Water hammer (abbreviated as water hammer) is an undesirable physical phenomenon that is characterized by a sharp increase in the magnitude of hydraulic pressure that occurs in a particular area. Moreover, this phenomenon is caused by a pronounced change in the speed of the flow. Water hammer can occur in the heating system of both private and apartment buildings.

What does water hammer mean?

Water hammer (water hammer) is a physical phenomenon characterized by a sharp increase in hydraulic pressure in a separate section of a fluid system, caused by a significant change in flow velocity.

In heating systems, the main type of coolant is water. Water is incompressible by definition, as are the vast majority of liquids. As the flow moves, obstacles may form in its path. Moreover, for a water hammer to occur, an obstacle must arise unexpectedly. When an obstacle appears, the fluid loses speed, the gradient of which tends to zero.

When the volume of liquid stops, the force of the pumping device that circulates the water continues to act on it. Under the influence of the pumping force, the hydraulic pressure of the fluid rises in the area. Pressure acts on the walls of pipelines and vessels.

When a movement barrier is suddenly removed, the liquid rushes to the zone of least resistance and pressure. At the same time, it acquires enormous speed due to the difference in pressure at the high pressure point and in the free zone. The liquid moves at high speed, and due to its incompressibility it can damage the elements and structures of the heating system. The force of the blow delivered is often much greater than the force of a backhand hammer blow. Therefore, strong water hammer can destroy metal products and devices. In this case, communications are depressurized and there is a danger of getting burned by hot water.

Water hammer theory

The occurrence of the phenomenon is possible only due to the lack of compensation for pressure drops. A surge in one place causes a force to spread throughout the entire length of the pipeline. If there is a weak point in the system, the material may become deformed or fail completely, creating a hole in the system.

The effect was first discovered at the end of the 19th century by Russian scientist N.E. Zhukovsky. He also derived a formula by which to calculate the period of time required to close the tap in order to avoid unpleasant consequences. The formula looks like this: Dp = p(u0-u1), where:

- Dp – pressure increase in N/m2;

- p – liquid density in kg/m3;

- u0, u1 are the average water speed in the pipeline before and after closing the taps.

To know how to prove water hammer in a water supply system, you need to know the diameter and material of the pipe, as well as the degree of compressibility of water. All calculations are carried out after establishing the water density parameter. It differs in the amount of dissolved salts. The speed of propagation of water hammer is determined using the formula c = 2L/T, where:

- c – designation of shock wave speed;

- L – pipeline length;

- T – time.

The simplicity of the formula allows you to quickly determine the speed of propagation of the impact, which, in essence, is a wave with oscillations of a given frequency. Now let’s talk about how to find out fluctuations per unit of time.

For this, the formula M = 2L/a is useful, where:

- M – duration of the oscillation cycle;

- L – pipeline length;

- a – wave speed in m/s.

To simplify all calculations, knowledge of the shock wave velocity upon impact for pipes made of the most popular materials will allow:

- steel = 900-1300 m/s;

- cast iron = 1000-1200 m/s;

- plastic = 300-500 m/s.

Now you need to substitute the values into the formula and calculate the vibration frequency of the water hammer on a section of a water supply pipe of a given length. The theory of water hammer will help to quickly prove the occurrence of the phenomenon and prevent possible risks when planning the construction of a house or the replacement of a plumbing or heating system.

Short description

A very common water hammer in an equipped high-quality heating system is a unique phenomenon that is based on the dynamics of various substances. The manifestation itself differs in that with periodic changes in the flow rate of the working fluid, an increase in pressure indicators is observed. The main coolant is water, the main indicator of which is incompressibility. During the circulation of the charged coolant through pipelines and heating elements, various hydraulic obstacles may arise along its path. In most cases, these are turns, sudden changes in the diameter of pipelines, as well as shut-off and control valves.

Attention! Water hammer can only provoke the sudden appearance of large obstacles. In such a situation, the flow speed quickly decreases, and the pressure level in the obstruction zone increases significantly.

Under unfavorable conditions, the coolant can damage those elements that present strong hydraulic resistance to the flow. These can be convectors, pipe turns, various devices, radiators and even boiler heat exchangers.

An accident may well occur as a result of gradual wear and tear of the operating structure and its elements, or as a result of the sudden impact of a strong jump in performance. In all situations, the consequences of water hammer entail material waste to eliminate the leak. In order not to find yourself in such a situation, you should understand the basic reasons for the formation of water hammer. The consequences of an accident are always unpredictable, ranging from the most common breakdown of the circulation pump to large-scale flooding of the entire house. It all depends on the quality and power of the system.

The most common consequences of water hammer

What should be present in the heating system of a private house to avoid water hammer

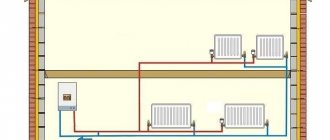

The heating system must be protected from water hammer, so the necessary elements are provided at the design stage. All of them are used in combination. It is worth noting that below is a list of devices that are selected based on the characteristics of the heating system: pump type, apartment or private house, diameters and length of pipelines. Only a professional who has studied the features of your home can fully select the entire set of devices and fixtures.

- special shut-off valves with soft closing - when purchasing elements of the heating system, you should give preference to faucets with soft closing. This will protect the system from a sudden surge in pressure and the coolant will have a more gentle effect on the pipeline and fittings when turning off the taps, which will protect against strong water hammer;

- an automatic system regulating the flow of coolant - a pump with this modernization smoothly releases liquid, thereby more carefully affecting the heating system as a whole. Working in automatic mode, such a device independently regulates the supply of liquid without human intervention;

- hydraulic accumulator (expansion tank) - this device must be present in the heating system of a private house. After all, it compensates for pressure differences, reducing the load. The principle of its operation is as follows: during a water hammer inside the tank, the rubber membrane is squeezed out by a water column. This compensates for the pressure inside the heating system;

- thermostat with a spring mechanism - its operating principle is identical to a hydraulic accumulator with the only difference being that the pressure compensator is not a rubber membrane, but a spring mechanism;

- membrane water hammer damper - this device is installed on hot and cold water in order to absorb pressure drops when opening and closing taps. The operating principle is identical to the two previous devices.

Using these devices, you can eliminate the occurrence of water hammer in the heating of a private home if you use them during the installation of a new system. There are also ways to prevent this phenomenon from occurring in an already functioning system.

Retrofitting a thermostatic valve

This auxiliary part is a compact tube. The final clearance can vary from 0.2 to 0.6 millimeters. The shunt is mounted in the direction of the circulating fluid. The main task of the part is to gradually reduce the pressure when overloads are detected. When designing autonomous systems, the shunting method must be used, since only in this case can the new pipeline be protected from failure.

This effect is due to the fact that worn-out pipes contain rust and other debris, which is a serious obstacle to achieving the desired result. It is for this reason that when using a shunt, it is advisable to install high-quality water filters at the very outlet of the equipped heating circuit.

Causes and consequences

The water hammer that occurs in the heating system is manifested in sound - knocking, clicks and vibrations felt when touching the pipe. The fluid in the circuit has mass, inertia of motion and is incompressible.

Where can water hammer occur?

When an obstacle appears in the path of water, motion energy accumulates, which is expressed in a sharp increase in pressure in a closed system - an impact. The reaction causes the shock wave to move in the direction of lower pressure with increasing speed.

Upon reaching the weak point, the impact energy is released, rupturing the defective section of the pipe if the wave power is sufficient for this, or causing vibrations in the pipeline. Frequently repeated water hammers will lead to the need for repairs after some time.

The reasons for the pressure surge may be:

We recommend: Double-circuit floor-standing gas boiler: specifics of device and choice

- air entering the system is due to improper installation of pipelines; air pockets are removed when filling the thermal circuit through special taps;

- quickly shutting off the liquid flow with a valve: a ball valve cannot be used for this purpose;

- changing the circulation mode: starting or stopping the network pump in the event of power supply failures at the facility;

- narrowing of the pipe flow area due to scale, build-up of other deposits in short sections;

- connection of pipelines of different diameters.

The magnitude of the pressure increase depends on the location of the obstacle on the line: at the beginning of the liquid path, the shock is weak, but as the plug moves away from the source, the power of the shock wave increases. Consequences of pulsed hydraulic action: damage to seals at joints, gaskets between flanges, shut-off valves, pump, heating boiler. Even the fin of the heating battery may rupture.

The destruction of individual elements of the system leads to damage to property when the room is flooded; if the water is hot with a temperature of ≥70ºC, then to injuries and burns to people. The second significant nuisance is the significant costs of bringing the heating system and apartment furnishings into good condition.

Changes and their reasons

Pressure surges indicate improper operation of the system. The calculation of pressure losses in a heating system is determined by summing up the losses at individual intervals that make up the entire cycle. Identifying the cause and correcting it early can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be caused by the following reasons:

- the appearance of a leak;

- expansion tank settings failure;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

The expansion tank regulates pressure drops

If a leak occurs, all connections must be checked. If the cause is not visually identified, each area must be examined separately. To do this, the valves of the taps are closed one by one. The pressure gauges will show the change in pressure after cutting off a particular section. Having discovered a problematic connection, it needs to be tightened, after further sealing it. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further decrease.

A gap of 1.25% should be added to the result obtained. The heated liquid, expanding, displaces air from the tank through the valve in the air compartment. After the water cools, it will decrease in volume and the pressure in the system will be less than necessary. If the expansion tank is smaller than required, it should be replaced.

An increase in pressure may be caused by damage to the membrane or incorrect setting of the heating system pressure regulator. If the membrane is damaged, the nipple must be replaced. It's quick and easy. To configure the tank, it must be disconnected from the system. Then use a pump to pump the required number of atmospheres into the air chamber and install it back.

You can determine if the pump is faulty by turning it off. If nothing happens after switching off, it means the pump is not working. The reason may be a malfunction of its mechanisms or lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, it needs to be replaced. During operation, microcracks may appear in the metal structure. This cannot be eliminated, only replacement.

Why does the pressure in the heating system increase?

The reasons for this phenomenon may be improper fluid circulation or its complete stop due to:

- formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- continuous replenishment;

- overlapping shut-off valves.

How to eliminate differences?

An air lock in the system does not allow liquid to pass through. The air can only be vented. To do this, during installation it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works automatically. The new model radiators are equipped with similar elements. They are located at the top of the battery and operate in manual mode.

Why does the pressure in the heating system increase when dirt and scale accumulate in the filters and on the walls of the pipes? Because the flow of fluid is hampered. The water filter can be cleaned by removing the filter element. Getting rid of scale and blockages in pipes is more difficult. In some cases, washing with special means helps. Sometimes the problem can only be fixed by replacing a section of pipe.

When the temperature rises, the heating pressure regulator closes the valves through which liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be corrected by adjustment. If this procedure is not possible, the unit should be replaced. If the electronic make-up control system fails, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, shut-off valves overlap, which leads to increased pressure in the heating system. To normalize this indicator, you just need to open the valves.

The batteries gurgle

The next cause of noise in metal heating pipes is air. If something is continuously seething and gurgling in the battery, like in the stomach of a sick cow, that’s it, darling. Soundproofing heating pipes, even if it were done, would not give anything - the sound will be heard through the walls of the radiator.

Are you on the top floor of a house with bottom drain (where both the heating system supply and return pipes are located in the basement)? Then look for a Mayevsky tap on the radiator or jumper between adjacent rooms - a device that helps bleed air.

In all other cases, it is worth looking for a counter-slope (of course, if the heating system works normally in all other respects, except for noise). A radiator hanging skewed or a section of the supply line to it, which is lower near the riser than near the battery itself - this is what you have to fix, most likely in the summer - stopping the heating system in winter for a long time, especially in the harsh climate of Siberia or the Far East, is unlikely would be a good idea.

Consequences of water hammer

This has already been briefly mentioned in the article, but we will still collect information about the dangers of pressure drops in this paragraph.

By and large, high blood pressure has no restrictions. Tens of atmospheres can easily turn into a large value. The situation looks even more deplorable if the heating main is long.

Let's say several tens of meters of pipes are laid in warm floors. Buying a thermostat that will prevent the floor from overheating can help eliminate the problem with pressure surges in this system. However, despite everything, the thermostat will not be able to help if there are mistakes when installing communications. For example, when the wrong pipeline diameter is selected, there is no slope. The situation is such that when the thermostat valve is closed, the liquid continues to circulate by inertia for a certain time and thereby creates a load on the pipeline.

To protect communications from such rare or constant water hammer, it is worth neutralizing their force or impact.

The inertia of the coolant and regular loads on the system cause wear of threaded and rigid connections, as well as all pipeline communications.

The most common consequences:

- hot water entering living spaces;

- breakdown of the main components, namely the boiler, circulation pump, expansion tank;

- injuries and burns of people.

Application of a professional thermostat with super protection

This device is a kind of fuse that continuously monitors the pressure in the system. This element does not allow the installation to function after the main indicator has reached the critical limit. The thermostat is equipped with a kind of spring mechanism, which is placed between the valve and a heavy-duty thermal head.

Its operation occurs at the moment when the pressure parameter exceeds the permissible thresholds. In such a situation, the valve simply will not be able to close completely. Thermostats must be mounted exclusively in the direction indicated on the housing.

Popular model of hydraulic shock absorber

A little about the renovation

With constant overvoltages occurring in pipelines, the need for repairs to the heating system often arises. Coolant leaks from the circuit occur through threaded connections, ruptures of the pipe or radiator elements along the seam.

There are 3 types of repairs:

- emergency. The need for it arises when the elements of the thermal circuit gradually wear out or in cases of a sharp increase in pressure. Performed in conditions where it is necessary to quickly restore the heat supply to the facility;

- current . It is carried out at the end of the heating season based on inspections by specialists of repair services and residents of residential premises. Worn parts are replaced, defects noticed during routine pressure testing of pipelines are eliminated;

- capital _ Complete or partial replacement of pipes, heating registers, circulation pump and other elements of the heating system is carried out.

Compliance with the operating rules of the heating system will avoid its premature breakdowns. So, the circulation pump should smoothly accelerate and stop.

To avoid water hammer, taps should be turned off gradually, without abruptly interrupting the flow of water.

We recommend: How to connect a well pump - installation and electrical diagram, installation in a well

Basic methods of protection

To protect materials, equipment and communications from water hammer, the following methods are used:

- Installation of thermostats with built-in shunt;

- Inserts made of plastic material;

- Installation of membrane devices;

- Control of pump operating modes based on data from the pressure sensor in the system;

- General preventive measures.

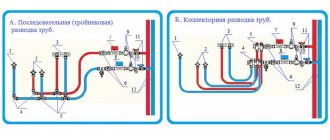

Temperature regulators with a built-in shunt are installed as shut-off valves. A shunt is a small-diameter tube that allows excess coolant to pass through when pressure increases.

Steel elements are most often subject to destruction from water hammer due to the rigidity of the structure and the lack of a shock-absorbing effect. To create a shock absorber, small sections of polymer pipes with good flexibility are often cut into place. During a water hammer, they compensate for the impact force by bending without being damaged.

Hydraulic accumulators and expansion tanks also do a good job of increasing pressure, taking on the excess pressure. A membrane made of rubber or polymer bends and compresses the air in the air chamber. Water from the heating flows into the freed space, reducing the overall pressure in the system.

Circulation pumps are equipped with a pressure control system. The sensor monitors the water pressure in the network. When the value increases, it sends a command to reduce the pump speed. This system is applicable for pumps with variable speed control of the impeller rotation speed.

General preventive measures to prevent water hammer and their consequences:

- Perform smooth control of shut-off valves;

- Turn on the pumps at low speed;

- Check the functionality of air vents and safety valves;

- Promptly and regularly bleed air from the equipment;

- Regularly carry out visual inspections for the integrity of structural heating elements;

- Monitor the integrity of the membrane of the expansion chambers.

Water hammer is a common and dangerous phenomenon in heating networks. Timely prevention will save heating communications and equipment from damage and preserve their integrity and performance.

Application of protective elements

The diaphragm type of this unit is mounted on a pipeline outlet as close as possible to the pump. Due to this, when the pressure increases, the required amount of coolant can be released freely. In many ways, activation of the safety valve depends on the model and manufacturer.

This could be an electrically powered function or an innovative, fast-acting device. The device is triggered when the pressure exceeds a safe threshold. This approach protects the modernized pumping unit in case of accidental shutdown of the unit. A large pressure surge is dangerous for the system, which is why the valve opens completely, and after a gradual decrease in performance, the regulator gradually closes.

A safety element in demand today

How to avoid the problem?

Proper protection of the water supply pipeline system will help reduce the intensity and neutralize the influence of excess pressure.

Protective mechanisms for autonomous systems against water hammer are in most cases aimed at smoothing the flow force of the water mass

To prevent the creation of excess pressure of a one-time and permanent nature, both in a separate section of the circuit and in the entire system as a whole, a number of basic measures are used.

Option 1. Smooth system shutdown

This is one of the main requirements when starting up and shutting down pipeline systems, which is clearly stated in regulatory documents.

The fact is that the energy of the hydraulic shock, due to the elasticity of the pipe walls, does not act with all its force at the same time. Due to compensation of elastic deformations, it is divided into several time intervals.

Therefore, with the same total impact force, the impact power at a certain moment will be significantly reduced. By smoothly switching on, the process of pressure build-up can be extended over time, minimizing significant damage to the system.

When choosing shut-off valves, preference should be given to products that have a relatively large period of water shutoff

Taps, the design of which provides for a large gap until the water is turned off, are installed at the stage of equipment installation.

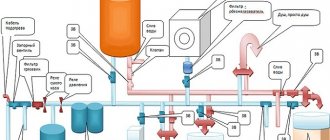

Option #2. Application of automatic devices

The automation must be configured to smoothly adjust the static pressure in the system. The installation of pumps with automatic speed control or electronically controlled units that are equipped with built-in frequency converters helps to achieve the desired effect.

The use of automatic systems will allow you to control the flow of liquid, as well as read readings of its pressure in the pipeline

Pumps equipped with automatic motor speed control are capable of smoothly increasing/decreasing pressure in the system. In this case, the software simultaneously performs two tasks: monitors changes in pressure in the water supply and automatically adjusts the pressure.

Automatic control systems for pumping equipment in autonomous water supply networks operate only in tandem with hydraulic accumulators. A hydraulic tank with an elastic membrane inside included in the circuit allows you to create a supply of water and form a compensating air chamber that will smooth out the consequences of excess pressure. In closed heating systems, water hammer can be prevented by a membrane tank—expanzomat. It is red in color, structurally similar to a hydraulic tank, but performs exclusively the work of compensating pressure during expansion of the coolant. If the water supply system includes additional pumping stations designed to pump water from the reservoir to the consumer, the responsibilities for reducing the effect of water hammer are partially assigned to them.

The relevance of using automatic elements

Such devices must be prepared to gradually adjust the static pressure. You can achieve the desired result if you install pumps with automatic speed adjustment that is understandable even for beginners. Installing electronically controlled units, which the manufacturer has equipped with a built-in converter, can also help.

Those pumps that are equipped with automatic speed control of an electric motor differ favorably from all analogues in that they can smoothly increase and decrease the pressure in the operating pipeline. High-precision software performs two important functions: it independently regulates the intensity of the pressure supply, and also monitors changes in liquid indicators in the water supply.

The relevance of using automation in heating

Methods for comprehensive system modernization

A comprehensive modernization of the system involves the installation of equipment aimed at neutralizing the effects of excess pressure.

Method #1. Application of compensators and shock absorbers

Dampeners and hydraulic accumulators simultaneously perform three functions: they collect liquid, while eliminating its excess volume from the system, and also help prevent undesirable phenomena.

A compensating device, the role of which is played by a hydraulic accumulator, is installed in the direction of water movement at those intervals of the heating circuit where there is a high probability of pressure fluctuations in the system.

A hydraulic accumulator or damper is a steel flask with a volume of up to 30 liters, including two sections separated by a rubber or rubber membrane.

When excess pressure occurs in the system, the water column of the first section begins to put pressure on the separating membrane, due to which it bends in the direction of the air chamber

When pressure increases, hydraulic shocks are “dropped” into the reservoir. By bending the rubber membrane towards the air chamber at the moment the water column rises, the effect of artificially increasing the volume of the circuit is achieved.

Pipes made of heat-resistant reinforced rubber or elastic plastic are used as shock-absorbing devices.

The elastic material of the shock-absorbing devices spontaneously absorbs the energy of the hydraulic shock at the point where the pressure has reached a critical value

To achieve the desired effect, it is enough to use a product 20-30 cm long. If the pipeline is long, the shock absorber section is increased by another 10 cm.

Method #2. Installation of a diaphragm type safety valve

A diaphragm-type safety valve is placed on a pipe outlet near the pump to release a predetermined amount of water when there is excess pressure.

The safety valve, equipped with a rigid seal that performs a quick pressure release function, is a reliable fuse for the autonomous system

Depending on the manufacturer and model type, the safety valve is actuated either by an electrical command from the controller or by a quick-acting pilot device.

The device is triggered when the pressure exceeds a safe level, protecting the pumping station in case of sudden equipment stop. At the moment of a dangerous surge in pressure, it opens completely, and when it drops to a normal level, the regulator slowly closes.

Method #3. Equipping a thermostatic valve with a shunt

The shunt is a narrow tube with a clearance of 0.2-0.4 mm, which is installed in the direction of coolant circulation. The main task of the element is to gradually reduce the pressure when overloads occur.

A narrow tube, the cross-sectional range of which does not exceed 0.2-0.4 mm, is placed on the side where the liquid enters the thermostat

We recommend: Closed heating system for a country house: diagrams, calculations, filling

The shunting method is used when constructing autonomous systems, the pipeline of which is made only of new pipes. This is due to the fact that the presence of rust and sediment in old pipes can reduce the effectiveness of shunting to “no”. For this reason, when using a shunt at the inlet of the heating circuit, it is recommended to install efficient water filters.

Method #4. Using a Super Safety Thermostat

This is a kind of fuse that monitors the pressure in the system and does not allow it to work after the indicator reaches a critical level. The device is equipped with a spring mechanism located between the thermal head and the valve. The spring mechanism is triggered by excess pressure, preventing the valve from closing completely.

Such thermostats are installed strictly in the direction indicated on the housing.

Introduction of shock absorbers

Hydraulic accumulators and dampers sold today are capable of simultaneously performing several important functions. They not only collect liquid, but also eliminate excess water from the system, and also help prevent various undesirable manifestations. Hydraulic accumulators perform all the functions of compensating units. They are installed only in the direction of the main water flow in those sections of the heating circuit where the likelihood of a sudden decrease or increase in the level of measured pressure is especially high.

A kind of damper, as well as a hydraulic accumulator, in practice, is a capacious steel flask that can easily hold up to 35 liters of liquid. They include two sections separated by a durable rubber partition. In the event of an increase in pressure, all water hammer is redirected to the reservoir. Thanks to the bending of the involved membrane at the moment of a sharp increase in indicators, specialists are able to achieve the effect of forced expansion of the circuit.

The shock-absorbing elements are pipes made of heat-resistant reinforced rubber or elastic plastic. To achieve the desired effect, it is enough to use a product 35 centimeters long. If the pipeline is long, then the shock absorber section must be increased by at least 12 cm.

High-quality water hammer absorber

Where and how to install: installation recommendations

The water hammer compensator is small in size; only a small amount of water can fit into the housing (usually less than 200 ml). It is installed in close proximity to the source of water hammer: a ball valve, a water comb, on a hose to a washing machine or dishwasher, after a circulation pump, on a heated floor comb.

The water hammer compensator is installed close to consumers or on the comb

You can attach it in any position: up, down, to the side. For membrane models, it is only important that there is free access to the nipple. Regardless of the design, it is not recommended to install the device on long branches from the main line. The supply pipe section should be as short as possible.

Rules for installing a water hammer compensator

When choosing, pay attention to the maximum operating and compensated pressure. The second point is the connection diameter. Usually it is 1/2 inch, but there are also 3/4 and inch.

When connecting a washing machine and/or dishwasher, a tee is installed on the hose. One free outlet of the tee goes to the machine, and a water hammer compensator is installed on the second.

Basic preventive measures

In addition to strict compliance with all established operating rules, an accident can be prevented if a number of preventive actions are carried out promptly and regularly. The whole reason is that in the main heating or water supply system, absolutely all processes are closely interconnected. A water hammer unexpected by the user is just the final destructive stage, which may well lead to various negative consequences. All this happens against the background of the relatively poor technical condition of pipes that have been used for years.

Changes in pressure and resulting vibrations only contribute to the formation of various cracks in the thickness of the metal. Over time, more serious defects arise, which, after the onset of water hammer, immediately appear in areas of too high internal stress. These can be various bends, mechanical connections and even welds.

Preventive manipulations include the following steps:

- Timely check of the pressure behind the elastic membrane of the expansion vessel in use. If during this procedure the technician discovers unsatisfactory results, then it is prohibited to operate the system without quality adjustments.

- Checking the functionality of the involved security groups. This applies to the air vent, safety valve, as well as the classic pressure gauge.

- Monitoring the position of the valves of the involved shut-off and control metal fittings.

- Periodically check the condition of all filters. These elements are responsible for retaining fine sand, classic scale, and rust fragments. If necessary, the technician will need to clean and then rinse the filters.

- Testing the system used for leaks. You also need to check the degree of wear of all elements.

Many experts recommend replacing the classic rigid pipe with a plastic product. It is more flexible in use and can expand quickly under pressure. But you need to be careful, as depressurization of the joints is possible.

A professional approach to prevention, which is aimed at overall maintaining the optimal condition of the heating and water heating system, necessarily includes basic types of work. It is not recommended to ignore this stage. This is due to the fact that heating repairs in a private house entail a large expenditure of finances and free time. All the described protective measures will be effective if you approach the work comprehensively. Only in such a situation can various undesirable consequences be neutralized and the life of the coordinated operation of the system extended.

Installing a high quality backwash filter

Manufacturers, characteristics, prices

It is best to buy a water hammer compensator from well-known companies. This is not the area where it is appropriate to save money. The most popular are several companies:

- FAR. The compensator from this company is without a membrane, with a spring and a locking disc. Connecting thread 1/2″, maximum pressure 50 Bar, nominal pressure 10 Bar. Withstands temperatures up to 100°C. Price from 30 $.

- Uni Fitt. The same design with a spring-loaded disk. There are two body options: brass and nickel plated brass. Connection 1/2 inch. Maximum temperature 90°C, nominal pressure - 10 Bar, peak pressure - 20 Bar. The length of the protected pipeline is 10 m. Price from $15.

The same models are sold at different prices in different stores

- Valtec (Valtek). This is a membrane type hydraulic shock absorber. There are models connected through a small ball valve with a pressure gauge. If necessary, open the ball valve and check the pressure in the compensator. The pressure in the chamber is 3.5 Bar, the maximum operating pressure is 10 Bar, the maximum compensated pressure is 20 Bar. Price from $25.

- CALEFFI (Caleffi). This company produces disk compensators. There are regular ones - with a 1/2″ connection, and there are 3/8″ ones for the sink. The parameters can be called good: the working pressure is no more than 10 Bar, they can compensate up to 40 Bar (for washing up to 30 Bar).

There are other companies, but they are not so popular. some due to being overpriced, others have not gained trust. At least for now.

Conclusions and useful video on the topic

Video #1. Water hammer, how it happens:

Video #2. Test of the effectiveness of the damper:

Water hammer in a water supply system is a common occurrence that can cause serious harm. And your task is to fix the problem as quickly as possible. After all, if the situation repeats, the elements of the system will soon fail. And repairs after that will cost much more.

Sources

- https://pechiexpert.ru/gidroudar-v-sisteme-otopleniya/

- https://mr-build.ru/newteplo/gidroudar-v-truboprovode-2.html

- https://montagtrub.ru/gidroudar-v-sisteme-otopleniya-prichinyi-posledstviya/

- https://microklimat.pro/sistemy-otopleniya/gidroudar.html

- https://teplofan.ru/sistemy-otopleniya/gidroudar-v-sisteme-otopleniya-chastnogo-mnogokvartirnogo-doma

- https://sovet-ingenera.com/vodosnab/v-drugoe/gidroudar-v-sisteme-vodosnabzheniya.html

- https://teplowood.ru/zashhita-ot-gidroudarov.html

- https://laminatepol.ru/30934-osnovnye-prichiny-vozniknoveniya-gidroudara-v-sisteme-otopleniya-nedvizhimosti.html

How do you like the article?

Sergey Vladimirovich

Ask a Question