Basements and ground floors of private houses located in areas with high groundwater levels are often subject to flooding, which can ultimately lead to the destruction of the foundation. A complete drainage system installed around the house will prevent this.

We will tell you how to arrange drainage and install a drainage well with your own hands. The article presented for consideration describes in detail the design of a system for collecting and draining groundwater to drain it from the foundation. Options for constructing wells are listed and installation methods are described.

For a visual understanding of complex information, it is accompanied by useful diagrams, collections of photos and video tutorials.

Main types of drainage wells

There are several types of wells, which differ from each other in their purpose, material of manufacture and size. The design of drainage wells of different types is almost the same.

They are a container with a closed bottom, into the shaft of which drainage sewer pipes are supplied. The well is completely immersed in the ground, and its top is covered with a hatch.

The main difference between wells is their purpose. Each type is designed to perform a specific function and is located in a specific place in the drainage system.

Characteristics of manholes

Inspection or otherwise inspection drainage wells are intended for:

- conducting routine inspections of the sewer system;

- monitoring the performance of the pipeline;

- periodic cleaning of pipes and carrying out repair work.

Inspection wells are installed in places where there is the greatest likelihood of contamination or silting of pipes. Their sizes are selected taking into account the characteristics of the sewer system. In small pipelines, as a rule, inspection wells with a diameter of 340 to 460 mm are installed.

It is advisable to equip a large drainage system with large-diameter inspection wells, equipped with all the necessary devices for carrying out routine inspections and repair work.

Large drains are equipped with drainage structures with an internal diameter of up to one and a half meters. Some containers are equipped with steps for convenient descent. An adult can easily fit into such a well to carry out work on cleaning or repairing the pipeline. Cleaning the system is carried out by flushing the pipes with a jet of water under pressure.

A type of inspection wells are rotary structures, which are located at the corner joints of pipes. They do not have to be installed on every turn; they are usually installed across the corner.

When installing rotary wells, it is necessary to take into account the design of the drainage system and install them so that all corner and cross sections of the pipeline can be brought to them.

Rotary wells are buried in the corners of the pipeline. They are installed in such a way that, if necessary, it is possible to quickly clean the sewer

Purpose of storage structures

A collector or in other words a water intake well is used to collect and accumulate water and its subsequent pumping into a reservoir or drainage ditch. It is a large container with a diameter of up to one and a half meters, into which all the pipes of the drainage system are diverted.

It is installed in places where it is impossible to install a filter well or to divert water collected by the sewer into a drain. As a rule, they are taken outside the site.

To drain accumulated water, a submersible drainage pump with a drain pipe is installed in the collector wells, which pumps the collected liquid into a natural reservoir

The water intake tank is usually equipped with an electric pump, which pumps the accumulated liquid into a reservoir or for watering a garden. Typically, an automatic system is installed in storage tanks, which, when the tank is filled to a certain level, pumps out water automatically.

Features of absorption tanks

Filter wells are used in areas with slightly moist soil, located far from natural bodies of water and not equipped with drainage systems. In this case, the amount of water to be pumped should not exceed 1 cubic meter. m per day.

The shape of the well can be round with a diameter of up to one and a half meters, or rectangular or square with an area of no more than 6 m. Typically, concrete rings or plastic containers are used to make the well.

The depth of the absorption well in the ground must be at least two meters, and the thickness of the filter layer must be at least 30 cm

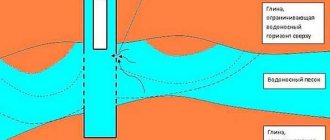

The structure of the absorption well differs from other types of drainage tanks in that it does not have a sealed bottom. Instead, a filter system is installed at the bottom of the well, which passes dirty water runoff through itself, cleans it of debris and discharges it into the deep layers of the soil.

Methods of pumping water

The ideal option for draining liquid from the reservoir is to connect to a centralized liquid drainage system. However, on personal plots this method of pumping is impossible. It is necessary to construct a waste pipeline through which the water flows by gravity beyond the boundaries of the summer cottage.

It is important to decide on the location of the discharge, be it a ravine or some kind of reservoir, and coordinate it with local authorities.

If drainage does not occur naturally as the well shaft fills, then forced pumping of water is resorted to. This requires an electric pump that can be immersed in a container.

Pump for pumping water with a float from storage drainage wells

A float sensor is attached to the pump on a small cable, which reacts to the fill level of the tank and sets the pump in motion. The efficiency of pumping equipment depends on the power of the unit and the degree of contamination of the pumped liquid.

Large debris can accumulate in stormwater wells. This must be taken into account when purchasing a pump. If groundwater is pumped out of the storage tank, then you will need a simpler unit that can cope with solid particles less than one centimeter.

Experts advise completely pumping out the well water every month in order to rinse its base with a stream of clean water under strong pressure. It is important not only to install the drainage system correctly, but also to regularly care for it. Then your home, garden and vegetable garden will be completely safe.

Material for making drainage wells

Wells for arranging a drainage system can be made yourself from concrete rings, or you can buy ready-made plastic containers of the required size and install them on the site. It’s up to you to decide how to make a drainage well, but it’s worth considering that the first option is cheaper, but much more labor-intensive to manufacture, the second is simpler, but somewhat more expensive.

Image gallery

Photo from

Polymer products for drainage devices

Brick drainage system object

Construction of a well made of concrete rings

Polymer sand elements

Making a well from concrete rings poses a number of problems. Due to the large weight of concrete structures, you may have to hire special equipment and invite assistants. They need to make holes for pipes, which is also quite difficult.

However, the complexity of installing a concrete well is justified by its great reliability, strength and durability. Concrete structures are practically invulnerable to any negative influences.

They can be installed in any place and even in areas standing on soils subject to hydrothermal movement and heaving during freezing, where plastic structures can be deformed.

Modern plastic containers are also very reliable, and in addition, they are convenient and easy to install, weigh little and are easy to assemble. Their body already has holes of the required diameter for connecting pipes.

Many people resort to a combined installation option in order to save money. For inspection and rotary wells, plastic tanks are purchased, and the filter and storage tanks are made of concrete rings. There is another available option - to make a well yourself from plastic pipes; how to do this is described below.

Plastic containers are available in different sizes; their bodies already have bends of the required diameter for connecting pipes

Which is better: prefabricated vs monolithic?

A prefabricated drainage well is assembled from various plastic parts, like a construction set. The monolithic product is already ready for installation; it just needs to be lowered into the hole dug for this.

Before purchasing a monoblock well, you need to carefully calculate everything; replacing part of it or extending the shaft after installation will not work

Monolithic options are cheaper and stronger than their prefabricated counterparts. However, they are produced in a rather narrow range of standard sizes. They are installed only to the depth specified in the instructions.

Individual elements of a prefabricated structure are easier to transport and load into a car than a large monoblock product. But in terms of compressive strength, even when assembled, they are inferior to an initially solid well. A solid body, by definition, is capable of withstanding large hydrodynamic and mechanical loads.

To extend the body, the prefabricated well can be equipped with several shaft rings in the middle part and an additional telescopic extension under the hatch (+)

Assembling plastic parts of a well for drainage involves the need to seal their joints. And each such joint is a potential hole and leak.

Plus, to tighten the elements you will need bolts and nuts. They should come together. If they are not available, then you should only buy galvanized fasteners, which are less susceptible to corrosion.

Basic principles of drainage arrangement on the site

To install the drainage system, the highest point of the site is selected, and a trench is dug from it with a slope of 2 to 5 cm, two meters deep, where the pipes are laid. Rotary wells are installed in the corners, and inspection wells are installed in the places of nodal connections.

To ensure the natural flow of water through the pipes, a trench for laying a sewerage system is dug at a slope of at least 2 cm from the top point of the site

The end point of the sewer system, where all pipes laid with a slope lead, is a filter or storage well, from where forced or natural drainage of water is carried out.

For the installation of drainage sewerage, it is recommended to use special corrugated pipes with perforation, made of PVC or polyethylene. They have no technical restrictions on installation and are very easy and simple to install. Depending on the size of the outlet holes in the drainage well, you can purchase pipes with a diameter of 50 to 200 mm.

There are small slits throughout the entire area of the drainage pipe, which are necessary for water to seep out from the soil.

For the full operation of the entire sewer system, it is necessary to carry out a number of preparatory measures. Sand is poured into a 5 cm layer at the bottom of the trench and compacted thoroughly. Then the bottom and walls of the ditch are covered with geofabric, which will serve as a filter to prevent siltation of the system.

This is followed by a layer of crushed stone, approximately 10 cm on which a perforated pipe is placed, covered with another layer of crushed stone and wrapped in geofabric with an overlap. On top of this “pie” is poured a layer of earth, which was selected when digging the trench.

To ensure the full functioning of the drainage system, it is necessary to carefully prepare the base and lay the pipes in the manner shown in the photo

Details

Features of excavation work

To build a modern drainage system with your own hands, mark out the construction site and remove the soil. You will need a string with wooden stakes. They are used to designate storm drains and a place for installing a well.

Next, remove the soil using a bayonet shovel, and you can level the edges and bottom of the hole with a shovel. To lay a storm drain, you do not need a large trench depth.

Attention! The pipes are not afraid of frost, so you can lay a well at a depth of no more than sixty centimeters.

The pit for the collector well must be deepened. To collect large volumes of wastewater after rainstorms, a large well should be built. In this situation, you will need a partner to lift the soil to the surface.

Crushed stone is poured at the bottom of the trench with the foundation pit. This measure will protect against soil movement and loss of tightness of the drainage system. Geotextiles are placed on top of the fill to prevent plants from growing into the system.

Production and installation of plastic wells

The installation process depends on the type of well. For viewing, rotary and storage structures it is necessary to make a concrete base. Absorption wells without a bottom require the installation of a filter system.

Image gallery

Photo from

Advantages of plastic wells

Online connection

Operational Benefits

Arrangement of the well neck

How to install an inspection and collector well

If you purchased a ready-made plastic container, then you only need to install it on a pre-prepared base. The installation of both types of wells is practically the same. The difference can only be in size, number of outlet pipes, as well as in horizontal or vertical arrangement.

Inspection rooms, as a rule, have a vertical design; storage rooms can be made horizontally or vertically. In addition, collector wells are usually equipped with a drainage pump and pipes are discharged into a drainage basin.

The pipes must be connected after installing the container on a carefully prepared base, after which the pipes are sealed and the well is backfilled

Before constructing a well for collecting and discharging drainage water, dig a ditch, carry out preparatory work as described above, and lay pipes, but do not fill it up yet.

Well installation consists of the following steps:

- deepen the area where you plan to install the well, it should be 40 cm deeper than the level of the pipes;

- pour and compact a layer of sand and crushed stone;

- prepare a concrete solution (3 parts sand and 1 part cement) and fill the bottom with it;

- after the base has hardened and is completely ready (this will take about 2 days), lay a layer of geotextile;

- Place the container on a concrete base and connect it to the pipe bends;

Finally, mount the hatch on top, fill the structure on all sides with crushed stone and soil.

Installation of a plastic absorption structure

To install a filter well, you will need plastic containers without a bottom. Their installation is carried out in the same way as described above, with the exception of pouring a concrete base. Instead, a filter system is made at the bottom of the well that purifies the incoming water naturally.

In order for an absorption well to work productively for a long time, it must be installed correctly, as shown in the figure (+)

A layer of gravel, crushed stone or other similar material 20-30 cm thick is poured into the bottom. Pipes are brought into the upper part of the well, the structure is covered on all sides with crushed stone or gravel, the top is covered with geofabric and closed with a hatch.

Making containers from plastic pipes

If you don't have a ready-made plastic container, you can make it yourself. To do this, you will need a plastic pipe of a certain diameter (35-45 cm for inspection and rotary structures and 63-95 cm for collector and absorption structures). In addition, it is necessary to purchase a round bottom and a plastic hatch in accordance with the size of the pipe and rubber gaskets.

Manufacturing algorithm:

- Cut the plastic pipe to the required size to match the depth of the well.

- Approximately at a distance of 40-50 cm from the bottom, make holes for the pipes and equip them with rubber gaskets.

- Attach the bottom to the container and seal all seams with bitumen mastic or other sealant.

Installation of a homemade drainage tank is carried out according to the above described scheme.

What are they for?

Wells are needed for the accumulation and drainage of groundwater, and are also used for control checks of drainage pipes and cleaning the system of silt and debris. The type of tanks is related to their operational focus. However, the principle of the device is the same for everyone. The design includes three main parts:

- the bottom is solid or in the form of a tee, with a device for collecting sludge;

- shaft - drain with corrugated or smooth walls;

- cover - a solid or storm hatch made of metal or plastic.

There are types of containers that do not have a bottom. Sometimes the tanks are sealed with a hermetically sealed hatch to completely prevent the entry of garbage waste along with surface runoff.

Inspection well for inspection of the drainage system

Silt formations and other sediments entering the well through pipes settle at the bottom. Therefore, it must be at least 40 cm below the connected drains.

On topic: Foundation drainage: 3 types + how to do it yourself

Construction of a well from concrete rings

For the well, it is necessary to purchase reinforced concrete rings, which are made from moisture-resistant concrete. The dimensions and diameter of the rings are selected based on the type and purpose of the well. But it must be taken into account that their depth must be at least two meters.

Concrete rings are available in various sizes (height from 10 cm to 1 m and diameter from 70 cm to 2 m), so choosing a product will not be difficult. For a well, rings with a height of 50-60 and a diameter of 70-150 cm are usually chosen. Their weight, depending on the size, ranges from 230-900 kg.

Concrete rings are lowered one after another into a pre-dug hole and placed on top of each other.

Of course, such a weight is not impossible to lift alone, so you will have to invite one or two assistants. The structure can be installed in two ways. If the diameter of the ring allows a person to fit inside, then you can simply place it on the ground, and then begin to excavate the soil from the inside.

The ring will press with its own weight on the ground and gradually sag as soil is dug out from under it. In this way, you can install all the rings, placing them on top of each other and fastening them together with metal brackets.

The second option is to first dig a pit, the width of which should be approximately 40 cm greater than the diameter of the rings. If the soil is soft, the bottom should be covered with a 15-20 cm layer of gravel, and then concrete rings should be lowered. With this method, if an inspection or storage well is being made, it is advisable to install a lower ring with a solid bottom.

After installing the concrete rings in place, it is necessary to carefully seal all the cracks with bitumen. You can make a viewing window in the ceiling for visual inspection of the well

If there is no bottom, then you will need to make it yourself. To do this, the lower part of the well is filled with concrete mortar with reinforcement. When installing an absorption structure, the bottom of the container is equipped with a filter system, as described above.

All joints between the rings are coated with a cement-sand mixture, and then, after drying, sealed with bitumen-polymer waterproofing.

Next, from the well, according to the developed scheme, a trench is dug for drainage pipes, but do not rush to lay them, since you will first have to do another rather labor-intensive job - making holes in the concrete to connect the pipes. This can be done using a hammer drill and pobedit or diamond bits for concrete. They have different diameters, so choosing the right size is easy, but their cost is quite high.

If you don’t have a concrete crown on your farm, and you don’t want to spend money on buying one, you can resort to another cheaper method. In the place where you intend to make the branch, attach the pipe and draw a circle of the required diameter with a pencil. Drill through holes along the contour of the drawn line with a hammer drill.

Holes are drilled with a concrete drill in increments of 1-2 cm from each other, one is made in the center of the circle

Point the crowbar at the central hole and begin to break it slowly, as the hole widens, take a large hammer or sledgehammer and complete the process. Now you can bring the pipes and, putting protective rubber seals on them, insert them into the hole made. Also coat the insertion points with bitumen. Install the ceiling.

The concrete well is filled with crushed stone on all sides to a height of approximately 50 cm, and then clay is poured to the very top and compacted well. Such a clay cushion will prevent water seepage and extend the life of the well.