Sewage wells are an integral part of the wastewater disposal system. With proper installation and the use of modern materials, you can expect that the structure will last for several decades and will maintain its performance throughout the entire period of operation. However, in some cases there comes a time when repair work needs to be done. Let's consider the reasons for the malfunction of sewer wells, methods of repair work and many other points.

Plastic and reinforced concrete wells: which ones cause more problems and why?

The most common types of wells are plastic and reinforced concrete. The modern version is plastic, which has recently been installed everywhere. Their high popularity is primarily due to the fact that the structure lasts for several decades and does not require repair work. There are many more problems with reinforced concrete structures, which is associated with the prefabrication of the structure, the presence of seams and individual structural elements.

Plastic and reinforced concrete wells are part of the sewer system, which allows you to audit, control and operate the sewer system.

Over time, the quality of concrete can change significantly, cracks and various other defects appear on the surface. Waterproofing is also affected.

Common problems

What problems do well owners face on their property? Among the first complaints you can hear is that the quality of the water has deteriorated, and its level has become lower than the original one.

Some owners prefer not to pay attention to the existing problem, thinking that the solution will come by itself.

This point of view leads to aggravation of the situation and a subsequent increase in the costs of repair work. What should alert the owner of a well and become an incentive to call specialists?

The main signs of impending problems may include:

- Muddy water. It indicates an increased amount of bottom sediments.

- Subsidence of the land around the well location.

- Floods occurring in the autumn-spring period.

Ivan Pokrovsky

Your well master

Order a well repair

“Describe what happened to the source. I will call you back at a convenient time, we will clarify the details and coordinate the arrival time of the specialists.”

Order in 1 minute

it will only take a couple of minutes

Main structural elements of a sewer well

First, you should pay attention to what structural elements the sewer well has. The main ones can be called:

- Working tank.

- Mine.

- Neck.

- Bottom.

- Inspection hatch.

Also, in the case of using reinforced concrete rings, a layer of waterproofing is created, which can be represented by tape or waterproofing plastic materials. In the case of a plastic well, almost all structural elements are one design due to seamless production.

This image shows the parts of a sewer well: Manhole - cover - concrete ring - bottom (base) of the well.

Reports from completed objects

- Complex repairs: converting a well into a well November 28, 2018

- Well repair: restoring the tightness of the shaft June 02, 2018

- A selection of repair work on several wells Spring 2018

- Guarantee of the quality of our services

- Sample contract for well services

- Areas where we work

Main problems with reinforced concrete wells

The main problems that may arise with a well made of reinforced concrete rings include the following:

- Horizontal displacement of the rings is observed in case of violation of the installation technology. Pressure from the soil, groundwater, as well as failure to maintain the level when installing the first ring can cause the integrity of the structure to be compromised. Horizontal displacement can lead to the fact that the waterproofing qualities are significantly reduced. Regulating rings, covers, cast iron kits and many other elements can also move.

- There is a small chance that the base material, which is concrete, will be destroyed. In addition, the ladder and brackets may be destroyed, which begin to become corroded.

- In addition, the waterproofing may be significantly destroyed, as a result of which sewage will enter the environment. Insulation can be destroyed for a variety of reasons, for example, due to displacement of rings or violation of installation technology.

Horizontal displacement of the rings, destruction of seams and the integrity of concrete can lead to a violation of the well’s tightness and the release of sewage into the environment.

All of these problems can significantly reduce the efficiency of the sewer system.

Materials for well repair

To ensure reliable sealing of seams or cracks in rings, waterproofing like a hydroseal from different manufacturers or a PSB mixture with liquid glass is used. P. The prepared solution or ready-made mixture is applied from the inside manually. If there is strong exposure to groundwater, it is advisable to coat the seams on the outside, but this applies to new buildings. The peculiarity of the material is its fast setting time; the hardening process lasts from 60 seconds to 15 minutes. Sealing strong leaks in a well can be problymatic, even with the use of waterproofing.

Horizontal displacement of rings and other structural elements: ways to solve the problem

Horizontal displacement of the rings can cause many problems. In such a case, there is a possibility of a leak. The ways to solve the problem are as follows:

- First, you need to clean the system of impurities, for which a sewage disposal truck is ordered. After pumping out all the impurities, the walls should be cleaned of dirt and plaque, which can be done by supplying hot water under pressure.

- Once the tank has been emptied and cleaned, the structural condition can be assessed. The degree of ring mixing is determined by a conventional measuring instrument.

- The next step is to remove the soil from the outside of the tank, since otherwise it will not be possible to move the ring back.

- There are several methods for reversing the ring. The most common method is to disassemble the structure down to the problem ring. When performing such work, the staples should be cut off, after which the insulation should be dismantled.

- After dismantling work is completed, the reason why the displacement occurred should be determined. As a rule, it consists of incorrect placement of the first ring or poor fastening of them.

Before carrying out repair work on sealing reinforced concrete wells, it is necessary to carry out sewage cleaning work to clean up sewage.

Important! After determining the cause of the problem, the correct installation of the rings and waterproofing of the seams are carried out. In the same way, problems with incorrect installation of other structural elements are solved.

Types of breakdowns

All possible causes of problems can be grouped as follows: 1. Unfavorable geophysical conditions - individual landscape features of a particular area can provoke the formation of voids between the outer walls of concrete rings and the soil. Loose masses of soil begin to form in them, which with their movement provoke the formation of failures. 2. Mechanical damage to the shaft structure - such changes are expressed in the violation of the sealing of the seams between the well rings, their displacement, which cannot but affect the quality of drinking water. 3. Seasonal changes - severe frosts, which provoke rupture of the seam between the annular blocks, abundant sweating of subsoil waters, which lead to landslides. Such damage is accompanied by a lot of problems with water quality and the intensity of filling the well. In order to bring the structure into proper condition in a short time, the specialists of our company recommend purchasing a repair service.

Destruction of sewer well material

There is a high probability of destruction of the basic materials from which the sewer well is created. Even concrete can be seriously damaged. The ways to solve problems are as follows:

- If metal brackets or stairs are damaged, the problem can only be solved by completely replacing them. In order to reduce costs when creating a sewer well, ferrous metal is used, which is highly susceptible to high humidity. Over 5-10 years, corrosion can damage the structure and reduce the strength of the material. You can replace the main elements yourself.

- Concrete is also susceptible to environmental influences. This is manifested by the fact that various cracks and high roughness may appear on the surface. Cracks become the reason for moisture to enter the environment; roughness leads to a significant complication of the surface cleaning process. Concrete can be restored by using cement mortar to cover the damaged surface.

- Waterproofing is damaged quite often. There are many ways to solve problems. There are many reasons for damage to insulation: mechanical, chemical, thermal effects.

Reinforced concrete is subject to corrosive wear; moisture penetrates into the pores and cracks of the concrete, eroding it and leading to the destruction of the iron structure.

From the above list of possible problems, waterproofing violation should be highlighted. It occurs extremely often and can cause many problems. That is why we will pay more attention to this problem.

Wooden wells and their repair

A well is called a wooden well, the shaft of which is a log house. The problem for such a structure most often becomes premature damage to individual crowns that need to be replaced.

Sometimes during a routine inspection it turns out that almost all the crowns are affected by rot. In this case, no cleaning of the logs and their subsequent processing will help; you will have to re-lay them.

The main problem of wooden wells is premature damage to one or more frame crowns. If necessary, they can be replaced with new ones

How to properly replace the frame of a wooden well?

If a decision is made to completely replace the frame of a wooden structure, we carry out the work in the following sequence.

Stage No. 1 - pumping water out of the mine

First you need to completely pump out the water from the well, using any suitable pump. It should be noted that pumping will have to be carried out constantly, because the water will flow continuously. After the structure has been drained, further work can begin.

Stage No. 2 – repairing damaged crowns

The lower crowns of the structure, which was assembled according to all the rules, must stand on special strong supports. They need to be carefully removed, which is usually not difficult. They are most often badly damaged and can be taken out one by one, carefully helping yourself with a crowbar.

As practice shows, a well frame does not “react” to this operation in any way, since years of operation have made it almost monolithic.

After this, we begin to carefully disassemble the frame from below. We lift the logs up. If it suddenly seems that some elements are well preserved and can still serve, we still dismantle them and raise them to the surface. We subsequently use them when installing a new log house.

After all the parts have been raised to the surface, we clean the mine from crumbled soil and remove the worn-out bottom filter. Then we seal its walls with a wide board to prevent crumbling.

To dismantle the old log house, you will have to dismantle the house above the well, after which you can begin dismantling the structure. Work is carried out from below the last crown inside the well

Stage No. 3 – assembling a new log house

The material from which it will be assembled should be taken care of in advance. For a log house, you should not use conifers, which release bitterness from resins into the water. It is optimal to choose moisture-resistant ash or oak. The latter must be stained, that is, it has undergone special treatment. It involves placing logs in running water for at least a year.

During this time, all tannins and other undesirable substances will be washed out of the wood, and the material will be better prepared for long-term contact with water. Oak logs treated in this way and dried are ideal for lining a well.

Working with a log house is similar to building a log house. All structural elements are folded in the required way, numbered and disassembled for subsequent installation.

The quality of the work performed is very important. Untidy gaps are simply unacceptable. Soil from the mine walls will definitely get into them, because you can’t caulk the log house.

The peculiarity of a well log house is that the lower part is cut without leaving any residue. If you make the upper part of the structure with it, you will get a traditional Russian version of arranging wells.

The above-ground part of the well frame should be larger than the underground part. This is quite simple to do: all the elements are extended onto the tree trunk and chopped “into a bowl”

Stage No. 4 – we put the crowns in the well

At least two people are required for the job. One will be at the bottom, the second at the top - for safety. A new bottom filter is poured into the bottom of the well. Then we put new supports-bars on it, on which we will lay the frame.

We assemble the first crown at the top and, having secured it with temporary boards, we carefully lower it into the shaft. We lower it onto supports. We assemble the next crown and lower it in the same way.

But it will already settle on the walls. Gently tap it so that the earth does not fall off the walls. In this way we raise the frame to the surface of the earth.

We immediately remove all dirt that has fallen to the bottom of the well: clay, construction waste, soil. Otherwise, our bottom filter, even before it begins its work, will be clogged with a plug made from mud trampled underfoot. After the mine reaches the surface, its dimensions change.

It should become wider. This is quite simple to do: all the elements are extended onto the tree trunk, and the structure is cut into a bowl. Thus, we bring the shaft to a height of about 1.5 m, maybe more if there are kids in the house.

The above-ground part can be fastened with metal dowels or staples. This is unacceptable for underground. Our well is almost ready, all that remains is to arrange its above-ground part to your liking.

Before replacing damaged log crowns, the logs lying above them should be securely fastened. With this design, the elements are “suspended” on trestles, which allows all the necessary work to be carried out

Replacing logs in the frame of a wooden structure

If the damage is not so global, repairing your wooden well will be easier. You can get by by replacing a few parts inside the log house. We carry out the work as follows.

If the damaged elements are below the water level, install a pump and pump out the water. Then we proceed to strengthening that part of the frame that is located directly above the destroyed logs.

For this purpose we install a special device. We install trestles on both sides above the well head. We lay four short logs on them. We fix two strong long boards on them, which we lower into the log house.

We nail crowns to them with long nails, located above the damaged elements. In this way, we seem to “hang” the remaining part of the log house.

Alternatively, instead of long boards, you can take strong ropes with hooks and secure the logs with them. After the strengthening has been carried out, carefully remove the damaged logs and lift them to the surface.

Guided by their size and shape, we prepare a new part to be inserted into the frame. It must be admitted that this is quite difficult to do, since the new log must be covered by the groove of the old upper part.

First, carefully cut down the lower part of the old log located below, so that it is on the same level with the groove. Then we take the prepared log, put it in place and carefully hammer it in with a wooden hammer.

Then we jam it securely. Instead of logs, you can use concrete elements cast to the dimensions of the old part. This significantly increases the efficiency of the repairs carried out.

After proper repair of a log house, a wooden well will last a long time. You can also update its house above the well, decorate it with interesting decor

Damaged elements of the above-water part of the log house can be repaired by concreting using sliding formwork. Before starting repair work, we prepare a site on which the worker will be located. The easiest way is to knock it down from strong boards.

The dimensions of the structure must be such that it fits freely inside the shaft. We hang the platform on cables on a beam lying on the head of the well and lower it into the shaft.

We attach the reinforcing mesh to the wall above the damaged area and install the sliding formwork. Prepare a cement mortar with fine filler and pour the mixture into the resulting gap.

After the composition has hardened, we will obtain reinforced cement, which is almost as strong as concrete. Upon completion of repair work, the well must be disinfected.

Ways to solve problems with waterproofing

Waterproofing is responsible for preventing waste from entering the environment. There are a variety of options for waterproofing materials. Ways to solve problems with its damage are as follows:

- Using a mixture that is created by combining gasoline and bitumen of a third grade no lower. It can be used to waterproof the resulting seams. The special properties of the resulting mixture determine that it is securely attached to the base.

- Also, high grade cement with various impurities can be used as an insulating substance. It is fed using a special gun, after which the excess is removed from the surface with a spatula.

- If the structure of the sewer well is to be dismantled, then special waterproofing tapes made of rubber can be used. The rubber layer significantly increases the waterproofing qualities of the prefabricated structure.

The bitumen mixture is an excellent waterproofing agent that will protect the well from the influence of external destructive factors.

In general, we can say that there are quite a lot of ways to solve the problem of violation of the waterproofing of seams formed by individual rings of the structure.

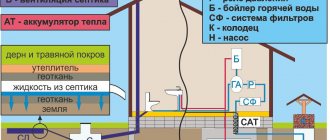

Distance from septic tank

The distance from the house to the septic tank according to the standards and unambiguous requirements of sanitation is a necessary parameter developed in the era of state standardization and ongoing scientific research on sanitation and hygiene. Sanitary standards and regulations do not allow making a septic tank closer than the prescribed minimum distance.

At the summer cottage

Violation of them is fraught not only with a fine from the sanitary inspection that monitors compliance with SanPiN, but also with liability under a special article of the Code of Administrative Offences.

However, in this case, the desire to remove it at a considerable distance from the residential building brings inconvenience to the residents. The erroneous principle “the further the better” in this case makes a person feel uncomfortable in case of an emergency or bad weather outside

The rules for installing a septic tank are not among the easily resolved problems, since this issue is given priority attention

In the countryside

SanPiN considers the norm for removing a structure as a variable figure; in some sources it ranges from 5 to 10 m. The upper permissible distance is provided for simple devices without a bottom or homemade ones, which may have flaws in design and construction.

It is possible to install a septic tank at a minimum distance, provided that the system operates using modern technologies and complies with the standards for a specific type of building - SNT or individual housing construction.

The difference in requirements, according to the new law of 2021, for a garden plot is its almost always minimum dimensions, while on residential plots there may be ranges that allow you to safely choose a location even according to the stated standards. From the moment the law comes into force, treatment facilities and their location on the site will depend not only on the status of the building, country house (and now garden) or residential.

In stock

It is necessary to take into account

The fundamental difference lies in the requirements for the capacity of the septic tank and its arrangement system. Because according to the requirements of SanPiN 2.2.1/2.1.1.1200-03, permanent or seasonal residence, the number of people living in the house and the approximate amount of waste produced per day should be taken into account. It is known to depend on the number of residents and their temporary or permanent residence.

Standard distances from the septic tank according to SNiP and SanPiN

Failure to observe even the minimum distance from the septic tank is fraught with various consequences:

- According to existing rules, an outdated or incorrectly located structure should be located no closer than 5 meters from the house, because leakage can lead to destruction of the foundation.

- The distance from the external sewer depends on the type and diameter of the pipes used - otherwise they may be gradually destroyed by caustic excrement and rotting sewage.

- The optimal distance of 4 meters from the trees to the septic tank is associated with possible risks due to the growth of a powerful root system, which large trees are prone to. For the same reasons, a similar distance from them to the house and well is maintained.

- The distance standards from a residential building can be significantly reduced if the developer has the opportunity to install a safe Topas septic tank. You can also purchase another version of the system that does not require cleaning with a sewer machine, otherwise the odors and insects attracted by them will be in close proximity to the house.

Minimum distance from the septic tank on a summer cottage according to SNiP and SanPiN standards

The installation of a septic tank at the proper distance is regulated not only by sanitary standards. In 1999, Law of the Russian Federation No. 52-FZ “On the sanitary and epidemiological welfare of the population” was adopted.

The Code of Administrative Offenses has a special article providing for administrative and financial liability for creating an epidemiological threat and violating environmental safety standards.

But the decision on the illegality of installing a septic tank is made based on a set of requirements - the type of soil, the type of device, its manufacturability and the cleaning method used. Each option is considered separately.

Layout of buildings on individual housing construction and SNT sites in accordance with SNiP standards

Violation of the integrity of the plastic well

There are much fewer problems with plastic wells due to the fact that the structure does not have seams. However, violation of recommendations for operation or installation work can cause cracks and other problems to appear. The problem with the degree of waterproofing in this case can be solved by using a special sealant. On sale you can find sealant versions on a wide variety of bases; it is important to choose the most suitable version.

Each sealant has its own instructions for use, which should be read before insulating the surface. As practice shows, if the sealant is used correctly, the structure will have the necessary insulating qualities.

Improper installation and violation of operating conditions can lead to thinning of the walls of the plastic well, the appearance of cracks that lead to leakage into the external environment.

Customer questions about repairs

My well shaft is crooked, can this be fixed?

If, when digging a well, rings without locks were used, or were not installed level, the shaft may be bent. Whether it is possible or impossible to fix, this question can only be answered unequivocally by seeing the condition of the structure, but in most cases it is impossible to do. In such cases, it is recommended to install brackets to strengthen the shaft and prevent further movement of the rings.

I am not in the Moscow region, but in the Vladimir region, is it possible for me to order your services?

We are ready to service wells not only in the Moscow region and the Moscow region, but also in neighboring territories. To clarify the details of cooperation, contact our specialist using the online chat, write to us by email or call us by phone +7 (915) 238-777-2.

The lower rings of my well have cracks and even part of the concrete wall has fallen to the bottom, what can be done in this case?

In this situation, a complete diagnosis of the well is required, with a technician descending into the shaft and visually inspecting the problem. Perhaps the shaft is so twisted that it will not be possible to repair the well, which could lead to the construction of a new one. If the curvature is not large, and the wall can be restored, the solution would be to repair the concrete ring, install brackets, and waterproof the seams.

The water has become cloudy and dirty, will repairs help?

You can probably get by with regular cleaning. In 90% of cases, the water becomes cloudy due to leaking seams, there is contamination at the bottom when the old layer of the bottom filter is washed away and silt, sand or dirt forms at the bottom of the hydraulic structure.

Signs of problems with the sewer well

There are several signs that indicate problems with your sewer line. The main points include the following:

- The appearance of an unpleasant odor.

- The appearance of an odor emanating from the water.

- Cloudiness of drinking water.

- Poor vegetation growth on site.

- The appearance of blockages.

Also, a visual inspection may indicate a problem with the alignment of the rings.

Cloudy water is one of the signs of problems with the sewer well.

How do you know if repairs are needed?

The first sign of the need for repairs is changes in the taste and appearance of the water. This may be cloudiness, the appearance of sediment, an atypical smell and taste. All these are signals that processes of rotting and decomposition are occurring inside, or as a result of depressurization, sewage water is entering the well. You should also not ignore visual signs that repairs are needed. Obvious mechanical damage: chips, breaks, obvious ground failures. You should not fix them yourself - the work may involve life-threatening manipulations, which will be promptly, quickly and professionally carried out by our company’s specialists immediately after you order the mine repair.

Ordering a structure restoration service

As previously noted, restoration work can be done by hand or this service can be ordered from a company that specializes in providing it. The features of the services provided include the following:

- First, you should choose a company that will perform the work of restoring the sewer well.

- After ordering the service, the company’s specialists will leave at the specified time to inspect the system.

- After assessing the condition of the sewer well, restoration work is carried out. Depending on the condition of the structure, it may take different times to resolve the problem. In some cases, the work may take several days.

You can carry out repair work yourself or call a special company. The quality of repair work will affect the further operation of the wells.

If you do the work yourself, it may take several days. In this case, problems may arise with the choice of material.

Why does a well need to be repaired?

Constant use of a well in a suburban area entails the accumulation of experience and immediate monitoring of emerging problems. Some owners try to fix problems on their own. But this requires knowledge, the availability of industrial equipment and tools, practical experience and a reliable partner.

If you don’t want to delve into the nuances and buy equipment or lack the necessary experience, the best solution would be to turn to well specialists.

To ensure that the repair of wells takes as long as possible, we recommend that you take care in advance of easy access for workers to the structure. This can be achieved if you first make sure that the house can be easily removed. Otherwise, additional time will be required to dismantle the external structure.

- Guarantee for well repair work

- We use high-quality consumables

- Responsible and experienced craftsmen

Experts warn owners against such rash decisions as:

- Ignoring problems encountered in the operation of the source.

- Postponing repairs to a later date.

- Attempts to independently troubleshoot the well.

- Excessive savings. Choosing a company specializing in servicing wells made of concrete rings, offering prices in the Moscow region much lower than market prices, leads to irreversible consequences. Low qualifications of personnel and lack of experience will lead to aggravation of the situation.

1 year warranty on all types of well repairs. Sealing current seams, correcting displacements of shaft rings, soil subsidence and other work.

Experts' opinion

A reinforced concrete well can cause quite a lot of problems. You can carry out waterproofing yourself, but in this case it will take a lot of time. It is also worth considering that periodic work needs to be carried out at intervals of several years.

Victor.

Repairing reinforced concrete wells can cause quite a lot of problems. Our company specializes in performing various works related to the maintenance and restoration of the sewer system. Please note that only if the work is carried out professionally, you can count on a long service life of the structure.

Igor.

I expected that the plastic well would not cause many problems, but after a few years problems appeared, which were manifested by the appearance of an odor in the drinking water. After pumping out the sewage, it turned out that the well was not sealed. Apparently the integrity was damaged during transportation.

Dmitriy.

Cost of services

In 80% of cases, we announce the cost of work over the phone before visiting the site.

Prices are fixed, regardless of the circumstances, the cost will not increase significantly during the work process.

| Type of work | Price |

| Comprehensive repair, shaft up to 10 rings | 14,000 rubles |

| Comprehensive repair, shaft over 10 rings | 15,000 rubles |

| Dismantling and installation of a rental house | for free |

| Ring Alignment | from 2500 rubles per ring |

| Sealing current joints with cement mortar | 1500 rubles per ring |

| Sealing current seams with aquastop solution / hydroseal | 2500 rubles per ring |

| Installing a pebble bottom filter | 3000 rubles |

| Installing staples | 1,000 rubles per ring |

| Clay castle | 6000 rubles |

* - when ordering a comprehensive repair of a source.

** - Repairing widespread damage, leveling reinforced concrete rings with a jack up to the 3rd ring on top by no more than 15 centimeters. Repair of the lower detached ring is possible with a gap of up to 10 centimeters.

Prices for all services

Construction of different types of sewer wells

The sewerage system has a very ancient history, so its design and technology have been brought to a very high quality state. This article will discuss the main issues related to the use of sewer wells in the sewerage system.

The regulatory act regulating the requirements for sewer wells and the procedure for their installation is SNiP 2.04.03-85 “Sewerage. External networks and structures." The document displays all the factors relating to sewer wells, including their location, classification, dimensions and operational characteristics.

To install a sewer system on a private property, it is necessary to use inspection wells, placing them on the section of the pipeline between the building and the wastewater receiver. In addition, one of the possible options for disposing of wastewater after it has passed through a septic tank is a filter sewer well. Inspection wells must be installed not only in private households, but also on local sewer systems. The installation site must be located behind the so-called red building line, which is a conditional boundary dividing the target area into certain segments. SNiP states that sewer wells must be installed every 35 meters if the pipeline diameter is up to 150 mm, or every 50 meters for a pipeline with a cross-section of 200 mm.

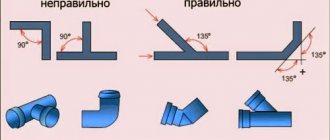

In addition, inspection wells are installed if the system contains:

- turns and bends;

- changes in pipe diameter or slope;

- branches of the structure.

Requirements for the operational characteristics of reinforced concrete wells are reflected in GOST 2080-90, and for polymer wells - in GOST-R No. 0260760. Most plastic structures are also supplied with manufacturer’s instructions, which outline the conditions for using the well.

Brick, concrete or reinforced concrete are used to make stone sewer wells, and rubble stone is used to create filter wells. Polymer wells can be made of polyvinyl chloride, polypropylene or polyethylene. In addition to structures made from a single material, there are structures on the market made from compounds of various resources.

According to SNiP, the dimensions of sewer wells vary as follows:

- when using pipelines with a diameter of up to 150 mm - at least 700 mm;

- up to 600 mm – 1000 mm;

- up to 700 mm – 1250 mm;

- from 800 to 1000 mm – 1500 mm;

- from 1200 – 2000 mm;

- from 1500 mm with a system laying depth of 3 m.

The volume of the structure is not indicated anywhere, but knowing the initial depth and diameter, you can calculate this indicator yourself.

The order of actions will look like this:

first, the exact location on the site where the well will be located is determined; then the selected area is cleared of any plants (bushes, trees, etc.); if necessary, buildings located on the construction site are demolished or moved; It is very important to ensure unobstructed access to the site.

Next, the preparation of the pit for the sewer well begins.

As a rule, a pit is created according to the following principle:

- first of all, a hole of the required dimensions is dug;

- then the bottom is cleaned;

- a check must be made to ensure compliance with the laying depth of the structure and the slope angles of the pit walls;

- in the case of stone structures, a 20-cm waterproofing layer must be laid at the bottom of the pit, compacting it as tightly as possible.

Two types of well pipe repairs

In order to determine the list of works for partial repair of the components of the well, an estimate must be drawn up; its content depends on the type of malfunction.

Do not forget that if one problem is not eliminated in time, it will lead to other, more serious ones.

The main goal of partial pipe repair is to restore the functionality of the system as a whole.

To do this you may need:

Well pipe repair

- pumping and cleaning the well;

- replacement of inlet, outlet or ventilation pipes.

When it comes to major repairs of structural components, you also cannot do without an estimate, but the list of works is slightly different:

Complete replacement of a sewer well

- the functioning of the system completely stops;

- then all components are changed (hatch, tray, neck, pipes, etc.);

- During repairs, plugs are installed where necessary.

Upon completion of the repair work, the soil must be completely restored.

How to choose a good master for well repair in Moscow

If you decide to repair a well in Moscow, then contact us - a company of well experts with an impressive professional “baggage”. We guarantee an adequate price for such a service and excellent quality of work. By placing an order for the service, you receive:

- Favorable price;

- Completing repairs on time;

- Visit of specialists to diagnose problems with the well;

- Specialists without bad habits and with Russian citizenship;

- Taking into account the client's wishes.

To protect the well from destruction and guarantee the purity of the water, craftsmen scrape adjacent rings, coat the cracks with a cement mixture, carry out waterproofing and replace damaged elements. Upon completion of work, the inner surface of the well shaft is cleaned and disinfected.

Our master conducts a consultation over the phone and discusses a convenient date for a specialist to visit the site. We provide high-quality and durable repairs to drinking wells. Masters all the subtleties and features of cleaning wells.

Installation of reinforced concrete rings for a storage well

To build a sewer well with your own hands, first of all, you need to “plant” the first ring of the shaft on an M100 grade solution. This is followed by:

- Make holes for sewer pipes. They must fit into the shaft ring at least 100-150 mm;

- The gaps between the pipes and the wall of the reinforced concrete ring should be sealed with cement mortar;

- Now at the bottom of the well you need to make a concrete trench, the diameter of which would correspond to the internal diameter of the sewer pipe;

- Then a second one is installed on the first casing ring so that their locking connections are located at the same level;

- The subsequent casing rings are installed in a similar manner;

- At the final stage, a lid with a hatch is installed to protect the tank from the accumulation of precipitation.

Increasing the water level in the well

Insufficient water levels can make it difficult to lift liquid to the surface, whether this operation is performed manually or using pumping equipment. There are two reasons for the decrease in level:

- incorrectly selected source location,

- insufficient mine depth.

In the first case, most likely, the error will be noticeable immediately, and the only solution will be to move the well to a new location.

Before moving the well, you can try increasing its depth.

- If the structure is no more than six months old, the structure can be lowered by removing soil from under the lower part of the structure. Excavation work should be carried out until a sufficient number of keys appear. After the well settles, its upper part is increased to the required height.

- Repairing an old well with your own hands when the water level drops is carried out in a similar way, but it is necessary to narrow the structure (use concrete rings of a smaller diameter, change the parameters of the brickwork, etc.).

Why does the seal of the fastening seams fail?

The first danger for any well is soil movement. They occur due to the movement of soil and groundwater, periodically changing their intensity and level. A lot of pressure is exerted on the walls of the shaft outside the well, and they, not being a monolithic structure, begin to shift relative to each other. This primarily results in cracking of the putty at the joints of the rings, and sometimes cracking in the area where the rings are held together with steel ties. Such ground movements are not capable of completely bending the shaft - they are too weak, but they can completely break the tightness.

The second factor is the use of low-quality materials. Poor-quality putty materials do not withstand emerging loads well, and can completely crumble out of the seam after just a few years. This leads to cloudy water in the well and requires immediate repair.

Types of inspection wells and the permissible distance between them

Observation

Installed for free access and maintenance of the system. The distance between wells is indicated in the table.

| Pipe section (mm) | Distance between wells (m) |

| 150 | 35 |

| 200-450 | 50 |

| 500-600 | 75 |

| 700-900 | 100 |

| 1000-1400 | 150 |

| 1500-2000 | 200 |

| >2000 | 250-300 |

Rotary

Mounted in places where pipes form a turning angle

- The distance between wells is calculated along a straight section of the pipeline.

- The length of the segment is indicated in SNiP. If you do not meet the requirement, you will have to install an additional well.

Variable

Structures are necessary in areas with changes in the height of pipe laying

- SNiP has not established standards for the distance between these structures, but the following requirements are imposed:

- One difference cannot be more than 3 meters. If the slope is greater than this footage, then a stepped overflow system with wells is created.

- If the difference is 50 cm, the well can be replaced with an overflow

Nodal

Used at the junction of pipes. The distance depends on the diameter of the pipe.

| Diameter (mm) | · Distance (m) |

| · 600 | · 1 |

| · 700 | · 1,25 |

| · 800-1000 | · 1,5 |

| · 1200 | · 2 |

When arranging an external sewer line, it should be taken into account that the distance from the sewer to a source of drinking water must be at least 30 meters.

You can't break it - you can't restore it

Initial data: there is a well with good, according to local residents or former owners, water, which is in very poor condition. From the outside it looks like a noble count’s ruins, but only a psychic can tell offhand what’s going on inside. If everything else in the estate is satisfactory, you can safely plan its return to active use. The main rule: do this wisely, with arrangement and the involvement of a good well master.

Anyone who says that putting a well in order after a long time is easy is wrong. Full restoration is possible, you just need to put in the effort and stick to the plan so as not to damage the structure further or create life-threatening conditions.