For those who decide to install an external sewer system on their own, you definitely need to know the features of laying pipes in the ground, as well as the principle of selecting building materials, so our article will be very helpful.

If you are interested in the placement of the pipeline in the house, you should read the article “Laying sewer pipes”.

Selection of materials

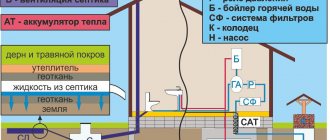

Through the internal sewerage system, wastewater is removed from buildings and transported through an external pipeline to treatment facilities - central or local (septic tanks).

In order for your sewer system to cope with its tasks effectively, you must know how to lay sewer pipes on your site.

For the construction of an external sewer system, it is advisable to use smooth orange polymer pipes:

- polyethylene (PE);

- polypropylene (PP);

- polyvinyl chloride (PVC).

If the laying depth is significant or the sewer pipes are expected to be subject to dynamic loads (in cases where sewerage passes under pedestrian and highway roads), it is better to prefer corrugated double-layer pipes made of PE or PP.

The connection of polymer pipes occurs through shaped products - adapters, couplings, bends, etc.

Most often, external sewer pipelines are constructed from orange polymer pipes with a diameter of 110 mm.

Painting pipes orange indicates their purpose - for external sewerage; they are more durable and strong than gray products used in the construction of internal pipelines.

Pipes laid underground for external sewerage are less susceptible to corrosion, destruction and, when laid with the correct slope, do not create blockages due to the smooth structure of the inner wall. The maximum permissible depth of such pipes in the ground is 3 m.

Pipe laying technology

Preparing the trench

Having decided on the material, familiarize yourself with how to properly lay sewer pipes. Installation of external sewerage begins with preparing a trench, which can be dug manually with a shovel or using an excavator.

The depth of the furrows depends on the depth of soil freezing in a particular area. According to SNiP P-G.3-62, the depth of laying sewer pipes is 0.5 m less than the soil freezing mark and is approximately:

- 3 ÷ 3.5 m – in the northern regions of the Russian Federation;

- 2.5 ÷ 3 – in the middle zone;

- 1.25 ÷ 2 – on the Black Sea coast.

The indicated figures are not categorical and may vary within certain limits depending on the terrain and groundwater level. However, laying sewer pipes in the ground must be done at least 0.5 m from the surface.

When using pipes of 110 mm diameter, depressions are dug in the soil 0.6 m wide and 0.05 m deep than the depth of the pipes.

The trench has its own characteristics:

- The bottom of the trench is leveled, the necessary slope is created, as a rule, 1-2 cm for each linear meter of the pipeline.

- After leveling the bottom, it is necessary to thoroughly compact the soil and arrange a cushion of gravel or sand 10-15 cm high.

- A sand or gravel bed must be compacted in an area located 2 m before the inspection well and at the junction of the pipeline with the inlet pipe.

- Where the sockets will be located in the sewer system, pits should be formed.

Pipeline installation

Next comes the actual installation of the pipeline. It is better to start laying from the foundation of the building.

The technology for laying sewer pipes looks like this:

- The pipes are laid with the socket down in prepared trenches.

- To connect two pipes to each other, the socket of one and the smooth end of the other are cleaned of dirt.

- The joints are lubricated with special compounds.

- The pipe is inserted all the way into the socket.

- All pipeline elements must be combined in a similar way.

Pro tip: When connecting parts of a pipeline, one pipe is inserted into the socket of the next one. In order for this connection to be reliable and of high quality, it is recommended to first measure the depth to which one pipe will enter the other and make a mark in the appropriate place.

If there is an outlet in the foundation of the house, the external sewer pipe is connected to it; if it is not provided, then a hole must be made. Diamond drills are ideal for this task.

For the turning device, bends are used - 15, 30, or 450. When the length of the sewer pipeline is more than 15 m, an inspection is installed in such sections.

Backfilling the trench

After laying the pipes, the slope angle is checked. If everything is done correctly, the trench can be backfilled. For backfilling, it is allowed to use the soil formed when digging furrows, but in this case it is necessary to remove large stones from it and break up dense blocks of soil.

Advice from a professional: When backfilling, large stones and blocks of soil larger than 30 cm in size are not allowed in the soil - such inclusions can easily damage sewer pipes.

The trench is gradually backfilled to a height of 0.3 m, in layers of 5 cm. Each layer is well compacted on the sides of the pipe; compacting the area above the pipe itself is prohibited.

Digging methods and necessary tools

to dig a trench :

- manual;

- mechanized.

Earthworks done by hand are valued higher than those done with mechanized equipment. An open excavation in the ground is usually made in a trapezoidal or rectangular shape.

To achieve a certain shape, it is better to use manual labor . This method is used when equipment cannot be brought to the work site. The street near the house is too narrow, there is no possibility to place a bulldozer or excavator.

The effectiveness of the manual method depends not only on the quality of the builders’ work, but on the type of soil. If it is too loose, the chances of normal digging are reduced. For manual digging, they also choose convenient weather, since workers will not be able to dig normally in bad weather conditions.

Digging a trench using a mechanized method is faster and more reliable. It is more accessible than manual labor, but is only possible if the bulldozer can drive to the construction site. When determining the cost, the calculation is based on the time spent on the work. The mechanized method will be relevant if a large volume of soil development is expected.

When using manual labor, a bayonet and shovel are used. A bayonet tool is used to dig up soil, and a shovel tool is used to collect it.

Mechanized digging involves:

- excavator;

- bar machine;

- mounted trencher.

With the help of an excavator you can dig trapezoidal trenches, a digging machine is suitable for working in heavy and frozen soils, and a mounted trencher is relevant for small trench widths.

The process and technology of digging a trench

Before digging a trench, it is necessary to take into account the width of the future pipes. In order for the sewer installation to proceed correctly, it is necessary to give the worker the opportunity to be at the bottom of the trench. To do this, its depth is determined.

The digging process itself is simple:

- Choosing the shape of the trench. There are several shapes for sewer trenches: rectangular, trapezoidal and mixed. Rectangular is used on dense soils when strengthening the walls is not required. A trapezoidal one is needed when buried at a distance of more than 1.5 meters. A mixed type of trench is suitable when the pipe needs to be located at the groundwater level.

- Width selection . This indicator is determined based on the diameter of the pipes used. It is also important to take into account the width of the tool for work: for manual work - a shovel, for mechanized work - the width of a bucket. Standard sizes range from 0.5 to 0.8 meters depending on depth.

- Marking the trench. Choose the shortest route for the route. Pegs are used for marking, and a string is pulled between them. The beginning of the route will be where the sewer leaves the house, and the end will be where the septic tank is located. If there are obstacles on the path of laying the route - trees, objects, then they are bypassed at an angle of 90 degrees. This further facilitates the joining of pipes. Before marking and digging, be sure to cover the lawn grass with a tarpaulin and also protect other objects from damage.

- Hand digging . First, remove the top turf layer. Then the soil is loosened with a bayonet shovel and removed using a shovel. When digging by hand, it is better to use a stepwise method, gradually going deeper inside. When the trench has reached the desired width, but is not yet so deep, use a cutting shovel. An assistant is needed here: one worker ties a rope to the base of the shovel, and the second pulls the soil to the surface.

- Mechanized digging. Specialized equipment arrives at the site and is capable of digging a large number of trenches in a few hours.

Sewage diagram in the trench:

The developed soil is left on the surface - in the future it will be useful for backfilling sewer pipes.

Pipeline insulation

Sometimes sewer pipes need to be insulated. The need for insulation of sewer pipes arises when the pipeline is laid above the freezing depth of the soil or at the exit from the building.

In this case, stenoflex or energyflex insulation is used. Thermal insulating material is wrapped around sewer pipes along the entire length of the pipeline and securely fastened. Upon completion of installation of the insulation, the slope is checked, and only then backfilling is carried out.

The best option would be to fill the pipe with sand in a layer of 10-15 cm, which is compacted along the edges. It is allowed to fill the soil left over after digging trenches on top of the sand.

When partial repairs of an already functioning sewer pipeline are required, it is more correct and reliable to dismantle the old sewer pipes completely, and then start laying new ones.

In reality, such a solution will take much less time than replacing individual sewer elements.

Source: kanalizaciya-prosto.ru

How to lay sewer pipes in a private house: step-by-step instructions

A person feels good where there are comfortable living conditions. And in order to create them, you need to think about how to lay a sewer system in a private house. Firstly, you should familiarize yourself with the features of this process, and secondly, decide on the material used.

It is worth noting that now, plastic pipes, albeit slowly, are still replacing metal pipelines. As for cast iron, they are used very rarely due to their weight and high cost. In contrast, polymer products are much lighter in weight, easier to install and durable.

The main stages of laying sewerage in a private house

In order for the system to function properly and no unforeseen situations arise, before laying sewer pipes in a private house , you need to competently draw up a detailed project.

It is desirable that the design of engineering systems be carried out at the time of drawing up the house project, but this is only relevant if new construction is planned.

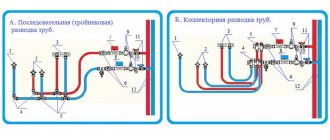

First of all, you need to take care of the compact arrangement of water intake points, which allows you to organize the reception of wastewater into a common riser. If the kitchen and bath are located at different ends of the house, then you will have to plan to build two risers and septic tanks, which entails additional costs.

Many experts recommend that at the stage of developing a scheme for laying external and internal pipelines, one should focus on some features of the movement of wastewater through pipes. The following rules must be followed:

- The toilet must be connected to the riser separately; in addition, other devices cannot be added to the connecting pipe;

- the connection of other devices should not be at a level lower than the toilet connection;

- all plumbing, except the toilet, may have a common connection to the riser;

- the diameter of the supply pipe must be no less than the size of the drain pipe.

Once the project has been drawn up, you can proceed to such stages of system installation as choosing a location for installing a treatment plant, arranging an internal sewer network, removing it from the house and installing an external sewer system.

If you are encountering this for the first time and do not know how to lay sewer pipes in a private house, but want to do it yourself, then it is advisable not only to read the installation instructions, but also to watch the video.

Tips for carrying out work

Fan pipes play an important role in the layout of the sewer system. They provide ventilation to the sewer system. Their quality affects the efficiency of the septic tank. The long service life of the sewer depends on the correct installation of the drain pipe.

Before pouring concrete into the pipework, you should check it for leaks.

The fan pipe continues the riser. It is brought to the roof of the house and connected to the riser, having previously installed an inspection. The background pipe is brought out into the attic at a convenient angle.

Piping tips:

- The distance to plumbing fixtures should be minimized;

- It is necessary to ensure that the diameter of the pipes increases as additional devices are connected.

- Devices with a large outlet should be located closer to the riser, and those with a smaller outlet – further away.

- When installing wiring, you must avoid sharp corners. When installing pipes, a certain slope must be observed.

When installing pipes, you need to anticipate places where blockages will occur. Their appearance must be prevented by installing inspection and cleaning. You should also take care of the correct laying of the external part of the sewer.

Installation of the external part of the sewer system

Detailed instructions will help you figure out how to properly lay sewer pipes in a private house. Remember to always follow the established procedure.

It all starts with laying pipes in a trench; you need to dig it in advance. The optimal distance between the trench and the pipe should be between 200 mm and 20 cm, it all depends on the diameter. Next you need:

- Dig a hole for a septic tank or treatment well; the depth must be at least 80 cm, and most importantly, 20 cm below the freezing level of the soil.

- Taking into account local conditions, as well as the depth of installation of the sewage system, it is necessary to ensure the optimal degree of slope of the pipes.

- Compact the bottom of the trench, freeing it from large stones and solid inclusions in advance. After this, a sand cushion is created.

- Having understood how best to lay the pipeline through the foundation from where it exits from the house, the pipes are laid along their entire length.

- To connect structural elements you need to use sealant.

- For pipeline turns, a smooth bend is used.

- The external system is connected to the VOC chamber using rubber seals.

After completing all the stages, you can backfill the system; for this, not only soil is taken, but also sand. In order for the installation of external sewerage to proceed without problems, you need to take care of purchasing components (elbows, crosses, fittings, tees, transitions, plugs).

When is it used?

It is impossible to organize normal conditions for a comfortable life in a house without a sewer system. Passing through the internal pipeline, waste is transported to external mains, along which it reaches the septic tank.

If pipes are laid in trenches correctly, such a system can exist for several decades. To organize a sewer system, trenches are first dug.

There are several situations when rutting is necessary:

- pipes should not be located in a visible place on the site;

- the distance from the object to the septic tank is large and it will not be possible to lay a pipe on the surface;

- climatic conditions;

- compliance with regulatory requirements;

- protection from mechanical damage;

- saving land on the site.

There are situations when laying pipes in trenches is impractical. This is influenced by the harsh climatic conditions in which a tenth of the country lives.

For example, if the average annual temperature in a region is too low, then permanent frost is observed. Sewage pipes laid in the ground may freeze. Because of this, they are placed on the surface of the earth. The location on top of the ground is also convenient for repair work.

Also, laying a pipe underground does not make sense if the outer section is small. Then you can install sewer pipes on top of the ground, leading them to the septic tank.

Stages of internal sewerage installation in a private house

You don’t know how to lay sewer pipes in a private house and where to start, but if you figure it out, everything is very simple. The installation starts from the plumbing fixtures and goes to the location of the external pipe. It is better to lay it under the floor. So let's get started:

- First you need to connect the S-shaped pipe or water seal to the plumbing fixtures.

- Then the first sewage pipeline is connected.

- The horizontal pipe structure is connected to the pipe through two elbows, the angle of which is at least 90 degrees.

- Do not forget about the importance of observing the slopes of the structure, for which you need to use clamps that are attached to the walls. Thanks to them, the structure is always in its normal position.

- The pipes coming from the toilet are connected to the main elements of the sewer system, connected by a perpendicular tee.

- To ensure the passage of the pipeline through the ceiling, you need to install a metal sleeve in the insulated pipe.

- And to go from a pipe with a diameter of 5 cm to 10 cm, you will need a special adapter.

- You can equalize the external and internal sewerage using an elbow.

It will be better if you observe the slopes of the pipes; with a diameter of 5 cm it should be 3 cm, and with a diameter of 10 cm - 2 cm. In order to seal the existing pipe joints, you need to use special hermetic mixtures.

Internal system diagram

Drawing up the diagram begins from the farthest plumbing fixture in the attic or top floor . All horizontal lines must be reduced to one riser. To save money and consumables, bathrooms on different tiers are placed along the same vertical line.

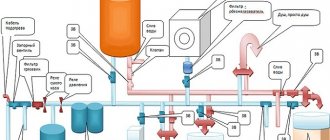

The sewage system in the house consists of:

- Water seals that prevent odors from entering the room;

- Drains from all plumbing;

- Pipes leading wastewater into the external sewer system;

- Elbows and tees connecting pipes into a single system;

- Clamps in walls that support pipes and give them direction and angle.

- Central riser.

The exact drawing of the internal system depends on the number of floors of the building, the presence of a basement, the amount of plumbing used and the number of users. The depth of the septic tank and connection to additional equipment (pumping station or household pumps separately for each device) also matter.

The diagram should display all elements to scale , so that in the event of a planned repair or emergency, you can quickly understand the wiring and find a breakdown.

Sewer outlet

Instructions on how to properly install a sewer system in a private house are not limited to a description of internal and external installation. She also describes how to properly remove pipes from your home.

You need to provide an outlet location in advance, and you also need to install several bends to connect the two parts of the pipeline.

Do not forget that you must install a metal sleeve to pass the pipes through the foundation, and insulate the space remaining between the walls of this device.

Source: kanalizaciyasam.ru

Laying sewer pipes in the ground: we equip and insulate external sewerage

Laying sewer systems in a private home does not require any complex skills, special tools or deep special knowledge. However, small errors during installation work can later lead to serious damage to the system.

The communications are subject to quite serious pressure from the soil layer; they are exposed to cold, moisture, etc. Therefore, it is necessary to ensure that the laying of sewer pipes in the ground is done correctly.

Blitz tips

- Before installing the system, work is carried out inside a private house - installation of a vertical riser to alternately supply pipes from the bathroom equipment to it, maintaining a slope of 5 mm per 1 m. When installing the pump, the slope is not necessary.

- During the planning process, the kitchen and restroom should be located near the exit of the sewer system to the street. In multi-storey construction, the arrangement of bathrooms is one below the other to reduce the number of risers and simplify the installation and maintenance of the entire network. For a large number of bathrooms or in the absence of a slope on the site, it is rational to use a pump.

Types of sewer pipes and their features

The process of laying external sewerage looks quite simple. The pipes are laid in a dug trench, connected to the system located inside the house, as well as to the collector, and then covered with earth.

Before drawing up an external sewerage project, you need to decide on the type of pipes. The dimensions of the trench, slope, etc. depend on the diameter, cross-section and material of these elements.

Pipes that are used to create external sewage systems are distinguished by many parameters, such as diameter and cross-sectional configuration, as well as material. Today, sewer systems are made of:

- cast iron;

- ceramics;

- concrete;

- asbestos cement;

- plastic;

- fiberglass.

Cast iron pipes weigh quite a lot, their internal surface is not very smooth, and installation is very complicated, so this type of sewage system is used extremely rarely in private plots.

Ceramic elements are easier to install, but they can be easily damaged if handled carelessly. Concrete structures of large weight are also difficult to install, so they are rarely used for external sewerage in a private house.

Inexpensive and lightweight asbestos cement structures have been popular in the past, but they are somewhat fragile, and the smoothness of their internal surface leaves much to be desired.

The undisputed leader in the sewer systems market is plastic. Pipes made of PVC, PP, PVP have all the characteristics necessary for external sewerage:

- light weight;

- significant strength;

- resistance to chemicals;

- ease of installation;

- smooth inner surface;

- ability to withstand very low temperatures, etc.

Fiberglass, which is a composition of polyester resins reinforced with special fiberglass, is also very good for sewerage. However, such structures weigh significantly more and are much more expensive.

To create a sewer system on a personal plot, round plastic pipes are most often used, the diameter of which is usually 110 mm.

When laying pipes using the puncture method, for example, under the road surface, as well as in other places with high loads, it is recommended to use double-layer pipes with a corrugated outer surface.

Note! Pipes made of polyvinyl chloride (PVP) can withstand heating only up to 40 degrees, while polypropylene (PP) structures can withstand temperatures up to 80 degrees. High-strength polyethylene (HDP), which is used in the production of sewer pipes, occupies an average position in terms of heat resistance.

Parameters and requirements

When independently digging a trench and laying pipes in it, they are guided by the SNiP 2.04.03 collection from 1985. The regulatory document specifies clear standards for the depth, width and rules for strengthening the trench.

For a private house, the requirements will be as follows:

- pipes are laid at a depth of 0.8 to 1.4 meters in a trench;

- the freezing depth in central Russia is 300 mm, so the pipe should lie 30-50 cm below the freezing level;

- from the surface of the soil to the pipe itself should be at least 70 cm.

When organizing the system under a concrete platform, as well as in places where road transport constantly passes, the minimum values of the system level are increased by 1 meter. This is necessary to reduce the risk of soil subsidence due to intense loads on it.

According to regulatory documents, when digging a trench, it is important to take into account the type of soil . For example, soil with a high clay content freezes less than sandy soil. Soil with gravel has the highest level of freezing. There is always a focus on the region. The degree of soil freezing varies in different cities.

According to SNiP, the minimum depth of the trench for sewerage should be 50 cm. When the pipeline is deepened by 1 meter, the walls of the trench are strengthened.

Procedure for creating an external sewer system

The laying of sewerage pipes begins with the project. It is recommended to make a trench with a minimum number of bends; the optimal solution is a completely straight pipe without any turns.

If you can’t do without them, and the length of the system is more than 12 meters, inspection wells are installed in such places, since this is where blockages and breakdowns most often occur.

Note! Even ideally straight sewers must be equipped with inspection wells every 25 meters.

It is important to correctly determine the depth of the sewer pipe. When determining it, the depth of soil freezing and the level of the entrance of the sewer pipe into the septic tank or pipe of the centralized sewer system are taken into account.

In addition, the required sewerage slope should be ensured, which is 2 cm for each linear meter of the structure.

Often, creating a sufficiently deep trench turns out to be too labor-intensive, and sometimes impossible. In this case, it is necessary to carry out thermal insulation work to protect the drains from freezing in winter.

According to the rules for laying sewer pipes, the minimum trench width is defined as the diameter of the pipe plus 20 mm on each side for pipes.

If the pipe is wider than 200 mm, the free space should be increased, otherwise it will be difficult to correctly install the structure. Once the plan has been drawn up and all factors have been taken into account, the work begins.

To install external sewerage you should:

- Dig a trench of suitable size. Place a sand cushion approximately 50 mm thick on the bottom. Carefully compact the bottom of the trench.

- Lay and connect sewer pipes. Connect them to the internal sewerage system and to the septic tank.

- Check the operation of the system and make sure it is tight.

- Fill the space on the sides of the pipes with sand, compacting it layer by layer. Backfill the sewer from above.

Note! The layer of sand or soil laid on top of sewer pipes does not need to be compacted.

When figuring out how to properly lay sewer pipes, you should take into account the recommendations of experts:

the number of joints and turns should be minimal; all pipes must be directed towards the flow of waste; sockets and shaped elements cannot be shortened; The pipes should be secured to ensure the correct slope of the sewer.

To maintain the slope, use a marking cord that is pulled along the bottom of the trench.

A few words about insulation

Insulation of sewer pipes is used quite often. For this purpose, special rolled or shaped insulation is used.

The first ones must be wound onto the pipe during the installation of the sewer system, the second ones are made for a pipe of a specific diameter and are simply put on it.

Since heat-insulating materials can lose a significant part of their useful properties when in contact with water, it is important to cover them with a reliable layer of waterproofing.

As an alternative or additional method of thermal insulation, a special heating cable is used, which is installed along the entire length of the pipe.

You can save time and effort if you buy pipes with a thermal insulation layer already installed. Elements are produced equipped not only with conventional insulation, but also with a heating cable.

When using such structures, it is necessary to carefully seal the joints so that moisture does not get on the insulation.

Source: aqua-rmnt.com

Distance to drinking water sources

An important parameter that must be taken into account when constructing a septic tank is its distance to the wells where drinking water is obtained. If placed incorrectly, the likelihood of sewage entering the well and contaminating the water significantly increases.

As a result of this, people using water will be infected with dangerous microorganisms - viral pathogens. This can cause significant harm not only to human health, but also to human life.

Even with the installation of modern fully sealed systems, there is still the possibility of a breakdown or any other emergency. To prevent waste from entering the water, it is necessary to follow the rules for choosing a location.

Distance requirements are determined by SNiP, they are based on the type of soil on the land plot. Quite often, soil with increased filtration properties significantly simplifies the construction procedure and slightly reduces the distance required by the document. However, regardless of the type of soil and filtration properties, a minimum distance of 25 meters must be maintained.

To determine the quality of soil filtration, a professional geological examination is required. The best type of soil is considered to be one that contains a lot of clay or sand. If this is the type of soil on the dacha plot, then the installation of the structure is carried out at a distance of at least 50 meters from the drinking wells.

Watch the video

How to lay sewer pipes - a step-by-step guide with examples

Waste water and human waste are first transported to mains located outside the building, and then end up in storage tanks or septic tanks.

To do this, you can use pipe products made from different raw materials. More recently, cast iron pipelines were used to create an external sewer line in one's own home. Today, everything has changed, and the external laying of sewerage pipes is made from polymer pipe products.

The reason was the fragility of cast iron compared to plastic, and in addition, products made from this alloy are heavy and require special equipment for installation.

Advantages of plastic pipes

The sewer plastic pipe has a number of advantages in addition to its low weight:

- withstands the influence of active chemical environments without problems;

- it is not subject to corrosive processes;

- has a smooth inner surface, so that deposits do not accumulate on it, which lead to a decrease in pipeline capacity.

When a sewer pipe is laid in the ground, all of the above positive characteristics are of great importance, since cleaning, repairing or replacing elements of the pipeline will require excavation work.

And this leads not only to additional time, but also financial costs.

Pipe products made from plastic have the following characteristics:

- affordable price;

- does not conduct electricity, which is very important today due to the presence of many household electrical appliances in the house;

- non-toxic;

- with its help you can mount highways of various configurations.

Despite all the advantages, you won’t be able to use them if you don’t know how to properly lay sewer pipes in the ground. Among the advantages of plastic products, it should also be noted that they do not lose their original appearance over time.

When arranging a sewer system indoors with your own hands, you need to use plastic products painted gray. When laying the outer part of the structure, polymer pipes of orange, red or brick shade are used to drain wastewater and sewage.

Selection of pipes for the device

Previously, when laying sewers, only metal pipes were used: cast iron or steel. Indeed, these materials are like no other suitable for laying in the ground. They are strong, durable, low cost, and easy to install.

However, along with advantages, metal structures also have significant disadvantages. The disadvantage of steel lines is the possibility of corrosion, and cast iron pipes are heavy.

In terms of strength and durability, cast iron pipes have no equal; this material can lie in the ground for decades without losing its qualities, but due to their heaviness, laying a water pipeline becomes much more difficult

A certain difficulty is present in sealing the joints of a cast iron pipe, as well as its internal surface, which, due to the characteristics of the material, will never be perfectly smooth. The latter characteristic affects the speed and quality of movement of waste inside it; over time, blockages can form in the pipe.

Asbestos-cement pipes can be used for sewer installation. They have a smooth surface, which eliminates the possibility of blockages, are simply connected using special couplings, and their weight is significantly less than that of metal structures.

But they also have a significant disadvantage - they are very fragile, which complicates their transportation and installation. Ceramic pipes have the same fragility.

Reinforced concrete structures have many advantages: they have exceptional strength, water resistance, and frost resistance. It is possible to make large-diameter pipes from reinforced concrete, which is impossible to do from other materials.

But laying such pipes is a big problem - due to their heavy weight, it is necessary to use special equipment, which is not always advisable in an individual household.

Today, when installing private sewer systems, polymer pipes are most often used, which, despite their strength, are lightweight, which allows them to be installed by one person. They are very simple and easy to connect, resulting in excellent tightness.

Orange polymer pipes are used for the installation of external sewerage. They have increased strength compared to gray pipes intended for internal piping, and also have the ability to withstand heavy loads

There are three types of polymer pipes - polypropylene, PVC or HDPE (low-density polyethylene). PVC structures, in addition to the above advantages, are also resistant to UV radiation and have slight changes in parameters due to temperature changes.

However, the PVC sewer pipeline does not withstand very low and very high temperatures, and can also be deformed under mechanical loads.

During its operation, the sewer system is subject to dynamic loads, which are best withstood by corrugated pipes. Even if it freezes, the integrity of the line will not be compromised, but deformation of its walls may occur.

The diameter of the pipes is selected based on the amount of plumbing equipment installed in the house. So, for a country cottage with two toilets, pipes with a cross-section of 110 mm will be sufficient.

If the house building has three or more bathrooms, it is necessary to use a pipeline with a diameter of 160 mm.

Image gallery

Photo from

Polymer pipes in the installation of an external branch

Polypropylene products in sewerage organization

Cold welding pipe connection

Range of fittings for plastic pipelines

Basic provisions of sanitary norms and rules

In 1985, Sanitary Standards and Rules were approved, according to which sewer systems must be installed.

The same document contains recommendations regarding the nuances of installation work. In particular, it contains information regarding the depth of the pipeline and other important points.

The rules for laying sewer pipes indicate that their laying depth must be at least 30–50 centimeters from the soil freezing mark in each region - the calculation is carried out from the lowest point of the pipeline.

When work is carried out in areas with increased load on the soil surface (for example, under the roadway), the products should be laid deeper, sometimes at around 9 meters.

The document regulates how sewer pipes should be installed in trenches:

- In the place where it is planned to lay a sewer drain from a private household, it is imperative to compact the ground. This will prevent erosion of the engineering structure by groundwater during heavy precipitation.

- The laying of an external pipeline is considered to be correctly completed if a pipeline slope is created, which should be from 1 to 2 centimeters per linear meter. This requirement must be observed because there is no pressure pressure in domestic sewer structures.

The technology for laying sewer pipes in a trench provides that in your own home, in a place where the pipeline bends sharply, you need to equip a special well.

This allows you to make repair work easier and to replace a section of the highway that has become unusable in the shortest possible time.

There is also a rule regarding the laying of pipes for sewer structures in the ground. It states that a layer of sand at least 15 centimeters thick must be poured onto the bottom of the trench, which will ensure the stability of the system and its convenient operation.

A similar layer should be placed on top of the sewer line. The use of backfill will simplify access to the pipeline if repairs are necessary.

Experts also recommend installing inspection wells in areas where there are significant differences in the depth of pipe laying. If the length of the network is large, several of them should be installed, maintaining a gap of about 25 meters.

Slab foundation and laying of communications

This type of foundation requires very precise calculations at the very beginning of the project.

After pouring such a foundation with errors, it will be impossible to lay the necessary communications. Therefore, a trench is dug first. All communications and sewer pipes are laid in it, dressed in special protective sleeves.

In a slab foundation, the sleeve plays a very important role. It protects the monolithic slab from high pressure and also facilitates the process of replacing a damaged section of pipe. If the sleeve is missing, it is simply impossible to replace the pipe in such a foundation. The pipe can also be damaged when the foundation is being poured.

Sequence of actions when installing a sewer system

First of all, before laying the pipes, they dig a trench. The easiest way to do this is to use special equipment, such as an excavator, or manually.

According to generally accepted technology, laying sewer pipes involves the use of pipes with a diameter of 110 millimeters. In this case, the width of the ditch should be at least 60 centimeters.

Simultaneously with increasing the cross-section of the pipe being laid, it is also necessary to expand the trench. After selecting the material, the pipe is directly laid in the trench, which has its own nuances.

Those who are interested in how to lay sewer pipes in the ground correctly should keep in mind that work must begin from the foundation of the building. If there is no pipeline for drainage from the house, a hole is cut under the base of the building and the network is supplied under it.

When there is an outlet, a socket is put on the end of the pipe leaving the building. In this case, special attention is paid to the alignment of the joined elements.

As a rule, along the entire length of the sewage and wastewater drainage pipeline there are bends and turns - they are the ones that most often cause failure of the sewer network and cause serious trouble to the owners of private houses.

It is in places where the pipeline changes its direction that various deposits begin to accumulate. Over time, they completely block the path of movement of wastewater.

Experts know how to install a sewer pipeline in a private household to prevent such troubles.

Therefore, they do not include advice from professionals, which are as follows:

- The laying of sewer pipes must be carried out using bends that have different bending angles - from 15 to 90 degrees. To provide convenient access to places where blockages form, revisions are installed above each elbow.

- After completing the formation of the outlet from the house, the pipes are placed in the trench with the sockets down and then they begin to join the products. The joining process is as follows: the edges of the products are lubricated with a special compound and they are inserted into the socket until it stops.

To correctly connect the elements of engineering communications in a private household or apartment, a simple technique is used. It consists of marking the pipes before starting work to determine the depth of their insertion into the socket. Based on them, the connection is finally made.