected to the well, rainwater will rush into it. It will not rise above ground level, but drainage will also be disrupted. Along with the water, various debris will also enter the system, and if the water leaves over time, the debris will remain in the pipes, which will significantly worsen the operation of the system. With regular rains, such sewers will have to be constantly cleaned.

If you connect the spillway to the drainage system, an even worse situation may develop. Water entering the drainage after an intense rainfall can completely fill the pipes and fall under the foundation, gradually washing it away. Let's also add to this the silting of pipes, which will have to be replaced, since it will not be possible to clear them of silt.

Therefore, storm sewerage requires the construction of a separate, sufficiently capacious well. You can do without this element only if there is a natural body of water nearby. In this case, the drainage will be organized there.