Growing garden crops depletes the land. Preserving its fertility is ensured by the application of fertilizers, the best of which is compost. There are enough materials for its preparation at any summer cottage: fallen leaves, mown grass, weeds and food waste. Compost can be made by dumping all the listed ingredients into one heap. This method leads to irrational use of the site area and does not look attractive enough. A special container for processing garden waste into fertilizer will help you avoid these shortcomings and get high-quality compost. The editors of the YaNashla website offer readers a review of the best composters for 2021, compiled based on customer reviews and expert opinion.

Humus and compost - what's the difference?

It is a mistake to assume that these two terms have the same meaning. What they have in common is only the essence of obtaining fertilizer, namely the process of decay. The difference lies in the components used, which will lay the basis for feeding and its vitamin and mineral composition.

Humus

This is decomposed manure - cow, horse, rabbit and any other, depending on the household living on the site. The entire process of debate or decomposition takes from 2 to 5 years. The finished humus should have a pleasant, fresh aroma, like soil in a forest. To improve the quality of the fertilizer, manure is mixed with soil, sawdust, straw, adding water if necessary to prevent drying out.

The presence of a heavy ammonia smell indicates that the humus ripening process is not yet complete.

From time immemorial, almost all crops in Rus' were fertilized with manure. It is excellent for sandy loams, retaining moisture in them. It makes clay soils looser and more aerated. Ready-made humus is the same humus that is a fertile component of any soil.

Compost

Not all summer residents have the opportunity to fertilize their plots with humus. In this case, compost will come to the rescue; you can make it yourself using a pit or a special container - a composter.

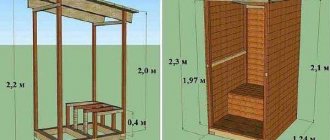

Basic elements of a woodshed for a summer residence

Regardless of how the storage is located - next to the building or separately - it has mandatory elements, the presence of which is determined by the rules for storing firewood:

- high-quality wood ventilation;

- lack of direct contact with wet environments - for example, open ground or a wet wall;

- protection from precipitation from above.

To ensure that these rules are followed, the storage design includes:

- foundation. It is rarely capital; blocks and beams laid on prepared soil or a sand and gravel bed are sufficient. In very damp areas (near a river, lake, swamp, with a high groundwater level), pile foundations are used;

- ventilated flooring-base. It is most often made of lattice or planks with rarefaction (gaps between the boards) and is supported by foundation elements. The flooring must have high strength, since it can withstand the load from the weight of the entire bunch of firewood, which can be up to several hundred kilograms;

- ventilated fence walls. The design is made in the form of a lattice or a continuous fence, but in the latter case it is necessary to provide at least one open side so that the firewood is well ventilated. Otherwise, mold and woodworms will become frequent “guests”, or even permanent “residents” of the storage facility;

- waterproof roof. It does not require insulation, but the waterproofing must be at the level - there is no need to wet the future fuel in the autumn rains. This requires sufficiently large overhangs and good drainage of rainwater. Otherwise, drops falling from the canopy, bouncing off the ground, will fall onto the woodpile and lead to damp wood.

Important: in addition to arranging the woodshed itself, it is necessary to provide for the preparation of the site next to it and the approach. The best option is a trampled (rammed) platform and path based on gravel (crushed stone, pebbles, sand) or paved/concrete/tiled areas.

What conditions are necessary for composting?

The simplicity of preparing compost only seems at first glance. In reality, proper composting conditions are necessary for the fermentation process to proceed correctly. The main factors that naturally influence the course of this process are:

- The presence of vegetation , which releases nitrogen during debate. To increase the nitrogen content, you can plant the tops of legumes.

- The presence of wood chips , small branches and sawdust provides the compost with carbon, loosens it and creates a homogeneous mass.

- Enrichment with oxygen speeds up fermentation. To improve aeration, the compost heap needs to be stirred regularly.

- Maintaining moisture is very important, since drying out the compost slows down the chemical reactions that accompany decomposition.

- Heat is an integral participant in the decomposition reaction of compounds. It is produced by microorganisms that carry out their life activities in a suitable habitat. The release of heat in the compost heap indicates a normal process of decay.

Tools for work

To construct a compost container, it is recommended to prepare the tools in advance. The work is carried out using a hammer, drill or screwdriver, nails or dowels, and a tape measure for measurements. If you plan to fill the bottom, you can use a concrete mixer to prepare the concrete mixture.

What is a composter and what is it for?

To prepare compost, a hole is traditionally dug. However, its use is not very convenient, especially when you own only 4-6 acres. The small area of the site, the smell emanating from the pit, and the inconvenience of mixing the compost heap force one to look for an alternative.

A composter is a container of a given volume, the special device of which provides for the creation of favorable conditions for the preparation of compost.

Each design must have:

- a lid where the material for composting is placed;

- holes for air intake;

- holes at the bottom to remove accumulated liquid.

Additional features may vary by model.

You can make a composter yourself from scrap materials - this is a good money saver. The advantage of purchased models is durability and beautiful appearance, which allows you to place the boxes anywhere.

Composters are made from different materials, such as wood. In such products, the contents are well saturated with oxygen; as a result, the fertilizer is crumbly, but sometimes a little dry. Metal containers retain moisture excellently, so the finished compost is moist and denser. There are also composters made of plastic that are resistant to low temperatures and ultraviolet radiation.

Bacteria culture

In a system of two heaps, the compost was regularly transferred, turned, and sometimes manure, ash, and peat were added. Such manipulations are permissible in a system of two sections, but if there is a culture of composting bacteria, they are unnecessary.

Science is constantly moving forward, and it is strange to refuse its achievements. You should not avoid using agricultural innovations even in such a seemingly insignificant matter as composting. A culture of specially bred bacteria allows you to process organic residues as efficiently as possible. It is available, inexpensive, and has a long shelf life. Bacteria work most successfully on homogeneous material. For example, lawn cuttings, loaded into the composter section to a height of approximately 1.5 m, settled by half a week after adding a bacterial culture. And after 2.5-3 months the compost was ready. While without the addition of bacteria, the compost rots for more than six months.

Well, why are there two sections in the composter if composting goes so quickly? Simply because it is impossible to use up all the old compost in a short time, and the new mass for composting needs to be put somewhere. So it turns out: in the spring you open a section with compost; unrotted grass and foliage, collected in the fall before frost, are thrown into an empty section; you gradually use up the finished compost, and put a new mass in the empty section, add bacteria and, over time, add more herbs. In practice, old compost is completely consumed in the fall, when its remains are mulched and covered with fruit bushes. As a result, the composter enters winter with one filled and one empty section.

What are the advantages of using

A composter is for a summer resident what a food processor is for a housewife. This is a convenient thing that will help save time, effort and money. Composters, especially closed ones, have many advantages, the most significant of which are:

due to compactness;

saving site area- absence of odor and environmental waste pollution due to a special design;

- reliable, durable materials resistant to external influences;

- reduction of composting time under optimal conditions inside the composter;

- high quality of finished fertilizer at the output;

- excellent thermal insulation properties , allowing you to prepare compost even in winter.

Modern composters have excellent performance and aesthetic characteristics, so they can be installed without harming the design of the site. In addition, manufacturers began to produce landscape devices in the form of a small mound, decorative stone or other natural elements. Such models will not only perform their functions, but will also decorate the place.

Adviсe

If you still decide to save your finances and create furniture yourself, then you should start with simple things that are easy to implement. You should not choose circuits with many complex connections.

Any type of tree is perfect. Everything will depend on what you want to implement. Before starting the manufacturing process, make a detailed sketch. Only after this should you start working.

Prepare your work area thoroughly. It is worth stocking up on the necessary materials, as well as finding the tools that you will need for the job. You can create stylish options by combining different materials.

Don't be afraid to pursue your most creative ideas. If you need practical advice, then contact an experienced specialist.

Types

According to the type of their functioning, composting devices are divided into:

- Open composters that operate during the warm season. This is the most economical option. It is easy to assemble and convenient to use in large areas where there is a lot of organic material.

The disadvantage of this type of construction is the spread of unpleasant odors and the possibility of overgrowing with vegetation. In addition, the fermentation period increases.

- Closed composters are more convenient to use. They are small, their volume ranges from 200 to 1000 liters. Such composters can be left outside all year round, and can be easily hidden in the garden if necessary. Moreover, chemical reactions inside proceed faster, which means the fertilizer will be ready sooner.

The only disadvantage of closed composters is the price. It is significantly higher than that of open type composters.

Selecting a location

Even the nicest compost bin will be an unfortunate neighbor for residential buildings and can interfere with the movement of cars and garden carts.

You should not place it at the main entrance to the dacha, otherwise an unpleasant smell will greet both you and all your guests. Find or clear a hidden area in the shade to prevent the sun from drying out the compost. And to the finished pit, lay a convenient path, wide enough for the cart. The ideal solution is to pave the path with bricks or stones to prevent the wheels from getting stuck in the grass and sand.

Models

Among the variety of industrial composters, the following three models are distinguished, which differ in their design features:

- Box. This is a simple model that looks like a regular plastic or wooden container with a lid.

Typically, such a device is easy to assemble, disassemble and does not cause inconvenience when moving to a new location. The most popular volumes of this model are 600 and 800 liters. - Thermocomposter . It operates on the principle of a thermos, retaining the heat of the contents due to the insulated body. The device can withstand frosts down to -40°C. In it, active chemical reactions occur all year round, slowing down only when the temperature drops below -15°C. Most often, thermocomposters are made in the form of a barrel or a sphere - this way they maintain the temperature better. The model is ergonomic and easy to use.

- Vermicomposter. This is an improved composter model in which fermentation occurs through earthworms. It has a different design, but most often a tray-type device is used. “Plant food” is placed in the container, where the worm is then placed. After he has processed the waste in the first tray, a second one is installed on top of him and so on. The vermicomposter can be installed on the balcony, in the garage, in the garden and anywhere. The result of the vital activity of the worm is natural vermicompost.

CONDUCTING ELECTRICITY

Then electricity is supplied to the workshop (copper wire is used for these purposes) and several sockets are installed to distribute the load. For lighting, spotlights with 500 W halogen lamps are installed under the ceiling. In not very cold weather, the heat generated by these lamps is enough to heat the room. Local lighting of the workplace is provided by lamps with LED lamps, which is very economical; for comfortable illumination of the workbench plane, 3 lamps of 6 W are sufficient.

Carpentry workshop for personal use. Ideas and personal experience // FORUMHOUSE

Watch this video on YouTube

How to choose?

Choosing a composter starts with its volume. For small areas (up to 6 acres) or for the disposal of food waste, a design with a volume of 200-300 liters is suitable. For a larger area, a larger capacity will be required - up to 1000

l. Sometimes summer residents purchase two or three composters at once and put organic matter into them one by one, thereby providing themselves with a continuous supply of organic fertilizer.

When choosing a composting device, we focus on its structural details. For example, it is important to pay attention to the presence of a bottom mesh that protects the contents of the container from rodents.

If it is not included in the kit, you should worry about purchasing additional items in a timely manner. Yes, and it won’t hurt to immediately decide whether it will be a summer composter or whether all-season placement of organic matter is planned.

Before purchasing a box, you need to pay attention to the entrance and exit hatches. They should be wide enough to make it convenient to lay armfuls of grass and scoop out fertilizer with a shovel. Having a large loading hatch will make it easier to stir the pile to increase oxygen access. An alternative to the unloading hatch can be a pull-out tray with ready-made fertilizer from the lower layers.

Expert opinion

Yulia Safronenko

Big fan of experiments and personal gardening techniques

Ask a Question

Hatch fastenings are a fly in the ointment for many models. During operation, it is discovered that the doors dangle and tend to fly off due to the wind. Therefore, before purchasing, you need to check how they rotate and how tightly they fit when closed.

The mobility of the composter is important, especially if it is stored for winter or regularly moved. If you plan to compost throughout the winter, a thermal composter with a thermostat, thermal insulation and peat included will be indispensable. For lovers of California worms, a vermicoposter is suitable.

Household block with woodshed

This building combines separate compartments for storing household equipment and firewood. Accordingly, the part for storing equipment should be more protected from bad weather and uninvited guests. Partially, the degree of protection depends on what kind of equipment will be stored - for power tools you need good waterproofing, but for wheelbarrows, hoses and shovels, a normal roof and the absence of strong humidity are sufficient.

Since a large supply of fuel is usually stored in a woodshed attached to a utility block (or built together with it), a foundation will be required. For it, you can use monolithic supports, block or piles. If there are wooden ridges (butt parts of large trunks, at least 0.7...1 m in diameter), they can be used as supports. To do this, the ridges are cleared of bark and possible damage (rot, fungus, blue stains), impregnated with an antiseptic (for example, waste motor oil) and coated with molten bitumen. For greater safety, you can make a second layer of waterproofing - after hot coating with bitumen, wrap it in roofing felt.

Approximate plan of the foundation for a utility block with a firewood shed

An example of a utility room with a woodshed

Please note that the part where the tools are stored has a solid sheathing, and the side and rear walls of the woodshed are sheathed “staggered”

An example of a frame design on columnar supports. The woodshed is located on the left

The construction principle is the same as for a conventional free-standing storage facility:

- organization of foundation supports (preferably on a previously prepared site with gravel/crushed stone/sand filling and compaction);

- fastening racks to supports using studs, mortgages or fastening profiles;

- assembly of transverse and longitudinal frame elements;

- arrangement of the rafter system;

- wall cladding (solid for the utility block, sparse for the woodshed). Part of the sheathing can be replaced with crosses or several beams packed transversely (parallel to the ground);

- roof installation (waterproofing, roofing material);

- hanging the door on the utility block.

The video will help you figure out how to build a firewood shed with your own hands.

Please note that the utility unit does not have to be designed for storing useful things. There may be a summer toilet or shower, even a summer kitchen or a place to spend the night

The best manufacturers

Kekilla Global (Finland)

Perhaps the first place can be assigned to the Finnish manufacturer Kekilla. Their composters are distinguished by excellent resistance to severe frosts, and therefore are considered universal. The most popular Globe model does not have any heavy or small parts. The design is rounded, easy to use, safe for children.

Due to the high composting speed, the device has a volume of 310 liters. the amount of finished fertilizer per season is comparable to 600 liters. In addition, the volume can be artificially increased by adding a pair of 160-liter rings, which are purchased separately.

The compost is reliably isolated from the environment, and after maturation it is easily removed with a shovel. To do this, simply remove the lid and body, opening access to the contents. The Finnish flag key on the composter is a sign of the highest quality products made from our own raw materials.

An analogue of the Finnish composter is the Russian Meridian, which has been on the market for 5 years. It has the same characteristics as its Finnish “brother”, but on the outside it has a pattern in the form of parallels and meridians. It has a favorable price.

Graf Thermo King (Germany)

Another thermocomposter model that has proven itself in practice. Its body is made of UV-resistant plastic, the foam structure of which perfectly maintains the optimal temperature inside the box. There is support for selecting summer and winter operating modes.

The lid consists of two wings and is securely fixed. Doesn't open even in strong winds. Loading of material, accordingly, is carried out from both sides, just like extracting the finished compost. The design of the device is beautiful, ergonomic, and easily fits into the landscape.

Volnusha (Russia)

This is a cone-shaped container, the body of which has a wavy shape (hence the name).

Made from frost- and heat-resistant propylene of increased rigidity, which, due to its shape, perfectly distributes the compost mass. At the same time, it does not oxidize and does not enter into a chemical reaction with other substances. The volume of Volnushi is 1000 liters, ideal for six acres. It has no bottom, so excess moisture will go into the ground. However, additional purchase of a bottom mesh is required to protect against rodents.

The housing has ventilation holes and four openings for compost extraction. Easily disassembled and transported in the trunk of a car. The disadvantage is that the lid opens in strong winds.

Manufacturing materials

Before making a compost bin for recycling waste with your own hands, select the material for its manufacture, most often consider the following options:

Wood

To make a wooden box, they use boards that are unnecessary in the household, ready-made pallets, timber; there is no point in using plywood, fiberboard or chipboard sheets that have too low resistance to moisture. Since untreated wood will not last too long, it is coated with moisture-repellent materials - various types of paints, varnishes, hydrophobic impregnations, waterproofing mixtures, bitumen mastics.

Note: Economical and effective ways to process wood are to impregnate it with machine or waste oil, you can simply wrap individual boards with plastic wrap and nail them to the frame.

Metal

Using regular steel for a box with high moisture and fertilizer that will be added to the soil to feed edible crops is not a good option, given that rust will contaminate the compost. Therefore, the best option is to use corrosion-resistant materials in the construction of the box, the most inexpensive of which are galvanized sheet (metal profile) and aluminum.

A metal box can be assembled from separate narrow plates or corners (to increase strength), screwed to a wooden frame made of timber treated with water-repellent compounds.

Rice. 6 Polymer composters

Polymers

Making a compost bin or barrel from polymers is the most successful option in terms of corrosion resistance and service life of plastics, reaching up to 50 years. The retail chain sells factory-made composters for dachas that have an aesthetic appearance, a variety of design and color solutions, and a convenient system for accessing the lower layers of humus. The price of plastic composters is not so low, a rather inconspicuous product can be bought for 2,000 rubles, the cost of imported boxes or large-volume products reaches 15,000 rubles.

Other materials

In addition to traditional components, a compost bin can be built from the following materials:

Net . Mesh types of compost containers are sold on the market, providing the best air exchange; similar devices can be made yourself from a chain-link type mesh. During operation, the mesh box will have to be closed on top with a waterproof lid, and during operation it will be difficult to mix the compost mass.

Note: When constructing a composter bin, a synthetic mesh is often used, which closes the gaps between the wooden boards, preventing the contents from falling out; with this design, the distance between the slats can be increased to 50 mm.

Rice.

Slate mesh boxes . Recently, slate has significantly lost its position when used as a roofing material; one of the ways to use it is to construct waste recycling containers from sheets. In many versions of boxes, the walls are made of solid sheets, which prevents air exchange.

Brick . A reliable and durable box can be made of brick or any building blocks; when laying, it is possible to make cells for air exchange; the main disadvantage of a monolithic structure is the difficulty in mixing and removing ripened masses.

Operating rules

- Do not overload the container - the finished fertilizer should be loose and slightly damp. The material should be immersed in it no higher than the maximum mark.

- It is recommended to install the composter on the ground or grass, but not on a wooden or concrete base. This is necessary to ensure access for worms inside the structure and to remove excess moisture.

- The best place to install a composter is a shaded and wind-protected area away from open fire.

- The bottom of the composter should be protected with a metal mesh to prevent mice from entering.

- When cold weather sets in, the device must be switched to winter mode or wrapped in film to maintain the internal temperature.

- Regularly 1-2 times a month you need to stir the compost heap to improve chemical reactions. In this case, it is better not to touch the lower, ripened layer.

Slate box

This option often turns out to be the most budget-friendly. In addition, if you wish, you can easily find a drawing of a slate compost bin and step-by-step photos of the assembly process on the Internet.

Advantages of the material: it does not rot, it is convenient to segment and process. The disadvantage is fragility, so the walls are usually mounted on a support made of boards.

We offer this method of creating a compost box with your own hands:

- mark the space for the proposed box;

- make recesses in the corners, install vertical supports;

- between the posts you secure prepared boards of the required length;

- Mount slate sheets on the boards. Holes in the sheets are not needed; it is enough to fasten them not tightly, with gaps.

How to make it yourself

A composter can be made from scrap materials - boards, old furniture, construction debris. Most often, wooden containers are made, since working with wood easily allows you to meet all the necessary conditions. Furniture is not good in this regard; it usually only lasts for one season.

For convenience, you can prepare a drawing of the box. It will be easier to navigate during the work process, as well as calculate the amount of material needed. The optimal size of the composter is 1 m3, that is, 1m×1m×1m.

To work, you will need a 5-centimeter beam and boards 2.5 cm thick. All material will need to be treated in advance with an anti-rotting agent, which will prevent the body from participating in fermentation.

First, posts are made from timber, which are dug into the ground and, if desired, fixed with cement mortar.

Next, the side walls are assembled, followed by the back and front. A 1-2 cm gap is left between the boards for oxygen access. A small gap is also necessary from the surface of the earth. For convenience, the front wall can be shortened a little, then the hinged door will lie at a slight angle. The side door will make it much easier to remove the finished compost.

Two- and three-section composters are made using the same principle. While the debate process is going on in one section, plant material is being laid in another. You can make the side walls of the device not from boards, but from fine-mesh stainless mesh, enclosed in wooden frames. The frames are attached to lumber posts, creating a perfectly aerated container.

There are many options for making composters. Here you can truly show your imagination and skills. It is only important to follow the basic operating principles of the device, which are responsible for the quality of the finished fertilizer.

Capital construction options

To build the box you will need new thick boards. Compost is created with the help of bacteria that process waste; this is an aggressive environment for any organic substances (the boards with which the box is built can decompose). That is why you need to choose reliable boards, treat them with a special compound to prevent rotting, and you can paint them well.

Between the boards you need to leave gaps, the width of which should be several centimeters. This is necessary so that the compost can receive a sufficient amount of air, this is a prerequisite!