Modern kitchen faucets come in several types; they differ in design, ease of use and cost. Over time, any model needs preventive maintenance related to updating parts; to carry out the work yourself, you need to know the structure of a kitchen faucet.

In order to save a considerable amount of money on calling a plumber by repairing the faucet yourself, you need to study the internal structure and operating principle of a specific type of faucet. The task is greatly facilitated by the fact that all mixing plumbing fixtures are unified, their parts are interchangeable, and the design can be divided into several groups.

Modern kitchen faucets

Design of two-valve mixers

Two-valve mixing devices are classic models that are morally outdated and at the same time find a certain demand among consumers. This is partly due to the low cost or the opposite desire to use them as a retro interior element.

The principle of operation of water valve mixers is to control the flow and temperature of water by closing the input channels separately on the hot and cold pipelines with axle-box taps. There are two main designs of shut-off valves, one of them is outdated due to its manufacturing technology, the second is modern and is more convenient and efficient.

The main material for the manufacture of most valve mixers is brass, which is coated with chrome on top. Retro-style models use uncoated brass or bronze; faucets can be painted on top in different colors.

Structural design of a two-valve mixer

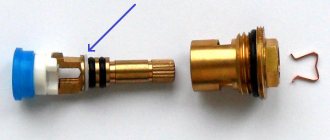

Worm-type crane axle box

In a worm-type faucet, the flow of water is blocked by a rod with an external thread located inside a threaded piston. When the rod rotates, the piston moves along the thread and the rubber disk seal at its end gradually closes the passage channel. It takes approximately three to four 360-degree rotations of the flywheel to move the internal piston from closed to fully open.

The main disadvantage of worm valves is the longest time among analogues in obtaining the required pressure and temperature of the water flow, which leads to excessive water consumption. The advantages include good maintainability and low cost of rubber gaskets with low wear resistance.

The device of a ceramic crane axle box

Crane axle box made of ceramics

Unlike worm-type valves, modern ceramic crane axle boxes operate on a different principle. The main locking elements in them are two ceramic disc plates with slots. In the closed position, they mutually overlap each other, preventing the passage of water due to the tight fit of finely processed surfaces. When the upper plate connected to the rod and flywheel is rotated, a passage hole appears between the ceramic discs and water enters the mixer body.

The feed volume in ceramic valve axle boxes is regulated by the angle of rotation of the flywheel; in contrast to worm-type types, half a turn of the flywheel is sufficient to fully open the valve. Obtaining the required flow and temperature of water in mixers with ceramic axle-boxes is faster compared to worm-type ones, and due to the high wear resistance of ceramics, their repair and maintenance are required much less frequently.

The disadvantages of ceramic models include the low unification of various products. If any rubber gasket for worm-gear models can be found in every specialized retail outlet or cut out yourself, then ceramic liners of a suitable design and size, if they are not included in the package, are difficult to find in the retail network and in many cases you will have to change the axlebox completely due to the lack of the necessary parts.

Internal structure of a single lever faucet with cartridge

The most common malfunctions

Mostly faucets used to supply hot water are subject to breakdowns. The most common causes of faucet malfunctions are:

- incorrect valve operation;

- abrasion of the threaded connection on the body;

- failed stuffing box;

- wear of seals.

In addition, leaks in faucets are often caused by foreign particles that settle between the seal and the valve seat, which leads to the destruction of the former. Also, the gasket is often damaged by very strong screwing of the device.

Recommendation! Due to breakdowns of faucets and drain tanks, water losses often amount to more than 30%. Therefore, it is necessary to get rid of leaks that appear in a timely manner.

You can change the seal for a water tap yourself, but it is still recommended to contact specialists Source ytimg.com

The most common cause of leakage is wear of the seal. If a breakdown occurs because of this, you need to urgently call a plumber who will perform the following work:

- the main valve shuts off the water in the house (most often it is located under the sink or in the toilet);

- unscrews the union nut using the appropriate wrench;

- then unscrews the handle with the spindle and takes out the seal;

- the gasket is replaced with another one - silicone is used for cold water, leather is used for hot water;

- the size of the seal must be approximately 1 mm larger than the diameter of the valve seat, this is quite enough for a tight fit and being in its seat;

- The edges of the installed seal are trimmed using scissors at 45 degrees around the perimeter.

Sometimes installing a new seal is not necessary, but repairs are still needed. Some residents of private houses are faced with the “roar” of pipes. In this case, too, it’s all the gasket’s fault. To get rid of extraneous noise, you need to disassemble the mixer and again cut the edges of the seal at an acute angle.

Design of single lever mixers

Today, single-lever (cartridge) faucets are the leaders in prevalence among similar types; they are distinguished by their simplicity of design and ease of use. The water temperature in a single-lever faucet is controlled by one handle, the pressure is regulated by raising it, and the temperature by turning it in different directions.

There are two main types of single-lever mixers, which have significant design differences and operating principles.

Cartridge mixing devices

In cartridge-type mixers, the main control element is a sealed barrel-shaped cartridge with a rectangular cross-section rod placed at the top. The main executive parts of the cartridge are two tightly fitted ceramic plates, one of which is fixedly fixed in the body and has three through holes - through two of them cold and hot water is supplied, and the third is used to drain the mixed water flow. The second ceramic plate contains a shaped oval channel, and it is connected through a system of mechanical parts to the handle.

The cartridge works in such a way that when the handle is lifted, the shaped depression of the control plate slides over the slots for cold and hot water, after which the mixed flow enters the mixer through the resulting channel. When you turn the knob to the right or left, the area of the open holes of cold or hot water changes - thus regulating the temperature of the water flow.

Cartridge types are convenient and easy to use; compared to previous types, they save more water resources. If the system has clean water and a high-quality cartridge, its service life can reach up to 10 years. The disadvantages include the need to completely replace the cartridge in case of any breakdowns, as well as high requirements for the purity of the water - if there are hard grains of sand in it, they can damage the surface of the ceramic plates and cause leaks, so a filter must be present in the water supply.

Operating principle of the cartridge

Ball mixers

The operating principle of a single-lever kitchen faucet resembles a joystick; in it, a one-armed lever is welded to a hollow ball that has three holes - one each for supplying hot and cold water and a third for discharging the mixed flow. The ball, held on top by a dome seal and a conical cap, rotates in a spherical seat that has three round holes with spring-loaded sealed gaskets - cold and hot water is supplied through two, and the water flow mixed in the ball enters the third.

When the ball with a lever welded to it rotates, different areas of the openings of cold and hot water and their ratio are obtained - this allows you to simultaneously regulate the volume of the drained water flow and its temperature.

In addition to ease of use, the advantage of ball models compared to cartridges is a longer service life and inexpensive replacement of consumables - when rubber seals wear out, the price of new rings is much lower than replacing an entire cartridge.

Note: However, ball valves require too frequent replacement of the gaskets worn out by the ball and are therefore a rare guest on the domestic market of mixing equipment.

Ball mixer - design

What are the consequences of selection errors?

Choosing the wrong ball valve model can have serious consequences.

So, if a steel product is installed in a cold water supply system, it can quickly (within 3-6 months) become unusable. The reason is the increased oxygen content in the liquid, which promotes intensive rust formation. For such networks, it is better to prefer products with a rubber-coated wedge.

We recommend that you read: Application and design features of gate valves

If, on the contrary, the system operates with a medium at high temperatures (150°C and above), it will be a mistake to use products with a fluoroplastic seal. To maintain tightness, taps with a metal-to-metal seal are better suited here.

It is not recommended to install household ball valves in pipeline networks through which process water containing solid fractions circulates. Impurities will quickly damage the O-rings and the device will no longer function properly.

Electronic faucets

It’s hard to imagine a high-tech modern kitchen without electronic faucets; they not only have a stylish appearance, but also make washing dishes and cooking easier and allow maximum water savings (up to 33%). The main changes that electronics brings to the functioning of traditional mixing devices are non-contact or touch switching on and off and maintaining the water temperature at a constant level.

Touchless mixing devices

In traditional types of faucets, which do not require contact with the handle to turn on, an infrared sensor is installed that reacts to the thermal radiation of hands brought to it. The sensor is connected to an electronic circuit that controls a solenoid valve that opens and closes the water. To operate the device, a DC power supply is required, which is supplied to its circuit through an electrical converter of 9 - 12 V or four AA batteries with a total voltage of 6 V.

The continuous operating time of the design described above is limited to an average of 1 minute and then the mixer automatically turns off, which is completely inconvenient when using it as a dishwashing or food processing device. Therefore, more practical touch-sensitive faucets are installed in the kitchen sink, which can be turned on and off by touching a hand (more precisely, any part of the body) to a part of the body or watering can.

Wealthy consumers are well aware of the brands of the leading German manufacturers of touch-sensitive kitchen faucets Grohe and Hansgrohe; the Chinese brands Gappo, Russian-Chinese Frap, Russian-Czech Lemark and Czech Vidima have lower prices for similar plumbing fixtures.

Controlling the activation of infrared and touch faucets

Faucets with thermostat

The kitchen faucet with automatic support of the set temperature includes two handles - one is designed to pre-set the flow, and the second is used to set the desired temperature on a side scale.

The main element of a thermostatic mixer is a special cartridge, it contains paraffin placed in a sealed glass, on one side of which a rod with a special control part is installed. As the water temperature increases, the paraffin expands and linearly shifts the rod by no more than 0.6 mm - this displacement is enough to increase the flow of cold water and bring the overall temperature to the set value.

Faucets with a thermostat have a complex design, are too expensive and impractical for use in the kitchen, where the temperature parameters of water are constantly required (from drinking temperature to hot for washing dishes), so their use in kitchen areas is not practiced due to the lack of rational sense. The situation is different with high-tech, ultra-expensive appliances that have a control panel and functions for programming temperature parameters, turning them on and off - they can be used in the kitchen, but more so as a piece of high-tech style furniture.

Thermostatic mixer design

Briefly about the main thing

After you have described what kinds of water taps there are, you need to determine the main purpose of the purchase - what exactly this or that model is needed for. Taking this into account, the shape of the product, material of manufacture, design and other important points are determined.

Recommendations for choosing a crane:

- Material of the body and internal elements. Today on the market you can most often find devices made of materials such as brass and bronze - these are the highest quality and most durable devices. Silumin products do not have a long service life, the same applies to the plastic filling of the faucet.

- Design. Double-valve products are usually chosen for classic interiors, single-lever ones are characterized by ease of use, and touch and thermostatic ones will appeal to connoisseurs of new products and comfort.

- Form. For the kitchen, it is best to choose taps with a curved spout; for the bathroom, short models. Medium-length items with a slight bend fit perfectly into the washbasin.

- Fastening method. Faucets can be floor-mounted, wall-mounted, mortise-mounted, built-in - this will depend on specific preferences and the location of future installation.

- Maintainability. The most durable are modern touch taps and products with a thermostat. It often happens that the valve on a two-valve device rotates, and on single-lever devices the silicone seals fail.

- Dimensions. Connecting elements are indicated in inches, so it is advisable to find out this parameter in the store. The diameter of the tip is also important - the liquid pressure will depend on it.

Attention! When purchasing, you also need to pay attention to the aeration nozzle - the more holes, the better the water is sprayed.

Today, faucets in stores are available in a huge assortment, this allows all customers to choose the model and design that best suits their specific needs. By following all the rules for operating shut-off valves, you can extend their operating time.

Ratings 0

Single lever mixer repair

If a single-lever kitchen faucet fails, you don’t need a special plumbing tool to repair it yourself; a regular adjustable wrench is enough. Sometimes you may need an auxiliary tool in the form of various types of screwdrivers, a hex wrench to unscrew the handle screw.

Among the malfunctions of cartridge and other types of mixing plumbing fixtures, the following situations most often arise:

- Mechanical damage to the body, spout, in this case the mixer is replaced, but if desired, it can be repaired at home. The fact is that the main material for making faucets is brass, which lends itself well to soldering.

A common malfunction of many faucets is the aerator mesh becoming clogged with dirt, which increases the pressure inside the body, and the most vulnerable element is the thin-walled gib. A crack may appear in its lower part and water leakage may occur.

In this case, the chrome coating is removed with sandpaper and the crack is sealed with a powerful soldering iron using ordinary solder and flux (rosin) - the soldering under the gooseneck will not be noticeable from the outside. In the same way, you can solder a spout that has been broken off from the body, after first removing the mixer from the sink.

- Weak water pressure. The main reason for this malfunction is the clogging of the aerator mesh with solid particles when using dirty water. As noted above, the lack of a passage for water often leads to cracks in the spout, so it is recommended to regularly unscrew the divider and clean its mesh from sand particles.

Aerator and its pollution

- Cartridge damage.

- The standard cartridge is produced in a thin-walled casing; during installation, it is clamped with a threaded nut using an adjustable wrench. It is difficult for an inexperienced user to calculate the clamping force, so with the slightest tightening of the nut, a crack appears in the body and the tap begins to flow water through the upper hole. Thus, a significant number of cartridges fail and the only way to repair the mixer is to replace them.

- The second common problem with cartridges is a broken rectangular pulley on which the handle is attached. It is problematic to reliably connect broken polymer elements of parts by gluing or other methods, so the cartridge also has to be replaced.

- Often, the internal parts of the cartridge, made of thin-walled polymer materials, also break; this becomes immediately noticeable by the easy movement of the handle and the inability to block or regulate the flow. The malfunction cannot be repaired and requires a complete replacement of the cartridge.

- Leak in the mixer body. The housings of single-lever cartridge mixers are produced in two types - some are pressed in and cannot be disassembled, in others disassembly is possible by unscrewing the lower threaded washer, after which you can get inside.

If over time the internal rubber rings in the mixer body have worn out, then in a collapsible design it is possible to replace them after removing the device from the sink and unscrewing the flexible hoses.

Replacing seals in the mixer body

To do this, perform the following operations:

- The water supply is first shut off and the mixer is dismantled. Usually a kitchen faucet is installed with a flexible water supply hose - in this case, the flexible hoses and the clamping nut attaching to the sink are unscrewed from its body.

- Unscrew the ring-shaped lock nut from the bottom of the housing and remove the fluoroplastic sealing ring.

- Pull down the rotary assembly with the spout and separate it from the second part of the body, thereby freeing the ring gaskets (cuffs).

- They buy similar body seals in a retail chain, but usually the chance of such a purchase is small, since all mixers have different designs and sizes, if they do not belong to the same brand.

Therefore, many craftsmen use winding under rings. To do this, they are removed from the recess and a suitable material with high adhesive ability is wound into the groove; it can be narrow (along the width of the groove) strips of fabric electrical tape; a medical adhesive plaster has excellent adhesive ability; some plumbers use FUM tape.

After winding one or two layers of lining material into the groove, the O-rings are returned to their place and the faucet is reassembled in the reverse order - thus extending its service life for a significant time.

Cartridges and their ceramic parts

Replacing the cartridge and eliminating the main problems

The main repair of faucets of this type consists of replacing the cartridge. To do this, you will need an adjustable wrench, a sharp knife or flat-head screwdriver, and a hexagon. The work is carried out in the following order:

- Shut off the water, close the drain with a stopper to prevent loss of small parts, then use a knife or screwdriver to pry up and remove the plastic plug in the front of the handle.

Since the clamping screw is located in a recess and determining the shape of its head is problematic, shine a cell phone inside the hole and then proceed to unscrew the locking screw with a suitable tool. Usually the screw head has a hexagon-shaped recess and a similar key is used to unscrew it.

- After unscrewing the fixing screw, the handle is removed from the rectangular pulley, pulling it up.

- Under the head there is a decorative cap attached to a threaded clamping nut; it is designed to be easily unscrewed by hand, but after using the mixer for a long time, the threaded connection becomes covered with limescale and the process of manual removal often ends in failure.

If time permits, you can pour vinegar, a solution of citric acid, or an effective household chemical to remove limescale from sanitary appliances into the space between the cap, and postpone the process of replacing the cartridge for a while. The second option is to pour boiling water between the cartridge and the cap and try to unscrew it.

But if the options outlined are for some reason impossible or the use of the product does not bring a noticeable effect, you will have to put significant effort into the decorative cap.

It is unlikely to be possible to unscrew it from the outside with an adjustable or gas wrench due to the smooth, round and cone-shaped surface, so you will often have to use pliers, holding the upper edge of the cap in the jaws and turning it counterclockwise. The surface of the cap and its edge will be damaged, but since it is closed with a handle, this will not affect the appearance of the mixer.

Sequence of operations for replacing a cartridge

- Next, unscrew the released clamping nut, which has a convenient hexagonal projection for using an adjustable wrench. When carrying out work, the probability of success is much higher than in the case of a cap, but sometimes situations arise when this nut cannot be unscrewed after a long period of use of the mixer.

If the use of lime scale solvents or hot water does not produce results, the nut will have to be removed from the housing mechanically. The task is simplified due to the fact that in many mixers the pressure ring has thin walls. To remove it, cut longitudinal radial grooves in the nut with a grinder, if necessary, cut off part of the hexagonal protrusion, and break out fragments of the ring from the body using pliers. To replace a broken nut, purchase a similar one from a retail chain or unscrew the part from an old mixer.

- Remove the cartridge from the mixer by pulling it out with your fingers by the rectangular rod. Typically, cartridge sizes are standardized for different types of faucets, so replacing it with a similar product will not cause difficulties - if you take it with you to a specialized store or market, you will always find the right product with similar dimensional parameters from any manufacturer.

- Clean the vacated housing cavity from dirt and limescale, and install a new cartridge, aligning its protrusions with the recesses in the lower part of the inner glass.

- Press the cartridge with the nut by hand with maximum force without using an adjustable wrench - this must be done in order to avoid major damage to the cartridge when its body is compressed by the clamping ring.

- Turn on the water and check the mixer for leaks; if water comes through the top, slowly rotate the ring with an adjustable wrench until the leak is eliminated, after which the operation is stopped.

- The assembly is completed by screwing back the decorative cap, securing the handle with a screw (the hex head screw can be replaced with a regular slotted screwdriver) and putting the decorative plug in place.

Stages of repair work in a ball mixer

Ball mixer repair

Before repairing a ball valve, it is advisable to purchase a standard set of spare parts with a set of seals - this will simplify the task of finding the necessary parts. To remove small parts you will need a thin screwdriver or tweezers; unscrew the outer cap with an adjustable wrench.

To repair a ball mixer, remove its handle and decorative cap by analogy with the method described above. In most models, removal of the cap is simplified due to the presence of straight sections on its surface for gripping with an adjustable wrench. After this, all parts can be easily removed.

The main malfunctions that have to be eliminated in a ball mixer are as follows:

- The top dome washer wears out and water leaks out the top of the faucet. The leak is eliminated by replacing the damaged product.

- Defects of the ball, the appearance of cracks and grooves on its surface. The part cannot be repaired and must be replaced with a new one.

- Abrasion of seat seals. Cylinder gaskets are replaced with new ones.

- Weakening of the spring, while the seat valves do not fit tightly to the surface of the ball and the mixer allows water to pass through. To eliminate the malfunction, the springs are stretched or replaced with new ones.

Construction of worm-mounted crane axle boxes

Installation and operating rules

The design of the ball water tap makes it easy to install it yourself where it is required. The crane must be mounted in a place so that during operation it does not interfere or is not subject to mechanical stress.

At the same time, unimpeded access to the crane must be ensured in case of control of operation, correction of repairable damage and dismantling if replacement is necessary.

The locking device is installed on metal or plastic pipes according to the following algorithm:

- The old faucet (if any) is removed and the threads are cleaned of any remaining tow and sealant.

- The threaded seal is wound tightly.

- A new, appropriately sized locking device is screwed on. Please note that the thread on which the product is screwed must not be rotten; it must have at least four turns. Otherwise, it is necessary to replace the entire pipe or part of it.

When installing a water supply system from scratch, first of all, you need to mark the place where the tap will be installed. Then the pipe is cut at this place, a corresponding thread is made, onto which the locking device is screwed.

To cut pipes, special equipment is used - a pipe cutter. But you can also use improvised tools, although it is not so convenient, and the cut will not be as even and smooth. You can read more about choosing a pipe cutter for copper pipes in this article.

Do you have a water supply system made of metal-plastic pipes? You can read about the types of pipe cutters for such a pipeline in our other article.

In both cases, before installation you need to pay attention to the arrow indicating the direction of flow and be sure to comply with this condition. Before screwing the faucet, it is recommended to wrap the thread with FUM tape. This will ensure the most reliable sealing.

After installation, it is necessary to check the functionality of the locking device. To do this, you need to turn on the water and check for leaks, gradual formation of drops, or smudges. It is also necessary to make sure that nothing interferes with the control of the crane, i.e. the lever or “butterfly” has free movement.

To install the device using the welding method, electric welding is used. During the welding process, it is important not to damage the ball mechanism and o-rings.

First, one pipe is welded, then the second, while on vertical sections the valve should be installed in the “closed” position, and on horizontal sections – “open”.

Using a fitting and a lock nut, a ball valve can be installed not only on a metal or plastic pipe, but also to connect pipes from different materials.

The operation of ball mechanisms does not cause difficulties; they are used either closed or open. It is theoretically possible to regulate water supply using a ball valve.

However, it is worth considering that such a faucet is, first of all, a shut-off device and too intensive use will lead to rapid wear of the seals. To regulate the flow, it is better to use ball mixers or a needle valve if it is impossible to install a mixer.

Do not install household taps where process water containing solid impurities passes through the pipes, because they will quickly damage the O-rings, rendering the locking device inoperable.

Before purchasing ball control valves for water supply installation, you need to check the plan and determine how many straight-through and rotary pieces will be required

Repair of a two-valve mixer

The main malfunctions of two-valve mixers are incomplete shutoff of water when it flows from the tap, and leaks in the body area or through the stem. In all of the above situations, the causes of malfunctions are abrasion of the sealing gaskets on the body, stem and shut-off valve (in ceramic valve axle boxes - when the surface of ceramic elements is damaged).

Repairing leaks in a worm valve

Repair of valve-type kitchen mixer taps is carried out in the following order:

- Use a sharp knife or flat screwdriver to pry off the plastic cap-plug from the hot or cold water flywheel and set it aside.

- Unscrew the flywheel mounting screw with a screwdriver and remove it by moving it upward from the splines of the rod.

- Using an adjustable wrench, unscrew the axle box using the hexagon in the upper part of the housing.

Next, depending on the type of valve, proceed as follows:

In worm-type axleboxes, the main causes of leaks are abrasion of the gaskets; they are located on the rod, body and in the shut-off valve seat; the last gasket is subject to the greatest abrasion and most often needs to be replaced.

To replace the valve seal, unscrew the clamping screw at the end of the piston, remove the gasket from the socket and put a new one in its place. If urgent repairs are required, but there is no suitable part at hand, place a piece of any material (rubber, leather, plastic) cut in a circle with a central hole into the socket and put the gasket in place.

When the seals on the rod or body wear out, purchase similar parts from a retail chain and install them in place of the worn ones. If the store fails to find rubber rings for the rod, you can remove them from the grooves and wind one or two turns of thin strips of FUM tape, adhesive plaster or fabric tape into the grooves and return the worn ring seals to their place.

Stages of replacing the gasket in a worm-wheel drive valve

Eliminating leaks in ceramic valves

To repair ceramic axle boxes, it is rational to purchase a repair kit in advance, which includes all the main gaskets and two ceramic plates. The main malfunctions and methods for eliminating them are given below:

- Water enters the spout when the lower silicone gasket wears out. To eliminate the malfunction, it must be replaced.

- The faucet is leaking under the flywheel; for repairs, two o-rings on the rod are replaced (if there are no replacement parts, use the winding discussed above).

- Water flows from the spout when the tap is closed; if you press the handwheel from above, the flow stops. The cause of the malfunction, which is most often found in ceramic axle boxes, is wear of the fluoroplastic ring, which is responsible for pressing the ceramic plates to each other, while water seeps into the gap between them. The defect is eliminated by installing a new fluoroplastic (copper) ring.

- Water flows between the axlebox and the mixer body; the malfunction is caused by wear of the rubber ring on the surface of the axlebox. This is one of the very rare malfunctions, since the gasket is in a stationary state and cannot wear out, unless it crumbles due to time and prolonged heating. The repair consists of replacing the outer rubber ring on the axlebox body.

- Water drips from the spout; the problem is that the surface of the most durable ceramic plates is damaged by sand particles and other hard abrasive particles during long-term use of taps to shut off dirty water. Eliminate the malfunction by replacing worn plates with new ones from the repair kit.

Replacing a worn fluoroplastic ring (white) with a copper one in a ceramic faucet.

In modern kitchens, single-lever faucets are more often used than others; they have high functionality, ease of use and reasonable cost. Due to the simplicity of their design, single-lever faucets are reliable in operation, and in case of malfunctions, any user can replace worn or broken parts (cartridge) with an adjustable wrench and basic technical skills.

Valve taps

In devices with a valve or wing, a valve axle is mounted in the internal part, which is necessary to block the flow of liquid. When the valve unwinds, the valve axle box rises from the seat and opens the passage to the flow. When closed, it returns back to the saddle, blocking the line. A rubber gasket installed in the valve serves for sealing.

The device consists of:

- lamb or valve;

- spindle;

- union nut;

- housings;

- saddles

The body is made in the form of a zigzag from the following materials:

- copper;

- brass;

- bronze;

- stainless steel;

- silumin.

The product can be cast, welded or dismountable. In the latter case, repairs are simplified.

The spindle is used to fix the valve stem in the desired position; it is a tube with a thread cut inside. The rod is also threaded to move along the spindle.

The valve is closed from above using a union nut, and a seal is installed between it and the body for sealing.

There are also corner valves that are installed at the bend of the water line. The only difference is in the shape of the body and socket. The principle of operation of the device is the same - to open the flow of liquid, the valve is unscrewed, the locking mechanism rises up, and goes into a seat in the housing.