To prevent flooding of the site and the buildings located on it, erosion of the foundation and dampening of the walls of buildings, a storm drain is laid. The water flowing through the storm drain contains sand and other solids that are not retained by the drain grates. To separate solids, a storm drain sand trap is needed. Thanks to it, it is possible to prevent the formation of blockages in the drain system.

A sand trap is installed as the last element of the line of surface drainage gutters, from which drainage channels then go into the collector, ensuring that up to 80% of solid impurities settle in it. The water passing further is practically clean, so water storage tanks and drainage pipes do not suffer from blockages.

Popular models of sand traps

Let us consider, as an example, several popular models of sand traps for sewage, indicating their main characteristics:

- Hydrolica Light. This is a horizontal type plastic trap designed to be installed in a plastic tray system. Equipped with a plastic grill. Its length is 50 cm, width - 11.6 cm, height - 32 cm. Load class - A15. Section width - DN100. The price of sand traps of this type is about 1000 rubles. Withstands loads of up to 1.5 tons. The catcher is used in systems of private houses, on pedestrian sidewalks, in parks, and on bicycle paths.

- Hydrolica Filcoten. It is made of composite concrete and can withstand a load of up to 25 tons. The length of the trap is 50 cm, width is 14 cm, height is 50 cm. Load class is C250. Section width - DN100. Similar devices are used in parking lots, garages, roadsides, and sports facilities. The cost of the trap is about 5,700 rubles.

- Hydrolica Super. Made from impact-resistant plastic. Has a reinforced steel nozzle. There are 2 types of traps available, differing in their dimensions and width of the flow area. Withstands a weight load of up to 60 tons. Dimensions of sand traps: length - 50/54 cm, width - 16/26 cm, height - 43.8/47.8 cm. Load class - E600. Section width - DN100/DN200. is 2100-4200 rub.

Sand catcher cost

Today there are many models of sand traps.

The main differences are in materials and sizes. For example, there are polymer concrete and concrete options. To choose a good sand trap for sewerage, you should be guided by the following characteristics: size, density of polluting particles, storm drainage performance. As for the cost of sand traps, it depends on the dimensions of the product and the manufacturer. For example, the BetoMax Basic model with dimensions 500x140x390 costs approximately 1,850 rubles. This is a fiber-reinforced concrete sand catcher, load class A-C. The CompoMax Basic brand of the same dimensions, but made of polymer concrete, will cost buyers 2,800 rubles.

But the price of a sand trap for storm drainage of the PolyMax Basic series with dimensions 500x160x420 is the most affordable - only 1,300 rubles. The structure is made of frost-resistant plastic. There is a special basket for removing waste. The Gemma Extra sand trap with three sections, each measuring 500x533x500, will cost a considerable amount - 12,400 rubles. The product is equipped with a cast iron top grill.

Of course, a high-quality and reliable sand catcher from a well-known brand will cost a lot of money. Therefore, some craftsmen are trying to make a sand trap for storm drains with their own hands in order to save a little money.

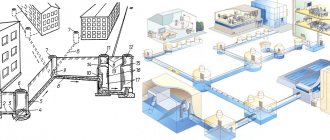

The process and specifics of installing storm drains

The rules for constructing storm drains are similar to those used when installing conventional gutters. However, if the house does not have a drainage piping system, it must be installed.

Construction of the roofing component

When installing a drain, home owners perform the following actions:

- holes are made in the floors of the house for water collectors. After installation and installation of rainwater inlets on bitumen, the places where they adjoin the storm drain are carefully sealed;

- then, install drainpipes and risers;

- elements of the drainage pipeline system are attached to the cottage or country house with clamps;

- upon completion of the work, trays are installed - when installing a linear type drain or a water drainage tube, if the drainage pipeline system is installed according to a point pattern.

Water drainage from the roof

Installation of the underground part

After drawing up a storm drainage plan - taking into account the slopes and the specific installation depth of the channels installed in a particular region of the Russian Federation - a trench is made.

If you need to insulate the pipeline with geotextiles and crushed stone, or you need to build a sand cushion, the plan for installing the underground part of the sewer system also takes into account the power of the storm drainage elements.

Next, perform the following actions:

- Before starting installation work, the bottom of the trench is compacted. At the same time, large stones are removed from the trench, the holes from which are subsequently filled with soil;

- a sand cushion is placed on the bottom, the thickness of which is 20 cm;

- the result is a pit in which the collector is installed. A plastic container purchased in advance is used as a collector. However, you can make a collector well yourself - just pour the concrete solution into the pre-prepared formwork;

- Next, tubes are placed in the grooves, which are connected into 1 system using fitting pipeline elements;

- then, inspection wells are placed on straight 10-meter branches of the storm drain;

- Sand traps are installed at the connection points between the water collectors and the pipeline;

- As a result, all elements of the storm drain are connected into 1 circuit. In this case, the junctions of such elements are carefully sealed.

Before filling the trench, its performance is checked by pouring water into it.

If no weak points are found during testing of the trench, then after the test the pipeline system installed in the trench is buried, filling it with soil. Also, in such a situation, gutters and drainage trays with gratings are installed on the storm drain.

Upon completion of installation, the owner of the cottage or summer cottage connects the storm drainage system to the general sewer system.

So, when installing a storm drain yourself in a private household or in a country house, you need to use all the recommendations and rules for installing a drainage system that were given in this article.

Using this information, you can easily troubleshoot problems that arose during the installation of the storm drain.

By improving the storm drainage in the house and in the surrounding area, the life of the house is extended, puddles and slush do not form on the roads to the cottage or dacha, and the rotting of plants also stops.

WATCH THE VIDEO

Each owner of a country house can independently install a storm drain - without turning to professional builders for help. In such a situation, you just need to get to the heart of the matter - and everything will work out.

Preliminary calculations and design

Construction of a storm drain without carrying out calculations is a waste of money.

After all, if the installed simple stormwater system does not work well, then there is no need to install it at all. At the same time, you need to spend a lot of money on installing too powerful a storm drain.

Information required for calculations

When designing a storm drain, the following data is used:

- the average volume of precipitation recorded by meteorologists in a particular area. Such information can be found in SNiP 2.04.03–85;

- meteorological information on the frequency of rainfall and snow depth. Such data is also used when installing storm drains to drain melt water;

- data on the drainage area - roof area. In such a situation, not the full value is taken into account, but the value of the projection of the area in the plane.

When constructing a linear stormwater system, the drainage area is equal to the sum of the areas of all drainage objects;

The principle of operation of the sewerage system in section

information about the physical characteristics of the soils that make up the suburban area.

Also, when carrying out calculations, pay attention to the presence and location of underground communication drainage systems already erected on the site

Calculation of the volume of drainage drains

The volume of drainage drainage is calculated using the following formula:

The correction factor values used in this formula are used at the following sites:

- 0.4 - on areas covered with crushed stone;

- 0.85 - on a concrete platform;

- 0.95 - on asphalt;

- 1.0 - on the roof.

After determining the volume values, the diameter of the pipeline drainage system is calculated according to SNiP.

Determining the installation depth of channels

Installation of trays or pipeline channels is done at the same depth at which they are installed in a particular region.

Owners of dachas and private households can find out specific depth values from a construction company or from a neighbor who has already installed a storm drain on his property.

In the central regions of the Russian Federation, storm drains are installed at a depth of 0.3 m, if the diameter of the tray is 50 cm as a maximum. Large reinforced concrete, metal or plastic drainage trays and pipes are installed at a depth of 0.7 m.

Due to the high cost of excavation work, many owners of country houses do not make deep indentations into the ground. In addition, when installing a storm drain with your own hands, there is no need to bury it too deep underground.

According to GOSTs, collectors and inspection wells are installed at the level of seasonal freezing, and not below. Also, these storm drain elements can be installed above this level - while the collectors and inspection wells are insulated with geotextiles and crushed stone, which protects the storm drain from freezing.

Due to the small recess, the complexity of installation is significantly reduced.

In such a situation, storm channels are installed at a specific angle to the drainage and treatment devices of the drainage system.

Construction and location of wastewater pipes

Accordingly, the installation level of the entry point into the collector well is below the installation level of the catchment or tube, which extends from the rainwater inlet. When calculating the depth of their installation, an installation plan is drawn up in advance and, taking into account the slopes of the drainage channels, all the necessary calculations are made.

Standards and norms of slopes

According to GOST, tubes with a diameter of 150 mm are installed at an angle of 0.008 (the amount of inclination is measured in mm/m). The tubes, which have a diameter of 200 mm, are placed at an angle of 0.007.

Depending on the characteristics of the area where the storm drain is laid, installers slightly change the values of the pipe slopes.

A slope of 0.02 is made at the junction of the drainage channels and the drainage basin, because in such a place the drainage speed increases.

Water flows slower to the sand trap than in other areas of the storm drain. In such a situation, suspended particles settle. In this regard, the angle of inclination in this place is made the smallest.

Catchments in storm drains that have a drain with a sand trap (drain funnel) are placed in those places where the pipe slopes intersect with each other.

Sand trap structure

The sand trap is an intermediate link in the drainage system. But this makes this design no less important. The sand trap has the form of a special container with a bottom, side pipes, and an upper receiving compartment. Between the receiver and the bottom there is a grid, which catches all the dust, clay, sand and other particles that come with the water.

It should be noted that an important element of the sand trap is the grate for storm drainage, since it protects the system from various debris entering the internal space of the structure. This detail also adds visual appeal to the system. Grates are made from various materials, but cast iron is most often used. Since the cast iron grating for storm drains has excellent wear resistance and corrosion resistance. It is also economical and aesthetically pleasing.

Cast iron is a strong, reliable and durable material.

And the price of cast iron gratings for storm drainage is quite acceptable for most groups of buyers. The average cost is about 1,500 rubles.

Sand traps from PVK - efficiency and reliability

Stormwater contains a large amount of fine soil particles, as well as sand. Therefore, purification should begin with the extraction of these suspensions. A sand trap for storm drains copes with this task perfectly. This type of installation takes in sand and removes water from it. The efficiency of such cleaning often reaches 80%. It should be noted that in addition to soil particles and sand, the sand separator is also capable of retaining up to 40% of petroleum products.

Design and types of storm sand traps

The installation has a tank, the manufacture of which uses reinforced fiberglass or concrete. Inside there is a system of partitions. It is thanks to it that purification occurs (gradual retention of sand by sifting).

The most popular today are stormwater inlets and sand traps, which are built into the surface drainage system. Their installation is carried out under drains or in places where several flows collect. Thanks to the presence of a grid, large debris is retained, which protects the entire system from clogging.

Often, a tray with a sand trap is used for surface drainage. This installation retains some of the sand, which also prevents the possibility of clogging the storm drain.

We offer a wide selection of sand catchers

You can buy a sand catcher from our company. We offer a large selection of ready-made solutions. Our clients have the opportunity to order design and installation. The PVK design bureau will do everything at a high professional level. Our specialists will draw up an optimal cleaning scheme and select all the necessary components for it.

The price of a sand catcher and the cost of work will depend on the productivity of the installation and the volume of activities performed. For more information, please contact our managers. To do this, call the number or send a quick request.

How to make a grease trap for a sink with your own hands?

With a little time and patience, it’s easy to make a homemade simple separator for the kitchen sink from scrap materials. In this case, you can do without drawings. For production we will need:

- plastic box with a lid, volume about 40 liters;

- tee and elbow PET Ø 50 mm;

- pipe Ø 100 mm (its length should be approximately 2/3 of the height of the body);

- pipe Ø 50 mm (same length) it must have a mounting extension and a rubber cuff.

The following tools and supplies should be prepared:

- jigsaw (preferably electric);

- sealant;

- sandpaper;

- adhesive-based rubber sealing tape.

When everything is ready, we begin the manufacturing process, following the following algorithm:

- We make holes Ø50 mm at the opposite ends of the box. There should be approximately 50mm from the top edge of the drawer to the holes. Don't forget to clean the edges with sandpaper.

- We install a Ø 100 mm pipe under one of the holes with its end face and glue it so that its lower edge does not reach the bottom of the box by about 30-40 mm.

- As soon as the glue has dried, install a Ø 50 mm pipe inside the previously glued pipe. In this case, the lower edge of the pipe should be approximately 50 mm higher than the lower edge of the pipe.

- We connect a tee to the upper end of the pipe, insert one of its free ends into the hole, the second will be directed upwards and play the role of ventilation.

- We install the inlet elbow.

- We seal all cracks and joints with silicone sealant.

- We glue sealing tape at the junction of the lid and the box.

- We close the lid, wait until the silicone sealant hardens, after which we can connect the grease trap.

Useful tips

When looking for a specific storm inlet model, it is imperative to take into account the largest volume of precipitation in the existing area. This parameter can be found in the SNiP reference book. You should also learn about the maximum snow cover parameters in the winter season.

Remember to periodically clean the filter in the rain catcher to avoid unpleasant odors.

Heavy structures with angular frames are recommended to be laid using special equipment.

When choosing a receiver of one class or another, it is better to play it safe and give preference to models designed for heavy loads than will actually occur.

If desired, the storm drain itself can be made with your own hands from scrap materials. Such a structure will be budget-friendly and will not cost much, but its preparation must be done wisely.

Step-by-step instructions for installing a rainwater inlet are presented in the video below.

The best manufacturers

Currently, manufacturers are famous because they combine reliability, quality and a decent price in their models.

- The devices are made of high quality material. They also have an increased degree of water purification. The cost of devices starts from 10,000 rubles.

- Kolomaki models are equipped with a special container for collecting impurities. The devices are made of polymer-copolymer, which improves their quality. The price of devices starts from 12,000 rubles.

- provides models that produce the purest water possible, separating it from sand. The device is made of plastic and is divided into two parts inside. The cost starts from 5,000 rubles.

Cleaning the sand trap

It is important to remember that the capacity of the sand trap tank is limited.

And periodically the garbage receptacle needs to be emptied. This is done very simply, the basket can be easily removed. Otherwise, the efficiency of the sewer system will decrease. When the container is completely filled, there will be no benefit from the storm drain. In addition to cleaning the basket, it is important to flush the storm drain, which is also carried out for preventive purposes. Washing is carried out with steam under pressure or a stream of hot water. It is advisable to alternate sewer cleaning with flushing.

Thus, storm drainage is an important structure that prevents the flooding of buildings and the area around the house by melt and rainwater. The system consists of many elements. One of the mandatory and important ones is a sand trap. This part purifies water from various blockages and prevents solid particles from penetrating into the drainage system and clogging it. The cost of a sand catcher is on average low, depending on the manufacturer, material of manufacture and dimensions of the model. Some people make their own sand trap.

Source

Service

One system can accumulate and store pollutants from 5-6 months to several years. If the oil catcher is equipped with a sensor indicating that the compartment with oil products is full, the collection tank is cleaned after receiving the signal. If there are no sensors, the degree of overcrowding is determined visually.

Regular equipment checks include the following:

- inspection and cleaning of the mesh and coalescence filter;

- control of the degree of sediment accumulation;

- replacement of the sorption filter (every 1-2 years).

Once every 2 years, it is recommended to completely unload the oil separator and flush the entire installation.

Care

Don’t forget to clean your sand catcher on time: if you have a home version of the product, you need to clean it once a week, if you have an outdoor version, you need to clean it after every rainfall. Cleaning cannot be delayed, because if the product overfills, then all the existing dirt will begin to go straight into the pipes and clog them.

A structure intended for long-term use must be thoroughly washed from time to time. The effective performance of the entire storm drain will directly depend on this kind of cleaning measures.

A general inspection of the product is carried out once every two years. To do this, the walls of the tank are washed under high pressure of liquid. Be sure to wash all existing filters. This will improve the quality of water in the sewerage system. Unloading should be carried out according to the degree of clogging. To ensure high-quality unloading of the device, all blocks are lifted from above to rinse them under serious water pressure. You can use special equipment for more detailed cleaning.

After cleaning the container from sediment particles and deposits, you need to quickly pump out all the liquids used. As soon as the cleaning process is completed, the sand trap is installed in its original place. After installing the device, it is filled with water to prevent it from being pushed out when the soil is high.

See below for details.

Sand traps

A sand trap, also called a sand separator or sand trap, is a standard feature of most sewer treatment plants. As can be seen from the name, its main task is to cleanse from mechanical impurities, and for this purpose the force of gravity and the principles of water movement are used. Most often, the device is used for surface storm drains.

It should be noted that in addition to primary cleaning, the sand trap performs another important function - it protects all equipment from clogging, premature wear and failure.

Sand separator design

The sand trap is placed as the primary link of the entire cleaning system and is installed at its beginning. Since this is a large-volume reservoir, the speed of wastewater drops and filtration begins.

Mechanical inclusions fall to the bottom under the influence of gravity. For more efficient cleaning, thin-layer modules are installed in the sand separator.

Thus, the sand trap consists of:

- two pipes for input and output of waste;

- housings made of reinforced fiberglass;

- thin-layer module (not included in the basic package of the sand trap).

Types of sand separators

There are horizontal and vertical devices, the former are more functional and have a higher degree of cleaning. Vertical sand traps are used when there is a small amount of waste or when there is a low concentration of suspended substances in contaminated water.

The devices also differ in the material from which the housing is made. Traditionally, concrete ones are used, but they are not without drawbacks: heavy weight, prone to cracking. Therefore, fiberglass products - made of fiberglass, a strong and durable modern material - are becoming increasingly popular.

Advantages of fiberglass sand traps:

- Absolute tightness of the walls.

- Easy to install and dismantle.

- Frost resistance.

- Strength.

- High functionality.

- Easy to maintain.

Technical characteristics of sand separators KTRu PO (For reference)

| Productivity, l/s | Diameter D, mm | Length L, mm | Rack height Patr. A, mm | Hole height Patr. V, mm | Diameter of port inlet/hole** N, mm | Number of service wells* | Product weight, kg |

| 6 | 1600 | 3000 | 1400 | 1350 | 160 | 1 | 310 |

| 10 | 1600 | 5000 | 1400 | 1350 | 160 | 1 | 510 |

| 15 | 1800 | 5800 | 1550 | 1500 | 200 | 1 | 740 |

| 20 | 2000 | 6200 | 1750 | 1700 | 200 | 1 | 974 |

| 25 | 2000 | 7600 | 1700 | 1630 | 250 | 1 | 1190 |

| 30 | 2400 | 6100 | 2100 | 2030 | 250 | 1 | 1820 |

| 40 | 2400 | 7800 | 2050 | 1980 | 315 | 1 | 1910 |

| 50 | 2400 | 9700 | 2050 | 1980 | 315 | 1 | 2300 |

| 60 | 2400 | 13300 | 2050 | 1980 | 315 | 1 | 2820 |

| 70 | 3000 | 10000 | 2650 | 2580 | 315 | 1 | 3530 |

| 80 | 3000 | 11300 | 2550 | 2480 | 400 | 1 | 3980 |

| 90 | 3000 | 12700 | 2550 | 2480 | 400 | 1 | 4400 |

| 100 | 3000 | 13000 | 2550 | 2480 | 400 | 1 | 4840 |

| 120 | 3600 | 11900 | 3150 | 3050 | 400 | 1 | 6500 |

| 150 | 3600 | 14800 | 3150 | 3050 | 400 | 1 | 8200 |

Popular models of sand traps

Let us consider, as an example, several popular models of sand traps for sewage, indicating their main characteristics:

- Hydrolica Light. This is a horizontal type plastic trap designed to be installed in a plastic tray system. Equipped with a plastic grill. Its length is 50 cm, width - 11.6 cm, height - 32 cm. Load class - A15. Section width - DN100. The price of sand traps of this type is about 1000 rubles. Withstands loads of up to 1.5 tons. The catcher is used in systems of private houses, on pedestrian sidewalks, in parks, and on bicycle paths.

- Hydrolica Filcoten. It is made of composite concrete and can withstand a load of up to 25 tons. The length of the trap is 50 cm, width is 14 cm, height is 50 cm. Load class is C250. Section width - DN100. Similar devices are used in parking lots, garages, roadsides, and sports facilities. The cost of the trap is about 5,700 rubles.

- Hydrolica Super. Made from impact-resistant plastic. Has a reinforced steel nozzle. There are 2 types of traps available, differing in their dimensions and width of the flow area. Withstands a weight load of up to 60 tons. Dimensions of sand traps: length - 50/54 cm, width - 16/26 cm, height - 43.8/47.8 cm. Load class - E600. Section width - DN100/DN200. is 2100-4200 rub.

General information

Problems in the absence of storm drains

If the storm drainage system is poorly constructed or does not exist, this will lead to such phenomena as:

1. to flooding of the site, the formation of a swamp.

2.appearance of puddles after rains, difficulty moving around the site.

3. erosion of the foundation by water.

4. Mold and mildew may appear on the walls.

5. to contamination of the object.

6.to deterioration of health.

Types of storm drainage

There are types of sewers for collecting rainwater:

1.point, in which water flows to a certain place.

2. linear, in which water collects linearly. The rain gutters are on the same line, connected to each other by wire.

Attention! In order for the storm drain to work effectively, it is necessary to install a sand trap for the sewer system.

Installation of drainage trays: basic rules

Installation of drainage trays is a very responsible operation. After all, the surface drainage system is located in a complex soil, which includes sandy loam and fertile soil. That is, you can’t count on high supporting ability.

In addition, such soil freezes 1-1.2 deep almost every winter. Therefore, heaving deformation will also act on the supporting surface of the tray, pushing the product out of the soil.

That is why when installing drainage trays you should be guided by the following set of rules:

- First, select a tray based on throughput capacity, based on the average monthly precipitation increased by 25 percent.

- Secondly, choose the optimal tray design and the material from which the product will be made, based on the location of the gutter. After all, a curb tray is not suitable for an airfield (based on its strength characteristics). In turn, the airfield tray will not fit into the home stormwater system (based on economic considerations).

- Thirdly, the minimum slope of a linear meter of the tray is 10 millimeters.

- Fourthly, do not skimp on the substrate - mount the tray on at least a 10-centimeter sand and gravel backing, or better yet, on a 10-centimeter gravel backing. Such a “cushion” will improve the strength characteristics of the soil and partially neutralize heaving deformation.

- Fifthly, stainless steel grates are easier to install (they weigh less than the cast iron version). In addition, they will last longer than their counterparts made of gray or ductile iron.

- Sixthly, the system must have a sand trap - the only protection of the drainage system from silting.

- Seventh, the grille must be secured using a special mechanism with a screw lock.

First, select a tray based on throughput capacity, based on the average monthly precipitation increased by 25 percent.

The process of assembling a drainage system based on drainage trays is implemented as follows:

- Along the curb or in another place chosen by the designer, the center line of the future drainage system is marked. To do this, just use pegs and twine.

- After this, meteorological observation data is requested, and based on this information, the average daily volume of runoff is determined, according to which the throughput diameter of the gutter is selected.

- The model and external dimensions of the water pipeline are determined by the flow diameter.

- Based on these dimensions, increased by 30-40 centimeters, the volume of soil excavation (trench dimensions) is determined. Moreover, the depth of the trench will be 10-15 centimeters below the height of the tray. After all, its edge, after installation, should be located below the zero level by at least 5 millimeters.

- At the next stage, a trench is dug, the selected soil is disposed of and a bedding is formed, with the help of which the slope is outlined and the bottom of the “pit” is strengthened.

- Next, drainage trays and sand traps are placed in the trench. Moreover, the outer catcher is connected with a DN100 pipe to the main (deep) drainage system.

- After this, concrete is poured into the space between the trench wall and the tray, fixing the drainage system in the selected location.

This drainage system is installed along the central paths on the site, laid between the gate and the entrance to the home. In addition, a ring water conduit is “circulated” around the blind area, which protects the soil from rain runoff. Moreover, a wall drainage system can be assembled from plastic, while a road drainage system can be assembled only from concrete blocks.

Sand traps

Plastic sand trap, Norma DN100

| Product code | 11042 |

| Weight, kg | 3 |

| Width, m | 0.148 |

| Length, m | 0.5 |

| Height, m | 0.423 |

| Load class | A, B, C |

Product details: Plastic sand trap, Norma DN100

Sewage drains contain large amounts of mineral and organic particles. It is necessary to systematically remove them and further dispose of them. Special equipment for these purposes, called a sand trap, should be installed in primary settling tanks. This is a standard unit that is intended for mechanical treatment of wastewater, separating sand and other small particles from the liquid through their sedimentation.

Classification of sand traps according to various characteristics

Based on the design and nature of water movement, the following types of sand traps are distinguished:

- vertical. Now they are used infrequently. In them, water moves from bottom to top;

- horizontal. Their water movement goes straight or in a circle;

- tangential. These models work due to the difference between the density of sand and water. These are round-shaped products, and inside the center there is a sedimentary element.

Depending on the material, the following types of sand traps are distinguished:

- made of concrete. They began to be created earlier than all other varieties. The design is extremely durable and has a long service life. It is heavy, which makes it quite difficult to install the unit. However, concrete sand traps are still in use;

- made of plastic. They are extremely affordable and therefore accessible. Also, the products are very lightweight, so no additional equipment is needed to install the unit;

- from polymer concrete. These sand traps are quite durable. They are presented in a large assortment. They appeared relatively recently. They are light in weight. The cost of the units is less than that of conventional concrete ones.

The presented sand traps are created from different raw materials. They differ in properties, technical parameters, and price.

What to pay attention to: important nuances

When choosing a sand catcher, the following important nuances must be taken into account:

- equipment dimensions. Here it is necessary to take into account the throughput of the system;

- load class. It cannot be exceeded. This will prevent premature destruction of the equipment;

- weight and material. The product must comply with both standard and enhanced loads;

- dimensions, features (for example, horizontal or vertical shape and other nuances).

Another important parameter is the availability of sand collection equipment. It should have a reasonable price.

Where to install

It is important to choose the right location for installing the sand trap. The equipment must be installed inside the general filtering system of the water flow. The load on the entire system directly depends on it. As for storm drainage, it is recommended to install a sand trap in an area with a direct transition from the water receiver gutter to the rest of the pipeline through which water enters the collector. If the location is chosen correctly and the equipment is installed professionally, the efficiency increases to 90%.

Operating principle of the BIOFOR grease trap

Order a grease trap

The BIOFOR sand trap is equipment designed for cleaning wastewater in cafes/restaurants/catering establishments from mechanical contaminants. Sand traps under the sink purify wastewater from small and large mechanical contaminants. They are recommended to be installed in workshops where there is a risk of large debris getting into the sewer system, for example, salad and vegetable shops. The operation of the sand trap is based on gravity and the speed of movement of sewage waste. During operation, large and heavy fractions remain at the bottom of the tank, and the water is cleaned of unwanted sand and heavy particles and flows further through the sewer. Biofor uses removable elements - both chambers can be easily removed from the sand catcher body, which greatly simplifies the process of servicing and cleaning the device.

Sand trap (Sand catcher)

A sand trap is a treatment facility whose purpose is to separate particles such as sand, small pebbles and other solid contaminants of mineral origin from surface wastewater.

The sand trap is the first link in the storm sewer complex, which provides the initial treatment of storm drains.

The main area of application for sand collection systems is industrial areas, public utilities, parking lots, gas stations, highways and almost all areas with hard surfaces. In some cases, a sand trap is used for the treatment of industrial wastewater and industrial storm sewerage. During rains, showers and snow melting, a huge amount of solid particles, among which sand predominates, are washed off from the surface of the earth into the storm sewer system. It is the presence of this substance in the sewer system that can cause many problems, including a complete stop in its operation.

A sand trap effectively solves this problem. During operation of the sand trap, gravitational sedimentation of suspended particles is observed, which accumulate at the base of the tank.

The principle of operation of the sand trap is as follows: surface waste water enters the treatment facility through the inlet pipe, in which, under the influence of gravity, sedimentation begins, that is, the elementary deposition of heavy mineral particles and other solid contaminants to the bottom of the treatment plant.

The efficiency of sediment separation from suspended solids reaches 80%. Sludge is pumped out using sewage disposal equipment. After being freed from this kind of contamination, the water leaves the sand trap through the outlet pipe.

Sand traps are made of fiberglass - a material that, due to its anti-corrosion and mechanical strength, has taken a leading position in the production of such treatment facilities. The sand trap is created using the machine winding method.

The design provides a cylindrical tank with a well for maintenance. The well is equipped with a ladder.

Sand Trap Characteristics Table

Performance

Case diameter, D.

Case length, L

To control the separation of sand, the treatment plant can be equipped with a sensor that signals the accumulation of a certain volume of sand and silt.

The finished structure is lightweight, which makes transportation and installation easier.

Fiberglass sand traps are installed in open ground without creating concrete formwork.

Tangential desander

A tangential sand separator is used in storm drains if there is a very high level of suspended solids of mineral origin in the storm drain.

The operating principle of this installation allows up to 90% of sand to be deposited. The supply of waste water to the walls of the sand separator is carried out tangentially, that is, tangentially.

The sand separator itself has a round shape, which helps create a rotational movement of the incoming liquid.

The tangential sand separator receives storm drainage, where each grain of sand begins to experience considerable gravity and impressive centrifugal force, as a result of which the sand begins to separate from the water, and light organic impurities are maintained in suspension without precipitating. This principle of operation allows you to retain a maximum of sand with a minimum amount of organic compounds. This is what distinguishes the tangential sand separator from traditional sand separators.

The tangential sand separator is made of fiberglass, which gives the installation anti-corrosion resistance, resistance to mechanical damage and an almost unlimited service life.

The sand separator has an inlet and outlet pipeline, a sediment reservoir and an airlift or pipeline for removing accumulated sediment.

What are sand traps made of?

Such filter elements are made of plastic, concrete, sand and polymers. The installation of a wastewater drainage system must be carried out using high-quality pipes or trays. At the same time, it is necessary to select internal sand traps. Such devices are made from plastic, concrete, sand and polymers. All components are mixed in certain proportions and placed in a special device. After this, the extrusion process takes place and a sand trap container is obtained under high pressure. The concrete sand catcher is endowed with high strength, while being lightweight and environmentally friendly. Sewage systems with greater capacity require sand traps made of polymer concrete.

What materials can a sand trap for storm drainage be made from?

Mainly, concrete (polymer concrete) and plastic are used to make sand traps. Concrete catchers are durable and can last quite a long time. However, their very considerable mass does not allow us to recommend a concrete sand trap for storm drainage for use on private land. In most cases, concrete or polymer concrete structures are erected at large industrial facilities, airfields, etc.

To equip the storm drainage system of a private house, it is recommended to opt for a sand catcher made of plastic, since it is lightweight and, unlike a heavy concrete sand catcher, can be installed independently without the use of special equipment.

Concrete sand traps require the use of special equipment during installation, and in terms of price they are not the most affordable devices. And in contrast to them, you can offer plastic. Modern plastic sand traps can successfully withstand enormous loads, so they can be installed both at industrial facilities and in small areas.

Plastic is not subject to corrosion, it is chemically neutral and can be used in any type of soil and in any water – depending on its chemical composition. Of course, plastic is lightweight. And even plastic sand catchers that are quite large in size will not require the use of construction equipment during installation in most cases. If necessary, a plastic sand trap for storm drainage can be quickly dismantled, replaced with a new one, moved to another location, etc. And plastic sand traps are much more affordable in price.

Overview of species

Due to the fact that treatment facilities are quite in demand and widely used, today several types of such structures can be distinguished (for example, local sewers for wastewater treatment, industrial equipment for hydrodynamic purification of flowing liquids and many other types). For the convenience of users and manufacturers, several classifications have been adopted that divide wastewater treatment plants into several groups depending on various factors and parameters.

For example, depending on the purpose and scope of use, treatment facilities are:

- industrial;

- household;

- for purification of storm drains;

- combined.

Another classification divides treatment facilities into groups depending on the volumes, compositions and inclusions of wastewater they are intended for. Depending on this criterion, the following structures can be distinguished:

- autonomous;

- local;

- industrial.

For example, autonomous (or individual) designs are suitable for a private home, local ones for a group of houses, and industrial ones for large-scale wastewater (they can even be modified into full-fledged treatment plants).

In addition to the classifications listed above, storage and flow structures are also distinguished.

Storage structures contain a special storage tank in which the bulk of wastewater accumulates. Later, the wastewater is transported to a special separation chamber, and then there is a uniform supply of water to the individual units. In general, the wastewater processing process is carried out within 72 hours.

In order to purify wastewater in flow-through structures, it is necessary to carefully calculate the design characteristics in advance. In this case, it is necessary to take into account such an indicator as the maximum flow value possible on the existing territory.

Calculation of basic parameters

There are sand traps of varying sizes and efficiencies for both domestic and industrial use.

To determine which sand catcher you need to purchase in terms of size and performance, you should carry out a calculation using the following data:

- volume of water discharged;

- pollution parameters;

- flow speed;

- daily sediment volume;

- territorial conditions for installation.

Let's calculate the dimensions of the structure of a horizontal block with a rectilinear flow of water, consisting of two main parts: working and sedimentary.

Example.

Initial data:

- volume of discharged water – 130000 m3 or qmax=1.50 m3/s (130000/24/3600);

- permissible flow speed – 0.15-0.30 m/s;

- hydraulic fineness of deposited sand – 18-24 mm/s;

- the planned number of residents is 415,300 people.

Solution:

- Three compartments are selected based on the calculation of 50,000 m3/day.

- Determine the required cross-sectional area of one compartment:

ω=q_max/vn, where- v – average flow velocity, m/s;

n- number of branches;

- ω=1.50/(0.25×3)=2.0 m^2.

- Calculate the length:

L=1000KHv/u, where- K – coefficient, taken from the table;

H – depth of the flow part, accepted for standard models in the range from 0.5 to 2.0 m, accepted 1.0 m;

- u – hydraulic sand size, mm/s, taken from the table.

- Find the width of one compartment, m: B=ω/H.

B=2.0/1=2.0 m. - Based on the obtained dimensions of the sand trap, choose a standard one from the table or design it individually.

- Flow rate at different values: υ_max=q_max/(BH n).

υ_max=1.50/(2⋅1⋅3)=0.25 m/s. - Time spent in the working part: T=L/υ_max.

T=13.43/0.25=53.72 s. - Calculate the amount of sediment per day m3/day:

W_day=(Nq_2)/1000, where- N – planned number of residents;

q_2 – specific amount of sand, taken from the table.

- We find the volume of one container: W_о=(W_day T)/n, where T is the time between sand unloadings, should be no more than 2 days.

W_о=(8.31⋅1)/3=2.77 m^3. - Find the depth of the container: h=W_о/B^2.

h=2.77/2^2 =0.69 m. - Calculate the height of sand sediment at the bottom: h_os=(W_day k)/BnL, where: k is the coefficient of sand distribution along the bottom, taken equal to 3.

h_os=(8.31⋅3)/(2⋅3⋅13.43)= 0.31 m. - Calculate the total building height: H_str=H+h_os+0.5.

H_str=1+0.31+0.5=1.81 m.

L=(1000⋅1.3 ⋅1⋅0.25)/24.2=13.43 m.

W_day=(415300⋅0.02)/1000=8.31 m^3/day.

A calculation of the dimensions of the horizontal sand trap has been obtained, which must be used as a guide when designing equipment:

- width,

- height

- and length.

BxHxL=2 x 1.81 x 13.43 m.

Other devices can also be used to remove mineral suspended matter from wastewater:

- hydrocyclones

- and centrifuges.

Their designs work thanks to the rotational movement of the liquid, which separates particles with different specific gravity. The heavier ones fall down, the lighter ones are carried away by the water flow.

Technical characteristics of pipes for rainwater drainage

Pipes that will be used to equip the stormwater system must comply with their operating conditions:

- strength - consumables must withstand various mechanical impacts, including compression, bending and shock;

- tolerance to ultraviolet rays - pipes installed on the surface of the site must withstand exposure to sunlight;

- resistance to aggressive reagents - sediments with various impurities will flow through the system;

- resistance to temperature changes - the consumable will remain in the same position all year round. Therefore, it is recommended to give preference to pipes that are resistant to winter and summer temperatures.

Kinds

Several types of stormwater systems are used.

- Open. Used in areas with small populations. A design of this type does not require a special device. Water flows through open gutters to grooves and is then drained away from the site.

- Closed. This type of storm drain into the sewer system has more elements and its design is more complex. The structure includes pipes, rainwater inlets, and sand traps. The water flows into special wells and is then removed from the territory. This type is used over large areas, in large populated areas.

- Mixed. Contains elements of both systems described above. It is used in closed areas, or when it is necessary to save construction.

Types of rainwater inlets for storm drainage

The shape of the rainwater inlet varies. There are the following main types of rainwater inlets:

- Rectangular. Such storm water inlets are usually installed on roads, streets, pedestrian crossings, and drainage canals as an addition. The device is mounted on a storm sewer well, and the frame is sometimes filled with concrete.

- Round. Most often installed on wells for collecting storm water. This variety is able to withstand heavy class B loads, temperature changes and other negative environmental influences. For installation, special fasteners are used.

- Storm water inlet with frame. Designed for point drainage and local intake of rain and melt water. Able to withstand loads of class C, therefore it has additional capabilities for use in high pressure conditions, for example, on highways.

The round shape is more difficult to install because it requires digging a round trench. Rectangular ones can be installed without any effort. In this case, the installation must be carried out in parallel with the installation of the road surface, then there will be no difficulties. If the rainwater inlet is installed after the installation of the road surface and landscaping of the area, it is better to choose a square shape.

We install storm drains, connect pipes and sand traps with our own hands

Every city dweller has an idea of what a poorly functioning city storm drain is. As a rule, after a person steps in a puddle on the asphalt, a lot of dirt remains on his shoes or boots, as a result of which the quality of the shoes he wears deteriorates.

For a city resident, the loss of shoes is considered minor damage, but for the owner of a private house it is more serious damage.

To prevent the destruction of the foundation, as well as to prevent precipitation from getting into the basement of the house or destroying the planted plants, the owners of country cottages or summer cottages drain storm water from the house.

A simple storm drain can be installed by any owner of a private home who is not a builder by training and does not have experience in this field.

However, installing an external storm drain is not considered the easiest process. The complexity of the work lies in the preliminary preparation of the project and carrying out specific calculations.

This material talks about how storm drainage is installed in a private house - how to independently carry out drainage in a private house (installation of storm drainage).

Purpose and advantages of grease traps

More complex models of grease traps are used in large enterprises and are designed to effectively purify wastewater from solid particles, fat-containing and oil impurities.

According to sanitary standards in meat and dairy production and in public catering establishments, the installation of grease collection equipment in the sewer system is mandatory.

Industrial devices are installed at the outlet of a treatment structure that performs primary wastewater treatment.

Installing a grease trap will protect the sewer system of any catering establishment or production facility from contamination with fat and oil inclusions

Industrial devices are developed by manufacturers to ensure that clean water, purified from foreign impurities, enters the sewer system by separating and further removing the fatty component of the waste mass.

Installing a grease trap will help prevent sewerage failure due to the effects of grease deposits. It also protects the environment from the release of harmful impurities that can cause irreparable damage to the environment.

Such separators are indispensable not only in production, but also in everyday life. They reliably protect sewer pipes from the occurrence of grease valves or blockages. At the 1st stage, the device receives household water and separates fat and oil accumulations.

At the 2nd stage, the final separation of fat deposits and the removal of effectively purified water into the sewer system is observed. The device traps non-emulsified fats and removes them from wastewater.

A grease trap installed under the sink is often used in home kitchens, cafes, restaurants, pastry shops and fast food establishments.

The use of grease removal equipment has a number of advantages:

- Equipment tightness. Due to the tightness of the housing, the possibility of foreign liquid entering the filter is excluded.

- Practicality and versatility. Installation of various additional devices is possible. The sensor for the accumulation of harmful substances is in particular demand.

- No unpleasant odors. Due to the tightness of the housing, odors that usually arise during the breakdown of fats do not penetrate into the room.

- Easy to install. Installing indoor grease traps does not require any special skills and is carried out in 4 stages.

- Ease of maintenance. Cleaning most models of grease traps does not require much effort; it can be done manually using available tools.

- Reasonable price. The devices have a low price compared to other types of filters.

In addition to these advantages, the device that collects fat also has a long service life. All equipment is made of high-quality and wear-resistant materials, which guarantees its durability.

An important advantage of using a grease trap is the preservation of the environment, which is especially important in modern times.

Terms of use

Like any equipment, a storm drain sand trap needs proper care and proper use. This is necessary to ensure the correct and reliable operation of the equipment, as well as to prevent other undesirable consequences that a clogged device can bring. The rules for using a sand catcher are as follows:

- It is necessary to check the operating process of the device at least once over a six-month period. At the same time, measure the layer of deposits in the container.

- When the layer of mud deposits reaches 30% of the total volume of the device, it is necessary to pump it out using a special machine. In terms of terms of use - this procedure is carried out once a year.

- Checking the serviceability, as well as completely cleaning the device, must be done once every two years. Cleaning involves removing dirt that has settled on the walls using a strong water jet. This process is called unloading. To maintain the good quality of the purification processes of the water flows entering the system, thin-layer filter units should be cleaned. This process will also help prevent clogs. The frequency of this event directly depends on how heavily polluted the water that enters the drain is. In any case, this process must be performed once a year.

- In order to completely unload the sand trap for storm drainage, it is necessary to lift all the blocks in the structure through a technical well. After this, they are washed with water, which has strong pressure and is directed towards the device. Otherwise, you can resort to special equipment for such cleaning.

- It is also important to remove dirt deposits from the walls, as well as in the gaps of the plates. After the washing process is completed, it is necessary to pump out the water that remains from the device, only then can it be installed back.

- When the maintenance of the sand trap for storm drainage is completed, it should be filled with water at the site of its installation. This technique will prevent the device from being squeezed out during installation if the groundwater is located high enough.

- Additionally, it is recommended to keep a book in which all processes and their dates that were carried out with wastewater treatment equipment will be noted. This will allow you to monitor the frequency of its maintenance.

Types of sand traps

Storm sand traps are classified according to two qualitative criteria.

The first is the execution option:

- Horizontal - a device in the form of an elongated rectangle, divided into two parts: a working zone through which water moves, and a sedimentary zone in which sand and other sediments accumulate. In such a sand catcher, water can move both linearly and in a circle.

- Vertical - is a solid large cylinder. Here, heavy particles themselves settle to the bottom, and the remaining clean water continues to move unhindered and exits through a special hole.

- Tangential - a round sand trap, into which wastewater is supplied tangentially through a tube. Getting into the tank, the liquid hits its walls, twists and creates a screw movement, during which the water is cleared of large suspensions - sand and other heavy particles settle, and the water stream passes on.

- Aerated - an elongated rectangular device, on the long side of which there is an aerator - a filter that purifies the water flow.

Advice. Tangential and aerated sand traps are considered the most effective - they retain 90-95% of sand.

The second sign is the material used to make the sand catcher:

- Plastic - lightweight, resistant to chemicals and temperature changes, but has low impact resistance.

- Concrete is strong and durable, but has impressive dimensions, making it inconvenient to install.

- Polymer concrete is a universal option that combines the strength of concrete and the lightness of plastic. Of the three devices reviewed, they tend to have the highest cost.

Sand trap installation

Sand trap design and operation

A typical desander is a closed tank, the structural elements of which are:

- Inlet pipe for sewage supply;

- bottom compartment (basket) for separating sand and other solid particles;

- lattice;

- outlet pipe.

Some catcher models also have airlifts (pipes for removing sediment).

The sand receiver is installed together with surface drainage channels

Let's consider what the principle of operation of a sand trap is based on.

Water entering the storm drain moves at high speed through the drain pipe. Once it enters the treatment tank, which has a large diameter, it slows down. Suspensions such as sand, silt and clay contained in it, under the influence of gravity, settle to the bottom of the tank. The water purified from them enters the storm sewer through the outlet of the device.

Sand trap installation

Correct installation of the sand trap will ensure its efficient operation, so you should adhere to the general operating scheme recommended by experts. Let's take a step-by-step look at how to install a sand trap with your own hands.

The work consists of the following stages:

- The area for storm drainage is being marked. The location of the trap should be located immediately after the gutters, before entering the waste pipeline system;

- A trench is dug for drainage trays. Its slope should be about 1-2 cm per 1 linear meter. The depth of the trench should be such that the upper edges of the trays are 5 cm below the soil level. The thickness of the concrete filling of the pit and the thickness of the sand cushion are also taken into account;

- The bottom of the trench is concreted. To make the system durable, it is also recommended to concrete the walls of the trenches. The concrete layer prevents distortion of structural elements during operation of the storm sewer. If the walls have not been concreted, the trench voids are filled with a mixture of sand and cement;

- All elements of the system are mounted and connected to each other. Reliability of docking is ensured thanks to the presence of special latches. If there is a desire to ensure maximum tightness of the joints, they are treated with a special waterproof sealant;

- Protective grilles are installed on top of all elements.

We discussed the importance of such a storm drainage element as a sand trap. A properly installed sand trap will protect the drain collector from contamination and extend its service life.

And in order for the storm drain to successfully cope with the removal of wastewater for many years, it is necessary to regularly clean the sand catcher from bottom sediments.

Expert opinion when installing sand traps

For sand collection devices, it is necessary to build a separate pit - regardless of the size of the device itself. It is also necessary to separately arrange a gravel or concrete pad for them. The upper section of the sand trap must be covered with a grid with locking joints. If the catcher is plastic, the grid must be plastic. The industry also produces concrete gratings for concrete catchers.

Alexei.

Particular attention should be paid to cleaning the sand trap and grate in the fall and spring, when the watercourse is particularly polluted. A sand trap for storm drains is an absolutely necessary device that will effectively protect the storm drain from debris and increase the efficiency of its operation.

Nikolai.

Where is the sand receiver installed?

A storm drainage system is a complex engineering mechanism that requires precise calculations

That’s why it’s so important to install each element of communication in its “right” place.

For a sand trap, this is a direct transition from water gutters to a system of installed pipes that will carry wastewater further along the collector to the central drainage well. In this case, the sand trap necessarily occupies the first place in the installation system and acts as the main element of the liquid filtration system. It is installed before all other filtration systems.

Inspection or rotary wells can also serve as traps for sand and small debris in a domestic storm sewer system, since the diameter of their tanks is larger than the diameter of the pipes through which water moves.

What else you need to remember when arranging a storm drain

In order for a storm drain to successfully cope with all its responsibilities for draining water flow, it is imperative to take into account some points. First, in order to prevent clogging and clogging of the system, it is necessary to provide inlet protective grilles. They can be made of different materials and come in a variety of shapes. But they have one purpose. Or rather, two. Firstly, the retention of coarse debris - branches, stones, leaves, etc. Secondly, the gratings will guarantee the safe passage of people and vehicles.

The photo shows sand traps, storm water inlets, gutters with gratings of various shapes and sizes.

Important! When designing a storm drainage system, it is necessary to ensure that the optimal slope of the watercourse is ensured.

The water will simply flow away, obeying the force of gravity. The angle of inclination must take into account the diameter of the pipe. The relevant standards are found in SNiPs for storm drainage. But in most cases, for a private, not too branched storm drain, it will be enough to provide a slope of 1-2 centimeters for each meter of pipe.

Before entering the sand trap for storm drainage, the slope should be reduced somewhat so that the flow does not mix inside the trap box, and the sand fractions have time to settle in it. Absolutely all sewerage elements must be sealed. Even the slightest leak is not allowed. This will prevent not only erosion of the soil and damage, for example, to the road surface, but also the formation of mold, rot, etc.

Pipes that are corrugated inside are highly not recommended for storm sewer installations. After all, it is often in them that debris accumulates. In the future, this will inevitably lead to the formation of a garbage plug, getting rid of which may not be a simple task, as it may seem at first glance.

When designing a storm drainage system, it is necessary to provide for as few possible joints, differences, and changes in direction as possible. After all, it is in these places that depressurization of the system most often occurs.

You should take your measurements especially carefully. Footage is a very important component of the project. Even in case of doubt, it is better to purchase pipes with an inlet. Modern plastic pipes can be cut to the required length very easily and quickly. But it will be very disappointing if in the end it turns out that literally 10-20 centimeters of pipe are missing. The same applies to purchasing all the necessary adapters, fittings, seals, etc. You need to make a detailed list of everything you need to purchase in advance.

When organizing inspection wells, it is recommended to install them more often. In this way, it will be possible to monitor the state of the entire system more efficiently. In general, the following rule works here: the smaller the diameter of the pipe, the smaller the distance between the wells should be. Indeed, in this case, the risk of a blockage also increases, and it will be a shame not to get to the area needed for cleaning just because the inspection well cannot reach there.

Installation features

Sewerage construction is carried out on the basis of design data. Preliminary calculations and creation of an assembly diagram are carried out in accordance with SNiP and SanPiN standards, ensuring full compliance with all requirements.

The pipeline is laid at a depth exceeding the winter freezing level of the soil. Procedure:

- excavation. They dig a trench for the pipeline. Immediately make nests for inspection wells;

- a sand cushion is poured onto the bottom of all recesses to level and give the desired slope;

- by laying pipes with a certain slope towards the receiving tank (usually for gravity systems 2 cm per meter);

- if plastic containers for wells are used, a concrete slab - an anchor - is first laid at the bottom. It prevents the reservoir from being squeezed out by groundwater;

- All connections are carefully sealed. Check the system for leaks. After this, the pipes are insulated and covered with soil.

When constructing pressure sets, the SPS is first assembled, after which the remaining trenches are laid according to the described scheme. For maintenance and repair of pumps, it is necessary to ensure access to the station at any time of the year.

Tips for choosing

It is recommended to rely on the following criteria when choosing a sand trap:

- the material of the product and its weight must be suitable for storm drainage;

- it is necessary to choose the optimal form for draining;

- the device must withstand high water speed;

- the dimensions of the device must be selected taking into account the entire sewerage system;

- the model should capture as many mineral impurities as possible.

The use of sand collectors will increase the permeability of water through the pipes and increase the service life of the entire drainage system.