Flotation is a purification method.

Effluent undergoing treatment passes through a settling tank, in which large fragments sink to the bottom because they weigh more than water. Non-sinking large particles remain in the water; flotation is a cleaning method that helps to isolate complex contaminants of this type. The method is one step at the stage of the sewage purification process.

What is the essence of the flotation method? The wastewater undergoes flotation to remove impurities that are lighter than the water composition. In English, the word flotation means “floating on the surface”, similar to the Russian word fleet. The purpose of the method is to raise particles whose density is close to water to the surface, and they do not sink.

Flotation based on physical laws.

Flotation occurs due to compliance with physical and chemical laws. It is based on the property of substances to be wetted. The peculiarity of the particles in this process affects their behavior when they are in the boundary state between liquid and gas.

The following types of particles are distinguished:

1.hydrophilic type has good wettability.

2.hydrophobic type does not wet out

If the substance is hydrophobic, it is amenable to flotation and is isolated by this method.

Efficiency of the method.

Certain conditions and factors contribute to increasing the effectiveness of the method.

The most important factors are considered to be:

1.level of hydrophobicity of substances. If this property is high, the substances will quickly join the air bubbles, forming large sludge complexes. Some particles include substances of two compositions, hydrophobic and hydrophilic types. Reagents are added to waste water to increase hydrophobicity and speed up the flotation process.

2.level of strength and size of foam bubbles. During flotation, the bubbles must reach a size at which they can easily rise to the surface.

Attention! Bubbles with a very large size float up faster, not having time to attach pollutants in sufficient quantities. The bubbles must be durable in order to be less likely to collapse as part of the flotation complex.

3.The foaming process must be uniform and continuous. Efficiency is determined by the uniform distribution of bubbles in the water and their frequency.

These factors are increased by adding special reagents to the sewage.

Flotation techniques

Flotators are classified according to the method of formation of gas bubbles. The most commonly used flotation methods are:

- mechanical;

- pressure;

- vacuum;

- biological;

- electrochemical.

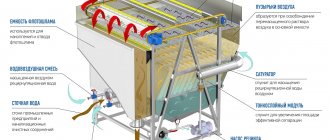

Pressure flotation is a simple method of wastewater treatment when reagents are added to the liquid and oxygen is supplied under high pressure using a pump. Bubbles form throughout the entire volume of sewage. This method is often used to purify liquid from activated sludge. The technology requires the presence of a saturation chamber.

Electroflotators do not have this unit. The technique does not require electroflotation or reagents. It involves removing suspended matter from a liquid using an electric current. The electrolysis process is carried out in the electroflotator: hydrogen is released at the cathode, and oxygen is released at the anode.

The principle of operation of a vacuum device is to reduce the pressure below atmospheric pressure in the flotation tank. This releases air dissolved in water.

Biological flotation is heating the sediment after primary purification using steam and allowing it to settle for several days. The resulting bacteria release gas bubbles. Thanks to them, sludge particles are flotated into a foam layer, where they are compacted and dewatered. Within five days, the moisture content can be reduced to 80 percent, making subsequent processing easier.

The principle of operation of the method is step by step.

Purification using flotation is broken down into stages.

1. Dispersed air is supplied to the cleaning liquid.

2.particles with hydrophobia move towards the bubbles.

3. Particles attach to the bubbles, reducing the water layer. A sludge complex similar to foam is formed.

4. It floats to the surface of the water because it weighs lighter than the structure where it is located.

Foam is removed using special equipment as it accumulates.

Ore classification by size

In each stage of crushing and grinding, different minerals are ground differently depending on their hardness, brittleness, viscosity and shape of the pieces. After any stage of crushing, part of the ore may turn out to be smaller than the specified size, which means an extra load for the next crusher. To better utilize the crushers, the ore after each crushing stage is classified by size by screening, similar to screening. Screens of various designs are used for this purpose.

Rice. 12. Grate screen

The simplest grate screen (Fig. 12) consists of parallel steel bars, inclined at an angle of 35–40 degrees. The distance between the grates (gap) corresponds to the size separation limit: usually it is not less than 25 mm. The ore slides freely along the grates and a small part of it falls into the gaps. Grate screens are cheap, but their efficiency (the completeness of separation of fine material) is low. They are used before and after coarse crushing.

Instead of steel bars - grates for vibrating, drum and other screens, gratings are used (Fig. 13).

Rice. 13. Screens used for vibrating, drum and other screens

The vibrating screen is a metal mesh stretched over a frame. The mesh vibrates or swings from a mechanical drive or electromagnets. To distinguish several classes of size, several grids are installed - one above the other. Vibrating screens are used after medium or fine crushing.

The drum screen has a sorting mesh in the form of a cylinder. It rotates about an axis inclined at a small angle. The ore is poured over the inner surface of the drum, gradually moving from its raised end to its lowered end. To simultaneously identify several particle size classes, several grids with cells of different sizes are installed concentrically.

Screening is not suitable for thin materials that clump and are easily sprayed. Therefore, finely ground materials are classified as pulps. This classification is called wet or hydraulic, and the devices used for it are called classifiers. Hydraulic classification is based on the fact that the larger (heavier) the particle, the faster it settles from the pulp.

Any hydraulic classifier is a vessel filled with continuously supplied ore pulp. During their stay in the classifier, large particles (sand) settle, and smaller ones are carried away by the drain. The lower the speed of movement through the pulp classifier, and the lower its viscosity, the finer the particles of material in the drain.

Classifiers of different designs differ in the shape of the vessel and methods of unloading sand.

Rice. 14. Rack classifier: 1 – trough; 2 – stroke; 3 – drive for stroke movement; 4 – drain threshold; 5 – sand unloading

The rack classifier (Fig. 14) has an inclined steel trough with a flat bottom. The pulp is fed through a chute from one end of the trough and drains from the opposite end through a threshold, the height of which can be changed. The sands that have settled to the bottom of the trough are gradually shoveled by a mechanized rake to its raised end and unloaded.

Rice. 15. Spiral classifier: 1 – trough; 2 – spiral: 3 – drain threshold: 4 – sand unloading

The spiral classifier (Fig. 15) differs from the rack classifier in the semicircular section of the trough. An auger is used here to remove sand. The mechanism of a spiral classifier is simpler and more reliable in operation than a rack classifier.

Rice. 16. Hydrocyclone

Classification is very productive in frequently used hydrocyclones (Fig. 16). Large and small pulp particles are separated here under the influence of centrifugal force. The pulp is fed into the hydrocyclone tangentially to its cross section at high speed. This causes the pulp in the apparatus to twist and move along a spiral path. Large particles are pressed by centrifugal force against the walls of the hydrocyclone, lose speed and settle in its lower part; small grains are carried away into the drain.

Figure 17. Scheme of crushing, grinding and classification

In Fig. Figure 17 shows an example crushing, grinding and classification scheme. It is based on two requirements: do not crush excess and produce material no larger than the specified size. To do this, before each crushing stage, the ore is sent to a screen, and only pieces that do not pass through its slots enter the crusher. The second requirement is satisfied by crushing or grinding in closed cycles: insufficiently small pieces or grains separated by screening or classification are returned to the crusher or mill.

Any crushing and grinding scheme must be clearly thought out and calculated. There should be no excesses in these expensive processes: they can significantly worsen the economics of production.

Pros and cons of the cleaning method.

The flotation method is considered popular. The method is used for industrial wastewater and in urban treatment systems.

Flotation has its positive characteristics:

1.low price method.

2.No complex special equipment is required.

3. Some particles are subject to flotation faster than they would settle to the bottom.

4.Even petroleum products can be extracted from water using this method.

5. The sludge that is formed contains almost no water, so its loss is small.

The method has not only advantages, but also disadvantages.

The disadvantages include:

1. not all dirt particles can be removed by flotation, but only those that are hydrophobic.

2.additional costs for reagents that have to be used in some situations.

3. any type of dirt has its own removal characteristics; there is no single method for extracting suspensions of different types.

What determines the quality of cleansing?

The effectiveness of the technique is influenced by the following factors:

- resistance of air bubbles to destruction;

- uniformity of foam formation;

- the degree of hydrophobicity of the particles - the higher this indicator, the more actively they interact with air bubbles.

The size of the bubbles is also important. Large ones float up quickly and do not have time to capture impurity molecules, while small ones are less durable.

The use of flotation techniques is indispensable for purifying wastewater from fats, fibrous inclusions, petroleum products, and other contaminants that cannot be settled. This method is used for sewer cleaning and mineral processing.

Additives that improve the flotation process.

The cleaning process depends on the degree of hydrophobicity of the substances and the quality of foam formation.

To improve these conditions, reagents are used, which are divided into two types:

1.collective

2.foaming.

Collection additives.

Often you have to work with substances that have a dual composition: hydrophobic and hydrophilic. They have a low degree of wettability to connect with the bubbles; the process in this case is ineffective. Collectors should be added to the wastewater, which also contain two groups of particles: non-polar or hydrophobic, and polar or hydrophilic.

Pollutants and collectors of a polar hydrophilic nature connect to each other, with the ends of the hydrophobic type being released.

Such collectors include surface active substances:

1.ammonium salts.

2.oils.

3.mercaptan.

4.petroleum products.

Foaming additives.

The quality of the foam formed affects the cleaning process. Certain additives improve its properties, prevent bubbles from collapsing, and increase their strength. This makes it possible to remove large amounts of pollutants from waters.

Foam stabilizing substances include:

1.cresol.

2.pine oil.

3.phenol.

Reagents used

To increase the efficiency of purification, chemical collectors are used:

- coagulants - reagents that promote the formation of flakes and are iron and aluminum salts;

- flocculants (polyacrylamide compounds) – substances that create larger and more stable flakes (flocs);

- acid and alkaline reagents that allow you to adjust pH. They are added to water to ensure normal operating conditions for the two previous types of reagents.

To stabilize foam formation, pine oil, phenols, and cresol are also used. They help protect air bubbles from destruction, making them elastic. This helps remove more contaminants from the sewer.

The use of chemical reagents to improve the process requires precise dosage selection, which can only be achieved experimentally.

Types of flotation.

The purification process involves the formation of dispersed air bubbles in water. For the method to work, bubbles of the required size must be formed. How can this be achieved?

1. Remove air bubbles from the solution.

When using a solution to separate bubbles, vacuum or pressure flotation is used.

With pressure flotation, air is pumped in, then the pressure in the network is sharply reduced, which creates the release of bubbles into the water.

In vacuum flotation, water passes through an aeration chamber, where it absorbs air. Next it goes into the disaerator to remove undissolved air particles. The third stage is the passage into the flotation chamber, here the water pressure is reduced, which creates many bubbles.

This method is used to remove fine impurities.

2.Pass air through the porous material.

The method for producing bubbles is considered the simplest according to the laws of physics. Before air is released into the drains, it passes through plates that have slots. The size of the bubbles depends on the diameter of the pores.

3.Using electrolysis flotation.

To form bubbles, two electrodes that pass current are placed in the water. During electrolysis, water breaks down into oxygen and hydrogen. Electrodes are made of aluminum or iron. Metals are capable of releasing coagulants that bind suspensions, forming particles in the form of flakes. Bubbles and flakes connect with each other and rush to the surface, forming foam.

3.Using mechanical dispersion.

To form air bubbles, mechanical methods are suitable, which have different formation paths:

1.use of impeller installation. Using an installation with a turbine, the water is mixed, forming bubbles of small diameter. This method is suitable for removing fatty substances and petroleum products. The size of the bubbles is affected by the turbine rotation speed. If the speed is high, then the bubbles are small.

2.use of gravity flotation. With the help of a wheel connected to a centrifugal pump, bubbles are formed that cope with the removal of fatty particles and fibers.

3. The use of pneumatic flotation occurs using pipe nozzles located at the bottom of the chamber. The method is used when cleaning aggressive substances if the wheel and impeller may be damaged.

The three methods of bubble formation are based on a vortex process accompanied by stirring.

Application areas

Flotation allows you to remove various impurities that are in a dispersed state from solutions.

They are formed as a by-product during the following production processes:

- production of artificial fibers;

- oil refining;

- leather processing;

- producing paper from cellulose raw materials;

- implementation of chemical technologies;

- processing of food raw materials.

Flotation is used to purify wastewater generated at machine-building plants and food processing plants, and also to separate sludge after the biochemical purification of dirty aqueous solutions of various origins.

Innovations

Techniques do not stand still, and flotation used in medicine has also recently been improved. In particular, it was possible to develop a centrifuge that is equipped with an angular rotor. In this setup, the containers do not oscillate freely, and the final rotation is not accompanied by contact with the coverslip.

At the final stage of processing the mixture in the installation, the test tube must be placed vertically in a special stand, then the solution must be added to it, keeping the top layer intact. When the meniscus becomes positive, a cover slip is placed and the tube is left to stand for no more than five minutes. Next, the glass is removed and examined under a microscope, also at two magnification powers.

What is it about

Ore flotation is a technique that makes working with minerals more efficient and profitable. Different elements differ in their ability to adhere to the surface where two phases come into contact, that is, a separation of media occurs. Flotation is a process that is based on the specific energy of the surface.

If we talk about particles, they can be divided into the following groups:

- hydrophobic;

- hydrophilic.

Key Benefits

Flotation is a purification that has a number of positive parameters, which has become the reason for such a widespread use of this technology in the world.

Key aspects:

- breadth of applicability;

- continuity of technology;

- low cost;

- ease of operation;

- use of simple machines;

- speed of obtaining results;

- selectivity;

- not so high level of sludge moisture;

- efficiency (up to 98%);

- the separated components can be recovered.

During flotation, effective aeration is produced, the percentage of liquid and surfactant decreases, and the number of microscopic organisms and bacteria decreases. Wastewater that has undergone flotation can be supplied to higher-level treatment plants.

Installation

Mounting of flotators is carried out according to the operating instructions. It is supplied in a set of documents along with the installation.

Stages of work:

- The machine is mounted on the foundation and secured.

- The pipelines are connected.

- Power cables are supplied to the installation.

- Install and connect automated control systems.

All installations undergo hydrotesting before sale .

When selecting the type of flotation equipment, it is worth considering:

- type of sewerage;

- degree of contamination of the liquid medium;

- volumes of purification.

Centrifuge: how it happens

The workflow of a doctor examining stool for the presence of helminths using a special installation is as follows:

- an emulsion is prepared in which 30 ml of solution contains 5 g of feces;

- the emulsion is filtered through gauze into a test tube;

- the tube is filled with flotation medium until the meniscus becomes positive;

- the test tube is placed on glass and balanced in the installation;

- The centrifuge is started for 10 minutes at a speed of up to 15 thousand revolutions per minute.

At the end of this process, the doctor receives a coverslip (it must be taken out vertically), which can be examined under a microscope. The study is carried out for about 10 minutes - they start with a tenfold magnification, then increase it fourfold. This makes it possible to accurately speak about the presence of microscopic organisms, as well as draw conclusions about their structures and the size of harmful organisms and their particles.

Who does the production?

Before purchasing flotation machines, you need to clearly define the parameters.

The parameters are selected based on the following conditions:

- Composition and nature of sewage waste.

- Temperature and uniformity of water supply.

- Where is treated water discharged?

In Moscow and St. Petersburg, quite a few companies are engaged in the implementation of installations:

- — TR brand flotators, cost from 313,500 rubles.

- Trading house "Water treatment equipment" - pressure units of the DAF brand.

- Rosintereko LLC - flotators and two-stage units of the Angara brand.

Important. It is necessary to take into account the requirements for processing and removal of sediment, the degree of disinfection.

...and hydrophilicity

By hydrophilic we mean those particles that can be moistened with liquid without much difficulty. For these substances there is no “discomfort” in a situation where the substance is in suspension.

While hydrophobic molecules tend to come into contact with gases, this feature has not been observed in hydrophilic molecules. Also, hydrophilic compounds in their bulk do not exhibit specific properties relative to oils, to which hydrophobic molecules “stick”.