Corrugated toilet bowls are used less frequently than smooth outlets, which is due to the presence of stiffening rings that give the cross-section a round shape. This type of pipe allows you to connect a plumbing fixture in an area of complex configuration. It is made of polymer material, which also simplifies installation. However, this type of communication has disadvantages that reduce its service life.

The purpose of the corrugation for the toilet.

Features and purpose of corrugation

This is the name of a type of pipe. It has a wide range of applications; it is also used as a transition element of the sewerage system - when installing a toilet. When installing this plumbing fixture, a large pipe is used. This is due to the significant cross-country ability of the product and the dimensions of the toilet outlet.

Communications of this group are made from thermoplastic. The pipe weighs little and can be installed with your own hands. There is a cuff on one side. There is a rubber seal in this area. The cuff connects to the toilet outlet and is relatively short. The length of the product varies depending on the position of the stiffening rings: from 23 to 50 cm. This allows you to change the parameters in accordance with the location of the plumbing fixture and sewer riser in the toilet.

The outer and inner diameters differ from the standard sizes of sewer system pipes, 134 and 75 mm, respectively. However, the end of the corrugation corresponds to the cross-section of the sewer riser outlet - 110 mm. This allows you to do without adapters at the stage when installing the drain tube.

How can you install or secure the device?

Toilets can be installed in two ways:

- attach to the floor;

- hang on the wall.

Of course, the most popular is the floor mount. It is produced by installing the toilet on dowels, which are fastening devices.

Wall-mounted ones have one advantage - when used, they take up much less space than the same floor-mounted ones. And with small room dimensions this will be a significant advantage.

Advantages and disadvantages

Corrugated toilet flush is in demand among consumers due to a number of positive qualities :

- easy installation: no special tools are needed, as well as extensive experience in performing such work;

- light weight of the product: installation is done by hand;

- low price;

- when displaced or in an area of complex configuration, a flexible pipe makes it possible to connect the sewer riser and the toilet outlet;

- corrugation helps to join elements of the sewerage system that do not match in diameter;

- resistance to corrosion;

- no need to dismantle the toilet;

- significant permeability due to the device: when stretched, the stiffening rings that make up the walls of the flexible pipe acquire a certain volume, which slightly increases the diameter of the product in the area between the cuffs.

Corrugation for the toilet: advantages and disadvantages.

This product also has disadvantages:

- low strength: when a sharp object, a splinter, gets into the pipe, the risk of damage to the walls increases, which may result in a leak that cannot be eliminated;

- Do not use a pipe that is too small or large, as it will sag under the weight of the contents;

- installation errors (installation at an inappropriate angle, significant bending) can lead to clogging;

- rapid clogging is also determined by the ability of the pipe to retain contaminants on the walls;

- insufficiently long service life;

- In terms of attractiveness, such a product is inferior to smooth-walled analogues;

- installation restrictions: it is impossible to cover the toilet outlet with plasterboard, as well as install it inside the floor.

The prohibition on installation in the thickness of the wall is due to the high probability of leakage. It is difficult to detect damage in time; as a result, sewage will enter the premises.

When should you install a corrugated connector?

Before purchasing, study the technical specifications.

It is permissible to install such a pipe when other options cannot be used:

- corrugation is used as a temporary measure, during the construction phase or in case of leakage of an existing pipe, and it takes more time to select, purchase and deliver a new one;

- changing the existing layout of plumbing fixtures in the bathroom: the toilet is shifted relative to the sewer riser, the floor level becomes higher;

- discrepancy between the diameters of the toilet flush and the pipe connection of the sewerage system;

- The plumbing fixture was replaced, and when purchasing a new one, the type of outlet was not taken into account: straight or oblique.

The reason may be due to repairs. In this case, the cladding is often mounted on top of the old coating. The bathroom also contains household appliances, such as a washing machine. Often problems during the installation of communications arise when you need to install a new plumbing fixture in a bathroom where the pipes have not been changed for a long time.

Types and sizes of corrugated pipes

Available options:

- rigid pipe;

- non-rigid

Corrugation options for toilet bowl.

The first type is much stronger. The significant thickness of the walls makes this corrugation wear-resistant. In this case, the connection to the sewer riser outlet is made when the deviation from the horizontal is small. Such a pipe serves for a long time, but due to its rigidity, its scope of application is narrowed.

Non-rigid products, on the contrary, are elastic. They easily take the desired shape and allow you to make a bend of any size. Such properties help to install corrugation on any toilet (with direct, oblique outlet). However, the pipe wall is thin, which reduces strength and wear resistance.

Non-rigid products do not last long. During operation, there is a risk of damaging the corrugation, since it is exposed to any relatively sharp object. An elastic pipe is used only when it is impossible to install a smooth-walled analog or rigid corrugation. Such products quickly begin to sag, which is why they are soon damaged because they cannot withstand the load exerted by the contents.

There are other types of corrugated products:

- reinforced;

- unreinforced.

The first option better withstands loads, is durable and wear-resistant. Thanks to these properties, corrugation lasts longer. It is distinguished by the presence of reinforcement in the walls. To strengthen the pipe, use wire of a minimum cross-section. It is poured into the thickness of the material at the production stage.

Non-reinforced products are inferior in strength. They cannot withstand significant loads, so they do not last long. This option is used as a temporary measure. Reinforced corrugation is also used on an ongoing basis. Only a flexible pipe is used for connection in a difficult area.

Varieties of corrugation sizes for toilet bowls.

There are products that differ in length. It is recommended to purchase a pipe with a margin of no more than 5 cm. Otherwise, the corrugation will sag, which will lead to blockage.

For the same reason, do not install too long products. If the corrugation is short, it will have to be stretched to the limit due to the stiffening rings. Because of this, the functionality of the product is reduced, since the load is placed not only on the stiffening rings, but also on the soft areas.

The diameter of the corrugation is 50-200 mm. In apartments, a 110 mm product is installed for connection to the sewerage system. The length is limited: 0.23-0.5 m. Communications that are less than or greater than the values of the specified range are not advisable to use.

Dismantling the sewer outlet

If the toilet is installed, then the old product must be removed before installing the new connector. When performing this work, you need to take into account a number of important nuances.

Before proceeding with the dismantling of the old element, water is drained from the tank and the water supply to the system is shut off. Since the toilet corrugation does not have increased rigidity, liquid remains inside it.

For this reason, first disconnect the part attached to the device, then the waste remaining in the product can be drained into the sewer hole. It is important to follow this sequence if the toilet is located at an angle to the sewer pipe or the old connector has become very stretched during operation.

When the toilet flush corrugation is in a compressed state, removing it may require dismantling the toilet. It is advisable to take these nuances into account, since over time the corrugation has to be changed.

Alternatives to corrugation for release

The only option is to use smooth-walled products. Their advantages: strength, low likelihood of clogging, durability. However, such communications take up a lot of space in the bathroom, since the wiring must be done correctly, observing the slopes. At the same time, the number of knees is determined; it is important that there are few of them. It is often impossible to connect the toilet outlet and the sewer riser pipe using a straight, smooth-walled pipe.

To install such products, you will need to dismantle the toilet tank. The communications have a widening at the end - a bell. Due to this, the connection is made. The seams are treated with sealant in case of leakage. At the end sections (in the socket) a rubber gasket is installed in a special internal groove. It seals the joint. Smooth-walled communications are purchased for permanent installation.

Vertical

For the toilet there is a vertical outlet.

This option is used when installing a sewerage system in a private home. In the apartment, communications are located in such a way that it is impossible to make a connection by connecting a vertical outlet to a riser.

The pipeline must be routed strictly under the toilet. It is acceptable to use fittings. However, an angle of 90° is considered sufficient. An alternative option is to use 2 angles of 135° each.

Advantages of vertical outlet:

- high drain efficiency;

- the supply pipe can be hidden underground, which will significantly improve the interior;

- the water level in the bowl is increased, thanks to which the surfaces are better cleaned;

- splashes are insignificant, which ensures hygiene;

- The tank in such models breaks less often.

The only drawback of this option is the need to dismantle a section of the concrete floor to lay communications underground.

Horizontal

This is a more common way to connect a toilet to a sewer riser. It is used on any objects, including in the apartment. When organizing the drainage of a plumbing fixture, angle fittings are used. Their diameter should be 110 mm. This option is more effective. It is distinguished by ease of installation, since you do not have to dismantle part of the concrete floor.

Oblique

Oblique outlet for the toilet.

The modern solution is considered to be a direct release, while the oblique release is a familiar and rather old option. It is still used today. The cross-section of communications in this case remains unchanged.

Considering the wide distribution of oblique releases, it will be easy to select components to replace the old ones. Toilets with direct and oblique flush are interchangeable. However, in each case, fittings of different shapes are used.

The disadvantage of this option is the need to accurately determine the distance between the toilet outlet and the sewer riser pipe. Any discrepancies will lead to distortion when installing the plumbing fixture. When the toilet becomes loose, the tightness of the seam in the area where the communications connect is broken. As a result, the likelihood of leakage increases.

Installation procedure

A smooth-walled pipe is replaced with a corrugated one if a leak occurs, or at the repair stage. In both cases, to install such a product you do not need to dismantle the toilet or cut communications. A corrugated tube is placed on the outlet of a plumbing fixture. If the components have been selected correctly, the connection density will increase. As a result, the likelihood of a leak in this area is reduced.

The other end is inserted into the riser pipe of the sewerage system. To increase reliability, rubber gaskets are provided. In addition, the end of the corrugation on this side is embossed. You need to choose the right model. At this stage, the dimensions of the toilet outlet are taken into account. The standard diameter of the sewer system pipe in an apartment is 110 mm.

Another important criterion is the length of the product. You need to measure the distance from the toilet to the riser. In this case, the shortest path is conventionally laid. It is possible to allow inaccuracies in measurements, since the corrugation easily increases and decreases in size.

It is necessary to determine the type of product: reinforced, hard, soft corrugation. In this case, take into account the duration of the period during which it is planned to operate such a tube. If you soon have a smooth-walled drain installed, you can purchase a simple corrugated version.

How to remove the old connector

For the toilet, dismantling the old connector.

The steps for removing different types of pipes differ:

- Dismantling of corrugated products. First, remove the elastic cuff from the toilet outlet. In this case, there is no need to make significant efforts, since there is no rigid fastening. The cuff is easy to remove, even if silicone sealant was used to seal the seam joint. You can remove it first; for this, use a non-sharp tool (corner of a spatula, knife, etc.). At the last stage, the corrugation is removed from the socket of the sewer riser.

- Plastic smooth-walled pipe. It must be cut to facilitate dismantling. The process may take some time, but the plumbing fixture will not be damaged in this case.

- Cast iron communications. It will be difficult to remove such a pipe without breaking the toilet. Another option is metal cutting. However, this may cause damage to the plumbing fixture, since there is not enough free space next to it.

After dismantling the tube, all incoming elements are cleaned: toilet outlet, riser pipe. This will ensure a tighter fit of the corrugation.

How to shorten a corrugation

It is not recommended to damage the integrity of the tube, as a leak may form under the influence of load. However, in some cases you have to take such a risk if there are no other options. To remove part of the corrugation, you need to carefully cut it off from the pipe.

After this, they determine which area needs to be removed. It is cut off, then this end is installed back into the pipe, but the seam joint is additionally treated with silicone sealant. You need to let the material dry completely, which can take up to 2 days. Then drain the water in the tank to check the quality of the joint. This option is used only if the corrugation is installed for a short period.

How to install

After dismantling, damage could remain on the riser pipe and toilet outlet: cracks, chips. It is important to inspect these areas before work begins.

Installation of corrugation for the toilet.

Installation instructions:

- The edge of the outlet is treated with sealant.

- The corrugated cuff is pulled over it. Moreover, it is important to control the position of the pipe. Misalignment can lead to leaks and blockages during operation.

- As the cuff is tightened, the corrugated tube straightens. It should cover 5-6 cm of the toilet outlet.

- When the sealing material sets and dries (after 3 hours), the plumbing fixture can be moved to its place.

- Considering that the other end of the corrugation is inserted into the riser pipe of the sewage system, its internal walls are treated with silicone.

- Install the second end of the pipe into the socket of the pipe.

- After 3 hours, when the sealant has dried, check the unit for leaks. First, no more than 3 liters are flushed through the toilet. If there are leaks, this amount is enough to detect them. Then the water is drained again, but in a larger volume - up to 10 liters. The load on the walls of the corrugation is higher, which means that a leak can be detected faster.

If there are leaks somewhere, they can be found using toilet paper or a napkin: the pipe joints are covered with the material; when drops of water appear, the paper will get wet.

Common mistakes

The corrugated tube is universal, but even when using it, difficulties arise. For example, when a product is greatly stretched or, conversely, compressed, this negatively affects the operation of the sewage system. Blockages form and the load on the plastic walls increases. In addition, the corrugation often creates too sharp a bend. In this area, the permeability of the contents decreases and blockages form.

Sealing the outlet

Silicone is used at the installation stage. However, the same material should be used to seal joints in areas where the corrugation and the riser pipe of the sewage system, as well as the toilet outlet, were connected. Silicone is applied in a thin strip over the seam, then spread over the surface. You can use the toilet after this for a few hours. This unit was already protected with sealant at the installation stage. For this reason, reworking the seams is a precautionary measure.

How to connect a toilet to a sewer

When connecting the toilet to the sewer pipe, you can use eccentric or corrugated cuffs, plastic bends and drain pipes. What are their advantages and disadvantages?

- Plastic outlet or drain pipe. This option makes it possible to make the most durable and reliable connection. The appearance of a toilet with a drain pipe goes well with the toilet, which takes on the appearance of a complete plumbing fixture. However, it must be taken into account that when installing a toilet using vent pipes there are a number of requirements:

- they cannot be pruned;

- their geometric shape cannot be changed.

- Corrugated cuff . It is easy to install, since the part can be extended in length and bent at any angle. However, it is necessary to take into account that the resulting connection has the least strength among the possible options and quickly becomes unusable.

- Eccentric cuff . The parts can be rotated around an axis, compensating for the deviation from the alignment of the connected plastic pipes. The strength of the resulting unit is lower than that of a connection with a fan pipe, but higher than that of a connection through a corrugated collar.

Elements for connecting the toilet: corrugation, eccentric collar, plastic outlet

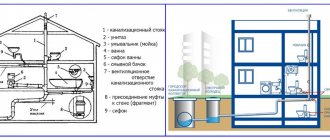

Fan pipe for toilet

According to the building regulations in force today, the process of constructing a sewerage system for a one-story house can be carried out without a drain pipe. This is due to the insignificant amount of one-time drains.

If the building consists of two or more floors or the housing is equipped with several bathrooms, then in order to ensure stable pressure in the sewerage system, it is necessary to include a drain pipe in the scheme.

This element connects the riser to the atmosphere, maintaining stable atmospheric pressure even in the event of a volumetric release of water from the toilet tank, which provokes a vacuum in the outlet line.

If there are several toilet rooms in a residential area, then the situation changes radically and a vent pipe installed on the toilet is a vital necessity. This rule applies in the following cases:

- the house has 2 or more levels, which are equipped with a sewer system and water supply;

- cross-sectional diameter of the sewer riser - 50 mm;

- there is a swimming pool or other equipment inside the building that discharges a significant amount of waste into the sewer system;

- The septic tank is located close to the house, which can cause a rather unpleasant odor.

In the above cases, vacuum without a drain pipe can lead to the rapid emptying of siphons under the toilet or sink, which will ensure direct contact of the “atmosphere” of the septic tank with the microclimate of the room.

Thus, the installation of a fan product in the sewer system ensures stable pressure in the outlet pipeline and preserves the integrity of water drains in siphons under special drain openings that cut off the unpleasant aroma of septic tanks from the home microclimate.

The construction of a sewerage and ventilation system with waste pipes is rational in the following cases:

- when installing a sewer riser in a private house with a diameter of 50 mm;

- if the house has two or more floors, each of which has bathrooms;

- in a private house there are hydraulic structures, for example, a swimming pool, generating powerful water flows;

- An autonomous sewerage system is located next to the residential building.

Typically, a toilet is installed on a sewer pipe with a typical diameter of 110 mm. The cross-section of the drain hole in the tank is 70 mm. As a rule, a pipeline with a diameter of 50 mm is connected to the bathroom.

It is connected to a riser with a siphon cross-section of no more than 110 mm. It follows from this that when one bath or toilet is operating, the internal diameter of the riser will not be completely blocked.

A washbasin, sink, dishwasher or washing machine connected to the sewer system is not capable of significantly changing the volume of water drained at a time.

One-time waste when using the above equipment is insignificant, therefore they cannot radically affect the situation. In these cases, the drain pipe is mounted to the toilet at the request of the property owner.

When installing a sewer pipe, it is necessary that the diameter of the product must be greater than the diameter of the riser on which the sewer pipe is mounted (regardless of the material used in the manufacture of the pipe).

It should end 40-50 cm from the edge of the roof ridge, so unpleasant odors will be quickly released into the atmosphere. The system outlet must be located outside the residential area.

More precisely, the drain pipe for the plumbing fixture (toilet) should extend beyond the bathroom and stretch through the attic to the roof of the building. Otherwise, the foul odors from your septic tank will permeate your living space.

Diameter of sewer pipe for toilet

The difference between the diameters is due to two reasons:

- when the toilet is flushed, a large volume of water passes through the plumbing fixture;

- Solid fractions and objects that can clog the pipe if it has a small cross-sectional size often get into the toilet.

But in this case, the question arises why the diameter of the drain pipes in bathrooms is small, but a significant volume of waste flows through them when they are emptied. This feature is explained simply.

The fact is that the permeability of the sewer pipe corresponds to this parameter at its narrowest point, and this is the bathtub outlet. Its sewer pipe diameter is minimal, and it is covered with a special grill. Therefore, there is no point in using large cross-section products in the bathroom.

If you install a bidet next to the toilet, then the diameter should still not exceed 100 millimeters, since the simultaneous operation of two plumbing fixtures, if it happens, is extremely rare.

Large-diameter pipes for toilets are installed not only because of the need to pass solids. The fact is that there should be a small gap left in them for air.

To understand why such a large diameter of a toilet pipe is needed, one should imagine a closed system in which wastewater moves at speed, completely occupying the entire internal space.

In this case, the displaced air in all outlets will be under very high pressure. It will squeeze out the water seals in plumbing fixtures, which will cause a lot of trouble for property owners. There will be a terrible smell in the bathroom and there is a high probability that you will have to wash the walls and ceiling of feces.

SNiP 2.04.01-85 describes methods for calculating the diameters of pipes for sewerage in an apartment. They are complex; they take into account the slope of the pipeline on horizontal sections of the main line, the angle of connection of the terminals with the riser and other nuances.

The same documentation contains tables that provide the ability to calculate the maximum permeability of pipe products at a certain diameter size.

As practice shows:

- To install the entire sewer system in houses and apartments with the optimal amount of plumbing equipment, a product with a cross-section of 100 millimeters will be sufficient.

- The diameter of the sewer pipe for sinks, bathtubs and other appliances should be half that size.

- If engineering communications are laid in an apartment building, then the diameter of the sewer riser pipe in five-story buildings should be 100 millimeters, and in buildings with more floors - no more than 150 millimeters.

- Common to a large number of apartments, the horizontal sections of the sewer system, which combine several risers and access to the sewer, can be approximately 200 millimeters in diameter.

- The diameter of a cast iron sewer pipe in an apartment or private household begins to decrease after a certain time due to the fouling of the inner surface by various types of deposits.

- The diameters of plumbing plastic pipes never decrease, since their inner surface is smooth and almost does not collect fat deposits. They also do not silt, sand does not collect in them, provided that they are provided with a sufficient slope and there are no irregularities inside the products

Some useful installation tips

To increase the service life of plastic fittings, following a number of rules:

- The sleeve must correspond to the dimensions of the toilet and waste pipe. For a non-standard type of device location, use an adapter with an offset of up to 200 mm.

- You cannot rotate a reinforced part at an angle of 90⁰.

- If the accordion is strongly pinched, the drain will not be effective, and the fittings may burst. To bend the element, it is necessary to connect 2 corrugated pipes.

- Such fittings are not intended for heavy loads, and the connector cannot be installed in the walls. It is also prohibited to use it as a channel for hot water.

Pull out the corrugation before connecting it to the sewer system. Otherwise, the sleeve will sag and a cavity will appear in which deposits will begin to accumulate. Clamps or supports will prevent rupture of the pipe shell. They can also be used when installing the adapter at a distance from the floor.

You should take care of the safety of the corrugation when installing a protective panel for masking communications in the toilet yourself, since a heavy object can damage it.

Necessary tool

When connecting the toilet with your own hands you will need:

- perforator;

- Bulgarian;

- electric drill;

- hammer;

- screwdriver;

- scissors;

- chisel (chisel);

- hacksaw;

- trowel (trowel);

- pliers;

- gas key;

- Adjustable wrench;

- sandpaper;

- file;

- paint brush;

- metal ruler;

- roulette;

- construction level.