Sewage pumping station (SPS) is a hydraulic structure for pumping domestic, storm and industrial wastewater. It is installed between the plumbing components of the building and the sewer main (septic tank), when it is impossible to organize a gravity discharge. The size of the stations can vary from a small tank behind the toilet to huge underground structures serving an entire village or region. The latter are of little interest to us - they are mainly ordered by the state. But modular sewage pumping stations, which can be installed on a site near the house, may be of interest to many.

Design and principle of operation of a pumping station for a country house

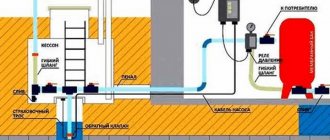

Let's consider the installation of a mine-type pumping station (standard design) for a private house. Capacity 1-25 m3/day, useful pressure 5-40 meters, body diameter 1600 mm.

Construction of a sewage pumping station

The reservoir (3) is a closed cylindrical container made of polypropylene or fiberglass. A hatch (2) is built into the station cover. Wastewater is supplied to the sewage pumping station through pipes (8) laid at a slight angle to the horizon (details in the article “Calculation of the sewer slope according to SNiP”). A manual waste bin basket (7) is installed at the dump site. To service valves (17) and check valves (18), the station is equipped with a ladder (5) and a platform (9). At the bottom of the tank there are 2 submersible fecal pumps with a grinder (19) - one working, the second reserve. The pressure pipeline (10) is connected to the pumps through an automatic coupling (13), the design of which allows the pump to be connected and disconnected remotely. To lift the pumping equipment and waste container, guides (11) and chains (12) are provided. The float sensors (16) are suspended at different heights. As the level drops or rises, the signal from the sensors is transmitted to the control panel (15), which controls the operation of the pumps.

The principle of operation of the pumping station is as follows: wastewater enters the reservoir through sewer or drainage pipes. After the water reaches a predetermined level, which is signaled by the sensors, the control panel will start the pump to pump wastewater from the home sewerage pumping station to the main line or septic tank. The level will drop, the signal from the lower level gauges will go to the switchboard, which will turn off the pumps.

Automation KNS

A sewage pumping station (SPS) for a private house can operate in both manual and automatic modes. The first is used during startup and commissioning of the system, the second is operational. Ultrasonic, submersible hydrostatic or float sensors are used to measure level height. Level gauges are selected individually for each SPS, but for modular SPS, mechanical float-type sensors are almost always used.

Level sensors, at least 4 in number, are suspended on their own cable. The height difference between adjacent floats should not be more than 20-25 cm. The upper sensor is an emergency sensor, located at the level of the wastewater supply. When it is triggered, the alarm is activated. The second sensor signals an increased level and starts an additional (backup) pump. The third sends a signal to start the station's working pump. The lower float is placed at a height of 15-20 cm from the bottom of the container. When it is triggered, pumping stops.

The control panel may have the following set of options:

- Step mode. Alternating operation of the main and backup pumps allows you to reduce equipment wear and extend their service life.

- Overload protection. In emergency mode, the pumps are turned on with a small time difference.

- Protection against overheating and dry running of pumps.

- Backup power input system. In the event of a power outage or critical voltage drop, the system switches to an autonomous power source.

Transportation of sewage pumping station

Automatic control

1. The KU switch is set to the automatic control position, contact SB is closed and bypasses the self-holding circuit. 2. Contact KK of the float relay is open when the liquid level in the container is low. The pump is not working. 3. If the liquid level reaches a certain level, the float relay contact closes, the magnetic starter turns on, and the pump begins to pump liquid out of the tank. 4. When the liquid level in the tank decreases, the CC contacts open and the pump stops.

About pumping equipment

Pumps are the “heart” of the station. If their operation is stable, then the maintenance of the pumping stations will be reduced to rare preventive examinations. Pumps for water pumping station are selected depending on the type of pumped wastewater (“gray”, “black”, storm water), average daily flow rate and total station pressure.

Pump types:

- Submersible. In modular household sewage pumping stations (sewage pumping stations), this type of pump is used most often. To pump out wastewater with feces, submersible pumps with a grinder on the axis of an electric generator are used. The waste is collected through a hole in the bottom of the apparatus. Gray drains and stormwater are pumped using a submersible drainage pump without a grinder.

- Console. Powerful pumps for dry installation, used for pumping industrial wastewater. They are taken to a separate (pumping) compartment. To install such equipment, a foundation needs to be poured.

- Self-priming. These pumps (vortex, centrifugal) with a large inlet diameter are designed specifically for pumping heavily polluted wastewater with particles of silt and sand.

The basis for choosing a pump is a standard design, which is ordered from a construction organization. Correctly performed calculation of pressure and throughput will help to reach the optimal operating mode of the pump, extend its service life and save energy.

Installation and maintenance of pump station

In accordance with the requirements of SNiP 2.04.03-85, the distance from the pumping station to residential buildings is taken depending on the station’s throughput. If this parameter is ≤ 200 m3/day, then the sanitary protection zone (SPZ) must be at least 15 meters. Specific average daily water consumption per person is 0.16-0.23 m3/day. A family of 5 people consumes about one cubic meter of water per day. If the wastewater after the pumping station is settled in a septic tank, then the flow rate is taken with a 3-day reserve. In any case, a simple calculation shows that the station’s productivity will be less than 200 cubic meters, which means 15 meters is the minimum that you need to focus on. But, in the end, everything is decided by the KNS project. After approvals, there may even be five meters of the CVD there - the inspectors will not say anything to you.

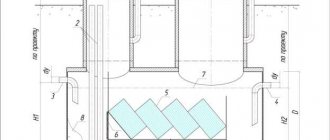

Installation of pump station

Installation of the SPS (modular) will take place in the following order:

- A pit is dug using a mechanized method. The bottom is compacted with a layer of gravel. On top - 10 cm of compacted sand.

- The formwork for the reinforced concrete base of the pumping station is assembled, after which it is poured. The concrete layer should be no thinner than 30 cm.

- When the concrete reaches grade strength (28 days), the installation of the pumping station begins. The container is leveled, and its base is secured to the foundation slab with anchors. If there is a danger of the station being pushed out by groundwater, then its body is “loaded” with ready-mixed concrete.

- The soil is backfilled layer by layer (50 cm each) and compacted. During the process, gravity and pressure pipelines are connected.

- Pumps are lowered into the tank and connected to guides and pipelines. Float sensors are installed.

- Electricity is supplied to the station and the control cabinet and grounding is done.

- The above-ground part of the tank is insulated.

Advantages of pumping station casings and pump pump units made of HDPE:

- High ring stiffness;

- Housing resistance to corrosion;

- High abrasive resistance;

- Operating temperature of the material is + 45 ° C, short-term - up to + 80 ° C;

- High resistance to most chemically active substances;

- Not susceptible to fouling of the internal walls of the housing with mineral deposits and dirt;

- Tightness due to the connection of body parts by welding with extruders;

- High maintainability;

- Low cost of construction and installation works.

- The warranty on the housing against leakage is 15 years!!!

- The service life of the housing is at least 50 years.

Maintenance of modular pumping station

The automatic pumping station, which removes household wastewater from the house (cottage), has a rather low operating intensity. Therefore, it is enough to carry out preventive inspection and maintenance of the pumping station once a season (in winter, once a month). The order is as follows:

- The readings on the control panel are checked with the workers (design ones). The discrepancy should not exceed 10%.

- The waste bin basket is periodically emptied manually.

- The loose fastenings of the manhole, stairs and platform are tightened.

- At least once a year, the water pumping station (walls and bottom) should be cleaned with water from a watering hose under pressure.

- The condition of the valves is checked from the service site by test opening and closing the valves. The pressure gauge on the pressure pipe and the gas analyzer are checked against the operating characteristics.

Repair. If the pump makes extraneous noise during pumping, the system is disconnected from power and the shut-off valve is closed. The device is removed along the guides to the surface, washed with cold water and inspected. If necessary, change gaskets, bearings, and tighten fasteners. After inspection (repair), the equipment is returned to its operating position, making sure that the automatic clutch latches.

Where can I order a sewer pump for a private home?

When deciding which installation to prefer, you need to determine the parameters of its use, since it can serve an entire building or just one point. In addition, it is necessary to take into account that:

- sewerage installations have different capacities;

- not all are designed to work with hot water;

- some of them have a high noise floor;

- not all of them are equally easy to maintain;

The equipment of the installations is different: it may include one or two pumps or a waste shredder.

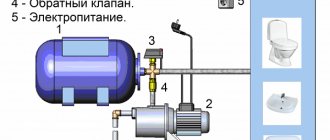

In-house mini pumping station

Let's say a washing machine or bathroom is located in the basement. How then to solve the issue of wastewater disposal, since in this case there is no need to talk about gravity flow? The problem is solved with the help of a mini sewage pumping station (in-house sewage pumping station), which is mounted on the pipe immediately after the toilet (shower drain, washbasin, etc.). It is easy to install yourself, plus it does not require a project or permit. The most powerful of these domestic installations can move wastewater up to 100 meters horizontally.

Mini KNS

Operating principle of mini pump station. When water enters the station tank, an area of high pressure is created. This detects a sensor that sends a signal to turn on the electric motor. When the pump pumps all the liquid from the reservoir into the sewer riser, the pressure will drop and the sensor will turn off the electric motor.

Depending on the characteristics of the pumped medium, in-house sewage pumping stations are divided into several groups:

- Sump station with chopper. Designed for pumping domestic wastewater, including large fractions (from the toilet). They operate at a wastewater temperature no higher than 35o C. The productivity of such installations is 70-100 l/min. The body and cutting mechanism are made of material resistant to aggressive environments.

- Sewage pump for hot gray waste (after a shower, washing machine, kitchen sink, bath). They are operated at temperatures up to 90°C and may have several supply pipes.

- SPS for cold gray wastewater. Relatively inexpensive pumps for pumping cold water from flooded basements or swimming pools.

- Versatile stations for intensive use. Several supply pipes of different diameters, a grinding system, a circuit with two independent pumps, check valves. Can pump hot and cold media.

Unfortunate terrain, remoteness of the sewer line, bathrooms in the basements... There are situations in which only a sewer pumping station can save us from the horror of every homeowner - a cesspool under the windows. The design of a water pumping station for a private house (cottage), as you can see, is quite simple, and if automated, its maintenance will take a minimum of effort and time. But, if you know a cheaper and faster way to pump wastewater, you can share it in the comments.

Alternative solutions

Although sewerage stations in private homes and offices began to be used not so long ago, nevertheless, the market already has a large selection of alternative options that are effective and at the same time affordable. One of them is submersible drainage fecal pumps . The main purpose of this equipment is to pump water from the basement from the ground floor. These pumps can also be used to pump out wastewater from cesspools.

If you purchased such equipment, then with a little modification you can make a sewer station on your own. To do this, you only need to purchase a container made of polymer material and some plumbing equipment:

- valves;

- fitting;

- sewer pipes.

Models of sewage stations based on fecal drainage pumps are currently available on the market. They are offered in a wide range. Among the models offered, you can find installations equipped with cast iron knives . Some models have cutting edges made of stainless steel and steel. The performance of these systems varies greatly, so you can choose the right option for your home or office.