A hydraulic seal for a well is used for the purpose of emergency elimination of the causes of filtration and active leaks of liquid through joints, cracks, holes in conditions of active water inflow. The waterproofing material is an effective non-shrinking product that does not contain harmful components that affect the corrosion of reinforced concrete.

Eliminating leaks in a well with waterproofing materials.

What is a hydraulic seal

Quick-hardening waterproofing compounds are dry mixtures based on cement, quartz sand and modifying additives that give the solution special properties:

- frost resistance F50-F300;

- operating temperature - from -40 to +70 °C;

- curing time - 3-5 minutes;

- eliminate the possibility of formation of shrinkage cavities and cracks;

- impart high adhesion to the material in relation to concrete surfaces;

- high resistance to fluid pressure;

- vapor permeability;

- low coefficient of elasticity;

- chemical resistance;

- environmental friendliness;

- durability.

Recommended for eliminating leaks in above-ground, underground and hydraulic structures with constant filtration of fresh or sea water.

Hydroseals are used on the following objects:

- basements, ground floors of buildings;

- mines;

- underwater objects;

- tunnels;

- concrete tanks with chemically active liquids;

- swimming pools;

- structures for drinking water (wells, storage tanks, etc.).

After installing the seal, the surfaces of the repair areas are able to withstand liquid pressure, alkalis and chlorine.

How (with what) to seal a hole in the foundation?

#1 Offline BJ

- Moderator

- 17,165 Posts:

- Auto: different

The foundation of the house, on one side the ground floor, on the other side the ground. A hole is cut in the foundation wall through which the 110 pipe (cable entry) enters. When it rains, water flows through the gap between the pipe and the concrete. How to properly fix this?

If you're afraid, don't do it. If you do, don't be afraid.

#2 Offline Abilinus

Forum member 145 Posts:

Auto: Santik

There is also “liquid rubber” - but it is better to use it over large areas. Those. treat the entire foundation. https://www.technoprok.ru/

And since you have it locally, you don’t need tires.

#3 Offline tank166

Moderator 11 439 Messages:

Car: SsY Kyron II

Of the Penetron listed on the website, the most suitable sealant would be Sazilast or its analogue - a polyurethane sealant for a professional pistol. But to do this you need to get to the outside of the pipe and make sure that the seam is small.

if there is nothing from the outside, then from the inside, using a perforator in the concrete, select a ring 80-100 mm wide and up to 150 mm deep, lay sealant or tape around the pipe, and then seal it with a waterproofing solution. Be it Penetron's, or Glimsov's, or whatever is suitable

and the very first rule is that before you fight water, you must try to eliminate its entry into the leak site - repairing the blind area, roof gutters, etc.

Modified by: tank166, 09/30/2014 – 17:12

Types of seals for hydraulic structures

Depending on the purpose of the waterproofing, the conditions for performing the work and the task at hand, hydraulic seals are divided into 2 main types :

- Pressure. Used to eliminate active leaks. The setting time of such compositions is 30-50 seconds. After gaining strength, the applied coating not only seals the hole, but also resists soil pressure, as well as the constant influence of groundwater.

- Non-pressure repair mixtures are intended for sealing seams, minor defects, and cracks in operating above-ground structures. The setting time of such solutions is 3-5 minutes.

The category of non-pressure waterproofing materials includes gel sealants, which, like dry mixtures, serve to seal seams and eliminate coating breaks:

- rubber;

- acrylic;

- polyurethane;

- silicone.

Such materials are produced in plastic tubes, and their use requires a special compression tool.

Areas of use

The composition is widely used in construction and manufacturing. Recommended by manufacturers for household work. By application we can distinguish:

- sealing well seams . Compounds are used for wells because they are durable and environmentally friendly. Do not cause harm to health and do not affect water quality, and do not allow groundwater to enter the reservoir;

- insulation of reinforced concrete structures of swimming pools, mines, tunnels, wells and underwater objects . Hydraulic seals for such objects are characterized by quick setting and are resistant to pressure;

- sealing microcracks in pits and basements . Leaks in basements and pits are a common occurrence: water seeps through voids, cracks - where there is a high groundwater content;

- pipe bursts . In the event of a breakthrough, the composition is used as a temporary emergency measure to ensure the ability to properly isolate and prevent further breakthroughs;

- household use . Here, hydroseals act as quick-drying solutions for various purposes. They are used for minor repairs and sealing of cracks, gaps and tears, as well as for sealing seams.

Hydroseals include silicone, acrylic, and polyurethane sealants. They combine different materials, can be matched to the desired color, and are durable and strong.

It is important to remember that compounds for sealing leaks are not a complete solution to the problem, but a qualitative part of it. By taking proper care of the waterproofing of the structure in a timely and correct manner, the hydroseal will serve as a good additional service. guarantee.

Information sources:

- GOST 26633-2012 (introduced 01/01/2014)

- What is a hydroseal - Ceresit (date of access: 02.11.2019)

- “Plasticizers” – Tinius K., trans. from German, 1964

Ready-made waterproofing seals

Dry waterproofing materials are supplied to the retail chain in paper bags or plastic buckets. Methods of using hydroseals depend on the chemical composition and manufacturer of the product.

The best indicators of the effectiveness of waterproofing seals.

Of the waterproof materials presented on the domestic market, the products of the following companies have the best performance indicators:

- Dry mixtures Peneplag and Waterplug (supplier "Penetron"). They are characterized by a short setting time (1.5-5 minutes), instant stoppage of leakage and good expansion ability. They are used in critical cases when other waterproofing materials are ineffective, and are washed off with water at the application stage.

- Mapei Lamposilex is a fast-setting and hardening hydroseal. Designed to eliminate leaks, fistulas in wells and other drinking water reservoirs.

- Bostik Bosco Cem Plug is a fast-hardening composition that has proven itself in underwater work and in conditions of continuous moisture filtration. It has high frost resistance and durability.

- Ceresit CX 1 is a product from a popular manufacturer of waterproofing materials. The CX 1 hydraulic seal is used to stop water leaks in enclosing structures and to seal large diameter holes in underground structures.

Preparation

Hydroseals are supplied in hermetically sealed containers and are a dry powder. To prepare a waterproofing composition, you need to take a small amount of this powder, pour it into a rubber or plastic container, and then start adding water. The chemical composition of hydroseals from any manufacturer is toxic and should not come into contact with the skin for a long time. Rubber gloves should be used as protective equipment. If the latter are available, you can mix the powder with water manually or using a spatula. When the mixture is ready for use, it begins to warm up. At this moment, you should quickly seal the hole with a hydraulic seal and wait for the resulting mixture to completely cure. The time period during which the hydroseal hardens can be adjusted by changing the heating or cooling of water and material. When mixing heated ingredients, they set faster. The exact hardening time is determined experimentally and depends on the brand of hydraulic seal purchased.

Technology of using ready-made compounds

When applying the repair mixture, the temperature of the environment and the base itself should not be below +5°C. Before installing the bandage, the area is cleaned of dirt and silt, and peeled sections of the coating are removed. If the pressure of the leak exceeds the permissible limits, then the hole is opened and a fabric tampon is inserted inside or a wooden plug is hammered in.

The dry substance, placed in a special container, requires dilution with warm water at the rate of 150-200 ml per 1 kg of mixture. High temperature of the liquid accelerates hardening, low temperature reduces it to a minimum. Mixing is carried out in 1 step with active mixing of the composition. The filling preparation time should be no more than 30 seconds. The period of use is 1.5-2 minutes after the end of the kneading.

The resulting mass is shaped into a ball or cylinder by hand or with a spatula. The prepared filling is pressed into the groove and held for 2-5 minutes until it becomes strong. This method can be used to seal large diameter holes with continuous filtration of liquid.

Using waterproofing seams in a well.

Repair of non-pressure cracks with a wet surface or sealing of joining seams in the case of installation of a well structure from prefabricated reinforced concrete elements is carried out as follows:

- Cracks are opened manually or mechanically to a width of up to 20 mm.

- The treated areas are cleaned of dirt and small inclusions.

- Blow with compressed air and coat with primer.

- Prepare a repair mixture and use a spatula to apply it deep into the defective areas.

- The solution is leveled and after it hardens, a layer of additional coating waterproofing is applied to the treated surface.

Elimination of leaks

First of all, prepare the leak site. The cavity of the hole or crack is cleared of loose material.

To do this, use a hammer drill or jackhammer.

If the leak size is small, then the hole is widened to 2.5 centimeters and deepened by 5 centimeters, giving the shape of a cone.

The solution is prepared in a clean, dry container. Measure out the dry mixture according to the instructions and combine it with water.

Do you know how to choose the right circulation pump for your heating system? Tips and recommendations from professionals published in this useful article will help you calculate the power of your equipment.

What is an automatic bypass and why is it needed, find out here.

On the page: https://ru-canalizator.com/vodosnabzhenie/truby-i-furnitura/obsadnye.html it is written which casing pipe is best to use for a well.

The formed lump of solution is pressed with a sharp movement into the prepared leak area.

Press and hold the hydraulic seal for 3 minutes. The following portions of the mixture carry out the final repair of the leak.

IMPORTANT! Hydroseals are applied to:

- reinforced concrete structures,

- brick,

- masonry.

The properties of the material will allow you to seal leaks on both horizontal and vertical surfaces.

If it is impossible to eliminate the leak in one go, work is carried out in several stages from top to bottom.

Making a filling yourself

Waterproofing materials for wells must meet the following requirements:

- have a monolithic durable surface;

- be resistant to shrinkage and delamination;

- influence of low and high temperatures;

- do not affect the quality of drinking water;

- quickly gain strength;

- eliminate deformation of the coating;

- do not contribute to corrosion processes.

A properly manufactured hydraulic seal will help quickly eliminate non-pressure leaks. It is not recommended to eliminate high-pressure leaks with homemade waterproofing mixtures.

Homemade pressure-free seal

Elimination of minor defects with a homemade non-pressure filling.

To prepare a repair composition for the purpose of sealing wet cracks and eliminating minor defects that arose during the operation of the well, non-shrinkage fast-hardening cement (BTC) grade M400-M500 is suitable.

BTC is a hydraulic binder that can set not only in air, but also in water. The material retains its initial strength well throughout its entire service life.

Sequence of making the mixture:

- Add the required volume of quick-setting cement and quartz sand in a ratio of 1:3 or 1:2 to a plastic or metal container. The proportions depend on the work conditions and the size of the defective area.

- Add warm water and stir.

- Then introduce the plasticizer.

- Continue kneading until the mixture is homogeneous.

- Make a seal and seal the hole.

Sealing for seams and small cracks

A waterproofing solution for repairing non-pressure wet cracks can be made using general construction cement grade M400 with the addition of liquid glass:

- astringent - 20%;

- quartz sand - 60%;

- liquid glass - 20%.

The prepared mixture should be of a homogeneous composition, dense and viscous consistency. To improve the physicochemical properties of the solution, modifiers are introduced into it, the structure of which is selected based on the conditions of the work.

The next option is to use an expanding Barrier cord. The product is used to seal seams and small cracks in structures made of prefabricated elements operating in conditions of high groundwater.

The need to perform surface preparation.

Before laying the material, it is necessary to prepare the surface. The defective area is manually or mechanically deepened by 30 mm, cleaned with metal brushes, dust is removed and washed with warm water.

Place the cord in the groove and press it tightly along the entire length of the seam or crack. As the hydraulic seal begins to gain strength, it begins to increase in volume, thereby reliably blocking the access of water to the interior of the well.

Upon completion of the procedure, a layer of waterproofing made on the basis of liquid glass is applied to the repair base.

Conclusion

Hydraulic seals can eliminate leaks even under pressure. Preparation of the mixture does not require specialized equipment. It is possible to make a hydraulic seal with your own hands, which will be cheaper. But in this case, it will not be possible to eliminate the leak, but only to repair the crack or seam. The cost of industrial compounds is higher, but they also have more possibilities.

The main thing is to adhere to safety rules and technology, and well water will always be clean.

Safety precautions for working in a well

When performing restoration work in wells and other drinking reservoirs using repair mixtures, for safety reasons, you must adhere to the following requirements:

- The hydroseal contains components that can cause skin irritation. Therefore, it is recommended to seal cracks only with personal protective equipment (glasses, thick clothing, mittens, etc.).

- When using power tools, you must use rubber dielectric gloves.

- The handle of a hammer, sledgehammer and other impact devices must be made of hardwood without cracks or burrs.

- The entire well repair process must be accompanied by at least 2 people.

- Work must be carried out only with a mounting safety belt equipped with a safety rope firmly fixed to the surface.

- Upon completion of the intermediate stage of work, the well section must be covered with an iron plate and a temporary fence installed.

- Upon completion of work, tools and additional devices must be removed from the site.

- Take off overalls, personal protective equipment and take a shower.

Selection of the optimal hydraulic seal

Any type of waterproofing seal is designed for the mixture application technology recommended by the manufacturer. The purpose of the solution depends on its chemical composition, which, depending on the set of components, may have different requirements for operating conditions.

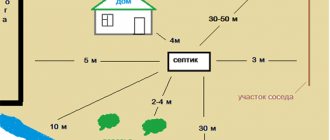

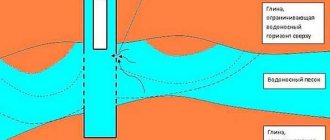

Waterproofing wells made from prefabricated concrete rings involves sealing areas of leakage through seams and cracks in the walls of the tank. Filtration of water can occur for many reasons - this is the seepage of liquid into the well from higher-lying horizons (overwater), the release of resource from the reservoir through connecting seams in the event of depressurization of the container, etc.

Restoration measures must be carried out in strict compliance with the technological instructions provided for the selected material and located on the packaging of the purchased product.

Instructions for creating a house

When you decide to build a simple well house with your own hands, the step-by-step instructions will look like this:

Structure frame. They begin to build it after measuring the diameter of the well made of concrete rings - this will become the distance between the sides of the frame. If the well is rectangular or square, the house will be a continuation of the walls. A base frame is made from timber with a cross section of 80*100 mm. If the house is being built from the ground, and not from the upper ring, then it is necessary to make two identical base frames, which are fastened together using 4 timber posts. It is better to use nails at least 100 mm long so that they firmly fasten all the structural parts together. From the center of the upper base frame, two racks of timber are erected, the height of which will become the height of the house. Next, the rafters are installed from the timber, cutting the ends of the beams at an angle of 45° and making cuts in those places where the rafters will connect to the upper base frame. To ensure the strength of the roof, crossbars and jibs are installed. It is imperative to provide a door in the frame, and it can be on the side walls of the roof (if there is no gate in the well) or on the slopes themselves. For the door, you need to install two beams parallel to the rafters and two beams horizontally.

Building a house for a well

Well house with wooden hexagonal base

A wooden house for a well will look great on a summer cottage

Base sheathing. If, in addition to the roof itself, the structure of the house has a base, it is necessary to sheathe it with boards, which is easy to do thanks to the already installed frame. Next, the side triangular surfaces of the roof are sheathed with the same boards.

The well is worthy of decoration in the form of carved elements on wooden products

The base of the well house can be finished with decorative stone

Log gate. The gate in the well is necessary to lift the bucket of water. It is made from a log from which the bark is first removed, after which the surface is sanded. The length of the log should be 30-40 mm less than the distance between the posts. This is necessary so that the gate does not cling to the side walls when turning. In the center of the end of the gate (log), holes with a diameter of about 20 mm are drilled on each side. The same holes are drilled in the side walls. To prevent the wooden parts of the structure from coming into contact with the metal bars on which the gate will then be held, it is necessary to install metal plates and bushings. Next, one rod is inserted into the wall on the left side, installing the gate, and one on the right, and on the right side the rod must be bent in a zigzag for ease of use. After this, you can attach a chain with a bucket to the gate.

Log gate

Beautiful well with stone base and tiled roof

Harmonious combination of a well house with other architectural buildings

Creating a roof. The roof sheathing is attached to the existing frame with an interval of 130-150 mm between the elements. Next, the roof is covered with roofing felt for proper waterproofing. For cladding, any roofing material is used: slate, corrugated sheets, tiles, etc. Corner joints are covered with wind boards.

Well with tiled roof

Various materials can be used for the well roof

Door fastening. According to the prepared drawings, the door is made from boards. To do this, a shield is formed from boards, which are fastened at the top and bottom with bars. For greater rigidity, another block holds the boards together diagonally. The door is usually attached to piano hinges, one part of which is attached to the frame, and the other to the door itself. To prevent water from getting into the openings between the doors and walls during rain, you can provide a sheet of rubber that is hung over the door.

Well house with door

The well door not only protects water from contamination, but also serves as a safety measure