Any leak in plumbing or internal communications is a problem associated with financial losses, so it must be resolved immediately. If the toilet leaks after flushing or the sound of a babbling stream is periodically heard from the toilet, it’s time to check the condition of the tank. Do you agree?

We will tell you about the most common breakdowns that occur with plumbing equipment that is mandatory for furnished housing. Here you will learn how to deal with them on your own. Taking into account our advice, you can eliminate such situations and competently repair an important device for life.

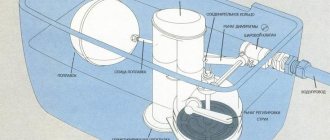

A few words about the design of the tank fittings

Before I tell you why a toilet tank may leak, I will introduce you to the design of the fittings so that you understand the principle of its operation.

Of course, there are currently a great many options for mechanisms.

However, the principle of operation of the tank always remains the same, since any fittings include three main elements:

- shut-off mechanism - is a tap that automatically shuts off the water as it enters the tank. The float is responsible for the water level at which the shut-off valve is activated;

Tank fitting options

- discharge system - is a valve that closes the drain hole. The valve is controlled by a button or lever;

- overflow system - prevents flooding of the apartment in case of failure of the locking mechanism. If the water in the tank rises above a certain level, the overflow system ensures that it is drained into the toilet.

Features of the tank

The mechanism for draining water from the tank is of two types. In the first, all the water is drained when you press a button or when you lift the handle up. The first option provides two buttons for rational use of water. When you press one of them, the water is partially drained, and using the second you can remove all the water from the tank.

If the flush works normally, then water flows into the toilet bowl quickly and without delay with a characteristic sound. If problems arise, the flow of water either does not stop and the walls of the toilet are constantly wet, or the water overflows from the tank.

This kind of breakdown can cause flooding of the toilet room, or provoke the formation of limescale on the walls of the toilet and, undoubtedly, lead to high water consumption due to its constant supply. Another sign of a malfunction may be the appearance of condensation on the cold water pipe that leads to the toilet.

Sometimes, to eliminate a leak, it is enough to clean the tank and parts from plaque and rust. They appear due to poor quality water and failure to follow simple plumbing hygiene rules.

To avoid further problems and eliminate the leak, it is important to find out the cause of the leak and determine in which part of the tank the breakdown occurred and check all the parts. To do this, you need to turn off the water in the riser, then clean the tank and study the design.

Flush design device

If previously the tank body was made of cast iron, today ceramics, earthenware or special plastic are used. All the main elements of the tank are connected to each other.

There are only three key mechanisms: inlet, adjustable float, flush and overflow systems:

- The inlet or fill valve stops the flow of water into the tank after it is filled. The required water level is “measured” by the float.

- Locking or drain mechanism . This is the flapper/valve that opens during flushing.

Modern models have buttons for this. They can be single or double to adjust the amount of water flushed. Old Soviet toilets use a chain, lever or rope that is attached to a lever with a bulb. These elements are connected by traction. And the pear is at the bottom of the tank.

The standard tank design is quite simple. In some models, the flushing mechanism consists of a siphon. Its membrane is the weak link and often fails, as do the spokes connecting the flush and the float

The toilet float regulates the operation of the locking mechanism and controls the level of water drawn in, the design of which depends on the type of water supply to the tank (bottom or side).

There are several types of floats, but each one has air inside:

- The first, hollow, is made of rubber. It is located at the bottom of the reservoir and functions as a rocker arm.

- The second, plastic, glass-like float. Located at the top of the tank. When the tank is filled with water, it rises up and works almost silently. The latter type is used only in older models; the first type is installed in modern toilets.

The overflow system protects the entire toilet room from flooding if the filling mechanism does not work for some reason. When more than normal water gets into the tank, it is the flush tank fittings that drain it into the toilet. If you find a leak, then do not panic, but remove the toilet lid and figure out what the problem is.

Preventive measures against leakage

To prevent a leak in the toilet from occurring at the most inopportune moment, it is worth monitoring the condition of the tank fittings and regularly carrying out preventive measures.

The main and at the same time the simplest thing is to clean all parts, as well as the internal surfaces of the tank. Upon careful examination, you will notice that even in a short time the walls and bottom are covered with a red coating, mineral deposits and even a substance similar to silt. The composition of contaminants depends on the quality of the water.

To minimize the entry of various contaminants into the tank, the internal wiring must be equipped with filters. They are installed on the cold water supply next to the riser

From time to time it is advisable to check the condition of the sealing elements, fasteners and parts that are located at the joints in order to anticipate the occurrence of a strong leak. A small amount of moisture indicates that the connection is leaking. Accordingly, you need to tighten the nuts or replace the seal.

Timely minor repairs and regular cleaning will save you from leaking water into the toilet, and therefore from unnecessary costs. An important factor that ensures saving water, clogging and breakdowns is the correct setting of the fittings, the specifics of which we recommend that you familiarize yourself with.

Causes of problems and their solutions

The reasons why the water in the toilet does not stop may be hidden in various technical problems. Each of them has its own methods of elimination that you can apply independently.

Liquid flows out through the overflow

There are times when the water in the toilet cistern exceeds the standard level. In this case, the liquid leaves through the overflow. The reasons why water is collected in large volumes can be the following:

- Deformation of the gasket in the valve;

- Loss of elasticity of the gasket, due to which the gasket does not completely cover the water;

- The gasket does not fit tightly to the hole where the water comes from;

- The pin holding the float is lost or rusted;

- The element at the valve hole in the drain tank does not fit tightly to it;

- The float lever has moved from its original position;

- There is a small crack in the valve body.

Only plastic elements can cause cracks. If the element is made of brass, then this is not the reason why the water in the toilet does not stop

.To correct the situation, the following measures must be taken:

- Place the lever so that it is located slightly lower than the entrance of the water pipe;

- Raise the float slightly from its original position, if the leak has stopped, secure the element in this position;

- If the leak does not stop when the float is moved, you need to look at the valve. The valve design has a pin that secures the lever. The stud needs to be checked. If it is missing or broken, it is easy to replace the element with copper wire.

In the place where the pin is attached to the valve there should be no holes, absolutely none. If any are present, it is necessary to replace the entire valve, as damage has occurred that causes the element to not work correctly.

If the leak does not stop even when the gasket tightly covers the hole, then it is necessary to change the device. In order to buy a supply element, it is recommended to take a broken sample with you. It’s better to call a plumber for installation.

Leaking in new plumbing

The problem is fluid leaking into the toilet before the tank overflows. The cause may be a crack in the plastic bolt or, in the case of steel material, the element has rusted.

You need to fix the problem in the following order:

- You must ensure that the water is filled before it overflows. Then turn off the water supply to the tank and pour it by flushing into the toilet;

- Remove the movable line from the tank;

- Unscrew all the bolts securing the shelf going to the toilet;

- Inspect the entire structure. If the element is working properly, you need to replace several bolts or buy new fittings;

- Cut off and replace rusty bolts;

- Drain the remaining water from the cuffs after dismantling them;

- Reassemble the structure in reverse order.

It is recommended to replace the gaskets with new ones, since the old ones no longer shut off the water. If absolutely necessary, you can tighten the cuff using wire or a clamp.

Water leaks between the toilet bowl and the cistern

Design of toilet flush fittings

1) the problem can be solved easily: just tighten or simply correct the part. Causes of the problem: a faulty cuff is most often the cause of water leakage. Regardless of what material the cuff is made of, there are clamps for both plastic and metal. Tighten the cuff with clamps carefully, not too tight, but not too loose. If the cuff device is corrugated, then it can simply move. In this case, simply return the part to its place and secure it.

2) Replacement of rubber gaskets, tightening of bolts and nuts. Causes of the problem: too weak fixation of the shelf to the tank. Just tighten the fastenings. Metal bolts rust and become deformed over time, but this does not happen to brass bolts. If tightening the bolts and nuts does not help, check the rubber gaskets. They need to either be completely replaced or repaired (dry, apply sealant, dry and reinstall with bolts).

3) Replacing the drain tank. Cause of the problem: Water leaking between the tank and the shelf may be a sign that the shelf is completely broken. This kind of problem is very serious. It is better for you to consult a specialist, because a breakdown often requires a complete replacement of the toilet bowl or even the flush tank. Plumbing products should be regularly inspected for cracks, including the cuff and pipes. toilet design Toilet design for a better understanding of the problem Water flows simultaneously with the flush The essence of the problem: every time you press the flush, water begins to leak from under the tank.

4) Check the serviceability of the drain mechanism inside the tank. Take the valve with your hand and press it lightly. If the leak has stopped, it means that the reason was hidden in the loose fit of the valve in the center of the tank. In this case, you just need to replace the gasket in the valve. But this reason is far from the only one.

5) The next reason for the tank leaking may be a displaced drain button. If the height adjuster has moved and the valve is higher than the drain hole, then a gap will form between the drain and the shut-off valve. You just need to return the water height regulator to its original position. The breakdown is quite simple and not at all costly.

6) A loose nut on the outside may cause water to leak out. You need to carefully and carefully tighten the nut and also check all the fasteners that secure the flush cistern to the toilet. Minor damage can be repaired and eliminated. The cost of replacing a toilet in Chelyabinsk, in particular here, is not high - look at the prices.

Water flows after pressing the water drain button

In some cases, a leak may appear immediately after the water is drained from the tank into the toilet. To solve problems you need to:

- Check the correct operation of the internal mechanisms of the drain tank. To do this, take the valve with your fingers and press it. If the leak is eliminated by this action, then the cause is a loose valve fit. To eliminate this, it is necessary to replace the valve gasket.

- Also often the cause of a leak in the tank is the displacement of the drain button. When the height adjuster moves and the valve moves into place above the drain hole, a gap is formed between them through which water passes. To solve it, just return the regulator to its original position.

- It is recommended to check how the nut fits on the outside. If the nut does not fit tightly, a leak will form. It is necessary to carefully and carefully tighten the nut until it stops. You should also check all tank fastenings.

Overflowing water from the toilet tank

A fairly common problem is when water constantly overflows from the toilet tank and it makes noise.

First of all, you need to find out the cause of this phenomenon. This is easy to do, just press on the overflow socket in the toilet cistern. If the leak goes away, it means that the overflow nut has come off. You need to carefully tighten it until it stops.

This can only be done by removing the shelf. Also, in a situation where there is overflow of water in the toilet tank, it often happens that the nut sticks tightly to the tank. To eliminate leakage, you need to turn the overflow clockwise, as if twisting it. This action will return the element to its place and the leak will go away.

In the case when the nut does not stick to the tank, and water overflows from the tank, do the following:

- If the nut is not completely unscrewed, but there is still a gap between the tank and the surface of the tank, it is recommended to turn off the water supply and drain the water from the container. It is important to wait until the walls of the tank are dry. Then wrap the gap with tow and fill it with paint. Wait 7-8 hours until the paint is completely dry and continue using the tank.

- When the nut is completely unscrewed, you need to turn off the water and pour the liquid out of the tank. Remove the overflow and put an additional seal on the thread. Then put the tank in place and tighten it.

To increase the tightness, it is recommended to lubricate this area with paint or sealants. It is important to place the tank so that the overflow is open and not clogged. If this is not observed, the water will stop going into the toilet and will flow onto the floor. It is also important to place the tank level; if it is tilted, the water will not stop flowing through the overflow or will flow onto the floor outside the tank.

Float valve clogged

In most cases, there is a common problem with the float valve. The valve becomes clogged due to constant overflow of water through the drain. This tank flush valve works something like this:

- Water is collected;

- The float rises according to the liquid level;

- The float lever presses on a plastic or brass plug;

- The pressure plug uses a gasket to close the nozzle from where the liquid flows.

Sometimes some toilet models do not have an overflow in the tank. To eliminate the problem in such a model, it is necessary to close the flow of liquid and remove the movable liner. Then disassemble the fluid supply valve. Next, remove the plastic plug and straighten the cotter pin to secure it, remove it. Holding the valve with the body with your other hand, remove the float holder from the body.

When you remove the locking lever along with the rubber gasket, it will fall out. After this, you will see the hole from which the liquid enters the tank. If there are foreign objects and debris in the tank, it is necessary to clean the channel with a long thin object (knitting needle, wire).

When the channel becomes free, you need to check the gasket on the lever. If there is a leak, the gasket is pressed in and should be replaced with a new one. When the elements are replaced and the channel is clean, reassemble the mechanism in the reverse order. If you do everything correctly, the leak will disappear and will no longer bother you.

Depressurized float

After adjusting the float, make sure that it floats on the surface of the water and the locking mechanism works as expected.

If it turns out that the float is “submerged” or even submerged in water, it is useless to adjust it, since it has become depressurized.

In this case, this part must be replaced. As a rule, it changes along with the shut-off valves.

Therefore, the dismantling instructions look like this:

- turn off the water supply;

- flush the existing water into the toilet;

- unscrew the nut of the flexible connection;

- then unscrew the nut that secures the shut-off valve.

A depressurized float can be soldered. To do this, melt a regular cellophane bag and seal the hole or crack with it. However, keep in mind that such repairs can only temporarily solve the problem.

After this, you need to take the shut-off valve and go with it to the nearest plumbing store to purchase a similar mechanism. Install the new part by performing the steps in reverse order.

Faulty locking mechanism leaks when the float is raised

Manual float adjustment

Let's move on to information that often worries owners of both old models and new units. Let's try to figure out how to independently adjust the float in the toilet in order to raise/lower the water level in the tank.

A larger volume of water is needed if what is available in the container is not enough for a high-quality flush, and they reduce the amount of water collected if they want to save money.

The adjustment process differs for different models. The outdated “yoke” can be adjusted in a very simple way, without even turning off the water. We remove the tank lid, find the float holder wire and simply bend it.

Due to their small cross-section, brass, aluminum and steel holders bend easily, so no tools are required to change the shape of the rod

Due to the bend, the inlet valve blocking device is activated earlier, therefore, the volume of water entering the reservoir is also reduced.

If the float holder is assembled from two rigid metal strips connected with a bolt, the adjustment process is somewhat more complicated:

After unfastening the drain lever or button, remove the tank lid. Loosen the nut on the float rocker and use pliers if necessary. We select the desired position of the float and tighten the nut with pliers. The water in the tank should not reach the overflow hole. Let's manually activate the drainage device and see to what level the container is filled. If the level of water collected in the tank does not suit us, we adjust the position of the float using the same method. If everything is fine, put the lid on and attach the drain lever or button.

- Step 1: Loosen the mounting bolt nut.

- Step 2: Selecting and fixing the optimal position.

- Step 3: Check the fill level of the tank.

- Step 4: Reassemble the cistern in reverse order

If the lever is not metal, but plastic, you cannot bend it - you will break it. Such devices are usually equipped with a screw or “ratchet” to change the shape of the lever. You just need to twist the screw or move the element on the ratchet.

Adjusting glass-type plastic fittings will take a little longer. The task is to move the float on the “sliders” (plastic vertical elements that support it) up or down, depending on the planned increase/decrease in the flush volume.

Very often one of the “sliders” (or both) is equipped with a scale from which you can determine the exact height of the water level. Manufacturers print correspondence tables in the instructions, from which you can see what height the water level will be when choosing a particular division on the scale.

To simplify the adjustment procedure, some manufacturers equip the design with a special screw. Let's look at how to use it using a photo gallery.

Carefully unscrew the drain button; to do this, just turn the plastic ring on the thread. Remove and set aside the tank lid, under which there is a float device.

We find the part we are interested in - a float or water shut-off valve. We are interested in the plastic adjusting bolt, which is a pin with notches.

Our task is to tighten the screw so as to reduce the maximum volume of water in the tank. Turn the ribbed bolt so that the float moves down several positions.

To check, we drain the water; if the volume of water and the quality of the flush are satisfactory, we perform the reverse steps. Replace the tank cap and screw the drain button back in.

- Step 1 – unscrewing the button.

- Step 2 - removing the tank cap.

- Step 3 - determining the location of the float.

- Step 4 - Locate the adjusting bolt.

- Step 5 - determining the required water level.

- Step 6 - adjust the bolt.

- Step 7 – flush diagnostics.

- Step 8 - button installation

In the same way, if necessary, you can increase the volume of water entering the tank. As you can see, the procedure is very easy and does not require special knowledge.

Repair of valve faults

Troubles usually happen unexpectedly, when there is no way to call a specialist or seek help from more knowledgeable people, so you always need to be prepared to act independently.

Failures of the float mechanism can disable the operation of the drain tank, and flushing it off with water from buckets every time is not an interesting task. Let's figure out how to quickly change or repair the float in the toilet if it has become unusable.

Violation of the tightness of the plastic ball

When the old float wears out, a crack may appear, which over time will turn into a hole. Liquid will begin to flow through the hole into the plastic ball, and it will no longer be able to float up and block the inlet valve. A problem arises - a constant flow of water in the toilet. Water losses quickly turn into financial costs.

Let's find out how to avoid this:

- turn off the water;

- remove the float;

- wipe it dry;

- cover the crack with waterproof sealant;

- dry;

- fix the float in the tank;

- We check his work.

There is no point in repairing a float with a large hole or completely leaky plastic; in this case, we rush to the store and purchase a new part to replace it.

If the float valve fills with water due to a ruptured membrane or a crack in the valve, this sealing device must be replaced:

After removing the button or lever of the drain mechanism, remove the tank lid. Now let's unscrew the float device for inspection and repair. To study the condition of the float and determine the reason for filling it with water, unscrew and remove the head of the float valve. We study the condition of the float membrane, find the cause of the leak - a breakthrough.

We take it with us to the store and buy exactly the same one to replace it. After installing the new membrane, assemble the float mechanism in the reverse order. We install it in the tank and secure the device.

- Step 1: Dismantling the float valve of the toilet fittings.

- Step 2: Disassemble the float head.

- Step 3: A ruptured membrane is the cause of the problem.

- Step 4: Reassemble the Float Device

Skewed float structure

Due to wear of the rubber (silicone) seals or due to poor water quality, the glass-type float device may become misaligned.

Does the plastic float “stick” with each release of water or does it even stop moving up and down relative to the guide “sliders”. Depending on its position, either the flow of water into the tank stops, or, on the contrary, it constantly pours, flowing straight into the sewer.

A common cause of breakdowns is poor quality tap water. It is characterized by a high content of lime and rust, which settle on the walls of the “glass” and on the rods (holders, guides)

First, try cleaning the mechanism without disassembling the entire structure. Perhaps the movement of the float is slowed down by debris that has fallen into the water. If this does not help, you will have to turn off the water, remove the tank, and then the float block. The drainage device may not be touched.

Then we carry out diagnostics and act on the results: we correct the position of the float and install it in place or completely change the block responsible for the water inlet.

Most often, breakdowns associated with changes in the position of the structure are corrected quickly, while it is better not to repair worn-out devices, but to replace them with new ones.

Fixing a problem in a flush tank with a button

When you press the cistern button, water flows into the toilet bowl. The float, after releasing the water, sinks to the bottom. At this time, the valve that closes the hole for water inlet also lowers. Water enters the tank, the float gradually rises, moving the lever. Having risen to a certain height, the float with the lever takes a position when the valve tightly closes the opening of the pipe.

The cover with one button is removed in the following order:

- Unscrew the locking ring around the button. Don't press too hard - most rings are made of plastic and can break.

- Remove the cover and begin repairs.

Advice! Be extremely careful when removing the reservoir cap. If you damage it, it will be extremely difficult to buy a new one.

If water does not stop flowing into the tank, the cause may be one of two problems.

- Incorrect float position. The problem can be easily resolved - remove the cover and adjust the float.

- If water constantly flows into the toilet, most likely there is a loose seal blocking the drain pipe. To check, simply press on top of the bulb. If the water flow stops, the reason is guessed correctly. Fixing this breakdown is very simple - hang any weight on top of the pear.

- The rubber bulb on the valve is worn out and does not provide a tight seal. It needs to be changed. Lock the float in the upper position. Unscrew the nut that connects the drain tube to the tank and remove the entire mechanism. Remove the old bulb, buy a new one of the same size, choose the softest one, and install it.

- You need to rinse the water out of the tank and remove any remaining residue.

- Unscrew the union nut between the float valve and the flexible connection and the bolts that secure the shelf to the toilet ears. With a little effort, tilt the cistern with the shelf back and release the rubber cuff between the toilet and the cistern.

- Unscrew the broken bolt and its paired one and remove it - both bolts need to be replaced, even if one has not yet lost its integrity. New bolts should be of similar size and made of stainless steel or brass.

- Remove the earthenware under the seat of the pear and clean it thoroughly; you also need to do the same with the surface of the shelf and tank. Coat the pear with silicone sealant. Due to the fact that plastic loses its elasticity over time, you will not be able to press the bulb tightly again after installation. If you do not want to change this part, the sealant will solve the problem.

- Assemble the tank and tighten it with new bolts, avoiding distortions. Do not apply too much force to avoid breaking the earthenware.

If the bolts holding the pear saddle are damaged, they need to be replaced.

Water flows out of the tank through the overflow

The way to solve the problem will depend on the cause of its occurrence.

- If adjusting the float lever does not bring any results, check the integrity of the pin that holds it. Replace the damaged pin with copper wire of the same thickness. Do not use steel wire; it is susceptible to corrosion.

- If the pin hole in the plastic valve has changed from round to oval and is worn, remove the valve. Take it with you to the store as a sample for size and model, buy a new valve and install it.

↑ back to contents

What is needed for repair?

For repairs, you will need the simplest tools that are found in every home: screwdrivers, a work knife, a hammer, a piece of sandpaper, pliers or a set of wrenches. You will also need sealing material - tow with grease and plumbing sealant.

It is also worth preparing a piece of rags to wipe your hands while working. If the water supply valve for the toilet is located in another room, it is better to work with an assistant.

How to fix a leak with your own hands?

First of all, you need to carefully remove the tank cap. Start by checking the valve that shuts off the liquid supply. Raise the float until the water stops flowing. If the leak is eliminated, you need to adjust the position of the float on the rod.

If this does not help, you need to remove the drain fittings and inspect the condition of the sealing rubber. Often it is enough to clean it of dirt to restore normal operation of the mechanism.

If this does not help, you will have to disassemble the tank in search of failed parts. These could be sealing gaskets between the tank and the shelf, bolts, tightening parts or parts of the drain fittings.

- The float may leak water due to a clogged rubber band. To clean it, you need to disassemble the float lever mounting assembly. After disassembly, the gaskets are washed and the rubber on the lever is replaced (it often develops wear). Video instructions will help you understand how this work is done:

- Another problem area is the rubber locking mechanism. Over time, it warps and the valve begins to jam. The problem is that with the low cost of the gasket itself, this part may not be available in the store. Buying entire fittings (for 800–900 rubles) for the sake of a 15-ruble elastic band is unprofitable. It is worth choosing a more or less suitable elastic band from the domestic range, cutting it and putting it in place. We offer video instructions for this operation:

- If you decide to change the entire fittings, you will have to turn off the water supply and empty the tank. Then unscrew the water supply hose with a wrench (a little liquid may spill out - replace the container). Then unscrew the fasteners and remove the tank. This will allow you to get close to the plastic nuts holding the reinforcement. We unscrew them, remove the shut-off valve and the float assembly, and install new parts. All stages of work are shown in the video:

Such repairs are already quite complicated for a novice plumber; it is better to seek help from an experienced specialist. But if this is not possible, you can figure it out yourself. The main thing is to do everything slowly, periodically checking the instructions for the fittings. Good luck with your work!

Pear malfunctions

The bulb is, at first glance, a simple, but rather problematic element of the cistern: if it fails, leaks cannot be avoided. There may be several reasons for this negative phenomenon, but in practice there are two most common:

- Loss of elasticity. A pear is primarily a rubber device, and as you know, over time, rubber that is constantly in contact with water loses its performance properties: it becomes less elastic and even hard. As a result, the contact of the pear with its saddle is disrupted, and cracks are formed through which water flows out. There are two ways to correct the situation: if the deformations are insignificant, try additionally weighting the pear with a pair of stainless nuts - they will allow the element to come into closer contact with the saddle, but if the pear has been serving for quite a long time, there is only one way out - replacing the product.

- Plaque on the saddle. The bulb may have poor contact with the saddle not only as a result of loss of its elasticity, but also due to corrosion of the saddle itself. The cause of poor fit in this case is deposits of rust and hard water salts. The fix is easy: just clean the seat.

Advice. The best way to remove dirt from the pear saddle is to use sandpaper.

Water flows in the toilet after flushing

The toilet tank is equipped with a valve that prevents liquid from spontaneously draining into the toilet. The normal position of the valve is permanently closed, with the drain hole sealed by an elastic seal.

When the controls (button, lever, etc.) are operated, the valve opens and the elastic seal rises above the hole. At this time, the liquid from the tank is drained into the toilet. When the control is released, the valve closes.

Spontaneous leakage after flushing indicates a loose fit of the elastic seal to the hole. There are several reasons why this type of malfunction occurs:

- Seal damage. The presence of cracks causes water to gradually seep through the valve.

- Malfunction of the locking mechanism. Wear of fittings components leads to a loose fit of the part.

- Plaque formation at the point of contact between parts.

To restore the functionality of the unit, it may be necessary to install new fittings. Installation instructions differ for different models.

List of required tools

In order to eliminate the leak, you need to acquire some tools and consumables. During the repair process, it is necessary to replace unsuitable seals, hoses, and gaskets.

When the toilet cistern is leaking, you may need:

- sealant for plumbing work (silicone);

- sandpaper;

- limescale remover;

- Screwdriver Set;

- knife;

- pliers;

- a set of keys;

- fum tape (sealing tape for water).