Sequence of stages

So, how to deepen a well in a country house or in a private house on your own - all the necessary manipulations can be divided into certain stages:

Scheme of deepening wells with repair rings

Important: It is best to carry out work to increase the depth in winter or in the last month of autumn. At this time of year, groundwater levels are at their lowest, so new rings can be installed very deep.

How to make a bottom filter for a well, its types and features - you will find all this on our website.

To pump out the water, you will need a well sump pump. We invite you to familiarize yourself with the popular models of such units.

How to carry out preparatory work

Before deepening a well from concrete rings, it is necessary to carry out high-quality preparation. At the first stage, the actual condition of well structures is assessed. In addition, it is necessary to ensure that the soil is capable of holding the newly installed rings, and also to determine the changed level of groundwater.

Important: All calculations, all necessary operations to determine changed operating conditions should be carried out before the start of excavation work to deepen the well. And only after the calculation manipulations are completed, they begin to deepen the well to the maximum possible depth.

The process of deepening wells can be carried out to a depth of up to 3 meters. In addition, the work is advisable in the case when the original design had no more than 15 rings, and each element must be installed relative to the other without displacement. If a slight displacement is detected, it is necessary to carry out work to level the column, for which brackets are installed at each of the water intake seams to fix the structure rigidly and prevent its rupture.

Naturally, any water-lifting structure is removed for the duration of the work, and the decorative upper house is also removed, if it was provided for by the design. In addition, all available water is pumped .

So, the question of whether it is possible to deepen a well from concrete rings is decidedly positive, but you will also need to prepare certain materials and tools:

It is necessary to prepare in advance everything that is needed to carry out work on deepening the well.

- a shovel with a short handle to make it convenient to carry out excavation work in a confined space;

- a pump to pump out water entering the work site;

- a breaker, if during the deepening process you need to go through hard rocks;

- a winch and buckets so that you can freely lift soil from great depths and lower the rings (this winch should be able to withstand a load of up to 600-700 kg;)

- a ladder, preferably a rope ladder, so that it does not take up much space;

- lighting.

Having this entire “arsenal” will allow you to deepen the well with maximum speed and quality. You will also need insurance for the worker who will be going down, and protective clothing - overalls, rubber boots, a helmet.

We talked about how you can make a rope ladder with your own hands in a separate material with video examples.

Find out how to organize water treatment in a private home or country house. Features of filter selection.

Reasons for water leaving the well

The water level in the well may not be constant. It depends on a combination of many factors beyond the control of the owner of the structure.

The hydrogeological conditions of the area come first. Prolonged drought in summer and severe frosts in winter can lead to complete drying out of the well. This is a completely normal phenomenon and does not require any human intervention.

Practice shows that after some time the water will return. Most often, those who dug their wells at the beginning of summer suffer from the consequences of this phenomenon.

Kawabanga! Dismantling of concrete floors and floor screeds

It also happens that the precipitation level is normal, but there is still no water in the well. In this case, the reason may be the appearance in the immediate vicinity of a new well or borehole with impressive water abundance, which can temporarily “take away” water.

In this case, you need to wait four to five weeks; if the water level has not recovered, you will have to deepen the well shaft.

And another reason for the disappearance of water can be the wear and tear of the materials in the water intake part of the well shaft. In this case, water will flow poorly due to capillary channels clogged with destroyed material.

In addition, they sometimes become very clogged with dense silt and sandy sediment, which is difficult to distinguish under the water column and to remove. To free the water intake part from contamination, the well will need to be cleaned, repaired and completely sealed.

What to Expect After Deepening

The deepening process depends on the footage, but not less than 1 day. Almost every contractor offers turnkey work. This service can only be used with a 100% verified contractor. If you are collaborating with a company for the first time, it is advisable to check how deep the well really was during delivery. To do this, you need to measure the initial depth with a cable with a load and compare it with what happened in the end.

Diagnostics and proper deepening should ensure an acceptable flow rate. Experts who maintain wells emphasize that they should be considered as a source for drinking and simple everyday needs, but as an inexhaustible reservoir, which is enough to provide irrigation, large-scale construction and similar events.

The specifics of most wells do not provide for volley pumping with a sharp decrease in the water surface. In the Moscow region, many wells are dug on quicksand soils, which, if handled carelessly, behave unpredictably and dangerously. Therefore, without knowing the nature of the water intake and having no idea about the procedure for deepening, it is simply contraindicated to begin any work.

Advantages and disadvantages of different methods

There may be several options according to which you can deepen a dry well at your dacha. Let's look at each of them and find out all the advantages and disadvantages of each.

Deepening with rings of smaller diameter

The method involves building up the shaft from below with repair rings of smaller diameter. The main advantage of this method is the speed and minimal costs of its arrangement.

What are the pitfalls? First of all, you need to understand that the most common diameter of concrete rings for constructing a well is 1 m. Thus, for repairs you can choose parts with a diameter of 0.8 or even 0.6 m.

Working on quicksand

Quicksand is a mixture of silt, sand and water. An unstable formation significantly complicates work; it moves in the aquifer and can appear unexpectedly. The usual technology of digging soil with a bucket will not be effective due to the rapid restoration of the mixture of sand and silt.

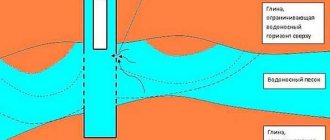

Quicksand diagram

There are several methods for passing quicksand:

- To deepen a well on quicksand, accelerated penetration is used. It involves installing repair rings on the shaft of the mine to speed up the lowering of the structure.

- The excavation of soil is ensured by the installation of a sheet piling - a barrier made of wooden panels. Several shields are made from boards, firmly connected to each other and pointed at the end. They are used to assemble a box, which is driven to the bottom using a stone hammer. The soil is removed from the box; this technology is effective for small quicksand.

Well deepening rings

Using the deepening filtration method

To facilitate the work of deepening the well, you can use the filtering method, which consists of the following steps.

First of all, take a plastic or metal pipe no more than one meter long and no more than 50 centimeters in diameter.

Similar articles

Insulation of a water supply well

Do-it-yourself needle well Abyssinian well

Well cementing control station

Methods for deepening a well shaft

Method of grinding concrete rings from above

To increase the depth of the well, three methods can be used. Each of them is good in its own way, but only one can be used for a young source, whose age is from 1 to 3 years.

So, how to deepen a well:

Important: if a curvature of the source shaft is detected during descent, then the diameter of the lower rings is reduced to 70 cm. In this case, the gaps between the rings of larger and smaller diameters will be closed with brickwork, natural stone or special cementation.

How to choose suitable reinforced concrete rings

Deepening a well from reinforced concrete rings

Before you deepen a well with your own hands, you should purchase the appropriate repair rings. Keep in mind that they will have to be lowered down when installed under existing well structures, so they should be of a smaller diameter. If the well shaft is straight throughout its entire depth, you should choose repair rings with a diameter of 80 cm and a height of 90-100 cm. The use of rings of this diameter allows you to reduce the gap between the existing elements of the shaft to 20-30 mm.

But you need to choose the diameter of the rings for repair, with the help of which the deepening will be carried out, taking into account the curvature of the barrel . If there are pronounced irregularities in diameter in this shaft, then products 700 mm in diameter are suitable for “insertion”. However, in this case there will be a very large gap between the previously and newly installed rings, and it will have to be eliminated with natural stone or pebble backing.

What equipment will be used?

Necessary tools for deepening a well.

Before starting construction work, prepare the necessary tools:

- a shovel with a short handle;

- pump;

- jackhammer;

- stairs;

- flashlight and other lighting devices;

- specialized clothing (rubber boots, helmet, overalls).

When using this equipment, drilling will not take much time and effort, and the quality of the design will be at the highest level. It is also worth remembering safety precautions while working.

Kawabanga! Installation of embedded parts

Problems when lowering the rings

Deepening must begin during the period when groundwater is at its lowest, this is October, early November.

With regular maintenance of the well, the durability of the structure is ensured. If after possible methods the result in deepening the rings remains the same, this entails the following:

- the distance between the ring increases, which can lead to vertical rupture of the structure;

- when the rings move, the shaft leads sideways.

To avoid such situations, they adhere to safety measures and carry out preparatory calculations for installing the well.

Advantages of plastic rings

In addition to deepening with concrete rings, it is possible to deepen the source using plastic rings, which is currently a more progressive and reliable solution.

Deepening and building wells from concrete rings is considered more difficult by some craftsmen, this is primarily due to the heavy weight of reinforced concrete. Here are a number of other advantages of this material:

- The plastic shaft is 100% sealed;

- Resistant to corrosion and chemicals;

- Resistance to temperature changes;

- Choice of sizes, colors, shapes of plastic rings;

- Service life - up to 50 years;

- Easy to install and operate.

The main thing is that the price of plastic wells is acceptable for ordinary homeowners.

- Guarantee of the quality of our services

- Sample contract for services

- Areas where we work

Go to the well deepening section

Go to our services section

When is it necessary to deepen the source?

If the well has been crushed so much that it does not provide the required amount of water, then there are three ways to correct the situation: deepen the old well, dig a new one, or drill a well.

When digging a new shaft, 5-6 rings can be installed per day, while when deepening, no more than 3 rings. The price of additional excavation is also affected by the need to use special equipment - a manipulator.

Since deepening a well with your own hands is a complex and costly task, it is very important to determine the feasibility of such work.

First, you need to make sure that:

If these factors are taken into account, then the problem is most likely in your well, and it needs to be deepened.

But before starting work, you should check everything carefully again:

These preparatory measures are very important, because if you do not take into account all the above nuances, then during deepening work you can block the aquifer or completely destroy the mine by getting into quicksand.

Attention! You can deepen the well only once and if it fails, the well will have to be filled in!

Sometimes the cost of digging a new well is cheaper than deepening an old one. Therefore, experts advise taking on the task of deepening a mine yourself only if certain conditions are met:

In this case, the well will have to be deepened to the second aquifer, that is, at least 5 meters, and no one can guarantee that the water will be suitable for drinking.

Deepening a well with your own hands or with the help of specialists is always an exceptional and last resort measure, and is used only when other methods of repair and restoration work are not effective.

In some cases you can’t do without deepening

To accurately decide whether the well needs to be deepened, you should find out whether weather conditions have affected the drop in water level. If the problem is related to insufficient precipitation, you should wait until the amount of liquid reaches normal on its own. You also need to pay attention to the quality of the water at the source. If it has an unpleasant odor or becomes cloudy with foreign particles interspersed, it is not necessary to deepen the well.

The source does not necessarily need to be deepened if the water in it is interspersed with foreign particles and has a cloudy color. Source usamodelkina.ru

In this case, you can only clean it. In addition, it is recommended to see if the water level in nearby sources has changed. If so, then the problem does not lie with your well. Also, a completely dry well will need deepening. There is a possibility that this procedure will allow him to function normally in the future. It makes sense to deepen the well if:

- its depth is more than 10 rings;

- there is no possibility to allocate space for a new well on the site;

- the old spring has good quality water, which completely suits you;

- rings made of plastic or concrete were not subject to deformation during operation;

- There is no water debit at all, or less than one ring per day.

If these requirements are not met, it is better to spend effort and financial resources on digging and equipping a new mine.

The water may become cloudy and in this case you can do without dredging and simply clean the well Source oskada.ru

Usually, first of all, the degree of soil strength is determined, the depth of opening of the aquifer and the inflow with depth are specified. Only after all geological data have been determined will restoration work begin. Keep in mind that quicksand may appear in the well (this is the name given to soil formed from clay, silt and sand, located above the aquifer under strong pressure). If it is touched, it may begin to move, which can negatively affect buildings located near the source and the well itself. Usually, when a collision occurs, work stops immediately. If the size of this soil is large, a new hole is dug. If the floater is small, then it is dug, but only after the onset of light frosts.

Technology of deepening with repair rings

Before starting excavation, it is necessary to clear the shaft of accumulated bottom sediments and analyze the condition of the aquifer using exploratory manual drilling to a depth of 4 meters.

Kawabanga! Concreting pillars for corrugated fence

Attention! Deepening a well with a plastic pipe is dangerous and impractical.

Now the source of life-giving moisture is ready for use!

Interesting video about deepening a well without repair rings:

Sealing the seams of reinforced concrete rings

It is necessary to seal the seams, because it will protect your water from dirt and groundwater, which can seep through unsealed seams.

How to seal seams:

- Many people recommend mixing cement, sand and regular PVA glue, and then applying a thick layer to the seams, rubbing in well.

- If you want something more reliable and quick-drying, use liquid glass instead of glue.

- Also, you can buy a special solution - Penetron - at any market or hardware store.

The last solution is the best. After all, it has special moisture-repellent properties that are designed for a long service life. It is enough to apply it in a layer of 2 mm to provide the seams with reliable protection from moisture.

Well deepening technology

You can restore a dry well yourself. Restoration work is recommended to be carried out in the autumn or winter months, because... At this time, the groundwater is low and you can enter the quicksand quite deeply.

For work, you need to stock up on special clothing made of rubberized material, high rubber boots, and a cable for lowering into the mine.

Self-deepening of the well.

There are several methods for deepening a well:

- digging;

- installation of reinforced concrete rings;

- recess with a plastic pipe;

- filtration.

Development of a well at the bottom of a well

This method is used to develop a well with casing and equipped with pumping equipment. The technology is quite simple and available as a method of homemade hydraulic structures capable of uninterrupted water supply.

The disadvantage of this method is the need for periodic expensive cleaning and disinfection of the barrel, as well as the constant need for power.

Recess with installation of reinforced concrete rings

To increase the volume of water in a well of 2 rings, you can use reinforced concrete rings. In this case, their diameter should be smaller than the size of the shaft.

Suitable sizes should be determined based on calculations:

- The shaft is straight along the entire depth of the well: meter rings with a diameter of 0.8 m are accepted.

- The shaft has distortions in the butt joints: rings with a height of 0.7 m and 0.8 m in diameter should be selected.

You need to deepen the well shaft in this way:

As a filter, it is necessary to fill the bottom of the shaft with a mixture of gravel and crushed stone.

Deepening a well shaft by digging

Digging a well is done as follows:

Digging is carried out until an aquifer appears, after which a filter of gravel and crushed stone of medium fractions is poured onto the bottom of the well.

Deepening a well shaft using a plastic pipe

Deepening a well with a pipe.

This technology is similar to the method of building up a well shaft with reinforced concrete rings.

The shaft casing should be done with a corrugated pipe with a diameter of 150 mm. This pipe is lightweight, quite strong and durable. In addition, it can be used when installing new casing throughout the entire depth of the mine.

Using this method, a well is constructed that has the correct depth, a long operational period and the absence of impurities in the water.

Deepening by filter method

This method will help increase the flow rate of the well. To implement this method, a special filter is used, which you can make yourself.

- meter perforated pipe with a cross section of up to 500 mm;

- metal grid.

You can take a metal or plastic pipe, wrap it in mesh and install it on the bottom, sticking it deeply into the ground to reach the next aquifer.

The step-by-step process looks like this:

The whole procedure continues until a new aquifer appears. After each immersion in water, the filter device settles deeper and deeper.

Features of deepening using the digging method

This method of increasing the depth of a well is often performed by professional workers, since it is very time-consuming and labor-intensive, especially if the initial depth of the structure exceeds 10 m. The preparatory stage here will be the same as in the previous case, after which they begin digging. A worker goes down on a safety net and evenly digs up the soil located under the lowest ring. Excess soil is placed in a bucket and lifted up with a winch. The base column of well rings will gradually sag under its own weight, and in this case the repair rings are placed on top.

Digging continues until the water begins to rise quickly - usually in this way it is possible to go deeper into several rings. After completion of the excavation work, the contaminated water is removed, all seams between the rings are sealed, and a bottom filter is installed. It should be noted that the disadvantage of this method is the possibility of the column or individual concrete rings of the structure getting stuck, especially on clay soils.

By deepening the well, you can restore normal water intake and save money on building a new well. In addition, the bottom will be thoroughly cleaned, so that the water will become even better.