When the plumbing works smoothly, no one pays attention to it, but as soon as problems appear, they have to be solved urgently. For example, if a pipe behind the toilet is leaking or another joint is leaking, it is unwise to ignore the situation, otherwise you can flood your own bathroom and flood your neighbors below.

Why does the corrugation leak in connection with the toilet, what other joints can water seep in, and what can be done to fix the problem? Now we will tell you everything so that you can repair the toilet yourself if necessary.

- What to do if there is a leak under the toilet

- How to fix a leak in a corrugated toilet

- Loose bolts are a common cause of leaks under the toilet.

- A pipe is leaking in the toilet behind the toilet: what to do?

Installing corrugation on a toilet - subtleties and nuances

The process of installing a corrugation is very closely related to the installation of a toilet - you cannot install a toilet and then connect it to the sewer with a corrugation. Everything will have to be combined and done in a strictly defined sequence.

- To begin with, the corrugation must be pulled over the toilet outlet. It is very easy to put on, but nevertheless, careless movements can lead to damage to the product. If you smear the sealing rubber in the socket with soap, the corrugation will fit onto the socket easily, with minimal effort - in any case, you need to tighten it with a twist.

- Next, we move the toilet to the sewer socket and insert the corrugation into it, after which we position the pot in the desired position and mark its attachment points.

- We remove the corrugation from the sewer socket. We drill holes for fasteners in the floor and return everything to its place, inserting the corrugation into the sewer.

- Now, after a test flush, when you are convinced that there are no leaks, the toilet bowl can be thoroughly fixed to the floor. In principle, that’s all, but there is one subtlety - in order for the rubber to properly seal the connection between the corrugation and the old cast iron sewer, the socket of the latter must be very well cleaned of rust and old seal. There are no other nuances here, and you will not need any additional sealing of the seams with silicone. It is not needed here - silicone spoils the rubber over time, so you should completely forget about it.

To conclude the topic about why a toilet corrugation is needed and how it is installed, I will say a few words about replacing the old, leaky corrugation with a new one. Such repairs are carried out very simply, without even having to remove the toilet. First, squeezing the corrugation like a spring, the liner must be disconnected from the toilet. Then, accordingly, pull it out of the socket. The new corrugation is installed in the reverse order - first it is inserted into the socket, then it is compressed and pulled onto the toilet. This is where the superiority of corrugated pipes over rigid toilet connections lies. Yes, I completely forgot - such a trick is only possible if in the established position the corrugation is stretched and not compressed to the limit. This point should not be overlooked during the initial installation of a plumbing fixture.

The junction of the inlet fittings with the drain tank

This is a fairly common problem in which the toilet leaks from below. It is often confused with the formation of condensation on the surface of the tank.

Important! If the leak is not eliminated for a long time, a dark smudge forms at the junction.

How to fix the problem:

- Using a wrench, tighten the inlet fitting nut to the tank if the reason is a loose gasket.

Important! This is especially true for tanks with a bottom supply.

- If the gasket is completely missing or worn out, turn off the water and disconnect the nut with the hose. Buy the same gasket that was installed and replace it.

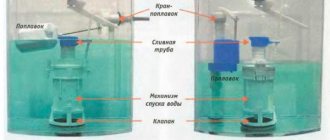

- In tanks with side inlet, leakage occurs from improper adjustment of the shut-off valve. Because of this, the water level in the tank is too high. Open the tank lid, then tighten the fixing screw and lower the float a little. The water will thus be shut off before it reaches a critical level.

Important! While working on the float, also check the condition of the sealing gasket. If necessary, replace it with a new one.

- Fuzzy operation of the diaphragm valve due to errors in the assembly of water intake fittings. Simply dismantle the fittings and check the condition of all threaded connections.

- Worn diaphragm valve. This malfunction can be eliminated by completely replacing the shut-off valves. On average, the replacement frequency is 1 time every 5 years.

Corrugation for toilet: advantages and disadvantages

If we compare the corrugation for a toilet flush with the old technology for connecting this plumbing fixture to the sewer system, then we can highlight at least a couple of global advantages.

- First of all, this is the speed of installation. If previously you had to wait for the sealant to harden, then in the case of a flexible outlet the toilet can be used immediately after connecting to the sewer.

- Versatility. The flexible corrugated outlet allows you to rotate the toilet bowl relative to the drain hole at almost 90 degrees in any direction. There is only one limitation for it - the outlet does not allow the toilet to be brought closer to the wall when installed directly. Well, there are other products of this type for this purpose.

- Reliability. It is ensured by a well-thought-out system of rubber seals. At such a connection, the joint leaks only in two cases - when the corrugation is installed incorrectly and when the sealing rubber dries out over time.

You can see what a corrugation for connecting a toilet is in this video.

This product also has disadvantages, which are caused not by the idea of the product itself, but by the quality of its manufacture - cheap products of this type can burst even before installation. This happens in the inept hands of a master, but it also happens due to the quality of the plastic. In general, you don’t need to buy cheap products, and everything will be fine.

Tighten loose bolts

Another reason when a toilet leaks at the junction is the loosening of the tank mounting bolts. They are usually metal or plastic. While the former can rust and break, the latter simply burst over time due to static load or if someone rests on the tank.

The problem is solved by replacing the bolts with new ones, and to do this you need to proceed as follows:

- turn off the water supply to the tank and empty it;

- unscrew the flexible supply hose;

- remove the bolts (if they are rusty, this will not be easy, but be careful not to damage the fragile tank);

- insert new bolts with spacers into the holes and tighten (just do not overdo it).

If it is still leaking at the joint, you will need to tighten the bolts a little more to seal the toilet. The main thing is not to squeeze it so that nothing bursts or cracks.

Corrugation for toilet installation technology

Author Anna Kmeta July 16, 2013

Few people remember that previously the entire sewer system was a cast iron structure, the main advantages of which were strength and reliability. Despite this, it had to be abandoned due to frequent pipe blockages, which could only be removed by cutting. Over time, toilets and their components have undergone many modernizations, which entailed changes in the cross-section of pipes, their length, and so on. All this led to the impossibility of using standard cast iron networks. In the modern world, not only new toilets have come to the aid of plumbers, but also their components, which are now made of plastic or rubber without sacrificing quality. One such device is a toilet corrugation. Let's consider the features of installing corrugations and their main characteristics.

What is a toilet corrugation?

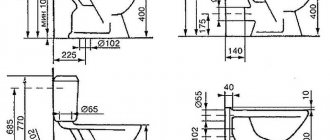

A toilet corrugation is a flexible corrugated pipe that is attached to the base of the toilet flush hole and the socket of the sewer riser. It has the following features:

- inside the corrugation has an absolutely smooth surface, which prevents the accumulation of debris and, as a result, blockages;

- to increase the density of the pipe and prevent its breakthrough or cracking during casting, steel threads are used;

- high-quality corrugation for a toilet cannot cost a penny, so it is better not to skimp on this plumbing item in order to avoid unforeseen situations and frequent repairs;

- This type of plumbing pipes is perhaps the only plumbing fixture that allows you to place the toilet in the planned position, which does not always meet established standards. It often has a curved shape.

Installing a toilet corrugation

The development of a corrugated pipe has made the installation of a toilet much easier, since now there is no need to remember the dimensions of its socket and the diameter of the riser. The toilet corrugation is equipped with sealing rings that are easy to tighten to avoid leaks. So, let's look at the procedure for installing the corrugation:

- One end of the pipe must be placed on the toilet drain hole, which must first be cleared of debris. To make the connection more tight and prevent the appearance of unpleasant odors, it is recommended to lubricate it with plumbing sealant, preferably silicone. It is imperative to ensure that the pipe is evenly fixed around the entire circumference. Then you need to wait a little for the sealing solution to dry.

- Place the toilet in the place where it is planned to be placed so that it does not rock.

- The second end of the toilet corrugation must be pushed into the sewer socket until it stops, having first cleaned the pipe of dirt and coated it with sealant.

- After the silicone has dried, you need to pour several buckets of water into the toilet to control the strength of the installed corrugation. If it does not leak, there are no cracks or sagging on it, you can use the toilet.

The toilet corrugation can only be replaced if it leaks or is damaged. On average, its service life reaches 15 years.

Tips and recommendations for further care

Successful operation of sewerage in an apartment building depends on the choice of pipes. Care is related to the characteristics of the material used. Plastic is sensitive to high temperatures. For normal work at home, it is recommended that the drain temperature be 40 degrees, short-term - up to 60 degrees, otherwise the material loses its properties and the pipe may leak.

Deposits also form on smooth surfaces of PVC products. Together with the drainage of hot water, they turn the cross-section of the pipes into an ellipse, which leads to a loss of throughput. Polyvinyl chloride is a flammable material, so fire safety rules must be followed. Aggressive substances corrode the connections and walls of the corrugation; it is not recommended to drain them into the sewer.

Types of corrugations for toilet bowls, their features and purpose

Apart from variations in size, the corrugation for a toilet bowl can be classified according to only three criteria.

- According to the degree of reliability. In this regard, we can distinguish between reinforced and non-reinforced corrugation for the toilet. What is the difference between them? In short, the reinforced corrugation (in its folds) additionally contains metal wire. In more detail, this wire prevents the corrugation from bending more than necessary, and at the same time breaking in the folds. This corrugation lasts several times longer and at the same time costs only slightly more than its non-reinforced counterpart.

- According to the degree of rigidity - based on the thickness of the plastic used to make the corrugation. Despite the fact that hard corrugation is reliable and durable, soft corrugation is still widely used, since working with it is much easier and more convenient.

- According to the direction of the bell. In this regard, three more variants of products of this type can be distinguished - corrugation with a straight bell, bent at 90 and 45 degrees. The first is considered universal. The second allows you to connect a direct-outlet toilet to a drain coming out of the floor. And the third is mainly used to connect the toilet to a horizontal sewer pipe located low above the floor. In general, these varieties are designed for various situations and none of them are completely universal, no matter how much one would like it.

All these points, or rather varieties, must certainly be taken into account when choosing corrugation - or rather, they must be correlated with local circumstances, on the basis of which the choice of one or another variety of corrugation is made

Particular attention should be paid to the length of the product - in the sense that you should not purchase a short corrugation in the hope that it will stretch. It may stretch, but then it can just as easily shrink back, forming a leak.

Everything should be in moderation.

How to fix a leak

To begin the repair, you need to prepare the toilet. Before the procedure, be sure to turn off the water supply by tightening the riser valve. The plumbing fixture unscrews the drain button, carefully lifts the lid and puts it aside. Further actions depend on the problem.

Tank is full

When the tank is filled, the compensating device constantly drains moisture. To determine if it is broken, you need to lightly hold the float with your fingers. If, when raised a couple of centimeters, the liquid continues to flow, then the problem is hidden in the module. If damaged or low installed, the part will not function properly. You can correct the position by bending the lever.

If moisture oozes out after lifting the float, then you need to carefully examine the valve. The fixing pin must be smooth, without deformation or corrosion. In operating mode, the part stands inside the structure and holds the lever. It is better to replace a failed element with a new one, or, in extreme cases, with large copper wire.

Finding the problem when it breaks Source saucyintruder.org

If there is no damage to the stud visible to the naked eye, we recommend checking the hole with which the component comes into contact. Moisture can leak when the well is deformed. The solution to the problem is to replace the valve mechanism.

If liquid flows into the toilet after flushing, then it is worth checking the seals. Carefully press the rubber gasket against the valve, trying to achieve maximum sealing tightness. If there is no leak, adjust the fit of the elastic part or replace it with a working one.

Toilet leaking causes and solutions

If water is leaking in the toilet, then the problem needs to be fixed as soon as possible, since constantly leaking water can cause flooding of your apartment and the apartment of your neighbors living below. All repair work can be done independently.

Plumbing product malfunctions

The main causes of leakage

If water appears on the floor of the toilet room, the reasons may be:

- wear of the gasket installed between the toilet bowl and the flush cistern;

- worn gaskets on the fastening elements of the tank;

- loosening of the threaded connection between the inlet and the float valve located in the drain tank;

- rupture or displacement of the corrugated hose connecting the toilet outlet to the sewer pipe.

Methods for eliminating leaks

How to fix a toilet leak? First of all, it is necessary to find out what caused the puddle to form. To do this, simply drain the water in the toilet and visually determine the location of the leak. If you can’t determine it visually, you can feel each element of the system with your hands. Moisture will appear at the leak site.

Replacing the gasket between the bowl and the tank

If the toilet runs, but no chips or cracks are found on the flush cistern during a visual inspection, then the reason lies in the wear of the gasket located between the toilet bowl and the cistern. Troubleshooting occurs according to the following scheme:

- the water supply to the toilet is cut off;

- The water is completely drained from the cistern. It is recommended to remove any remaining water with a cloth;

- the hose supplying water to the tank is disconnected;

Disconnecting the line from the toilet tank

- the bolts securing the tank are loosened;

What will the job require?

- Silicone sealant (or polyurethane foam).

- Screwdriver.

- A new part to replace the broken one (if necessary).

- Hammer.

- Burlap or twine.

- "Sandpaper."

- Drill, set of drills.

- Turbine (angle grinder).

- Pliers.

- Knife.

Angle grinder (impeller)

Now that we've sorted out the tools, the hardest part remains - identifying the cause of the leak. There can be many of them, it all depends on the location of the leak.

Prices for silicone sealant

silicone pipe sealant

How to prevent the problem

Preventative measures will help avoid plumbing leaks after draining. Professionals advise monitoring the condition of the devices and following the operating rules. It is forbidden to place heavy objects on the seat and pour boiling water into the earthenware bowl.

How to prevent the problem Source zen.yandex.com

A small leak in the tank mechanism increases the daily fluid consumption by 50 liters. Regular inspection will help prevent the problem:

- fittings;

- fasteners;

- valves

Damaged or deformed parts must be replaced and the nuts periodically tightened. The internal walls of the tank and mechanisms are cleaned of dirt, corrosion and limescale once every 6 months. In the toilet, sudden temperature changes and condensation should be avoided.

Cleaning the walls of the tank Source youtube.com

Important Details

Despite the advantages listed above, plastic corrugation is not designed for heavy loads, so installing it in a wall is excluded. If the distance to the toilet is significant, you need to choose the correct length of the adapter.

Otherwise, excessive stretching will thin the already thin walls, which will lead to rapid wear of the water fittings.

The corrugation should not be stretched before installation to prevent the outlet from sagging.

Stretching should be done immediately before connecting to the sewer drain. To avoid blockages in the future, it is important to avoid counter-slope and sagging of the corrugation. If necessary, a support is installed under the pipe. You should always remember that heavy and sharp objects can damage a corrugated plastic pipe.