The drainage system plays an important role in any type of building. The principle of rainwater drainage is clearer than daylight - it is responsible for the redistribution and removal of precipitation , which is presented in a liquid state or has become so.

The objects protected by the drain are the façade, foundation, and roof.

The functioning scheme of a sloping place is based on the location of funnels (the number will be determined by the individual characteristics of the project), which “receive” liquid precipitation and, through appropriate pipes with or without contours, transport water to the place designated for drainage.

Definition and purpose

The drainage system is an important element of a country house.

Without it, all precipitation flows directly into the yard and creates inconvenience when moving. If you do not install gutters to drain water, it will begin to flood the foundation, which will lead to its destruction. These are additional costs for repairs and restoration of the home, which are sometimes more expensive than the drain itself. You can do without a gutter if the roof is pitched, that is, precipitation falling on it is diverted to the back of the house and does not cause significant damage to the walls. If the distance from the supporting structures is large enough, then gutters are not needed at all.

Basic designs of drainage systems

There are three types of drainage systems.

Semicircular gutters in the form of a pipe cut in half carry water very efficiently.

Their open, trough-like shape makes them prone to clogging with leaves and debris, which is the reason many homeowners choose to install security guards. Additionally, their curved sides mean they don't sit flush with the bezels, so brackets are usually required to hold them in place. Semicircular gutters are not particularly decorative.

"K" style gutters somewhat resemble the letter "K" when viewed from the side.

This is the most common type for homes built in the last 50 years, although many owners of older homes still install them today. Thanks to the flat back of the K-shaped gutter, you can nail it directly to the fascia board without using staples. But what really makes Type K gutters so popular is their typically decorative face, which generally resembles a cornice. With a flat bottom and straight, outward-sloping sides, K-type gutters can generally carry more water than half-round gutters, making them especially suitable for rainy climates. On the downside, K-design gutters are a little more difficult to clean than half-round gutters because the inside corners collect rotting debris.

Custom gutters have a sleek, modern look.

Unlike K-type gutters or half-round gutters, fascia gutters are not sold in sections that fit together, leaving seams that are prone to rust and leaks. Instead, exterior gutters are made specifically for the home from one long piece of aluminum. Fascia gutters are expensive and should be installed professionally. You can pay twice as much for them as half-circle gutters or K-style gutters that you can install yourself.

Gutter installation

The drainage system consists of catch basins located around the perimeter of the building into which water flows from the roof. Next, it is directed into funnels connected to drainpipes. The lower end is directed into the ditches or storm drain grate. The structure is mounted under the roof in such a way that water falls directly into the gutter without overflowing from it - there are special installation rules and calculations for this. Additional consumables – brackets and screws.

Depending on the amount of precipitation in a given region, gutters of various capacities are used, as well as pipes of larger or smaller diameter.

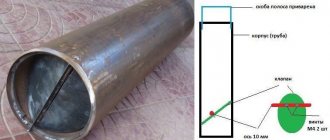

The design can be factory-made, one-piece - with corner parts or plugs so that the water does not leak out and all is directed into the sewer. Homemade gutters are simpler: a gutter collects water from the roof and drains it into the corners of the building. This is a less effective method, as it leads to waterlogging of the soil. In rural areas, rainfall is collected in large barrels and used to water the garden or flower beds. In private country houses, rainwater drainage systems are specially installed to store water.

Gutter structures are distinguished according to the material they are made of. There is a small selection here:

- metal - copper, aluminum, galvanized steel, ordinary painted steel;

- plastic - PVC or other types of polymer materials.

For any material, it is necessary to select reliable fasteners in the required quantity so that the drain does not sag. This is especially important in winter when ice forms.

Typical roof drainage system

Different manufacturers offer a standard set of drainage system elements. They may differ in size, material of manufacture and appearance. The system consists of horizontal gutters installed under the edge of the roof covering, and downpipes connected to the gutters by drainage funnels.

Perpendicular elements are joined together by funnels. In addition to them, the catchment complex includes: plugs, connectors, tees, fasteners, corner elements, elbow and mark

The composition of the system is configured depending on the configuration of the drainage system.

Gutter and connecting elements for it

A semicircular gutter is a tray for collecting and discharging precipitation from the roof. The cross-section of the gutter is an open semicircular or angular shape. The design is selected to match the architecture of the building. The tray size must match the expected load. The latter in turn depends on the roof area.

Gutter rotations are used to change the drain line. The standard angle is 90°, but there are also products with a parameter of 135°.

When installing a turn, follow the following rules:

- the joints of corners and gutters must be sealed with adhesive or rubber seals;

- the distance from the ends of the turn to the brackets should be no more than 10-15 cm - in these places the strength of the system is lower.

The gutter connector is a semicircular strip with clamps and latches. The element is used to join gutters into a single line. To seal the joint, a rubber seal is required.

The standard gutter length is 3 m. Some manufacturers offer products with a standard size of 3-4 m. When calculating the system, it is necessary to select the length so that the number of joints is minimal

Mounting brackets . The choice of a specific model depends on the drainage installation technology, the location of the main elements and the stage of repair/construction.

Possible options for hook brackets:

- Long . Used to fix the drainage system to the roof covering. The elements are attached to the rafters, as a rule, even before the installation of the sheathing.

- Short . Suitable for installing gutters on a building wall or front board. Hooks can be installed before the roof covering is placed or after the roof has been installed.

- Universal . Prefabricated elements used before or after laying roofing material. The length of the universal hooks can be adjusted.

The plug is installed at the end of the gutter. For reliable fixation, latches are provided, and a rubber gasket is provided to increase the tightness of the connection. The design is, as a rule, universal - the plug is suitable for the right and left edges of the tray.

Elements of the outlet pipeline

The drainage funnel is suitable for areas where it is not possible to install a conventional drainage system. It is applicable for roof valleys with complex architectural shapes. A drain pipe is directly connected to the drainage funnel.

Outlet funnel. The element is installed under the tray. The funnel redirects the flow of water into a vertical pipe. Depending on the location, there are pass-through, left or right elements

An elbow is an element that is necessary to change the direction of the drainage riser, i.e. pipe bypass near the architectural protrusions of the building.

The drain pipe is intended for arranging a vertical waste pipeline. The diameter of the element is selected based on the water flow, the typical length is 3 m.

A tee is necessary to connect several gutters to one vertical riser. Using a tee reduces material consumption and improves the façade appearance

The mark is a bent tip. It is mounted at the bottom of the drainpipe to drain water from the foundation and base of the building.

Pipe holders are clamps for attaching vertical pipes to the wall. Holders are made of plastic and metal. Fasteners must be able to withstand the load on the drain riser and be less noticeable.

Manufacturing materials

Aluminum construction

There are offers on the market for installing factory-made gutters. If you have experience and tools, you can make and strengthen gutters for draining water from the roof with your own hands. The difference is in cost. The cheapest materials are considered to be plastic - most often polyvinyl chloride. Metal systems are more expensive, and the most expensive material is copper. It is also the most bulky, so when arranging a copper drain, the method of fastening and the quality of the walls come to the fore.

Particularly durable structures are made from titanium alloys, but their price exceeds the budget level, so they are installed less frequently.

Aluminum

Metal gutters made of aluminum are highly resistant to temperature changes. The material bends easily and does not corrode. Service life more than 80 years.

There are disadvantages:

- low coefficient of elasticity – unstable to mechanical damage;

- expands when heated, so joints are made with a gap so that the entire system does not deform;

- the cost is higher than that of plastic or galvanized steel;

- During installation, it is necessary to insulate all materials that are in contact with aluminum due to high electrochemical corrosion.

The material is lightweight and does not violate the integrity of the walls.

Cink Steel

One of the most popular materials for the manufacture of drainage systems. This is due to its flexibility, thanks to which it is possible to make designs of varying complexity.

When using a galvanized gutter without additional coating with polymers or coloring compounds, its service life is just over 10 years, therefore, when making structural elements yourself, they are first cut out and then covered with a protective layer.

If the drain is installed after the construction of the house, it is made of lightweight materials to reduce the load on the fastenings and walls. Galvanized steel is well suited for this situation because it is lightweight.

Polyvinyl chloride

PVC is a polymer that can be painted in different colors, so it can easily be matched to the overall design of the facade. A homemade structure can be made by cutting a pipe of the required diameter and attaching it to the gutters. It will take longer, but will be cheaper.

You need to keep in mind that PVC becomes brittle in the cold. To prevent water from stagnating, a drainage slope is made inside - one-sided or two-sided. Thermal expansion may cause changes in size, so it is necessary to make gaps between the joints to prevent cracks from forming in the heat.

In general, the material is durable and impact-resistant, and can withstand up to 50 years if used properly - this is comparable to the service life of metal structures. During heavy rainfalls, water passes through the drain silently, and the inner surface does not have to be cleaned of organic film. The advantage is in weight - the design does not place excessive load on the facade.

Metal with polymer coating

Galvanized steel or aluminum with a polymer coating look attractive in appearance and come in a variety of colors. The layer of protective material serves as additional protection against corrosion, so it must be handled with care during installation. The slightest scratch or chip will shorten the service life, since in this place the metal will begin to rust and leak.

Cink Steel

PVC

Metal with polymer

Copper drain - pros and cons

Copper gutter system

Gutter systems made from copper sheets are the most durable and reliable because the seamless production technology allows for one-piece gutters that are not prone to breaks or cracks.

The material is not susceptible to harmful environmental influences. The maximum that can appear on the plates is patina, but buyers order it specially, as it gives the effect of antiquity to copper products. Several shades of patina can be created artificially.

A heating cable can be connected to the copper gutter so that icicles do not form in winter and snow does not accumulate. Copper can be soldered, so mechanically damaged areas are repaired or replaced. The service life of a copper roof and gutters is up to 150 years.

Copper gutters are made round or rectangular - it depends on the design and style of the facade. The softness and plasticity of the material allows it to be made into products of any shape, as well as used for decoration.

There are 2 standard sizes of copper drainage system - small and large. In the first case, the width of the gutter is 125 cm, the pipe is 90 mm. In the second, the gutter is 150 mm, the pipe is 100 mm.

The only drawback is the heavy weight. This requires the installation of additional fastenings for the drainpipe and reinforced fastening of the gutter to the roof elements.

Additional materials on the topic

Gutters for flat roofs

More details

Aquasystem drainage systems

More details

How to make a round roof

More details

Your feedback, comments, questions

Dear visitors! We will periodically answer your questions in the comments as we are busy. In order for us to respond to you promptly (within an hour), you can: call, write a personal message or leave a request for a free consultation by phone.

Gutter sizes

Using a homemade method, you can make a gutter of any size from galvanized steel sheets, based on the area of the roof, its slope and the maximum amount of precipitation falling in a given region.

The greater the roof slope, the higher the downward speed of water will be, so the gutter is made deep and mounted in such a way that the edge of the gutter overlaps the edge of the roof by 2 cm.

The volume of the gutter should correspond to the amount of precipitation that falls during the rainiest time of the year.

If you are making a drainage system from plastic pipes, select a certain diameter and cut it in half so that each half fits the calculated volume.

Weir installation technology

The exact set of necessary tools depends on the material of the gutters.

In any case, you will need:

- perforator;

- screwdriver;

- level, plumb;

- tape measure, pencil, cord;

- pliers;

- ladder;

- hammer, mallet.

The sequence of work for installing a drainage system can be divided into three main stages.

Correct installation of brackets

When installing brackets, the order of work is as follows:

- Marks are made at the corners of the slopes, indicating the locations of the outer brackets.

- The first bracket is fixed to the front board.

- An extreme hook is installed on the back side of the load-bearing base, maintaining the required slope - 3-5 mm per 1 m.

- A cord is pulled between the brackets and intermediate elements are placed along the line.

After placing the hooks, the rope must be removed.

The edges of the roof covering should overlap the gutter by no more than 1/3 of its width. This arrangement will ensure that the flowing water accurately enters the tray

Attaching the gutter system

It is better to start installation from the place where the vertical drain will be connected. You need to make a hole in the gutter for the funnel using a hacksaw, and trim the edges. You can install an adapter between horizontal and vertical elements using connectors.

Following actions:

- Place a plug on the outer tray.

- Place the gutters one by one in the brackets, maintaining overlaps of 5-10 cm between the elements.

To ensure better sealing, rubberized connectors should be placed on the joints.

Installation of vertical risers

The installation of risers begins with the installation of clamps. To do this, a vertical line is plumbed down from the funnel and marked on the wall.

It is imperative to provide clamps near the junction of the drainpipes; the maximum distance to the fastenings is 10 cm.

It is advisable to first assemble a vertical riser on the ground, and then fix it in the fastening system

Next, additional elements are mounted, vertical and horizontal bends are connected to each other, and the lower mark is set. In regions with heavy winter precipitation, it is advisable to equip the drainage system with a heating circuit; instructions for installing it are set out in the article we recommend.

Installation stages

Installation of a gutter

The implementation of plastic drainage systems occurs according to the following scheme:

- Blanks of the required length are made. The edges of the plastic are cleaned.

- The brackets are fastened in increments of 90 cm along the perimeter of the roof, taking into account the angle of inclination in the desired direction - towards the drainpipe.

- Connecting parts for gutters are installed taking into account linear expansion. Funnels are drilled.

- The gutter is placed on brackets and strengthened. In the places of the funnels, glue or rubber seals are used. Plugs are needed to prevent water from draining in places where drainpipes are not provided. They are installed taking into account the thermal expansion of the material.

- Drainpipes are connected to funnels and attached to the wall. If the pipe length is more than 8 meters, the fastening spacing is 90 cm.

- The end of the drain pipe is directed into the storm drain grate. If there is no such thing, then the end is extended to remove precipitation outside the pedestrian zone, and at the end, using a candle or blowtorch, a “tear drop” is made so that the water flows in the right direction.

When arranging a metal drain with your own hands, do not use a grinder, as it destroys the protective coating. All work on cutting parts is performed using metal scissors.

The heating cable can be laid in two ways - along the lower edge of the roof and inside the gutters. This maintains a positive temperature and prevents ice from forming.

Installation

Fastening the gutter can be carried out by specialists, but this work can be easily done with your own hands. Installation is carried out according to the manufacturer's instructions. In some cases, production is carried out to order, then it is necessary to develop drawings in advance according to which the system will be connected.

Let's look at how to install Murol gutters step by step, taking into account SNiP standards:

- Special hooks are used for fastening, the installation of which determines the success of the entire work. To correctly install metal or plastic gutters, you need to choose the diameter of the bracket (pipe holder) required. It should be slightly larger than the circumference of the gutter, but not so much that the guide is freely located in it. Hooks are installed in increments of no more than 90 centimeters (according to GOST 7623-75);

- When installing gutters, the overall angle of inclination of the system is taken into account; the dimensions are taken from the directory, but on average the slope is 2 millimeters per linear meter. In some cases, a larger angle is required, check this information based on the type of roof;

- The entire drainage system consists of receiving funnels, guides that drain water, filters and rotating elements (elbow, tee and others). Funnels are installed first after the hooks. They need to be installed based on the type of drain (there are external and built-in). Also, the installation of intake holes depends on the slope and area of the roof. For example, if the roof has an area of up to 10 meters, then only one funnel is installed at the corner of the house, if more, then 2 or more;

- In some cases, trays must be mounted in the middle of the system. Then the plastic or metal is cut, and ebbs are installed in the hole; Photo - installation of a drainage funnel

- For pipes, it is necessary to provide plugs that will close it from leakage. For round ones they are selected round, for square ones - square, etc.;

- In most cases, wall gutters need to be secured using pipe locks, after pre-treating the joints with sealant. They allow you to quickly connect all components of the system to each other;

- In vertical sections, installation is carried out using clamps. They are attached to the wall, and then the main line is installed in them;

- Often, the installation of gutters requires additional manufacturing of rotating elements; their installation will help save drainage area. Elbows and tees will help distribute the drainage along the roof and ensure the most efficient operation of the system;

- Afterwards, the technology is completed by installing the final element - the finishing bend.

Photo - step-by-step installation with photos

Serious maintenance of the system is not required, but it is necessary to regularly flush the pipes to prevent them from silting. This can also be done by cleaning the drain with a broom twice a year. The best way to protect drains from dirt and leaves is to use grates, as in the photo.

Photo - grill

Video: instructions for installing gutters

Cost of products

The cheapest are considered to be structures that are made by hand from aluminum, galvanized steel, and plastic. The price of plastic gutters depends on the amount of material used and the complexity of the system, the number of brackets and wall mounts.

Factory models made of metal with a polymer coating are more expensive - they are made to order, taking into account the size of the buyer.

The most expensive are copper gutters. They are not available for free sale, since the price of the entire system is too high, and the sizes differ in each specific case.

Comparison of common materials for drainage systems

Wood, which was once a common material for gutter construction, is susceptible to rot and weathering. So while you may still see wood gutters in very old, historically significant areas, today's gutters are typically made of aluminum, vinyl, zinc, steel, or copper.

Here's a comparison of the five materials.

Aluminum is the most popular material for gutters, both with and without seams.

Aluminum gutters come in three standard thicknesses: 0.025 inches, 0.027 inches, and 0.032 inches. While the thinnest aluminum is the least expensive, it can also dent or bend; Thicker metal is a little more expensive, but overall it's worth it, especially if you live in an area with heavy snowfall in the winter.

PROS:

- Does not rust

- Lightweight and easy to install

- Available in many colors and can also be painted

- All weather

- Service life up to 25 years

MINUSES:

- May wrinkle or bend

Methods for further drainage

Once the water from the roof has been collected and directed vertically, there are several ways to use or remove the water from the area:

- Water is drained from the roof into a tank or other container for further watering. The tank is located from the wall of the house at a distance of 1 to 5 meters, sometimes the container is installed buried in the ground.

- Sometimes wastewater from the roof is directed into a well with organized water filtration. Crushed stone is usually used as a filter. Water passing through a stone filter is gradually purified. Such wells should be no closer than two meters from the house, since heavy rains or heavy melting of snow will cause the groundwater level near the house to rise.

- It is possible to provide for the drainage of rain and melt water into the general sewer system. For public sewerage, coordination with the relevant services is required, which will set additional charges.

- Since rainwater is classified as clean, a drainage system can be installed to direct the flow into the nearest body of water.

Types of drainage systems

If the drainage on the site is carried out according to all the rules and its characteristics provide for an increase in water flow, then it is possible to direct rain runoff into such a system. But sometimes the drainage is shallow and its purpose is to improve soil characteristics, then with full precipitation from the sky, such a ditch will overflow.

To protect the basement and foundation from unorganized rain flows, you should install your own drainage system. There are many ways to drain stormwater away from your home, but there are three most common ones.

Surface drainage system

It works on the principle of urban storm drainage. To do this, after a small penetration into the ground, rain trays are laid using a trench method, which provide for a gradual decrease in level. They are covered with grates on top to trap debris. The length of such structures and their dimensional characteristics are calculated taking into account the expected level of precipitation in this area.

Deep drainage system

Deep drainage is the most common method of water disposal. To do this, make a trench with an initial depth of about 80 cm, then lay a sewer pipe, which is installed on a crushed stone backfill and covered with soil.

Vertical drainage

It is carried out in the form of a system of several wells , circulation in which is ensured using a deep drainage pump. This ensures complete pumping of all water flows; this type of drainage is rarely done, as it requires serious costs and special knowledge.

In conclusion, it should be said that it is imperative to drain rainfall and melt water If you do not do such work and install drainage gutters with pipes, you will have to repair the facade and make a new blind area every two to three years. This threatens to cost even more than installing a drainage system and simple drainage. If it is not possible to arrange drainage from the roof due to the characteristic features of the roof, then you need to arrange it so that the edge overhangs protrude from the wall of the house at a distance of at least 0.5 m, and extend beyond the blind area, water from them should fall on the ground.