It’s rare that a suburban village or partnership, even near Moscow, can boast of having a main water supply and sewerage system; in general, the owners of suburban real estate have to acquire their own amenities. And in order not to pollute the environment, including the aquifer, with waste from their own vital activity, wastewater treatment systems have long outgrown the simplest cesspools, turning into more advanced structures.

There are a lot of different treatment plants and stations on sale for treating wastewater from mechanical impurities, but despite all their effectiveness, their significant drawback is their considerable cost. Therefore, for many private owners, the best option is homemade devices, which are deservedly popular among FORUMHOUSE craftsmen. Let's consider what a septic tank is, existing sanitary standards, parameters for choosing systems and the most popular varieties.

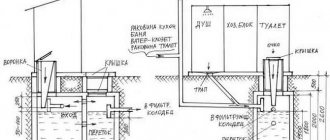

Septic tank operation diagram

A septic tank is one of the elements of a complex autonomous (individual) domestic wastewater treatment system designed for collecting, settling and purifying wastewater. Accumulation and sedimentation occurs in a sealed container (when there are several chambers) or containers; from the settling tanks, the wastewater flows into a filtration well or onto soil filtration fields (underground, aboveground). The law prohibits the discharge of even settled and treated wastewater from a septic tank onto open areas of land. The system necessarily includes inspection/cleaning wells and ventilation risers; the vent riser is brought to the roof level to prevent the possibility of characteristic odors. Septic tanks are periodically cleared of sediment by a sewage disposal machine; if the volume of the septic tank is correctly selected, this procedure, even if you live permanently in the house, is required no more than once a year, or even several years.

Sanitary and building codes and standards governing the location, design and construction of septic tanks

Until recently, the main regulatory documents relating to septic tanks and biological protection stations were SNiPs and SanPiNs, developed at the end of the last century and the beginning of this one:

- SNiP No. 2.04.03-85 (recommendatory), SP 32.13330.2012 (current standard) - parameters for the organization of external sewer networks and structures.

- SNiP 2.04.04-84 and SNiP 2.04.01-85 - parameters for organizing internal and external water supply (outside the city, water supply is most often from a well and a well, and some provisions intersect with the rules for organizing septic tanks).

- SanPiN 2.1.5.980-00 – protection of surface waters.

- SanPiN 2.2.1/2.1.1.1200-03 – septic tanks are classified as environmentally hazardous objects; this set of rules regulates the creation of protective zones around them.

Last year, a new standard for organizing autonomous sewage systems with septic tanks and soil (underground) filtration of wastewater was adopted - STO NOSTROY 2.17.176-2015. Now this is the main document that contains the design and installation rules, as well as the requirements for the results of the work.

The following rules apply for the location of treatment facilities relative to other objects on the site:

- There is 5 meters between the septic tank and the house.

- Between the septic tank and the water intake (well, borehole) - at least 20 meters, if there is no connection between the aquifer layer and the filter field through soil with high filtering capacity, from 50 to 80 meters if the segment has loamy, sandy or sandy loam soils.

- Between the septic tank and the side of the road - 5 meters.

- Between the septic tank and the border of the site - 4 meters.

- Between the septic tank and trees - 3 meters (1 meter to bushes).

- Between the septic tank and a reservoir with running water (stream, river) - 10 meters.

- Between the septic tank and a body of standing water (lake, pond) - 30 meters.

- There is 5 meters between the septic tank and the underground gas main.

The main operating characteristic of a septic tank, on which its performance, the efficiency of wastewater treatment and the frequency of pumping will depend, is volume. It is calculated based on the number of household members, daily consumption rates and the capacity of the structure. According to sanitary standards, one person consumes 200 liters (0.2 mᶟ) per day. Throughput is the capacity of sedimentation tanks with a three-day reserve, plus a small increase for bottom sediments. To operate normally, a septic tank for a family of four requires a volume of 2.7 mᶟ (0.2x4x3+0.3=2.7). The volume of all chambers is calculated, but from the bottom to the level of the overflow pipes. To be on the safe side, you should add on the salvo drop or the arrival of relatives and make the volume a little more than the calculated one, as the super-moderator of our portal’s forum advises.

Vadim (spb)Super moderator FORUMHOUSE

Three cubes are enough for four people.

Fundamental structure of a settling tank

There are 2 main types of settling tanks: contact and flow. Contact is simply a sealed container in which household waste is kept until it is removed by sewage disposal equipment. Such a sump prevents dirty water from entering the soil. It is the simplest, but regular cleaning is required - the drains must be removed as soon as the container is full. This is not very convenient, and such blind containers are not very common.

Sometimes such containers are improved by installing a discharge pipe in the upper part so that the settled water is drained into the soil. For a small family this is a perfectly acceptable option.

A flow-through settling tank is much more convenient, although it requires some effort to set up. It consists of several containers (minimum 2) through which wastewater flows sequentially. More or less purified water from the last container can be discharged into the soil through an underground pipe.

If you add anaerobic bacteria (living and working without oxygen) to the sewer sump, the wastewater treatment will go much faster.

Options for choosing a septic tank

If the location of individual treatment facilities is regulated by standards, and the volume is selected depending on the amount of wastewater, then what type of septic tank will be, the design of the system and the method of organizing soil filtration depends, first of all, on the groundwater level (GWL) and the throughput (filtering) capacity of the soil. At low groundwater levels, almost any composite or monolithic structure is allowed. But if the soil has weak permeability (clayey soils), then it is necessary to increase the area of the filtration field, the length of the filtration tunnel or the layer of drainage cushion under the filtration well.

If the water level is high, then it is permissible to use only monolithic septic tanks (reinforced concrete, plastic containers) with several chambers and an additional sealed storage tank. From the storage tank, through a float drainage pump, the settled wastewater will flow to the bulk filtration field (cassette and tunnel infiltrators are used). Underground filtration directly from the septic tank in a situation with close occurrence of perched water is unacceptable.

LadomirModerator FORUMHOUSE

It is necessary that the distance from the bottom of the filter structure to groundwater is at least a meter.

Popular types of homemade septic tanks

Among the participants of our portal, three types of homemade products are most in demand:

- From concrete rings;

- Monolithic reinforced concrete;

- Plastic (from Eurocubes).

Warranty terms and conditions

Since 2021, we have introduced an extended manufacturer's warranty program for Eurolos for the BIO, PRO and Grunt series for 10 years. To participate in it, you only need to submit an electronic application on the guarantee page, indicating the serial number of your treatment plant.

Read more about the terms of warranty service in the passport of your equipment.

Certificates and expert opinion

Construction of a septic tank made of concrete rings

When the State Water Inspectorate allows, the majority of forum members prefer concrete rings, from which two sealed chambers and a filtration well are usually assembled, connected to each other by overflow pipes. To get the most impermeable structure possible, choose rings with a groove connection; they are not only more resistant to possible ground movements, but it is also easier to achieve the tightness of such a seam. External and internal waterproofing is used with bitumen primers or solutions based on CPS with the addition of liquid glass. There are two options for the arrangement of cameras - sequential and combined.

In the first, settling tanks are placed one after another, and the FCs are placed at a short distance, each with its own neck and inspection cap. The optimal design for a septic tank of this type was developed in one of the forum topics by a participant with the nickname MatrasMSA with the help of moderator Ladomir.

MatrasMSAUser FORUMHOUSE

The plot is 40x60 meters with a slope, a bathhouse/guest house is currently being built, three people live on weekend visits and sometimes guests, in the future there will be a house for permanent residence. The groundwater level is low, it is problematic to get to the water, the well is 88 meters deep, according to neighbors, the soil is loam. I am planning a septic tank like this: the first and second wells are three rings each (1.5 m in diameter) with a concrete bottom, the third well is the same, but the bottom is on the ground.

During the discussion, the following typical recommendations for the device were given.

Ladomir

- A straight tee is placed on the pipe entering the septic tank, the lower part is buried 15-30 cm into the drains, similarly on the outlet pipe.

- The outlet from the septic tank is 5-10 cm lower than the entrance to it, measured along the lower pipe tray.

- The overflow between the chambers is done at a depth of 0.4 m from the height of the drain column in the septic tank.

- The height of the drains into the septic tank is the distance from the bottom to the bottom tray of the pipe coming out of the septic tank.

- The branch pipe entering the filter well does not need to be equipped with a tee; it is routed in such a way that the wastewater flows into the center of the FC.

- Under the filter well, gravel/crushed stone is added, 0.3-0.5 m thick, and sprinkled on the sides, in a layer of up to 0.2 m.

Taking into account all the adjustments and recommendations, a septic tank diagram appeared: an almost finished preliminary design of a two-chamber device with a filter well made of reinforced concrete rings.

The combined septic tank (designed by A. Egoryshev) is compact due to the arrangement of sedimentation tanks and FC in a triangle and is suitable for small areas. All wells are closed with blind covers, in which inspection holes are cut out, a common neck (service well) is installed on top, and the fan riser is discharged through the cover of the service well. To prevent differences between settling tanks, a concrete slab with a hole for the FC is poured at the bottom of the pit, a drainage pad (filter cassette) made of ASG, 10 cm thick, is poured under the slab, on a double layer of geotextile.

On our portal, this scheme was proposed by a craftsman with the nickname s_e_s_h, who posted the design and a similar construction process in his topic back in 2009, “alive” to this day, which proves the relevance of systems of a similar operating principle.

s_e_s_hUser FORUMHOUSE

The requirements for the septic tank, taking into account the standards and needs of the family, were as follows:

- Good treatment of domestic wastewater at the outlet of the septic tank.

- A volume sufficient for permanent residence in a house of 3-4 people (bath, shower, 3 sinks, washing machine and dishwasher, 2 toilets).

- Winter operation.

- Reliable design with the ability to easily maintain the septic tank itself and underwater communications.

- Neat and discreet final appearance.

- Minimum possible cash costs.

The result was an economical design without sacrificing functionality.

However, both options are suitable only for areas with a low groundwater level; with a high groundwater level, no matter how you isolate the wells, there is a danger of them being flooded with high water and polluting the area with wastewater.

About settling tanks - a little theory

The operation of settling tanks of all types is based on the fact that the force of gravity exists in nature. Under its action, heavy particles fall down the container, and lighter water, freed from impurities, rises up. Sludge and debris collected at the bottom of the container must be removed periodically; they cannot dissolve.

It is impossible to use sludge from the bottom of the settling tank as fertilizer; there are many harmful and hazardous chemical compounds there.

Based on the type of device, the following types of sedimentation tanks are distinguished:

- Vertical - they are the easiest to arrange, this is the most common type in private houses and country houses;

- Horizontal - designed for apartment buildings or small enterprises, capable of purifying up to 15 thousand cubic meters of wastewater per day;

- Radial - arranged for the primary treatment of wastewater at treatment plants, they are capable of passing up to 20 thousand cubic meters per day, the wastewater flows through a central pipe, and sludge is regularly removed from radial wells.

Modern industry offers a wide range of bioactivators. It is a mixture of microorganisms - aerobes and anaerobes. The composition is selected by scientists for different purposes - starting the system, special conditions or enhanced action. All properties are indicated in the instructions, you just need to choose the appropriate composition.

A bioactivator for sewage is a colony of living bacteria.

If the activator is placed in the sump, then aggressive chemicals (chlorine, varnishes and paints), medications, especially antibiotics should not be poured into it, so that the bacteria do not die.

Work of a reinforced concrete septic tank

Monolithic reinforced concrete septic tanks can be used at any level, only the location of the filtration structures will differ. It is difficult to resolve difficulties when digging a pit, but it is possible.

researcher FORUMHOUSE user

To make it faster, the pit is dug with a tractor, on one side it is dug with a bucket that is wider and half a meter deeper than the bottom of the main pit for the septic tank (it seems like a pit), and a regular drainage pump is installed there. All the water from the main pit quietly migrates into the pit and is pumped out from there by a pump and poured out 25-30 meters away. For the duration of work in the pit, pouring and treating hardened concrete with water repellents, this solution is just enough.

Otherwise, the process is standard - formwork, reinforcement cage, pouring with the addition of modifiers to the solution, waterproofing (internal and external). A monolithic structure with a low groundwater level was chosen by a member of the Rybnik portal.

RybnikForumHouse user

From the foundation to the rotary well (PW) - 1.4 m, the PW itself has dimensions of 1x1 m, from the PW to the septic tank there is a trench, 7.5 m long, 40 cm wide and 1 m deep. The pipe will enter the septic tank at a depth of 85 cm from surface (taking into account a slope of 2 cm per 1 meter). A second pipe (from the house) will also enter the septic tank. Next, a pipe of clarified water comes out of the septic tank, which will run 23 m along the fence and enter a filter well measuring 1.5x1.5x4 m.

For the reinforcement frame, rods with a diameter of 8 mm were used, restraints (frogs) were bent from them, cement M500 (intended, among other things, for concreting underwater structures in a fresh environment), a special additive that reduces the permeability of concrete, was used for pouring. Flat slate sheets are used as formwork. Details of the process and a step-by-step photo report are in the topic about the classic septic tank made of monolithic reinforced concrete.

Step-by-step instruction

By following this step-by-step guide, you can build a septic tank for an autonomous sewage system with your own hands in a few days.

- Decide what material the sump will be made of. There are 4 popular materials: concrete, plastic, Eurocube and old tires.

Any company will gladly give used Eurocubes free of charge, subject to pickup.

Everything is clear with concrete; we will consider the device using this example. There are a huge number of plastic containers on sale; their service life is about 50 years. Eurocube is also a standard size polymer container, but with a metal lathing, which makes it stronger. It is advisable to use old tires from KAMAZ; others are too small. This is a cheap, but most inconvenient material, since creating a seal in such a container is problematic.

- Decide on the location of the pit, the approximate size is 4 or 6 cubic meters. It is imperative to comply with sanitary standards - 10 meters from the house and 20 meters from the water source. Think about the passage; a sewer truck should drive to the septic tank.

- Measure, calculate and purchase everything you need - cement, sand, water, mixing containers, pipes and fittings. A concrete sump requires formwork and reinforcement. The thickness of the fittings is at least 8 mm, pipes are at least 3 pieces. You also need to think about the lid - there should be a hole in the sump to remove solid sediment, which is covered from rain and snow.

- Dig a pit, approximate dimensions - depth 2 meters, width one and a half meters, length up to 3 meters.

- Assemble the formwork, fill the walls and bottom. First divide the entire length of the future sump into 3 parts. The first two-thirds is the sump itself, the remaining third is the drainage tank. We form a partition between the sump and drainage tank, assemble the formwork and fill it. While the concrete is damp, we insert a pipe almost at the very top of the partition - this is an overflow through which clarified water will flow into the drainage container.

- We install a pipe into the wet concrete on the outside of the sump tank through which the wastewater will flow. We also place a pipe on the outside of the drainage through which water will be discharged onto the soil.

- Let the concrete take hold, this will take about a month. On hot days you can add additional water.

- We close the sump. For this you can use ready-made slabs or metal sheets. Be sure to leave a hole through which waste is removed.

- We connect the drains from the house and start the starter bacteria. If there is little drainage, you can add water according to the instructions for the activator.

The work has been completed and the area can be improved. A self-made sump will last for decades without requiring special care.

How does a septic tank made from Eurocubes work?

Another common type of septic tank is made from Eurocubes. The principle of operation of this model is the same as that of previous designs, but the chambers are not made of rings or a monolith, but of plastic containers, post-treatment through FC, filtration fields or filtration trenches.

To insulate the structure, EPS boards are used; the pipe inlets and outlets are sealed using special cuffs or seals for septic tanks. To prevent the plastic from being crushed by the ground and the cube from floating up (at high groundwater levels), concrete sarcophagi are made.

Vadim (spb)

A thickness of about 15 cm of concrete should be enough; formwork (metal lathing) of a Eurocube is quite suitable as reinforcement. Only the reservoir must be filled with water so that it does not get crushed when pouring. Sprinkle with sand - this will also reduce the load. If you remove the reinforcement from the concrete slab under the cube, then when the walls are poured, it will become attached to it and will not go anywhere.

Options for constructing septic tanks from Eurocubes with and without sarcophagi are in the profile topic on the forum.

Conclusion

With correct calculations and adherence to the scheme, the efficiency of wastewater treatment in home-made devices is not inferior to factory designs. But the feasibility of independent construction depends on the groundwater level. With a low groundwater level, it is cheaper to make a septic tank with your own hands, and with a high groundwater level, it is better to buy a ready-made sealed product.

The participants of our portal and experts in the topic “How to understand which sewer system to make?” will help you make the final choice. The topic about autonomous sewerage systems includes information on regulatory documentation, treatment plans for different groundwater occurrences and useful videos. Our other topics will help you install an aerobic septic tank and figure out whether bacteria can be added to the septic tank. This article about collective wastewater treatment systems talks about the advantages and disadvantages of sewage systems “for three”. The video contains recommendations from a specialist on choosing sewer pipes.

Subscribe to our Telegram channelExclusive posts every week

Compressor aeration units

They take up less space on the site - only 1.5 m², because purify sewage by constantly saturating it with oxygen. In the VOC this process occurs with the help of pumps, and in the AC there is compressor equipment.

Compressor aeration units

Compressor septic tanks are more designed for permanent residence. Continuous aeration allows you to achieve the required degree of cleaning in less time, with smaller structure sizes.

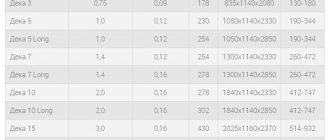

Autonomous sewage system Eurolos Pro

| Production, m3 per day | Dimensions and weight | Gravity station | Standard installation | |

| PRO 3 | 0.6 , for 3 people | 119kg ⌀ 1.27 x 1.8m | 86500rubles | 23000rubles |

| PRO 4 | 0.8 , for 4 people | 124kg ⌀ 1.27 x 1.9m | 94600rubles | 24000rubles |

| PRO 5 | 1 , for 5 people | 131kg ⌀ 1.27 x 2.0m | 100400rubles | 25000rubles |

| PRO 6 | 1.3 , for 6 people | 141kg ⌀ 1.4 x 2.0m | 111100rubles | 27000rubles |

| PRO 8 | 1.6 , for 8 people | 157kg ⌀ 1.5 x 2.0m | 126600rubles | 30000rubles |

| PRO 10 | 2 , for 10 people | 178kg ⌀ 1.7 x 2.0m | 160200rubles | 35000rubles |

| PRO 12 | 2.4 , for 12 people | 243kg ⌀ 1.8 x 2.0m | 171200rubles | 38000rubles |

| PRO 15 | 3 , for 15 people | 272kg ⌀ 1.91 x 2.0m | 194300rubles | 43000rubles |

| PRO 20 | 4 , for 20 people | 300kg ⌀ 1.91 x 2.25m | 248400rubles | 55000rubles |

| PRO 25 | 5 , for 25 people | 355kg ⌀ 1.91 x 2.5m | 285800rubles | 60000rubles |

| PRO 30 | 6 , for 30 people | 398kg ⌀ 2.1 x 2.75m | 313100rubles | 70000rubles |

Video: example of our Eurolos PRO installation

Familiarize yourself with the configuration options and how the treatment plant is delivered, installed, and pre-configured.