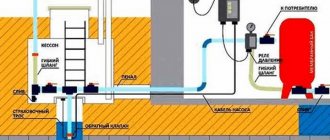

Decentralized or autonomous water supply systems are installed strictly according to schemes. They include a list of requirements and calculations that must be fulfilled. However, to ensure the reliability and efficiency of the water supply system, simply installing a high-quality source and laying pipes will not be enough. It is impossible to do without a well-thought-out connection diagram and automation that would be responsible for controlling the pump. The design is based on the use of a water pressure switch, which is installed in the pumps

The simplest and most cost-effective solution is to purchase a pressure switch that can be turned on and off as needed. A compact and well-thought-out device is responsible for maintaining pressure inside the structure, making the pressure optimal. However, in pipe systems, the installation of such a unit is undesirable due to the complexity of communications, in which constant monitoring of the main parameters of equipment operation is necessary. In this case, it should be noted the preference for more advanced block-type automation, which includes a variety of sensors.

Principle of operation

To fix the unit, a spring pressure group is used in the design. The contact closes when the minimum pressure is reached. After this, it switches on automatically. At the moment when the maximum coefficient (set by the user) is reached, the pumping unit will turn off as the contacts open. The design is equipped with special adjustment mechanisms that allow you to manually adjust the value.

It should be noted that the best manufacturers equip their products with a forced or dry start button. The design may also have auxiliary connectors (instead of the usual terminals) necessary for connection, a soft start key and an operation indicator.

Operating parameters

The criteria for choosing such a device are varied. Such a choice should be made only after purchasing the pumping station itself, as well as the hydraulic accumulator. During the purchasing process, you should focus on the parameters of the working network you are using:

- pressure in the chamber of the installed hydraulic accumulator;

- minimum pressure value that is set by the user;

- the maximum value at which automatic shutdown will occur.

It should be noted that in the chamber (air) of the hydraulic accumulator there should be 0.2 atm less than in the water supply structure (recorded by the sensor). Otherwise, the elastic plate will soon become unusable.

The following types of structures are found:

- Manager. The signal is sent to the power control unit.

- Power. Power contacts are connected to the pumping unit.

Before purchasing, you need to check the permissible switching power of the structure.

Characteristics and pressure settings

This is small-sized equipment, which includes a fitting, with the help of which subsequent connection to the pipeline network is carried out via a terminal group. These components will be needed to connect the device to electrical cables. More detailed information is provided by the manufacturer in the form of step-by-step instructions that can be used at home. Springs help to register pressure-related parameters through a threaded regulator.

The more the springs are compressed, the more force will be applied, and the higher the coefficient must be for the relay to operate. It is also possible that there is a significant difference in pressure coefficients. The coefficient increases by tightening the spring. It should be noted that in domestic conditions, factory settings are used, which fully correspond to the assigned tasks. Used in popular models and hydraulic accumulators. Even with optimal standards, in some cases personal intervention and manual adjustments may be required.

How to regulate

| Numbering | Sequence of actions/adjustments |

| 1. | Conventional models are equipped with several springs, the diameter of which varies. |

| 2. | A large spring is used to control the coefficients. |

| 3. | A small spring detects the current difference in levels. |

| 4. | In the process of compressing a large spring, the maximum and minimum values will increase simultaneously. |

| 5. | In the process of compressing a small spring, the superiority of the maximum coefficient will become more obvious. Thus, the maximum indicator will become dominant. |

Design and principle of operation of a pressure switch

The design of the pumping station pressure switch is not complicated. The relay design includes the following elements.

Housing (see picture below).

- Flange for connecting the module to the system.

- A nut designed to adjust the shutdown of the device.

- A nut that regulates the compression force in the tank at which the unit will turn on.

- Terminals to which the wires coming from the pump are connected.

- Place for connecting wires from the electrical network.

- Ground terminals.

- Couplings for securing electrical cables.

There is a metal cover on the bottom of the relay. If you open it, you can see the membrane and piston.

The operating principle of the pressure switch is as follows. When the compression force in the hydraulic tank chamber intended for air increases, the relay membrane bends and acts on the piston. It starts to move and activates the relay contact group. The contact group, which has 2 hinges, depending on the position of the piston, either closes or opens the contacts through which the pump is powered. As a result, when the contacts are closed, the equipment starts, and when they open, the unit stops.

DIY installation

The pressure switch, according to buyers, is best installed directly at the outlet (on the hydraulic accumulator). In this area, there is a significant leveling of flow turbulence and pressure surges during normal operation of the pump and during its startup. Also among the common mistakes when choosing a device is the lack of due attention to the recommendations of the manufacturer itself regarding the performance qualities of branded equipment.

The main limitations are related to the microclimate. Most popular models function normally at temperatures of +4° and above, as well as humidity of 65% or less. Such equipment must be installed in well-heated rooms. Before installing pumping equipment control sensors, you should install the following elements yourself (most of them are installed during the construction stage):

- sewer drain;

- check valve;

- a filter responsible for fine water purification;

- input type valve;

- pipelines;

- pump;

- coarse filter.

New products in the field of relays are equipped with special fittings that facilitate the process of connecting the structure to other elements of the system. Some budget models can be installed in a block with a pump. Units that have appropriate protection from water can be installed in a well, caisson or with a pump. Description and equipment will depend on the selected model.

In addition to the main selection criteria, it is recommended to pay attention to the optimal humidity and temperature coefficient for the operation of the structure, which has a huge impact on the device, its service life and performance.

When to adjust the relay

As mentioned above, the relay automates the process of pumping liquid into the water supply system and into the expansion tank. Most often, pumping equipment purchased ready-made already has basic relay settings. But situations arise when urgent adjustment of the pressure of the pumping station is required. You will have to perform these actions in cases where:

- after starting the pump motor, it immediately turns off;

- after the station is turned off, there is a weak pressure in the system;

- when the station is operating, an excessive compression force is created in the hydraulic tank, as evidenced by the readings of the pressure gauge, but the device does not turn off;

- The pressure switch does not work and the pump does not turn on.

Most often, if the unit exhibits the above symptoms, then relay repair is not required. You just need to configure this module correctly.

What should you pay attention to when purchasing a product in an online store?

- Before installing the unit, you need to order a high-quality pressure gauge online, without which it will be difficult to monitor the operation of the product. Installation is carried out on the pipeline. This will help control the pressure coefficient within the system. You should not neglect this, because external signs can sometimes be incorrect.

- Preference should be given to the rating of quality manufacturers. Counterfeits negatively affect the operation of the system, which can lead to an emergency and breakdown of individual elements.

It should be noted that the greater the difference between the maximum and minimum coefficients, the greater the volume of liquid will be in the accumulator. In this case, there is practically no need to turn on the pump.

- Household kits performed better under conditions of regular use. In this case, the maximum coefficient should not exceed 4 atm. Operating range – 1.4-2.8 atm, for plumbing.

How much does the kit cost?

When choosing high-quality electrical equipment, you need to navigate several criteria simultaneously. An important aspect is considered to be cost. In construction markets, the products offered will cost the modern buyer $5-150, depending on the brand name and basic characteristics. Before going to the store, it would be a good idea to look at what types of relays there are and familiarize yourself with their purpose.

Experts recommend making such purchases online, through numerous online stores. This will allow you to save a lot and spend as much time as needed on choosing a product.

Connecting the water pressure switch

The water pressure switch for the pump is connected to two systems at once: electricity and water supply. It is installed permanently, since there is no need to move the device.

Electrical part

To connect a pressure switch, a dedicated line is not required, but is desirable - there is a greater chance that the device will work longer. A cable with a solid copper core with a cross-section of at least 2.5 square meters must run from the shield. mm. It is advisable to install a combination of automatic + RCD or difavtomat. The parameters are selected based on current and depend more on the characteristics of the pump, since the water pressure switch consumes very little current. The circuit must have grounding - the combination of water and electricity creates a zone of increased danger.

Connection diagram of the water pressure switch to the electrical panel

The cables are inserted into special inputs on the back of the case. Under the cover there is a terminal block. It has three pairs of contacts:

- grounding - the corresponding conductors coming from the panel and from the pump are connected;

- line or “line” terminals - for connecting the phase and neutral wires from the panel;

- terminals for similar wires from the pump (usually on the block located above).

Location of terminals on the water pressure switch housing

The connection is standard - the conductors are stripped of insulation, inserted into the connector, and tightened with a clamping bolt. By pulling the conductor, check whether it is securely clamped. After 30-60 minutes, the bolts can be tightened, since copper is a soft material and the contact may weaken.

Pipeline connection

There are different ways to connect a water pressure switch to the plumbing system. The most convenient option is to install a special adapter with all the required outputs - a five-pin fitting. The same system can be assembled from other fittings, it’s just that it’s always easier to use a ready-made version.

It is screwed onto the pipe on the back of the housing; a hydraulic accumulator, a supply hose from the pump and a line that goes into the house are connected to the other outputs. You can also install a mud pan and a pressure gauge.

An example of tying a pressure switch for a pump

A pressure gauge is a necessary thing - to monitor the pressure in the system, monitor the relay settings. A mud trap is also a necessary device, but it can be installed separately on the pipeline from the pump. In general, a whole system of filters for water purification is desirable.

With this scheme, at high flow rates, water is supplied directly to the system - bypassing the hydraulic accumulator. It begins to fill after all the taps in the house are closed.

Which company is better to buy?

The principle of the devices given below has no visible differences. The simplest algorithm for their operation is used:

- the relay connects to the pumping system at the moment when the coefficient in it reaches a critical level;

- When the maximum value is reached within the system, the relay will automatically break the connection between the established contacts.

ACP

One of the best and most popular models is “PM-5”. The design is from a Chinese manufacturer, which is often confused with a dry running product. When reviewing the provided characteristics and diagram, you can come to the conclusion that they differ. The advantages include the price of the kit. This cost also has a dark side. The main disadvantages include:

- the warranty period is a very cloudy value, they do not live to see it expire;

- there is no real protection from dust and moisture;

- regular contacts are used, not silver-plated (at a key moment the contacts may not open).

Grundfos

Reliable designs from a time-tested Danish concern. His reputation is clean.

Advantages:

- a huge range of quality products;

- the main difference between the models is the response limits;

- only certain devices belong to the low-current category (they cannot be connected directly to the network, and in rooms with high humidity);

- high reliability indicator;

- protection level – IP52 (caissons and basements are an incomplete list of premises in which their installation is allowed).

Based on numerous reviews, we can come to the conclusion that the cost of designs, like product recognition, is based on the popularity of the brand. Products from domestic manufacturers with similar characteristics are in no way inferior to foreign ones, and their average price is much lower.

Italtecnica

Products from the Italian concern. This is the best kit to buy for a private home. Along with pumping equipment, a modification called –PM/5 is used. Conquers the markets due to high reliability, quality and reasonable cost. Installation takes place in the cold water circuit. The regulation limits are measured in bars and have a value of 1 (for the lower) and 5 (for the upper). Warranty period – one year.

Provided that the overall system is connected to the station and not to the pump, then the configuration will be carried out with modification G. The main differences lie in the setting limits, which will be 1.4-2.8.

Advantages:

- insulating gasket on the body;

- use of a special coating (non-stick);

- the contact group consists of copper lamellas;

- The case material is plastic.

Condor

An excellent example from a German concern, which has won many positive reviews from users. A special feature of the models is that they show complete reliability in operation.

Advantages:

- the diameter of the connectors allows for connecting a pressure gauge;

- ease of repair;

- have universal settings compared to similar devices;

- adjustment is made by rotation;

- the main element is two-pole (both zero and phase open simultaneously).

Flaws:

- overpriced.

Unipump

A domestic manufacturer whose products are aimed at the European market. In addition to reasonable cost, they are characterized by the production of high-quality products. They gained a high rating largely due to various modifications.

Advantages:

- the connection occurs only ¼ inch;

- pressure gauge included;

- works in conjunction with pumps with a power of 1.5 kW or less.

Flaws:

- marriage is common.

Danfoss

The most popular series of this Danish manufacturer is considered to be KP-1. The cost of the kit is high, however, it is more than justified.

Advantages:

- an adjustment scale that does not imply the use of a pressure gauge;

- The contacts used are gold-plated, which makes “sticking” almost impossible.

Popular relay models

Among the numerous components of water supply systems that are present on the Russian market, main categories can be distinguished. Expensive models have an upper limit of 4-8 atm. Most experts advise purchasing options such as:

- Grundfos FF 4–8;

- Grundfos FF 4–4.

Their limit is standard - 8 and 4 atm. The main advantage of such an acquisition will be the ability to self-adjust. It should be noted that both models belong to the category of low-current products, so it is not advisable to connect the units to a 220 V network. For ease of use, it is recommended to use a special control panel. Also, not every family can afford such a purchase.

Often, the buyer chooses a cheap and affordable unit. For example, a 4-atm device will cost 4,000 rubles, while its 8-atm counterpart costs 6,000 rubles.

Inexpensive models also have a limit of 5-8 atm. An example is the MDR 5-8 and MDR 5-5 designs. Their upper limit indicator is 8 and 5 atm, respectively. The first purchase will cost 2.9 thousand rubles, while the second will cost 2.1 thousand rubles. Installation of both devices is carried out on a membrane tank. It is possible to connect to a network of 220 V, as well as with an indicator of 380 V. For the first case, you will need a single-phase pump. Otherwise, you will need to purchase a three-phase model. Their current ratings are high. They are also characterized by an excellent degree of reliability.

Budget designs. These include PM-5 from the Italian concern. He copes with the assigned tasks 100%. It is worth noting that the average price for a similar product is several times less than that stated by Grundfos. The price of the device is 400 rubles. Works great in combination with household pumping units. Among the positive characteristics, you need to pay attention to the quality indicator and the ability to work with a 220 V network. However, during the connection process you may encounter some difficulties. It is not possible to connect to a 320 V network.

Maintenance, problems, operation

Preventative actions and repairs:

- mechanical sensitive parts need to be checked and adjusted

- It is advisable to clean the contacts

- If it doesn’t work, don’t rush to disassemble the mechanism - first try lightly tapping the body with a not too heavy object

- Rocker joints are lubricated with grease once a year

- do not tighten the adjustment nuts completely - the mechanism will not work

If the device does not hold pressure, does not work correctly, or does not work at all, refrain from hasty conclusions and do not throw it away. Dust, debris, sand in the membrane space prevent it from reacting normally. Steps to fix the problem are:

- Unscrew the 4 bolts on the bottom, remove the cover with the inlet pipe and the cover.

- Carefully rinse the membrane and the cavities around it.

- Install all elements in reverse order.

- Set the thresholds again and carry out a test run.

Experts recommend that before setting up the relay correctly, do not exceed the upper threshold by more than 80% of the maximum permissible values for a specific model, which are indicated in the instructions (standard about 5 - 5.5 atm.).

For high-quality operation, there should be no air in the pipeline. Periodically (once every 3-6 months) you need to check the set response thresholds, pressure indicators in the HA, and bleed or pump in air. Before you start setting up, you need to find out whether the pressure switch for the hydraulic accumulator and the unit itself can withstand the required loads, and whether its technical capabilities meet them.

Rating of the best budget relays

If you are looking for inexpensive designs, they can be purchased for $10. They are characterized by a simple device and a set of basic characteristics, as well as low accuracy. However, the main disadvantage is the service life. The cheapest set is not the best option to buy. The initial cost will be minimal, but soon you will need to purchase a new relay or auxiliary components.

If you are not planning large expenses, but it is necessary to establish an uninterrupted water supply, then you should pay attention to the average price category. Such models are distinguished by acceptable accuracy and high reliability. The cost of the set will be $20-40. Among the main advantages, it should be noted excellent functionality at an affordable cost. This is precisely why they are in high demand among modern consumers.

The best cheap relay models

Italtecnica PM/5-G

Relay made in Italy. Optimal replenishment is carried out from a 220 V network. Inside the system, the water should not exceed a temperature of 40 ° C. The main indicator is adjustable in the range of 1.2-2.5 bar. For a switch this figure is 1.8-4.5 bar. The kit includes a pipe with a ¼ thread. The permissible power indicator is 15.4 thousand watts.

Price – 700 rub.

Italtecnica PM/5-G

Advantages:

- acceptable price;

- manual adjustment;

- assembly.

Flaws:

- not detected.

Aquario PS-5/2

Italian assembly from a famous brand. It is powered by a 220 V network. In this case, the operating pressure coefficient will be 10 bar. Factory settings are standardized: off - 2.8 bar, on 1.4 bar or less. Manual adjustment allows and allows operation in the range of 1-5 bar. Declared protection class IP54. Operates in systems with cold water, and the temperature of the working environment should not exceed 40°C.

Cost – 650 rub.

Aquario PS-5/2

Advantages:

- reasonable cost;

- design;

- there is the possibility of manual settings;

- build quality;

- protection class.

Flaws:

- there are fakes.

Gilex RDM-5

An excellent model from a domestic manufacturer. Power supply from the network is carried out from 220 V. The declared protection class is IP44, which allows installation in rooms with high humidity levels. It becomes possible to install auxiliary pumps whose power will not exceed 1100 W. The water temperature in the system should not exceed 35°C.

Price – 600 rub.

Gilex RDM-5

Advantages:

- reasonable cost;

- quick installation;

- protection class.

Flaws:

- defects often occur;

- the declared protection class will not save the body from rapid corrosion;

- contacts burn out quickly.

WWQ RD-2

Model from a Russian manufacturer. The functionality allows you to work in systems where the water temperature does not exceed 40°C. The ¼ thread is used to connect the unit to the system. It is worth noting that to ensure normal performance, it should not exceed 0.5 MPa. It is powered by a 220 V network. The manufacturer designates the protection class as IP44. This allows installation in rooms with high humidity levels. The housing is also protected from small debris getting inside the product.

Price per set – 550 rub.

WWQ RD-2

Advantages:

- reasonable cost;

- reliability indicator;

- ease of installation;

- protection of the housing from moisture and dust.

Flaws:

- The dimensions of the connecting pipe may not be sufficient for comfortable installation.

Unipamp LP-3

A budget device from a time-tested domestic manufacturer. It is a dry running protection relay. Recharge is carried out from 220 V. In this case, the temperature inside the system should not exceed 40°C. The declared protection class is IP44, so it can be used in rooms with high humidity levels. ¼ — diameter for connection. At a pressure of 0.5 bar or less, the equipment is turned off. Thus, the device will not run idle in the absence of water. It should also be noted that the working medium used performs the cooling function that the device needs. The circuit will open at 2.8 bar.

Price – 500 rub.

Unipamp LP-3

Advantages:

- reasonable cost;

- there is idle protection;

- reliability;

- simplicity of design.

Flaws:

- service life.

Initial setup from scratch

If the springs on your relay are completely weakened, you will have to make the adjustment from scratch. In this case, the work is carried out in the following sequence:

- They start the pumping equipment and build up pressure in the system to a level where the water pressure from the tap farthest from the pump becomes more or less acceptable to you. Let's assume that the measuring device showed a value of 1.5 bar at this moment. We turn off the pump.

- Now you need to disconnect the pumping station from the power supply, open the cover on the relay and start tightening the nut on the large spring until a characteristic click is heard, indicating the contacts are closed.

- The relay cover is installed in place and the pumping equipment is started. In this case, the pressure must be increased to 2.9 bar.

- Now the unit needs to be disconnected from the power supply again, open the cover on the relay again and tighten the nut of the small spring until a click sounds when the contacts open.

- After the settings have been made, the relay will operate at a lower pressure of 1.5 bar and turn off the pump at an upper pressure of 2.9 bar. We return the cover on the relay to its place, and connect the station to the power supply.

Video instructions for adjusting the pressure switch of a water supply unit with your own hands:

Rating of the best expensive relays

There are a huge variety of pressure switches for water, and sometimes making a choice is not at all easy. Electronic mechanisms belong to the category of expensive devices. Their main advantage is ease of use, including making settings. Due to this, they are characterized by high operating accuracy.

However, it should be noted that for private houses (domestic needs), this indicator cannot be called key. The accuracy of operation does not play a role in the correct operation.

For domestic water supply systems, expensive devices may simply not be suitable. This is due to the increased sensitivity of the sensors. This will require increased voltage. If the choice was made in favor of such devices, you will need to purchase auxiliary and equally expensive equipment that would allow you to maintain a certain indicator in the network. Well-known brands produce products in the region of $40-75.

The best expensive relay models

Danfoss KPI 35G ¼

This model can rightfully top any rating of quality structures. Presented by one of the best manufacturers. It is an electromechanical type control device that can be used in any conditions, both domestic and technical. High-quality equipment has received over 10 quality certificates and diplomas, which indicate a high level of reliability and efficiency of the products. The range of settings allows you to work with indicators in the range of 0.2-28 bar. The differences can also be adjusted. Designed to work with gaseous and liquid media. Able to withstand significant loads. On request, the manufacturer can equip the device with gold-plated contacts.

Price – 6100 rub.

Danfoss KPI 35G ¼

Advantages:

- ability to work under high load conditions;

- high-quality assembly;

- use of quality materials;

- manual adjustment.

Flaws:

- price.

Grundfos FF 4/4 DAY

Equipment of Danish origin. Used to control pumping equipment. The model is an electromechanical device operating on 220 V. The declared protection class is IP54. Designed to operate with a working pressure of 4 bar. The connecting pipe has a 3/8 inch thread. Compared to various Chinese devices of the same type, this equipment cannot be compared with it. The power of the equipment, the quality of assembly and the materials used are quite high. It should be noted that the purchased equipment is easy to use.

Price – 6000 rub.

Grundfos FF 4/4 DAY

Advantages:

- use of quality materials;

- design;

- reliability;

- ease of use;

- assembly.

Flaws:

- price.

Condor Werce MDR 5-5

The brand of this device is considered one of the best manufacturers of pumping equipment and automation. Manufactured in Germany and is an electromechanical sample with a load rating of 5500 W. In fact, the pumps have sufficient power and are powered from a 220 V network. The designated protection class is IP54. Installation on a hot water supply line with a working pressure of 5 bar is permissible. The coolant should not exceed a temperature of 80°C.

Cost – 4700 rub.

Condor Werce MDR 5-5

Advantages:

- installation is allowed in both hot and cold water supply systems;

- build quality.

Flaws:

- significant price.

Whirlwind ARD-1

A Russian-made product, assembled in China. The functionality of the unit meets all the needs of the modern consumer. An irrigation mode is provided. There are protection functions against frequent switching on, system breaks and leaks. If necessary, the system will restart itself, which will allow you to obtain data regarding the water level. There is also protection against idle (dry) running. It is powered by 220 V. The maximum load is 1500 W. Equipped with IP65 protection.

Price – 3550 rub.

Whirlwind ARD-1

Advantages:

- ease of use;

- quick installation;

- assembly;

- performing manual settings;

- initial characteristics;

- wide functionality.

Flaws:

- not detected.

Aquacontrol RDS-M 1-2

Product from a domestic manufacturer. This electronic equipment has quite extensive functionality. Leak protection available. It is possible to automatically restart the system. The dry-running protection response delay is 0.5 minutes. Recharge from a 220 V network. In this case, the liquid temperature should not exceed 40 ° C. A 1.5 cm pipe is used for connection. Power indicator – 1500 W. Basic parameters are set quickly and easily. To do this, you need to turn the screw using a screwdriver directly on the control panel.

| Session | Adjustment range |

| Dry running protection | 30-180 seconds |

| Shutdown | 0-6.5 bar |

| Inclusion | 0-6 bar |

The changes made can be observed using the arrow, which is located on the scale of the pressure gauge provided by the manufacturer.

Price per set – 3000 rub.

Aquacontrol RDS-M 1-2

Advantages:

- reasonable cost;

- build quality;

- design;

- making adjustments;

- ease of setup.

Flaws:

- not detected.

TOP 8 surface pumping stations

| Photo | Name | Rating | Price | |

| #1 | AQUAROBOT JET 100 L | ⭐ 5 / 5 1 - voice | Find out the price | |

| #2 | UNIPUMP AUTO JET 100 L | ⭐ 4.95 / 5 1 - voice | Find out the price | |

| #3 | Marina CAM 100/25 | ⭐ 4.9 / 5 | Find out the price | |

| #4 | GILEX Jumbo 70/50 N-24 | ⭐ 4.85 / 5 1 - voice | Find out the price | |

| #5 | DENZEL PSX1300 | ⭐ 4.8 / 5 | Find out the price | |

| #6 | VORTEX ASV-1200/50 | ⭐ 4.75 / 5 2 - votes | Find out the price | |

| #7 | GARDENA 3000/4 Classic (1770) | ⭐ 4.7 / 5 | Find out the price | |

| #8 | Quattro Elementi Automatico 1000 Inox (19 l.) | ⭐ 4.65 / 5 1 - voice | Find out the price |

Which pumping station would you choose or recommend?

Take the survey

Types of devices

Manufacturers offer various options for devices that are electromechanical or electronic. They may be included with the pump unit, or this element can be installed independently.

The relay may be included with the pump unit

Important! The cost of electronic devices can exceed the price of mechanical analogues by five times or more.

Electromechanical relay

Devices of this type have long been successfully used in the installation of water supply systems. Despite the simplicity of the design, they have proven themselves to be reliable and easy to use.

Prices for water pressure switch for pump

water pressure switch for pump

Electromechanical relay

The operation of a mechanical device is based on the closure and disconnection of contacts due to changes in the position of a flexible membrane located inside the product. It is associated with two spring elements that respond to its position. One spring (larger) is set to maximum pressure, the other to the delta between the upper and lower limits.

When the pressure reaches a minimum, the plate weakens, the contacts become closed and the electric drive of the pumping equipment begins to work. If the pressure reaches the highest threshold, the contact under the spring is released and the engine is turned off. The elasticity of the springs is changed by adjusting nuts. To set the relay to operate at a higher pressure value, they are tightened. Attenuation leads to a decrease in the parameter.

Electromechanical pressure switches

Electronic device

To control the operation of the relay, models of this type use electronic sensors that measure pressure using a piezoresistive effect.

Electronic water pressure switch for pump

Electronic devices are equipped with various additional options, for example, the ability to softly start or shut down the station in an emergency. They are easier to configure, and pressure thresholds are set more accurately. It is worth noting that for domestic use, high accuracy is usually not required.

Most often, electronic models are equipped with their own small-volume hydraulic tank, which further protects the system from water hammer. The products are characterized by high reliability and durability, but are rather capricious regarding the quality of the pumped liquid. Therefore, to protect the relay it is necessary to install filter elements.

Electronic pressure switch Optima EP-1 with dry-running protection

Important! When setting up a relay that has a piezoresistive sensor, there is no need to open the box. The entire procedure is carried out using the buttons located on the front panel.