The pressure switch is the central element in the water pump. The efficiency of the entire system depends on its correct functioning. This important element performs several tasks at once. First of all, it regulates the water supply. Feed parameters are set before use and changed as necessary during operation. Proper adjustment of the water pressure switch for the pump ensures safe and high-quality operation of the entire water supply system. We will talk about the correct setup and nuances of selection and installation in this review.

The relay provides comfortable water pressure

Selecting the correct connection diagram for the water pressure switch for the pump

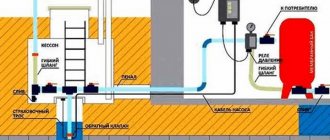

First, it’s worth understanding what the plumbing system consists of:

- its first part is the water intake point. It may be a water pipe or a well;

- hydraulic accumulator;

- pressure switch;

- water purification system. It usually consists of filters and several containers;

- water tap for which comfortable water pressure is provided.

Composition of a modern water supply system

First of all, it is worth understanding what pressure the residents of the house need. It is also important to find out the water pressure at the water intake point. This point is important because at a pressure below 1.4 atm, water is not drawn due to the relay being turned off. Such problems can also arise if you use a city water supply, because the water pressure in it is not always more than 1.0 atm. When drawing water from a well, these difficulties will not arise, and the water supply pressure will depend only on the technical characteristics of the pump.

To ensure uniform and normal water pressure, you should choose the right pumping equipment

It can be seen that each relay has its own setting option; it is usually described in detail in the instructions for a specific device model. All types of relays have a general purpose and mechanism of action.

Model for pumping station

Manufacturer's choice

There are a large number of different models of devices on the market. They differ in price, appearance and have slightly different characteristics.

| Image | Manufacturer and model | Characteristics | Cost, rub. |

| Gilex RDM-5 | Operating temperature from 0° to 40° Pressure range 1.0 – 4.5 atm. Voltage 220 – 230 V, 50 Hz Maximum rated power HP 2 | 900 | |

| Pressure switch PM 1 15, Grundfos | Operating temperature from 0° to 40° The pump starts at a pressure of 1.5 bar and runs as long as there is flow. Dry running protection | 5 655 | |

| Pressure switch PM/5(p)1/4, UNIPUMP | Mains voltage - 230 V, 50 Hz. The maximum switching current is 12A. Working pressure - 5 bar Power - 1500 W. | 467 | |

| Pressure switch PA 5 1-5 bar, WATTS | Pressures from 1 to 5 bar. Pressure drop 0.5 – 2.5 bar. Current 16 A. Maximum coolant temperature 90° In the room 55° | 997 |

Installation and connection

Connecting any mechanism begins with the preparatory stage. First you need to choose the location for installing the relay. According to knowledgeable people, the device should be installed directly near the pump outlet. In this place, turbulence and pressure differences are remarkably leveled out. Before choosing a location, it is imperative to familiarize yourself with the operating conditions of the selected device, because some of them can only be used in heated rooms.

Example of device installation location

The next stage of preparation will be the selection of the necessary pressure thresholds:

- Minimum – determines at what pressure the pump starts operating.

- Maximum – controls the moment the pumps stop working.

- The difference between these two values is called the pressure range. This indicator is directly proportional to the frequency of pump activation.

Important! It should be noted that the minimum pressure value should be 0.2 atm higher than the pressure of the pump accumulator chamber.

Device with a special threshold setting scale

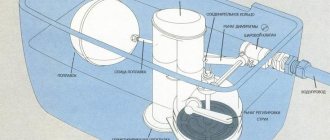

The third point of preparation is the registration of parameters. On a household appliance, this process will not cause difficulties, since it is adjusted using a pair of springs, which in turn are regulated by threaded regulators. The relay has two springs:

- a large spring serves to control the upper pressure limit;

- small – determines the pressure difference.

1 – spring for setting the upper limit (pump shutdown);

2 – differential adjustment spring (pressure difference) During preparation, several more devices are installed: shut-off valve, valves (return and breakdown), cleaning filters and sewage drain. Installation should be carried out by professionals or people who at least have an idea of the operating principle and installation rules of such devices. Installation (and then adjustment of the water pressure switch for the pump) must be carried out exactly as written in the instructions:

- First, a tee is installed at the selected location on the pipe, to which a drain valve or fitting connected to the water pressure switch is attached.

- During installation, a threaded connection is used, which should be properly sealed using FUM tape.

- There are devices that cannot be installed in the usual way. They are equipped only with a rigidly fixed nut. During installation, rotate the relay directly.

- Electricity is connected using a cable. Its cross-section must match the requirements of the device, depending on the power.

- The kit sometimes includes a grounding terminal. If available, a grounding cable must be installed.

Appearance of the disassembled relay and electrical connection diagram

Example of a mounted and connected device

Should we consider electronic analogues?

Mechanical devices, of course, are more popular, but electronic models have some undeniable advantages:

- Constantly adjusting the pressure switch for the pump by tightening the springs is a thing of the past. The electronic version does not require long setup after installation.

- It will be very easy to install. Any person without special education or special skills can cope with this task.

- The service life is practically no different from conventional mechanics.

This device does not require constant adjustment

Prices for electronic water pressure switches for a pump can range from two to four thousand rubles. It depends on the manufacturer, the materials used in production and the store selling it. If you spend some time searching for the right device, you can buy a quality unit at a fair price. If you are purchasing it for long-term use, saving on it is not the best option.

Expert opinion

Valery Drobakhin

VK design engineer (water supply and sewerage) ASP North-West LLC

Ask a specialist

“It would be much better to spend money on a slightly higher-quality model than to constantly change cheap devices that break.”

Primary indicators

The block is immediately hung on the pump.

For a submersible pump you need to choose it yourself. But in any case, the block is already adjusted during manufacture. Many of them have the following start and stop settings: 1.5 - 3.0 atmospheres . But some models may have smaller values.

The lower start limit is at least 1.0 bar, the upper stop limit is 1.2 - 1.5 bar more. In the instructions for the station, the lower start-up setting may be designated as P, or PH.

This value may vary. The difference between the lower and upper response limits can be designated as ΔP (deltaP). This indicator is also regulated.

How to configure the pressure switch of a pumping station

Owners of private houses understand that if the relay malfunctions, the entire system may malfunction. The stability of the entire system, and therefore the comfort of all residents of the house, depends on the correct adjustment of the water pressure switch of a household water supply station.

Pressure regulation unit with mini-manometer

Setting up the relay should begin with checking the indicators established at the factory. Typically, the minimum pressure level is 1.5 atm, and the maximum is 2.5 atm. The check is carried out using a pressure gauge. At this point, it is necessary to turn off the pump and ensure that the tank is empty. To measure pressure, a pressure gauge is attached to an empty tank and readings are taken from it.

A pressure gauge will help check the relay performance

Expert opinion

Valery Drobakhin

VK design engineer (water supply and sewerage) ASP North-West LLC

Ask a specialist

“This check can be avoided by purchasing a ready-made unit. But if you purchase all the components separately, you will have to carry out the first adjustment of the water pressure switch for the pumping station.”

Preparation for the process

Before making adjustments, you should eliminate possible problems that could disrupt the operation of the pumping station. And also carry out routine maintenance measures for the pump and storage tank.

You should check the tightness of the suction pipe, replace worn oil seals, stuffing box packing, and plumbing windings on threaded connections. In favorable conditions, it will be easier for the pump to achieve the desired pressure.

Check the air pressure in the air chamber of the expander . It should be inflated with the same pressure or 10% lower than that set to start the pump. If the lower pressure changes during regulation, then inflate taking into account the new value.

It is necessary to pump air into the expander when there is no pressure in the water supply. To do this, turn off the power to the pump and drain the water through any valve. Without closing the valve, check with what force the air is pumped into the expander and pump it taking into account the new value. When air is added, some water will flow out of the water supply - this is acceptable. You can pump it up with any car pump.

After performing maintenance on the station and adjusting the air pressure in the expander, you can proceed to readjusting the adjustments.

Procedure for adjusting the water pressure switch for the pump

Like any other, this device allows you to supply water to your home water supply with the same pressure. This device is activated after the pressure indicator specified by the setting is reached. At the factory, of course, they set the basic indicators, but most often they are not enough to ensure comfortable pressure, so after the purchase you will have to set your own parameters. Specialists, of course, will do everything efficiently and well, but sometimes it is better to understand an important issue on your own.

Unit ready for installation

Adjusting the pressure switch RDM-5: brief instructions

To correctly adjust the water pressure switch for the pump, you should follow a simple algorithm:

- Fill the tank with water until the required maximum value appears on the pressure gauge.

- Turn off the pumping station for a while.

- Open the housing and gain access to the adjustment springs. You will have to carefully rotate the small nut. At some point the mechanism will work. As you rotate counterclockwise, the pressure level decreases. When rotated clockwise, it increases.

- The lower limit is set by opening the tap and slowly draining the water from the tank.

- When the pressure gauge readings are correct, the process is stopped.

- A large nut is used to adjust the lower parameters. When you rotate it, you will also have to wait for the contacts to respond.

The principle of setting threshold values

This action should be performed once a month, but this is ideal. It is advisable to conduct it at least once per quarter. A small difference between the pressure limits obliges the pumping station to operate with a high frequency of turning on and off the pumps. This operating mode allows you to ensure an uninterrupted supply of water to the tap and at the same time its pressure always remains at approximately the same level, but this will affect the longevity of the pumping station. The large range creates some differences in water pressure, but the pumping station is subject to less stress due to constant switching on and off and, accordingly, will not require repair or replacement for a long time.

Important! It is worth noting that the difference between the minimum and maximum pressure must be more than one atmosphere.

Common faults

Article on the topic: Water pressure regulator in a water supply system : what it is, design and principle of operation, types, how installation is performed, review of models, average prices, useful tips and recommendations - read our review.

The most common cause of breakdowns of pumping stations is a lack of water in the system. The load that appears when there is a lack of water causes the pump to fail in a very short time. In order not to spend money on constantly replacing pumps, you should immediately buy a good relay model and not worry about this cause of failure.

Why is there no fluid in the system?

The main reason for this problem is the large volume of liquid consumption when the volume of the well or reservoir is simply not enough. In the summer, problems often occur that cause interruptions in water delivery. Drought or pipe repairs can cause an unexpected loss of water supply.

The most unpleasant cause is an accident at a pumping station. In this case, you will have to change the pump and all related parts, and at the same time the house will be left without water supply for some period of time.

Corrosion can cause failure of pumping equipment

It is to protect against these unpleasant situations that a water pressure switch for a pump with protection against dry running was invented. This function of the device is capable of opening the contacts and completely turning off the pump. The pump motor will only turn on again when the water flow returns to normal. The indicator, which includes protection against dry running, is set at the factory during manufacture. Most often it is 0.5 atm. This number cannot be changed.

Electrical diagram for connecting the dry running sensor

In addition, manufacturers offer a flow switch that combines its functions with a pressure switch. This version of the device is also capable of ensuring correct operation of the water supply system.

Note! During adjustment work, you should definitely pay attention to the power specified by the manufacturer. The station should not be adjusted to a pressure that it cannot withstand, according to the manufacturer.

Water supply control

Regular use of personal piping in an enclosed space may result in the pumping station turning on and off frequently. In this case, the pressure switch does not affect the operation of water-bearing equipment.

If the pressure increases and the pump is quickly connected, it is recommended to check the condition of the hydraulic accumulator. Inside its structure, the surface of the permeability membrane will be greatly deformed. It is this part that is designed to control the increase in pressure.

Experienced specialists recommend introducing monitoring of the performance of plumbing equipment. If the relay constantly fails, then to maintain performance it is necessary to seek specialized help.