Water at their summer cottage is required not only by the owners to comply with sanitary and hygienic standards. It is necessary for watering plants, caring for the territory and pets, refreshing and swimming in the hot summer. Agree that it is difficult to lift the entire required volume from the source manually with buckets.

However, there is a way to alleviate the difficult fate of summer residents - this is a homemade water pump. Even if you don’t have the funds to buy pumping equipment, you can become the happy owner of a useful technical device. To build it, sometimes literally just the power of thought is enough.

We have collected and systematized for you valuable information about making almost free homemade products. The models presented for consideration were tested in practice and deservedly received recognition from the owners. A thorough description of the manufacturing technology is supplemented with diagrams, photographs and video materials.

Design #2 – manual pump with direct spout

A very simple device for pumping water from a barrel or a shaft well. The advantages of this design: speed of assembly, low cost.

Required parts:

- PVC pipe d.50mm – 1 pc.;

- PVC coupling d.50mm – 1 piece;

- PPR pipe d.24mm – 1 pc.;

- PPR branch no. 24 – 1 piece;

- PVC plug d.50mm – 2 pcs.;

- piece of rubber, diameter 50mm, thickness 3-4mm – 1 piece;

- check valve 15mm – 1 piece;

- empty silicone bottle 330ml – 1 piece;

- tightening screw clamp – 1 piece;

- screw-nut or rivet – 1 piece;

- union nut no. 15 – 1 pc.

We begin the assembly of the entire structure with the manufacture of a check valve.

Construction of a check valve. We prepare a check valve from a Ø 50mm plug. We drill several holes around the perimeter of the plug Ø 5-6mm. In the center we drill a hole of suitable diameter for a screw-nut pair or rivet.

On the inside of the plug we place a rubber disk Ø 50mm. The disc should not rub against the walls of the plug, but should cover all drilled holes. We tighten it in the center with a screw-nut or rivet; a screw will not work. If difficulties arise with materials or manufacturing, you can replace it with a factory-ready check valve.

What a factory-made check valve used to operate a pumping station is is described in detail in the article we recommend.

Preparing the pump sleeve. The length of the sleeve should be commensurate with the depth of the well or container with water. We cut the PVC sewer pipe Ø 50mm to the required length, from the narrow end. We insert the newly made valve into the pipe socket. For reliability, we fasten it on both sides with self-tapping screws.

For the second end we prepare a plug with a pre-drilled hole Ø 25mm. This hole in the plug is made according to the diameter of the PPR pipe Ø 24. Great precision is not required, the plug serves as a sliding support.

Piston assembly procedure. Cut off the spout of an empty silicone container. Next, you need to heat the balloon and insert the sleeve into the PVC so that the diameter of the balloon exactly matches the diameter of the sleeve. Place the silicone can on the valve from the reverse side of the arrow (the arrow on the check valve shows the direction of water movement).

We cut off the excess balloon. We secure it with a union nut no. 15.

Pump rod design. The length of the rod should be 50-60 cm greater than the length of the sleeve. You need to heat one end of the rod and insert a check valve. The arrow on the check valve should point towards the inside of the stem. Until the pipe has completely cooled down, we tighten it with a screw clamp.

Final assembly of the pump. We insert the rod into the sleeve and attach a plug (sliding support) through the coupling on top. To top it off, we attach a 24mm PPR bend to the end of the rod pipe. All you have to do is connect the hose and you can pump water.

The pipe material can be any, and the cross-section is not necessarily round. It is important to select the appropriate piston for the liner

The outlet serves as a support for the hand. For convenience, you can take a tee and plug one side of it.

Option #3 – furnace that creates a pressure difference

The craftsmen whose idea was embodied in this miracle of engineering called their brainchild a “pump furnace.” They, of course, know better, but at the initial stage of its operation this pump looks like a samovar. However, it doesn’t really heat the water, but creates a difference in pressure, due to which its work is carried out.

For such a pump you need:

- steel barrel 200 liters;

- Primus or blowtorch;

- pipe with tap;

- mesh nozzle for hose;

- rubber hose;

- drill.

The pipe with the tap must be cut into the bottom of the barrel. Close the top of the barrel with a screw cap. A hole is pre-drilled in this plug and a rubber hose is inserted into it. The mesh nozzle is needed to close the second end of the hose before it is lowered into the reservoir.

Recent Entries

Lilac perennials that are beautiful, compact and do not crowd out other plants Why when buying seedlings you should not take the sellers’ word for it and how to determine the age of the plant using 3 signs Tomato seedlings have turned purple or whitish: why the color has changed and how to save the plants

This version of the pump can even be called ingenious and, most importantly, this “device” will probably work well

Approximately two liters of water are poured into the barrel. A heating element (primus stove or blowtorch) is placed under the barrel. You can simply light a fire under the bottom. The air in the barrel heats up and exits through a hose into the reservoir. This will be noticeable by gurgling. The fire is extinguished, the barrel begins to cool, and due to the low internal pressure, water from the reservoir is pumped into it.

On average, it takes at least an hour to fill a barrel. This is provided that the hole in the hose has a diameter of 14 mm and a distance of 6 meters from the place from which the water is to be raised.

Design #3 – manual pump with side spout

The previous design has one, but significant drawback. The spout moves with the stem. This design is not much more complicated, but much more convenient.

The sleeve needs to be improved. Add a 50mm PVC tee to the design with a 35 degree bend. The tee must be inserted into the upper part of the sleeve. In the rod, near the piston, we drill several large-diameter holes, the main thing is not to overdo it and not to disturb the rigidity of the entire structure.

The piston moving upward pushes the liquid into the outlet pipe. The top cover serves as a support for the piston rod

Now water will begin to pour into the space between the rod and the sleeve. When the piston moves upward, water will begin to flow into the spout.

Design #4 – piston well pump

This pump design is suitable for wells no more than 8 meters. The operating principle is based on the vacuum created by the piston inside the cylinder. A useful homemade product can be an excellent alternative to factory-made pumping equipment and will help solve the problems of water extraction for servicing a summer cottage.

In such pumps, the top cover is either absent or has a slot-like hole, since the rod is rigidly connected to the handle

Necessary materials:

- metal pipe, diameter 100mm, length 1m;

- rubber;

- piston;

- two valves.

The performance of the pump directly depends on the tightness of the entire structure.

You will find a detailed description of the manufacturing process of a piston pump for use in a summer cottage in one of the popular articles on our website.

Step #1: Assembly of the unit sleeve

To make a pump sleeve, you need to pay attention to the inner surface; it must be even and smooth. A good option would be a liner from a truck engine.

From below, a steel bottom needs to be welded to the sleeve along the diameter of the well head. Either a reed valve or a factory valve is installed in the center of the bottom.

A cover is made for the top of the sleeve, although this part is more aesthetic, you can do without it. It is necessary to pay attention to the fact that the hole for the piston rod is made slot-like.

Step #2: Construction of the Pump Piston

For the piston you need to take 2 metal disks. Between them lay not very thick rubber 1 cm, slightly larger in diameter than the disks. Next, we tighten the disks with bolts.

As a result, the rubber disk will be clamped and a sandwich of metal and rubber should be obtained. The idea is to create a rubber rim along the edge of the piston, which will form the necessary piston-liner seal.

All that remains is to install the valve and weld the eye for the stem.

Step #3. Making a petal valve from rubber

The reed valve consists of a rubber disc of not very thick thickness. The disc size should be larger than the inlet holes. A hole is drilled in the center of the rubber. Through this hole and a pressure washer, the rubber disk is secured over the inlet holes.

When sucked, the edges of the rubber rise and water begins to flow. During the reverse stroke, clamping pressure is created: the rubber reliably blocks the inlet holes.

Step #4: Final Assembly and Installation

It is advisable to cut a thread at the head of the well and at the bottom of the pump sleeve. The thread will allow the pump to be easily removed for maintenance and will make the installation sealed.

We install the top cover and attach the handle to the rod. For comfortable work, the end of the handle can be wrapped with electrical tape or rope, laying turn to turn.

If the pump does not pump water, it is necessary to eliminate all leaks, including in connection with the well head (+)

The limitation on the depth of the well is due to the theoretical impossibility of creating a vacuum of more than 1 atmosphere. If the well is deeper, you will have to modify the pump to a deep pump.

Option #4 – black grille for sunny weather

This product will require special devices. Where, for example, do you get a black grille, the hollow tubes of which contain liquefied propane-butane? However, if this part of the problem is solved, the rest does not cause any particular difficulties. So, there is a grille, and it is connected to a rubber bulb (balloon), which is placed in a can. There are two valves in the lid of this can. One valve lets air into the container, and through the other, air with a pressure of 1 atm exits into the air duct.

It’s really better to make the grate black, because black products always heat up more actively under the bright summer sun

This is how the system works. On a sunny day, water the grill with cold water. Propane-butane cools, and the gas vapor pressure decreases. The rubber balloon is compressed, and air enters the can. After the sun dries the grate, the steam will again inflate the bulb, and pressurized air will begin to flow through the valve directly into the pipe. The air plug becomes a kind of piston that expels water through the shower head onto the grate, after which the cycle repeats.

Of course, we are not interested in the process of watering the grate itself, but in the water that collects under it. Experts say that the pump functions perfectly even in winter. Only this time, frosty air is used as a coolant, and the grate is heated by water extracted from the ground.

Design #5 – deep-well piston pump

The difference from a conventional piston pump is that the pump sleeve must be installed at the depth of the well. In this case, the length of the rod is more than 10 meters.

The sleeve of such a pump can serve as a wellbore, and the role of a spring can be played by a suspended load (+)

There are two ways to solve this problem:

- Make the rod from a lighter material, for example, aluminum pipe.

- Make a rod from a chain.

The second option requires some explanation. In this case, the rod is not rigid. The bottom of the liner is connected to the bottom of the piston by a return spring.

Design #6 – American or spiral type

The spiral pump uses the energy of the river flow. To operate, the minimum requirements must be met: depth - at least 30 cm, flow speed - at least 1.5 m/s.

Option 1

Necessary materials:

- flexible hose d.50mm;

- several clamps according to the diameter of the hose;

- intake – PVC pipe 150mm;

- wheel;

- pipe reducer.

The main difficulty in such a pump is the pipe reducer. This can be found in decommissioned sewer trucks or obtained from factory equipment.

For greater efficiency, an impeller is attached to the pump

The flexible hose is attached to the wheel in a spiral using clamps. An intake made of PVC pipe 150mm is connected to one end. The second end of the hose is put on the pipe reducer.

Water is taken in by the water intake and moves in a spiral, creating the necessary pressure in the system. The lifting height depends on the flow speed and the immersion depth of the intake.

Option 2

Necessary materials:

- flexible hose d.12mm (5);

- plastic barrel d.50cm, length 90cm (7);

- polystyrene foam (4);

- impeller (3);

- sleeve coupling (2);

We cut an intake hole in the bottom of the barrel. Inside the barrel, it is necessary to lay the hose tightly in a spiral and connect it to the sleeve coupling.

Inside the barrel, the hose is laid tightly, pressed against the walls with a strip. The barrel can be metal with foam floats

To impart buoyancy, foam floats must be glued inside the barrel. Finally, screw on the impeller.

For this design option, the drain hose must be 25 mm. in diameter.

Design #7 – wave energy pump

As the name suggests, such pumps use wave energy. Of course, the waves on the lakes are not that big, but the pump works around the clock and is capable of pumping up to 20 cubic meters per day.

Option 1

Necessary materials:

- float;

- corrugated pipe;

- two valves;

- mounting mast.

The float is a pipe, a log, selected depending on the rigidity of the corrugated pipe, experimentally.

Corrugated pipe can be made of plastic or metal. The weight of the log must be selected experimentally

Two valves operating in the same direction are mounted in a corrugated pipe.

As the float moves downwards, the corrugated pipe stretches, resulting in water intake. When the float moves up, the corrugation contracts and pushes the water up. Therefore, the float must be quite heavy and large.

The entire structure is rigidly attached to the mast.

Option 2

This design differs from the first option in that the corrugated pipe is replaced by a brake chamber. This diaphragm-based scheme is very often used in simple DIY water pumps. Such a pump is quite versatile and can receive energy from wind, water, steam, and sun.

The brake chamber should be disassembled and only two holes left for the valves.

Instead of homemade valves, you can use ready-made plumbing valves. The washers must be of sufficient diameter so that the diaphragm does not tear (+)

Manufacturing suitable valves is a separate task.

Necessary materials:

- copper or brass tube;

- balls of slightly larger diameter - 2 pcs.;

- spring;

- copper strip or rod;

- rubber.

For the inlet valve, cut off the tube and drill it out so that the ball sits tightly on the tube. It is necessary to ensure that the ball does not allow water to pass through. To prevent the ball from falling out, solder a wire or strip on top.

The design of the exhaust valve differs from the intake valve in the presence of a spring. The spring must be installed between the ball and the copper strip.

We cut out a diaphragm from rubber to the size of the brake chamber. To drive the diaphragm, you need to drill a hole in the center and stretch the pin. We insert the valves from the bottom of the brake chamber. For sealing, you can use epoxy glue.

It is better to find non-metal balls for valves, so they will not be subject to corrosion.

Option 3

Based on the design of the two previous options, you can think about building a more advanced model.

It is advisable to choose a log that is dry and not resinous, so it will be lighter, pay attention to the absence of cracks

For this pump it is necessary to drive four stakes (1) into the bottom of the reservoir. Then make a float from a log. You need to make cuts in the log so that it does not rotate when swinging on the waves.

For durability, it is recommended to treat the log with a hot mixture of kerosene and drying oil. It must be done carefully, processed in a water bath: there should be no open flame.

The log travel limiters (3) and (4) are nailed in such a way that the log does not damage the pump rod (5) during maximum movement.

Conclusions and useful video on the topic

You can make your own pump, piston well pump, pumping mechanism and other pumping equipment. To do this, you will need materials and units that can be found in almost any garage. Suitable waste is from repairs, installation of plumbing systems, decommissioned equipment, etc.

The type of construction is determined by the conditions dictated by the situation. In some cases the driving force is the flow of the river, in others it is the vibrations of the waves. If these factors are not present, you will have to install a device that runs on electricity. And if this is not available, you can use a swing-type pumping mechanism. As a result, in any situation you can get out of the situation.

If the theoretical part is not enough, then videos can be used as visual aids. They tell in detail and show what and how to do to make the pump work efficiently. This will be in addition to the recommendations and instructions given earlier.

The described homemade water pumps can be used for various purposes:

- The equipment will help organize watering in your garden plot. Liquid from the reservoir is pumped into the tank.

- Distribution of water throughout the area. From the tank (even if it is dug into the ground), the liquid also needs to be pumped to the consumer, namely to the beds. You can use a pump for this.

- Fill the tank for industrial purposes. Water used for cooling or other purposes may not be taken from a centralized water supply system, but from a stream, lake, or reservoir.

These designs are of particular importance in cases where the problem needs to be solved urgently. So, for example, if the main pump fails, and it is not possible to repair it (or replace it) immediately. Moreover, most models do not require connection to an electrical outlet.

HelpfulUseless

Design #8 – device from a washing machine

Often, parts or even entire units from old things remain on the farm. You can remove a centrifugal pump from a washing machine that is no longer needed. This pump is perfect for pumping water from a depth of up to 2 meters.

Necessary materials:

- centrifugal pump from a washing machine;

- petal valve from a washing machine or homemade one;

- plug, bottle stopper;

- hose;

- preferably an isolation transformer.

If you use a ready-made valve from a washing machine, it needs to be modified. One hole needs to be plugged, for example using a bottle cap.

Excess pump holes must be plugged. If the case is metal, grounding is required

We connect the petal valve to the hose and lower it into a pit or well. Connect the second end of the hose to the pump. For the system to start working, it is necessary to fill the hose with the valve and the pump itself with water. All that remains is to connect the transformer, and the pump is ready for use.

How to make a hand pump for a well with your own hands?

Another manual well pump - a diaphragm - can be made on the basis of a brake chamber. Only one hole needs to be left in it, the rest are clogged. On the opposite side of the remaining open hole, it is necessary to make several holes in which check valves will be installed using epoxy resin.

The valves are made from thick-walled copper tube. At one end, its internal diameter is increased using a drill, after which a ball is placed here. Its diameter should be equal to the increased (reamed) diameter of the tube, as a result of which the narrow part of the tube will be clogged. Then a piece of wire is soldered to the drilled end of the tube so that it does not allow the ball to fall out - and the valve is ready.

Hand pump for raising water

Another valve is done in the same way, only a spring is soldered to the wire, which will hold the ball closed - you get a normally closed check valve.

All that remains is to install the valves in the chamber and glue to it a round rubber membrane cut from a car inner tube. A rod is secured in the center of the membrane with nuts, the free end of which is released into the hole in the brake chamber that is left open.

Design #9 – water pump from compressor

If you have already drilled a well and have an air compressor, do not rush to purchase a water pump. It will be successfully replaced by a structurally simple airlift device.

Necessary materials:

- spout pipe 20-30mm;

- air pipe 10-20mm;

The operating principle of the pump is very simple. It is necessary to drill a hole in the spout pipe and place them closer to the bottom. The hole should be 2-2.5 times larger in diameter than the air pipe. All that remains is to insert the air pipe and apply air pressure.

One of the most efficient and simple pumps, does not clog and can be assembled in 5 minutes

The efficiency of such a pump depends on the height of the water level, the depth of the reservoir, and the compressor power (performance). The efficiency is about 70%.

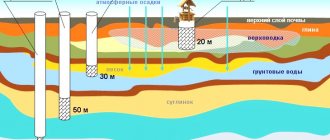

Types of hydraulic pumps

Manufacturers offer several types of devices for collecting water from aquifers:

Piston hand pump

Traditionally, this particular device is found in the areas. It effectively copes with the task of collecting liquid from shallow depths of up to 7-8 m. It is based on a working piston moving along a cylinder.

It is installed 1 m above ground level. Due to the mechanical control of the lever, the manual pump pump drives the piston. When moving in one direction, liquid is taken into the cavity; when moving in the opposite direction, a portion of water is sent upward. This is how pumping occurs.

Rod hand pump

A hand pump for water is used in areas for sampling from lower horizons of 7-30 m. The principle is similar to the operation of a piston pump, but the length of the “piston” (plunger) is much longer and resembles a drill rod.

Due to its significant dimensions, the plunger apparatus creates a vacuum at a low depth and supplies liquid upward through the inlet pipe.

Gate (rotary-plate)

It has low power and is often used for pumping liquids from barrels or open reservoirs. Outwardly they resemble a tube, at the end of which a pump with a rotor is mounted. It has high mobility unlike other varieties.

If necessary, it can be used in various operations, since it is light in weight, and a regular hose is used for sampling.

Membrane

The device is capable of pumping out even contaminated liquid. The design uses self-cleaning ball valves. This solution allows us to minimize the possibility of jamming of the mechanism. A special feature of such models is the absence of quickly wearing or rubbing parts. The body is made of cast gray cast iron.

When choosing a specific instance, you need to pay attention to the following models:

Hand pump for water at the dacha BSK

It is used without modernization at a horizon not lower than 6 m. When installing an additional check valve, it is capable of sampling from a 9-meter level. Aesthetic appearance allows you to decorate any area. For fastening, the structure has a flange that allows you to fix the device on a pipe or platform. Possibility of installation to a vertical surface is provided. The estimated cost is 4800 rubles.

Hand pump for water at the dacha D-40

D40, Membrane (diaphragm)

Membrane type device. Capable of self-cleaning from possible contamination. Effectively copes with pumping liquids of any type. The cost is 6300 rubles.

Hand pump for water at the dacha RNP 1.3/30

Used in liquid media, including contaminated liquid. Capable of passing contaminants up to 1 mm in diameter. The maximum maximum concentration of pollution should not exceed 30 g/m3. Operates at a horizon of up to 5 m. The body is made of cast iron. The stroke type is double-sided, which increases the performance of the device. The cost is 16,200 rubles.

Hand pump for water at the dacha “K” (impeller)

Used for depths up to 9 m. The design includes 4 valves and a wing. Working with the handle, the operator alternately opens and closes the valves through which the liquid is supplied. The cost of the product in a steel case is 3,100 rubles.

A manual pump for pumping should be in any household. This small alternative device will successfully replace the pumping station in the event of an unauthorized power outage. It will also be useful in case of failure of pumping equipment. This will make it possible to pump up the volume, albeit in a limited quantity, but not be left without it at all.

Design #10 – gear water machine

The heart of this design is gear pumps for pumping oil from agricultural or truck equipment. The power steering power plant from KrAZ has similar characteristics.

Unit characteristics:

- pump working volume – 32 cm3;

- maximum pressure – 2.1 Atm;

- operating speed – 2400 rpm;

- maximum permissible rotation speed – 3600 rpm;

- nominal pumped volume – 72 l/min.

If possible, a motor from a washing machine is connected to such a pump. The motor of household appliances has a number of advantages: it runs on a single-phase 220V network and has a starting system (capacitor).

Gear mechanisms can be left- or right-handed, you need to pay attention to the direction of the arrow on the body

Pulleys and a belt may be required to obtain the required RPM. The advantage of a gear pump is that the gears are able to create the necessary suction force even without first filling it with water.

The only note: after operating the pump, to prevent corrosion of the steel gears, it is necessary to let the pump run idle for about 20 minutes.

Electric pump

How to make a water pump with your own hands so that it works from the network? It is necessary to prepare a 12V engine (possibly from a car window washer);

Sequence of steps:

- Remove the cover from the motor and disconnect a couple of contacts.

- Using soldering, attach the wires to them and bring them out through the cover.

- Place the cover on the motor. For reliability, coat with sealant.

- Carefully remove excess from the pump body and cover.

- Attach a silicone tube to the nozzle. Connect the pump to the power supply. Testing can begin.

Check it out here too!

Do-it-yourself hot smoked smokehouse: 100 photos, review of the best drawings, project selection and construction options- How to make a cage for a parrot: basic requirements, tools and materials, step-by-step photo instructions. Tips from experts on arranging a cage

- Do-it-yourself trolley - how and from what to build a decorative and tool trolley (135 photos and videos)

In conclusion, we note that there are a lot of pump modifications. Whichever one you choose for DIY assembly, be patient and careful.

Do not hurry. Try to think everything through carefully. This will give you confidence that the unit you assemble will serve you for many years.

Design #11 – pump from a bicycle wheel

Productive pump based on two wheels.

Necessary materials:

- PVC sewer pipes and outlets;

- bicycle wheel;

- nylon rope;

- small pulley;

- several pistons;

- mounting rod.

The operating principle of this pump is similar to that of a dragline.

First you need to build a sleeve from a sewer pipe that will be immersed in water. A drain is placed on the top of the sleeve through which water will flow. Next, install a small pulley on the bottom (a wheel rim from a wheelbarrow will do) and a bicycle wheel on top.

We attach a series of pistons along the entire length of the rope, first passing them through the sleeve. The rope should go around the pulley and the bicycle wheel.

The device is very effective, especially if you use a bicycle drive. It will be much easier to twist your legs.

By rotating the bicycle wheel, each piston on the rope captures water and, like an elevator, lifts it upward. The water column pours into the outlet.

Design #12 – “homemade” for a small stream

This pump can operate on an ultra-low amount of energy. Of course it’s good if there is a river or lake. But what to do if the river becomes very shallow in the summer? A swing type pump will help.

Such a pump allows you to use very small amounts of energy from a small stream.

The main part of the structure is two buckets rigidly connected to each other through blocks (4). It is necessary to make a drainage system from the stream from galvanized steel (3). In order to reduce wear, a piece of plastic is placed under it. The drainage system is rigidly connected by a leash to a rope (5).

Leash 6 is made of rigid wire and the length is calculated so that the drainage system moves to the desired angle

The entire system must be adjusted so that when one bucket is filled, the drainage moves to the second bucket. The energy of the buckets is transmitted through the crank (8) to the pump (10).

Features of drains

If the septic tank or cesspool is not cleaned in a timely manner, this can lead to serious problems. As a result, the throughput capacity of the soil may deteriorate, which will lead to the accumulation of large amounts of wastewater in the tank.

To collect wastewater from a country house or dacha, a cesspool is built on the site or a septic tank is installed. In any case, it is necessary to periodically pump out silt deposits and solid impurities from this structure. Even when using a modern multi-chamber septic tank, in which bacteria are responsible for processing waste, periodic cleaning of sewage waste will be required.

It’s good if there is free access for a sewage disposal truck to the treatment plant. Otherwise, you will have to use a factory-made or homemade fecal pump. In any case, the installation of such equipment must be carried out according to all the rules, so when doing the work yourself, it is worth familiarizing yourself with the nuances and sequence of installation.

If the septic tank or cesspool is not cleaned in a timely manner, this can lead to serious problems. As a result, the carrying capacity of the soil may deteriorate, which will lead to the accumulation of a large amount of wastewater in the container. The accumulated wastewater will spill onto the site and cause deterioration in the sanitary condition of your site.

Design #13 – Shukhov wick pump

The Russian inventor Shukhov became famous for many buildings, including the radio tower in Moscow. Below we will discuss another of his inventions - a water pump.

Pulleys are made composite. The depth of the groove should be slightly less than the swollen rope

The pump uses a special rope to operate. This rope consists of woven cotton threads with a total thickness of 5-6 mm, enclosed in a sheath. The thread is passed through the pulleys.

When movement occurs, the rope gets wet and wraps around the pulleys. The pulley (5) with the help of a spring (4) presses the rope against the pulley (3) with force. The squeezed water flows into the tray (7). Figure “c” shows sections of pulleys (3) and (5), respectively.

To operate the entire system, an electric motor of only 5-10 watts is required. Typically, such engines have 1500 rpm.

To reduce speed and increase force, you can use a worm gear, shown in figure “c”. It is quite possible to make it by hand. To do this, you need to find a suitable gear and make a worm from wire. Small forces on the shaft allow manufacturing inaccuracies.

With your own hands you can assemble not only a pump that pumps water for domestic needs, but also a device that can be successfully used in landscaping a site. The following article will present successful options for homemade fountain pumps.