Will tee or collector distribution of water supply pipes in an apartment be better? In order to answer this question, you should not only carefully study the installation principle in both cases, but also evaluate the pros and cons of each option. Comparing the features of installation and operation with the conditions of a specific facility (house or apartment) will allow you to make the optimal choice. The importance of choice cannot be underestimated - the ease of use of water supply systems (hot and cold), durability and maintainability of communications depends on it.

What is a collector?

When installing a water supply system from scratch or replacing an old one, you need to think about the location of all consumers: toilet, washbasin, washing machine.

In a typical apartment, the number of plumbing fixtures varies from four to ten. Experienced plumbers recommend their customers to install a water collector.

A water collector is a kind of distributor, which is an important plumbing element of a cold and hot water supply and heating system. It is installed on the central riser and hidden in the plumbing closet. Access to the distribution comb should not be blocked by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Collector design and principle of operation

The direct function of a collector in a water supply system is to distribute one water flow into several flows of equal pressure.

Combs with two, three and four outlets are available. If more branches are needed, the distributors are connected to each other. In this way, a water supply collector is assembled for the required number of outlets.

The collector is connected directly to the riser. On two opposite sides of the device there is a threaded connection (internal thread on one side, external thread on the other) for connecting to the main line and connecting the combs to each other.

A plug or an additional plumbing device, for example, a membrane water hammer absorber, is installed at the free end of the collector.

The diameter of the inlet hole is 20-40% larger than the outlet hole. For example, on a standard manifold for installing water supply in an apartment, the diameter of the inlet hole is 3/4 inch, the outlet hole is 1/2 inch.

1. Manifold with valves. 2. Manifold with ball valves.

Both ball valves and valves can be installed at the outlet openings, allowing not only to open and close the water flow, but also to regulate the power of the flow in this area.

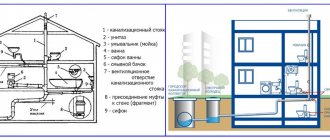

Scheme

First of all, it is necessary to correctly draw up a wiring diagram for the future system.

It itself assumes that all pipes will be connected to the manifold through special ball valves.

This makes it possible to carry out repairs on the damaged area without covering all the others. Also, this scheme allows you to distribute the pressure in the system evenly between all devices. But at the same time, the price of this system is very significant, and the distribution link itself also takes up a lot of space.

On paper it is necessary to draw not only the wiring diagram, but also all, even seemingly insignificant points, which include:

- installation locations, as well as dimensions of plumbing fixtures;

- the exact length and position of all pipes;

- places of turns, as well as bending angles of pipes;

- where water filters and meters will be located;

- the maximum possible diameter of communications in each location;

- number of fittings.

This is important: you can begin and carry out all stages of installation only after complete disconnection from the central water supply.

Why do you need a collector?

A water supply system with a separator and a separate pipe supply to each consumer will cost more than a classic wiring. Is it worth overpaying for a collector for water and heating?

- The device is used to regulate water pressure in the apartment. In standard wiring, the pressure in an open tap often decreases if someone opens another tap or flushes the toilet. This threatens not only discomfort, but also burns due to too hot water, which suddenly begins to flow. The well-thought-out diameter of the manifold eliminates pressure problems. No matter how many taps are open in the apartment, the water pressure remains the same.

- There are taps at each outlet that allow you to regulate the flow of water along the branch. If the mixer is being repaired, it is not necessary to completely turn off the supply of cold and hot water from the risers. It is enough to switch only a certain branch.

- The absence of joints and tees built into the wall minimizes the risk of leaks. If a faucet or fitting fails, it can be easily replaced by disassembling the manifold system in the cabinet. The lining in the bathroom will not be damaged.

- If you need to add another consumer to the water supply system, you will not have to redo the entire wiring. Connection will be inexpensive and will not require much time.

When installing a water supply system using a collector, its cost increases. The number of pipes to the collector, be it metal, metal-plastic, polypropylene or cross-linked polypropylene, compared to tee wiring, increases by 8-10 times. However, modern pipes, especially metal-plastic and polypropylene, are not very expensive, so such a system is available to most residents.

Protection against water hammer in the apartment's water supply system.

To protect the apartment's water supply system from water hammer in the collector system, it will be necessary to install a water hammer compensator. Such a compensator is a kind of damper and the pressure surge is absorbed in it. The compensator consists of a piston and a spring; when the tap is suddenly closed, the excess pressure is compensated by the spring-loaded piston.

It's worth remembering, however. Such a compensator should be located where water will constantly circulate past it, otherwise water will stagnate in this area and pathogenic organisms will begin to develop. Those. It is impossible to remove the compensator on a blind pipe from the collector.

Reservoir classification

Separating combs for water supply differ in both their design and materials. Before choosing a collector, study the entire range on the market.

Separators are made from different materials:

- Stainless steel is resistant to corrosion, fire and high temperature. The weight of the stainless steel collector is light, which makes it easy to attach it to the wall. This is an absolutely harmless material that gives the product an attractive appearance.

- Brass is an incredibly durable metal that is not afraid of corrosion and high temperatures. Brass combs are expensive, but they guarantee maximum strength.

- Dividers made of polypropylene are not afraid of rust and are lightweight.

Manifold made of polypropylene.

Some craftsmen can make a collector with their own hands from polypropylene pipes, which is in no way inferior in quality to factory products.

Collectors differ in the way the pipes are attached. Depending on the material of the pipes used, the comb model is selected.

1. A comb for installing taps and any plumbing fixtures at your discretion. 2. With compression fittings - designed for installation of pipes made of metal-plastic or cross-linked polyethylene. 3. For installation of polypropylene pipes. 4. Under the Eurocone. Suitable for installing pipes from almost any material through an adapter (Eurocone).

Separating combs differ in the number of bends. Minimum – 2 outputs, maximum – 6. Bends that are not currently in use can be closed with plugs. If it is necessary to make more than 6 outputs, several collectors are connected to each other.

Pipe selection

The arrangement of the water supply network begins with the selection of pipe materials. Recently, domestic steel mains are not often installed. This material has already lost its popularity.

Its place was taken by cheaper and more practical structures made of plastic and metal-plastic. You can also use copper water supply systems, but their too high cost in this option causes the rejection of this material.

- Copper. Despite its many positive properties, this highway is not without some disadvantages. The first is harmful cuprous oxide, which is formed upon contact with an aqueous environment. Secondly, tin is used in solder when soldering. This material turns into powder over time, causing the joint to leak.

- Metal-plastic. This material does not belong to the line of cheap materials, but it can be joined without the use of special tools. The laying of such a pipeline is permitted in an open area, where the joint can be quickly redone at any time.

- Plastic. These systems are called plumbing design standards. But plastic is different. And in order to make the right choice, you need to know the properties and features of these materials. For example, a material such as polybutylene (PB) is distinguished by optimal thermal conductivity. Joints made of this type of plastic are absolutely reliable.

Polyethylene (PE) is not an expensive material, but for hot water supply (DHW) you will have to install reinforced products.

Despite significant disadvantages, this material has a very significant advantage of not bursting after freezing. Therefore, such a highway works successfully indoors without heating or outdoors. Polyvinyl chloride (PVC) is chemically resistant, but fragile and degrades when exposed to ultraviolet light. Polypropylene pipework for arranging water supply in an apartment will not be very expensive. This water supply line is currently used more often than others. This material is distinguished by its strength and durability.

The soldered polypropylene joint on the wiring reliably withstands pressure loads of up to 12 atmospheres, and is not much different from the base material. In a city pipeline there can be up to 6 atm, so this range is ideal for polypropylene wiring in an apartment. The routing of pipes for water supply in an apartment where polypropylene is used is characterized by higher hydraulic resistance than previous analogues and increased thermal stability.

When describing the characteristics of polypropylene wiring, it is necessary to remember their disadvantages. Polypropylene has only two of them. First, polypropylene cannot be glued, and when welding, you need to use special equipment and strictly follow all plumbing technology. Secondly, polypropylene has a significant coefficient of thermal expansion, which must be taken into account when performing installation.

Watch the video

Which pipes to choose for water supply.

The installation of water supply pipes in an apartment where polypropylene is used is recommended by craftsmen as the only system at this time that, after proper installation, does not require constant maintenance. It is also necessary to add to the above that polypropylene is soldered at a lower temperature than other types of plastic.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

General installation tips

Before installing the pipeline, it is necessary to install all fasteners and complete welding work. Pipes that were stored or transported at sub-zero temperatures before installation are kept for at least 24 hours at temperatures above 10°C. Before starting installation, it is necessary to level them and prevent deflections in the future.

Pipes are secured to walls and supports with clamps or hooks. The distance from fasteners to threaded connections must be more than 5 cm

For water risers, pipes with an outer diameter of at least 20 mm are used, for floor wiring - with a diameter of 16 mm and 14 mm. It is better to use as few dismountable connections as possible. It is necessary that all connecting elements correspond to the type (series) of pipes and, like fittings and revisions, are located in accessible places.

Horizontal sections of the water supply system must have a slope towards the drainage fittings to allow water to drain; the slope is made towards the device through which air will escape when the system is filled with water. When installing vertical structures, do not allow them to tilt more than 2 mm per meter.

When installing the pipeline vertically, the hot water supply pipes are placed to the right of the hot water supply pipes. When installing horizontally, the cold water supply is placed below the hot water supply to avoid the formation of condensation.

Close the channels or embed the pipeline only after a test run of the system and checking it for operability, leaks and damage.

When operating a hot water supply, a phenomenon called thermal expansion occurs, which is especially typical for products made of polypropylene. This can cause pipes to lengthen, leading to damage and leaks.

Correct placement of fasteners and self-compensation of such pipeline sections as bends, turns, and “snake” gaskets prevent deformation.