During repairs, improvement of a house or cottage, the owner may have difficulty choosing suitable pipes. Emergency situations occur when an old pipeline leaks and there is a risk of flooding. To get rid of such problems, new high-quality communications should be established. In the modern market, metal-plastic pipes for heating are in great demand.

What are metal-plastic pipes

The products are mainly used in the installation of water supply systems. Pipes have different characteristics, so when choosing, you need to take into account operational features and other technical nuances. There are several types, each of which has its own purpose.

Design

Metal-plastic pipes are a complex structure. Based on the name, it becomes clear that the key materials from which they are made are metal and plastic.

The products consist of 5 layers:

- modified polyethylene (cross-linked);

- adhesive layer;

- thin aluminum layer;

- another layer of glue;

- protective polyethylene shell.

To make the outer and inner parts, plastic is used, produced using a special technology. This makes the finished product hard and resistant to mechanical stress.

Scope of application and possible operating conditions

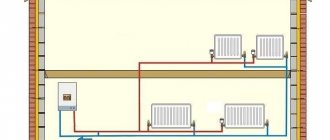

At the moment, various communications are assembled from metal-plastic pipes, both for private homes and for industrial premises. Most often, the products are used for the installation of heating systems, hot and cold water supply. Thanks to these pipes, the negative impact of oxygen on heating equipment: boilers or radiators is reduced.

It is worth noting the high flexibility of the products, which allows them to be used when installing a “warm floor” system. Metal-polymer heating pipes allow you to create a wide variety of configurations, with many bends and turns, which facilitates installation work.

Metal-plastic is an indispensable material if you need to install plumbing protected from moisture that appears as a result of condensation. Thanks to this advantage, communications can be laid in walls made of plasterboard or concrete. When installing hidden pipelines, most craftsmen use metal-plastic.

When choosing this type of pipe for installation, one condition must be observed - the system in which they are installed must necessarily have a pressure stabilizer. Of course, products made of metal-plastic are practically not afraid of high pressure, but its frequent changes can have a negative effect on the material.

Advantages

The popularity of metal-plastic pipes is explained by their many positive qualities.

Experts highlight the following advantages of using products in heating systems:

- Long service life. Pipes produced by leading manufacturers can last about 50 years.

- They do not clog, do not accumulate deposits and do not rust. Compared to metal analogues, the inside of metal-plastic products is absolutely smooth, and it is not subject to oxidation. For this reason, its properties will not change after years of operation.

- Ease of use. Metal-plastic products are very easy to install - just secure them well. They are light in weight, bend easily and are highly resistant to damage.

- Efficiency. Polymer materials, compared to metal products, have a lower thermal conductivity coefficient, which eliminates possible heat losses.

- Wear resistance. Regardless of the speed at which the coolant moves inside the pipeline, this will not affect the quality of the products.

- The number of connections is reduced. Thanks to the elasticity of the material, the pipes easily bend around irregularities and corners. This reduces the number of fittings to be installed, making the entire system more reliable.

- Availability. Metal-plastic products are now in wide demand; many companies are engaged in their production. Installation work does not require a lot of time and material resources.

As can be seen from the list of positive properties, metal-plastic products are reliable and durable, which is why they are found more and more often in modern communications.

Flaws

Products made from modern materials also have certain disadvantages that must be taken into account before installing a heating system.

The following disadvantages stand out:

- the pipes themselves, as well as the connecting elements, are somewhat more expensive than plastic products;

- small selection of diameters: from 16 to 63 mm;

- if communications are laid in the walls, the joints may weaken over time;

- if water freezes inside the pipe, the likelihood of it bursting increases;

- exposure to thermal radiation and ultraviolet radiation reduces the quality of the material;

- Metal-plastic products are not suitable for installing a fire extinguishing system.

If you follow the rules, then a heating system assembled from metal-plastic pipes will last for many years and will not cause difficulties during operation.

Why do you need a layer of aluminum?

Aluminum foil acts as the third layer in the structure. It is made from pure or alloyed aluminum. This layer is necessary for protection. It makes the pipes oxygen-tight.

The thickness of the foil layer is the most important characteristic that must be taken into account when choosing. It determines what internal pressure the pipe can withstand, and generally determines where it can be used.

The thickness of the aluminum layer varies from 0.2 to 0.7 mm. The best option when laying a heating system is to use pipes with parameters from 0.3 to 0.55 mm.

A solid structure is welded from a layer of foil in several ways:

- Using a laser. This method is used to create a seamless butt joint. Finished products have smooth walls and excellent performance properties. The aluminum layer can be of any thickness.

- Ultrasonic welding. In this case, the ends of the foil are overlapped so that no noticeable thickening is formed in the bonding area. The walls are not perfectly smooth. These are more affordable pipes; when compared to seamless ones, they are not as strong and durable.

To create more reliable systems, it is recommended to choose seamless products.

Bonding layer

Manufacturers use special compounds to connect plastic to metal. Thanks to their properties, the multilayer structure becomes a single whole. Manufacturers use various adhesive compositions and unique formulas known only to them. The user only needs to ensure the safety of the product by studying the quality certificates.

Glue is needed not only to connect different structural elements together, but also to give elasticity to the product. The bonding layer is the most vulnerable point of a metal-plastic pipe. If the glue becomes less elastic, the structure may begin to delaminate and leak.

For metal-plastic products used in hot water supply and heating, the binding layer plays a significant role, and it must be of high quality. Even visually you can determine how firmly the layers are connected to each other. If it seems that they are not fastened well enough, you should refuse to use such a pipe.

What types of plastic are used for production

During the production of pipes, manufacturers can use different types of plastic, which changes the properties of the final product. As a rule, high-strength PEX polyethylene, manufactured using a special technology, is used for the production of heating products. It can withstand a burst pressure of 70 bar. This type of polyethylene has good resistance to chemicals, will not oxidize, and deposits will not form on its internal surfaces. Optimal for creating complex systems and various connections to thermal equipment, for example, batteries or boilers.

PEX polyethylene has a low internal wall roughness of only 0.004 mm. He is not afraid of exposure to high temperatures, up to +90 °C. Compared to polypropylene products, metal-plastic pipes are characterized by less linear expansion.

A more heat-resistant material is PE RT polyethylene. It is a thermoplastic, so it can be welded. Technologies are constantly evolving, and now new pipes are appearing - PERT-Al-PERT. They are as flexible as metal-plastic products, and at the same time they can be connected to the system using mechanical or welded fittings. The consumer properties of PE RT products are higher compared to PEX, and at the same time they are more technologically advanced in production.

HDPE (low-density polyethylene) is also used in the production of pipes. Such products are characterized by high strength and density. They melt at a temperature of +130 °C. At the same time, they are chemically resistant to oils and fats.

Most often, such products are used if it is necessary to install an external pipeline through which cold water will be supplied. For the production of pipes, PE-100 grade polymer is used. Using these products, installation of pressure sewerage is allowed. They are not suitable for hot water supply and heating systems.

No. 5. Type of plastic in the inner and outer layer

The following types of plastic are used for the production of metal-plastic pipes :

- cross-linked polyethylene PEX and linear polyethylene PE-RT. They provide pipes with maximum strength, reliability and resistance to various types of loads. Such products better withstand mechanical stress, temperature and pressure changes in the system, and have a long service life. To install a hot water supply or heating system, it is better to take just such pipes;

- low-pressure polyethylene (in the marking of pipes it can be designated by abbreviations such as PEHD, PE-RS, PE or HDPE) is also used in the production of metal-plastic pipes, but significantly narrows the scope of their use. This polymer is not able to withstand temperatures above +750C, therefore it is used exclusively for transporting cold water. In addition, it wears out quickly when exposed to direct ultraviolet rays, so it is advisable to protect the pipes from sunlight. Pipes made of low-density polyethylene are cheaper, but if operating conditions are observed, they can last for decades.

What diameters are the pipes?

The key characteristic of pipe products is diameter. These values are now standardized, which facilitates the arrangement of communications.

Parameters to pay attention to when choosing pipes:

- Inner diameter. This is the main characteristic on which throughput depends. Also taken into account when selecting fittings.

- Outside diameter. Can vary from 16 to 63 mm.

- Wall thickness. Depending on the cross-section of the pipe, it ranges from 2 to 3.5 mm.

At the moment, metal-plastic products with different diameters are produced, which must be taken into account when arranging the pipeline.

Most popular sizes:

- 16 × 2. The number 16 indicates the external section, and 2 indicates the wall thickness. Such products have an internal cross-section of 12 mm. This product is now the most in demand and is used to install water supply and heating systems in apartments. Due to the properties of the material itself and good throughput, lime will not accumulate inside the pipes, thereby blocking the flow of coolant. The determining factor when choosing is the low cost of connecting fittings. In installation diagrams, this diameter is relevant if you need to make a tap to the faucet in the bathroom or kitchen. To equip main pipelines, products of larger diameter are used.

- 20 × 2. Most often they are used when installing a “warm floor” system. The internal diameter of these pipes is 16 mm. More expensive fittings are produced for them, but the products themselves are characterized by greater throughput compared to the previous version. Therefore, if the water pressure is unstable, it is better to use them, especially if a long route is being made. The products can withstand pressure up to 10 bar, similar to steel products.

- 20 × 26. The internal diameter is 20 mm, the external one is 26 mm, the wall has a thickness of 0.3 cm. With the help of such elements, risers and “warm floor” systems are mounted. This is the preferred choice if pipelines are installed in a private home. Internal pressure surges are possible in the system, so high throughput will not be superfluous.

- 26 × 32. Products with a large diameter are the basis of any heating system. They have high throughput, which ensures a stable supply of coolant. Riser pipes and main pipelines are assembled from them.

- 32 × 40. They are used in both industrial and civil construction. With their help, central or individual heating and water supply systems, as well as water treatment and air conditioning, are created.

- 40 × 50. The wall thickness of such pipes reaches 0.4 mm. They are used if it is necessary to create a technological pipeline that provides water supply or heating in an industrial enterprise. Suitable for laying routes along which chemically aggressive media or compressed air move. This is a reliable and high-quality material that can last at least 20 years.

There is a wide variety of products depending on the diameter. Do-it-yourself heating from metal-plastic pipes is usually done using products with a diameter of 26 × 32.

No. 1. Performance

Of course, some of the performance qualities of metal-plastic pipes may differ depending on the materials used in production and their thickness, but most products currently sold have the following characteristics:

- maximum water temperature inside the pipe +950C;

- at a temperature of about +950C, the maximum pressure that the pipe can withstand is 10 atm;

- at water temperatures up to +250C, the maximum operating pressure can reach 25 atm;

- the pipe can withstand a short-term increase in the temperature inside it up to +110...+1300C.

Features of using metal-plastic pipes for heating

Products made of metal-plastic, due to their design features, are suitable for arranging heating systems. But they have one weak side - the presence of an aluminum or foil layer that acts as a base.

The fact is that the polymer material and foil have different thermal expansion. With a sharp change in temperature, polyethylene will increase in volume faster than foil. Because of this, the entire structure may simply delaminate.

When creating a heating system, you must adhere to the following rules:

- It is necessary to reduce the surface tension, for which compensation loops are used. Thanks to them, the likelihood of a system breakthrough is reduced.

- The pipeline must not be exposed to sunlight. If avoiding this is problematic, hidden installation is done.

- Water hammer and spontaneous temperature fluctuations negatively affect product quality. Therefore, it is recommended to minimize the likelihood of these moments.

In any case, you will need to familiarize yourself in detail with the technical characteristics of the product. As practice shows, the main mistakes are made during installation and selection of materials.

Recommendations for use

There are several important rules that you should pay attention to before using the calibrator:

It is strictly forbidden to use a device such as a pipe calibrator when installing communications made of metal-plastic, the cross-sectional indicators and dimensions of which do not correspond to those indicated on the device labeling; it is prohibited to use this device for straightening metal-plastic pipes; after performing 250 calibration measures, the tool knives become dull. Therefore, they must be periodically sharpened to the desired state.

A needle file or regular sandpaper is perfect for this procedure. After this, they can be used for further calibration. The calibrator fittings should be protected from mechanical damage and exposure to high temperatures. Since this may affect its performance characteristics.

Important! It is advisable to store the calibrator in a dark place to prevent direct sunlight.

Installation of metal-plastic communications using a calibrator is quite simple. Therefore, it will not be difficult to learn the correct algorithm for doing the work.

The chamfering device may require sharpening after some time.

Experts recommend that before directly installing a pipeline structure using a calibrator, watch special training videos on this topic. This will allow you to avoid unwanted mistakes and carry out the correct installation of metal-plastic communications.

Fitting

This is the name given to the pipeline elements with which pipes are connected and branched. Despite the plasticity of the material, one-piece fittings are produced, with the help of which complex structures are fastened. At the moment, metal-plastic connecting elements are widespread, since in most cases this modern material is used to create heating systems. All fittings are classified according to the method of fixation.

Detachable

This type of connecting elements is used by many professionals. Its advantage is that in the event of a breakthrough in the system, it is not necessary to dismantle part of the communication for replacement. Fittings provide a more reliable connection compared to soldering or welding.

This is explained by the linear expansion of the material: when heated or cooled, it accordingly increases in volume or returns to its original state. If soldering was used, then these properties of the system can become the main problem, because the likelihood of violating the integrity of the joint increases. By working with fittings, such situations can be avoided.

Due to the fact that these connecting elements are reusable, they are called detachable. The key structural part is the collet, which looks like an O-ring. It is through this element that the required level of tightness is achieved. In addition to the collet, the fitting design includes a ferrule ring and the body itself, which is made of brass.

Press fitting

It is used indoors, since the elements do not withstand frost well, which significantly reduces the service life of the fittings. Installation outdoors may cause an emergency on the pipeline section. To install such a structure, a special tool is used - pliers, with which the ends of the pipes are compressed. Press fittings are produced monolithic. Their design consists of a body, a fitting and a sleeve with a gasket.

One point needs to be taken into account - press fittings are a disposable connecting element, therefore they are most often used when installing a “warm floor” system and laying communications in the walls.

To connect pipes where the pressure can reach 10 bar, these fittings are used, because they are made of durable material. As experts assure, if you follow the installation rules, the connecting element can last about 50 years.

Crimping

The main advantage of this type of connection is ease of installation, so each owner can do the installation with their own hands. But you need to take into account that such fittings are short-lived, since their design uses a rubber seal. The element itself is quite expensive and cannot be monolithic (installed into the wall).

Crimping parts have optimal technical characteristics suitable for arranging water pipelines. You don't need to use special tools to make a reliable and durable connection.

Main characteristics

A calibrator is a special device that performs three main functions:

- calibration; chamfering; adjusting the shape of the pipe end after cutting and other operations.

These activities allow you to prepare metal-plastic pipes for installation of connecting elements. For joining, as a rule, crimp fittings or press models are used.

Today you can find several types of this device, which are used for pipes with different cross-sections. When choosing a calibrator, it is recommended to pay attention to its markings. The diameter of the device can be 12, 16, 20, 26, 33 mm.

Such devices facilitate a gradual transition between pipeline elements that have different sizes. The calibrator includes the following parts:

- body made of polypropylene (PP); plate with cutting edge (knife).

Let's consider the main advantages of using such a device when installing metal-plastic structures:

- compactness; savings due to the fact that cutting of uneven ends of pipeline parts is eliminated; ease of installation; high speed of work; reliability of the device.

Similar devices are made from different materials and may have differences in design

It is also worth noting that the device is symmetrical for convenient performance of work. Using a calibrator allows you to simplify the installation of the pipeline structure and carry it out as correctly as possible.

Marking

There must be inscriptions on the outside of the pipes. To make the right choice, you need to understand what they mean. Not all types of pipes are suitable for a particular task. The marking is applied by the manufacturer. In metal-plastic products, the materials of the outer and inner layers may differ.

What designations are found:

- PE - R . Indicates that polyethylene was used to make the inner and outer layers.

- PP - R . Material of manufacture: polypropylene.

- PE - X . The composition contains cross-linked polyethylene. There are also other markings indicating the method of stitching the material.

- PE - RT . Made from heat-resistant polyethylene.

After these designations the diameter and thickness of the tube are indicated. Another marking that can be found is PN, which indicates the nominal pressure that the product can withstand. The unit of measurement is usually bars. Additionally, the maximum temperature and type of permissible coolant are indicated.

Insulation materials

Metal-plastic pipes Henco 20x2 and 16x2 can be supplied in a special heat-insulating shell made of polyethylene foam. To create additional protection, it is covered with a seamless film, painted blue or red.

The thermal insulation layer is certified UNI ET ISO 9002-94. It has a thermal conductivity parameter of 0.055 W/mK at a temperature of +40 degrees. The material can be used in temperatures from -35 to +95 degrees. Its thickness can be nine or four millimeters.

The presence of a thermal insulation shell allows you to prevent the appearance of condensation when laying hot or cold water supply circuits. The material reliably protects pipes from freezing when laying them underground.

Review of manufacturers and prices

Metal-plastic products are manufactured in many countries: Russia, Germany, Italy, China, Turkey and so on. The modern market is constantly growing, so manufacturers have to withstand fierce competition. The main goal of companies is to create truly high-quality products that meet all requirements.

When choosing communications, price is of considerable importance, especially if you plan to equip long-distance highways. Metal-plastic pipes for heating can have different prices per meter, which are indicated on the website of the manufacturer or official dealer.

It must be taken into account that the final figure is formed based on the quality of the product and the popularity of the brand that produces the product. For this reason, there are products on the market at prices starting from 600 rubles per meter. Of course, this is an inflated cost, because you can buy pipes for 50 rubles.

Among the available companies, it is worth highlighting Aquapipe and LTM from Turkey and China, respectively. Despite the relatively low cost, the products are of decent quality and meet all standards.

Metal-plastic pipes for heating, price per meter in rubles:

- Valtec - from 70;

- Fado - from 102;

- Golan - from 175;

- Henco - from 35;

- Kermi - from 78;

- Polvax - from 70;

- Rehau - from 165.

Even well-known brands offer affordable prices for their products. It should be borne in mind that the price also depends on the diameter of the product.

Prices for metal-plastic pipes

metal-plastic pipes

Scissors

They have a simple design. The main tool in it is a wedge-shaped knife, which is made of hardened steel.

Another important design element is the latch. It prevents the tool from opening uncontrollably. A very sharp knife can cause serious injury, so this precaution is important.

These devices have very comfortable handles; they make it possible to hold the scissors firmly and make precise cuts.

The tool also has a knife with teeth, which has an additional function, and a button with which you can return the mechanism to its original position.

These tools are best suited for home use. The modern market segment provides a wide selection of products in this line. But the following companies gained the highest popularity:

- Rothenberger;Reed;General.

Watch video: scissors for cutting metal-plastic pipes

How to identify a fake

When installing pipelines, it is very important to use high-quality pipes, which will allow the system to last for decades. Counterfeits are simply not able to withstand the existing loads; after 2-3 years they can leak. In addition, in low-quality products, the aluminum layer deteriorates over time, which can also become a problem.

A few tips to help you spot a fake:

- The pipes must be accompanied by a certificate. Of course, if there are documents, this does not mean that the product is 100% high quality, but if they are not there, this is a reason to think about it. If the supplier is conscientious, he must attach to each batch a corresponding document indicating the originality of the products.

- Visual characteristics. The marking and appearance of the pipe must be the same as indicated on the manufacturer’s website. You need to be vigilant when purchasing products.

- Pipe cut quality. If the aluminum is butt welded, everything is fine, but if the seam is made “overlapping,” the product is of low quality. You also need to pay attention to the thickness of the aluminum - it should be identical throughout the entire diameter. The same applies to the outer and inner layers.

By adhering to these rules, the likelihood of buying counterfeit goods can be minimized. The key to the efficiency of a heating system is properly installed high-quality pipes.

Pipe benders

When installing pipelines, metal-plastic pipe materials have to be bent. At first glance, this is not a difficult job. But, if done incorrectly, the inner aluminum tube may be damaged.

Experts recommend pipe benders for this type of work. You can’t do without them when you have to constantly bend tubular products at different angles. Moreover, the bends turn out to be perfectly smooth and are performed without much physical effort.

Pipe benders make it possible to work with different types of assortments and are the safest devices for installation. In addition, it should be noted that the devices are easy to use. All you need is to set the desired bend angle, insert the workpiece into the machine and bring the handles together.

The only drawback of pipe benders for metal-plastic pipes is the fact that when they are not used often in everyday life, then it is better to rent them. And it’s worth buying them in cases where pipe bending has to be done constantly.

The best products in this class for the metal-plastic range are products from German manufacturers. Domestic products are also distinguished by good quality of work.

Installation nuances

Metal-plastic has gained such wide popularity primarily due to its ease of installation. An important feature of this product is that it is distributed in coils, and not in separate pieces, like polypropylene products. This allows the pipe to be cut to the length required.

Another point is that the products are very easy to bend without the use of additional tools. Such deformation does not in any way affect the performance characteristics of the material.

Before laying communications, you need to install ball valves, filters and a device for measuring water flow into the system, which is usually done by plumbers.

Connection and connection of metal-plastic products is carried out using fittings, which are sold in all hardware stores. Thanks to their large number, it will not be a problem to choose the right element even for a complex harness.

Sequence of installation work:

- A piece of pipe of the required length is cut with special scissors.

- During cutting, the edge of the product can be damaged. This shortcoming is corrected by such a tool as a calibrator.

- For strong fixation with the fitting, it is recommended to treat the edge of the pipe with a chamfer.

- A union nut and a fitting collet are put on the product.

- The shank of the connecting element is carefully inserted into the pipe; it must fit completely.

- The union nut is tightened - first by hand, and then tightened using a tool.

- Another section of pipe is connected in the same way.

Even a beginner in the field of construction can cope with joining metal-plastic, which can easily be attributed to the advantages of the material. Study the long-burning solid fuel heating boiler using the link.

Pipe cutters

When cutting large-volume metal-plastic pipes, you cannot do without a pipe cutter. Using this tool you can ensure the full functioning of any residential building.

These installation tools are available in manual and electric versions. Comparing these two options, it should be noted that the cost of the first devices is lower, and the level of functionality and ease of use is higher. Manual mechanisms are very convenient to use for working in confined spaces and hard-to-reach areas.

It is also appropriate to carry out installation in rooms where there is no electrical network. Naturally, an electrical device will not be able to work in such a situation, but a hand tool can cope in such conditions.

In construction stores you can purchase various pipe cutters for installing MP mains. All information about the product is provided in convenient catalogs. After viewing them, you can compare the technical capabilities of various models and find out their cost.

The leadership in the manufacture of these products is held by the already named Rothenberger. Also, a large number of products in this line belong to Chinese companies. The price and quality of these products are significantly lower.