Step 3. At this stage, a tray is installed in the sewer well (SNiP allows this and is even recommended). Otherwise it is called a gutter, which will be located from the entrance of the pipe to the exit. Its cross-section must correspond to the diameter of the pipes. The gutter can be made from part of a sewer pipe.

The technology for arranging sewer wells has been worked out to the smallest detail and documented. Construction regulations prescribe a basic series of regulations that the work carried out must comply with. In particular, SNiP has number 2.04.03-85 and is called “Sewerage. External networks and structures." The document regulates the location of different types of structures, the dimensions and requirements for the structures being erected. Regardless of the purpose, private or public use, the installation of sewer wells must be carried out in accordance with the rules and requirements. For example, an inspection object must be placed in front of the entrance of the local sewerage system to the centralized collector, outside the red building line. It is especially important to know that according to SNiP, inspection wells for pipelines with a pipeline size of up to 150 mm are installed every 35 m, and for 200 - every 50 m direct-flow sections of pipelines. In addition, installation of structures is indicated when:

- Rotary changes in the water drainage system;

- When the diameter of the pipeline changes or there is a slope;

- Where additional branches enter.

Documents regulating the requirements: for reinforced concrete products - GOST 2080-90, for polymer structures - GOST-R No. 0260760. Manufacturers offer specifications for plastic structures, supplementing existing regulations. Stone structures can be made of prefabricated, monolithic concrete, reinforced concrete mixtures, and bricks. The filter structures are made of rubble stone. For the manufacture of polymer structures, it is permissible to use polyvinyl chloride (PVC), polypropylene (PP), and polyethylene of the required density (PE).

Important! Models can be made from a combination of materials.

Let's consider the classic installation scheme for concrete drainage trays.

Brick sewer well

Brick construction includes:

- Base or bottom. Located on the same level with the passing highway.

- Walls.

- The tray is of an open type, made in the direction of flow in a smooth rotation.

- Floor slab.

- Luke.

- Wall brackets are designed to make pumps easier to clean and remove possible blockages.

Advice: In order for a person to freely descend and work there, the diameter of the device must be at least one meter.

The use of modern plastic products makes their construction and maintenance easier. They are produced as almost finished products with holes for the inlet and outlet of pipes, with a tray for drains. The instructions allow you to install prefabricated plastic structures very quickly, the material is environmentally friendly, durable, and the price of the finished structure will be quite reasonable.

How does a filtration well work?

After the septic tank, a well is installed in the sewer system, which serves to filter wastewater. Its main purpose is to receive wastewater after preliminary treatment, and then pass it through a layer of soil, in this case it acts as a filter. This water treatment element is most often installed when it is impossible to discharge wastewater into the central sewer system or underlying soils.

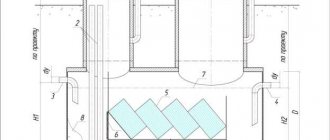

- 1 – hatch cover.

- 2 – exhaust pipe.

- 3 – neck body.

- 4 – cover for insulation.

- 5 – pipe for supply.

- 6 – gravel on the outside.

- 7 – body.

- 8 – shield.

- 9 – filter layer inside.

Advice: When planning the place where the filtration well will be installed, you need to take into account the distances to the buildings of the site and other wells from which drinking water is obtained (according to SNiP it should be no less than 10 and 30 meters, respectively).

The shape of the filtration structure can be very different, but when planning the construction of a sewer well from reinforced concrete rings, a foundation must be made along the perimeter of the base. The rings must have holes, through which the filtered moisture will flow out.

Construction of a sewer well from concrete rings. The internal part is filled with gravel, expanded clay, broken bricks and other material with a fraction size of 10 to 70 mm. The outer part along the entire perimeter is sprinkled with the same composition as the inner part, but not more than one meter. There should be a supply pipe approximately 15 cm above the filter layer.

Tip: To prevent the bottom filter from being washed out, you need to place a wooden shield under the stream of water, which is pre-treated with an antiseptic composition.

How does a storage well work?

This is the largest in size; it receives drainage from all domestic wastewater. Device Features:

- The device is most often installed within suburban areas, closer to its borders. This makes it possible for a sewer truck to approach conveniently.

- According to regulatory documents, a structure of this type must have a concrete bottom and waterproofed walls.

- The storage type is made from various materials.

- The construction of reinforced concrete sewer structures is influenced by the size of the rings and the estimated depth of their occurrence.

- A finished concrete slab is laid at the bottom of the pit. Using a crane, rings are placed on it.

- To improve the fixation of well rings, they are fastened together with special brackets.

- The entire structure is covered with a slab, in which there is a hole for a hatch.

Storage well covered with bitumen

- Internal joints are sealed with sand-cement mortar, and the outside of the structure is covered with bitumen, which eliminates possible leaks.

In manufacturing, you can use brick. Then:

- The bottom of the pit is filled with concrete.

- Round or rectangular walls are erected.

- The outside of the masonry is insulated with tar or roofing felt.

- On the well itself, a floor slab is made of concrete.

Brick storage well Storage containers made of fiberglass or plastic are becoming increasingly popular.

Storage wells made of plasticWhen installing such devices, no special equipment is needed:

- A container is lowered into the previously made hole.

- Adjustable in depth.

- Connects to sewer pipe.

- It is filled with soil with small stones, and the manhole cover must remain visible.

Advice: Regardless of the material used, all storage systems must be located at least 10 meters from the foundations of buildings. It is not recommended to plant trees near wells. You can plant a shrub that has a small root system.

How the construction of sewer wells is carried out can be clearly seen in the video. This article provides general recommendations for the construction of such structures.

To find the radius, you will need to take the square root of V/ (3.14 x L).

Peculiarities

Any drainage system must have a sewer well or chamber. Such equipment should be located at the entrance to the septic tank, which is located on a suburban area. Sewerage structures also have a different name - wet or drainage well.

An autonomous type sewer system is a complex standard design of an engineering system, the installation of which will require plumbing and construction knowledge. The key component of each autonomous sewer system is a special well.

The system should have several wells:

- observation;

- turning;

- well for household waste;

- well for rainwater.

The owner of a country property must understand the features and differences of each type of structure.

Features of the creation of sewer wells are described in the sanitary and technical standards of SNiP. The documents describe the location of wells, markings and the need for preliminary preparation.

Features of the arrangement according to SNiP are as follows:

- before work you need to decide where the well will be located;

- markings will be required on the ground;

- trees and bushes that interfere with construction work must be uprooted;

- easy passage of equipment must be ensured to the construction site;

- You will need to draw up a detailed diagram that is agreed upon with the water utility and neighbors.

The following technical requirements apply to sewer wells:

- inspection structures should be located in increments of 30-40 m if the hatch diameter is 15 cm, or 50 m if the diameter is 20 cm;

- at each pipeline bend, as well as at the branch pipe locations, rotary type wells should be located;

- in places where the diameter of the pipes changes or there is a sharp slope, the installation of a drop well will be required;

- there must be a minimum distance of 3 m between the storage well and the living space;

- the diameter of a modern sewer well can be 40-70 cm; auxiliary pipes can be used for the outlet.

Manufacturing materials

The following materials are used in production.

Polymer

Polymer wells are the most common variations of such devices. Some users use unconventional methods for their production, which involve the use of automobile rubber. This method is considered the simplest and least expensive. However, such a solution is not airtight and has a long service life.

Plastic

Plastic is the simplest and most durable raw material for constructing wells. There are ready-made polymer models on sale; you can also create such a structure with your own hands. This will require the use of a corrugated pipe and a plastic plate. Construction requires little investment along with certain skills. Advantages of plastic:

- small weight;

- high level of reliability and strength;

- replaceability of the bottom tray;

- all elements are sealed;

- You can order a container of any size.

Flaws:

- high price;

- specified placement depth;

- Often plastic is a non-separable product.

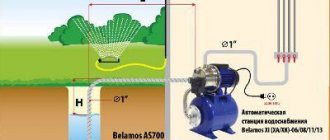

Collapsible models are endowed with versatility, since the depth can increase or decrease. Most often, plastic wells are used as rotary or inspection structures. However, due to their tightness, such structures can be used instead of a water collector. Liquid is pumped out using a pumping station.

Reinforced concrete

Reinforced concrete is a classic material for sewerage installations. Construction is made from concrete rings with further treatment of all joints with sealant. Such cesspools are highly functional. The advantages include the following criteria:

- universal characteristics;

- long service life, which exceeds 50 years;

- quick installation;

- high strength indicators;

- reliability of the material;

- affordable price category.

Flaws:

- large mass;

- installation will require the use of a winch and other special equipment.

Such tanks are often used as inspection structures when the pipeline is located at a significant depth. Thanks to high-quality sealing, concrete products can play the role of water collectors.

Here, too, it is not difficult to obtain an unknown quantity. For example, you need to find the height of a well.

Equipment process

Since reinforced concrete sewer wells are prefabricated structures, installation of such sewer wells requires installation and concrete work.

Well with a rectangular base and ceiling

Well ring with bottom

First, a base - a round or rectangular slab - is lowered into the prepared pit.

The size of the base is determined by the diameter of the rings used.

There are also rings in which the base is pre-made as a single unit with the product.

It is clear that such a part is used only as the bottom of a well.

This allows you to improve the waterproofing properties of the device.

The required height of the well is selected based on the standard sizes of the rings; for precise adjustment to the required dimensions, standard additional rings with a height of 10, 15, 20 and 30 cm are used.

However, when installing networks, they always try to reduce the number of parts to a minimum in order to simplify installation and avoid unnecessary seams - they do not benefit the tightness of the structure.

It is mandatory to waterproof sewer wells if groundwater occurs above the bottom of the well.

In this case, the level of the insulating layer must be at least 0.5 m higher than the primer level.

Since the well always provides for the passage of a larger or smaller number of pipeline branches, corresponding holes are punched in some of the rings (in the case of an inspection shaft - in the lower one, in the case of organizing a drop - maybe in others).

As a rule, this is done in advance, since doing them in a ring installed in a pit is not very convenient.

A sand cushion with a thickness of at least 100 mm must be installed under the base slab, and the horizontal position of the slab itself must be strictly verified.

If a reinforced concrete sewer inspection well is installed, a tray is made of cement in it according to the rules set out above.

All parts that make up the structure are also held together with cement. Since all components have mounting loops, if these embedded parts interfere with the installation of the following elements, they are bent or cut off.

Purpose of differential wells in the sewer system ↑

If there is a serious difference in height between the exit from the house and the end point of the sewer network, then the wastewater through the pipes will flow at a high speed. And the speed and mass of water is energy that can easily destroy everything in its path.

A well with a vertical drop is a guarantee of damping the speed of water flow. A drop well in a sewer system has to be installed when:

- it is necessary to reduce the flow rate;

- the sewer pipe has to be laid under or above existing utility lines with gas, water, etc.;

- the pipeline must be laid under the road;

- a well with a flooded outlet into a reservoir or septic tank is installed;

In all these cases, the level of water flow changes; from a height it drops sharply and accelerates. To prevent wastewater from causing harm to the elements of the sewer system with its increased energy, it is necessary to make a differential well with a water absorber.

Advice! According to construction standards, if sewer pipes have a cross-section of up to 600 mm and a height difference of up to 50 cm, you can dispense with draining into a regular inspection well.

The principle of operation of a typical differential chamber of an external sewer system. There are several types of differential well structures that differ structurally and functionally. The choice depends on the topography and characteristics of the soil on the site, as well as on the configuration and features of laying the sewer pipeline.

Internal structure of a sewer differential well ↑

Depending on the collected wastewater, the sewer system can be domestic, storm (rain) and industrial. But well structures with a flow difference have the same structure and design everywhere. A typical sewer well consists of:

- Support bottom.

- The working chamber is in the form of a vertical shaft.

- Necks.

- Covers with hatch.

The differential type of these structures is generally equipped in a similar way. Only in its working part there are bumpers or gentle overflows for extinguishing water. They are the main distinguishing element of such a device.

Types of structures with difference ↑

Differential wells for storm and domestic sewage systems are divided into four types according to their functions and structure:

- Shafts with inlet at the top and outlet at the bottom.

- Chambers with a water breaker in the form of a glass or pipe.

- Containers with one vertical or angled water absorber.

- Collectors with a multi-stage water trap system.

- Paired chambers with an overflow channel installed at an angle between them.

Schemes of wells with a difference According to SNiPs, the first option with a weir of a practical profile is allowed to be used only with differences in height up to three meters and pipe cross-sections up to 600 mm. In other situations, you will have to make a well with flow dampers. In some designs, water is extinguished at the bottom, while in others special bumpers are used. The last type stands apart, which involves accelerating the flow. It is installed specifically to increase the speed of the water flow in order to reduce the likelihood of pipe clogging. The following are used as building materials for wells with drops:

- reinforced concrete or concrete;

- polymers;

- brick;

- fiberglass.

The most expensive, but easiest to install, are factory-made fiberglass and plastic products. The cheapest way to make a well is from reinforced concrete rings, but installing them requires a crane. You can also pour such a structure with your own hands from concrete or lay it out of brick - simple, but labor-intensive.

Otherwise, with regard to the installation of the shaft, base, floors - the rules are the same as the previous ones.

Conclusion

As you can see, choosing and using a sewer well for its intended purpose is not at all difficult. The main thing is to correctly calculate the volume of the structure in accordance with the performance of the sewer system used.

You can find more useful and interesting information by watching the video in this article.

To service underground pipelines, inspection wells are installed for sewerage. With large branching and length of lines, they are also necessary in private properties.

For sewerage, an inspection well.

Dimensional rulers, work on arrangement of wells

According to SNiP, sewer wells must have the following dimensions:

- Pipelines with a diameter of up to 150 mm - at least 70 mm;

- Diameter up to 600 mm – from 1000 mm;

- Diameter size up to 700 mm – from 1250 mm;

- Diameter 800-100 mm – from 1500 mm;

- With a diameter of 1500 mm and above and a depth of 3 m and above are subject to individual consideration.

Volumes are not separately regulated; everything must be calculated from the depths and diameters specified on the diagrams. As for the work, the general cycle includes preparatory actions, installation and completion.

- Layout or marking of the territory, according to construction rules;

- Clearing the area of bushes and vegetation;

- Demolition/relocation of interfering buildings. The impossibility of action is stipulated by special standards;

- Preparation and arrangement of the entrance and road to the construction site.

Arrangement and installation of a standard sewerage structure, preparatory work according to SNiP:

- Excerpt from the pit;

- Cleaning the bottom;

- Reconciliation with the project in terms of ground level, wall slope angles;

- For stone structures, arrangement of a waterproofing bottom layer, as shown in the diagram or plan (layer of at least 20 cm), subsequent compaction.

All preparatory work has been completed and the next stage is installation.

Stone wells

The steps and actions are:

- Preparation of the base involves laying a slab or arranging a cushion of M-50 concrete 100 mm thick;

- Arrangement of a concrete tray reinforced with steel mesh (M-100) of the required shape;

- Sealing the end holes of the pipeline with concrete and bitumen;

- Creation of an insulating layer of the internal cavity of the rings of the structure;

- Installation of the rings occurs only after the tray has gained strength (2-3 days), then the floor slab is laid. The solution used for work is M-50;

- Sealing joints with cement mixture;

- Waterproofing with bitumen;

- Mandatory plastering of the tray with cement, followed by ironing;

- Installation of clay joints at the entry point of the pipe/pipes with a width of at least 300 mm and a height of 600 mm greater than the diameter of the pipeline.

Subsequent testing work takes place within 24 hours and includes complete filling of the structure with water with the pipeline being blocked with temporary plugs. If no leaks are detected, the well walls are backfilled, a blind area measuring 1.5 m is installed, the joints are insulated with a hot bitumen mixture - the work according to SNiP is completed, the system can be put into operation.

The installation schemes for brick structures are practically the same as concrete ones, but instead of aligning the rings, they are laid out with stone. Waterproofing work is completely identical. In this way, stone wells of any type of sewerage system are installed: domestic, industrial, stormwater or drainage. But each design has its own nuances:

- The storm drain is equipped with lattice hatches that have a drainage function;

- Drainage wells themselves are drainage systems, so installation does not require special calculations.

Differences in configuration are determined by the series:

- KFK/KDK - domestic wastewater;

- KLV/KLK – storm drain;

- KDV/KDN – drainage wells.

The size table gives a complete picture:

Drop wells

A more complex configuration determines the volumes and SNiP requirements for differential wells. In addition to arranging the tray, you need to do the following:

- Installation of risers;

- Have water pumping equipment;

- Install a water wall;

- Create a practical profile;

- Set up a pit.

Otherwise, with regard to the installation of the shaft, base, floors - the rules are the same as the previous ones.

Important! The exception is a riser drop well - it requires installation of a metal pipe at the base, which will prevent the destruction of the concrete structure.

The diagram looks like this:

- Riser pipe;

- Waterproof pillow;

- Metal base (plate);

- Receiving funnel (riser).

A funnel is required for compensatory discharge processes formed in the riser due to the rapid movement of flows. Do-it-yourself creation of drop-off wells in private areas is not recommended, unless it is a pipeline with a diameter of 60 cm and a level difference of up to 3 m, but such pipes are practically not used in individual systems, and are successfully replaced by other types of wells. SNiP requirements for drop-off wells are simple, installation is recommended in the following cases:

- It is necessary to significantly reduce the depth of the pipeline;

- If there are intersections with other underground utilities;

- Adjustment of wastewater flow rate is necessary;

- In the case where the well is the last one before the direct release of wastewater into a river or lake.

The same reasons can serve as a reasonable justification for installing a drop well on your own property.

The next stage is the transition to the construction of the mine. Wells made of concrete are assembled in a zero pit, where working elements have not yet been installed.

Choosing a site for construction

First of all, it is necessary to find the right place to build a water intake structure and determine its depth. If there are similar structures in neighboring areas, the task becomes easier. To do this, you should talk to your neighbors and find out the following information from them:

- What is the depth of the water intake structure on their site.

- What volume of water does it produce?

- When was it built?

- Features of its use.

When choosing a site for construction, you should be guided by the standard distances from SNiP 30-02-97. According to them, the following minimum distances are allowed between the well and other objects on the site:

- from the foundation of the house to the water intake structure the minimum permissible distance is 5 m;

- the minimum distance at which a well can be built from buildings for domestic animals is 4 m;

- to any outbuildings on the site – 1 m;

- trees must be at least 4 m away;

- a minimum of 1 m is set back from the bushes to the water intake structure;

- there must be at least 50 m from septic tanks and cesspools to the source of drinking water.

According to SNiP, there should be no cesspools above the water intake well.

Differential sewer well

It can be of five types:

- shaft bends are made up and down;

- in the form of a glass;

- with vertical water damper;

- multi-stage option;

- with corner overflow channel.

A brick sewer well includes:

- Bottom, with a single-level highway.

- Walls.

- Open tray.

- Floor slab.

- Safety hatch.

- And also wall brackets.

To carry out work and lower the operating personnel, the diameter of the device must be more than 1 meter.

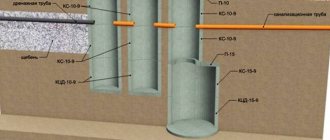

Installation from concrete rings

For more information about installing sewerage from concrete rings, see this article. Initially, a pit is dug according to the conditions of excavation for the pipeline. After completing the excavation work, the bedding is laid, which is formed from coarse or medium-fraction crushed stone. The thickness of the bedding is about 1500 mm. This element makes it possible to resist subsidence of the entire structure. After carrying out the above measures, a layer of hydraulic insulation is installed. It can be a roll or a sheet. The formwork for the tray is applied to the insulating layer. It is possible to install a ready-made slab. The next stage is the transition to the construction of the shaft. Wells made of concrete are assembled in a zero pit, where the working elements have not yet been installed. Watch video The rings are laid on cement screeds. Hatches are installed in ready-made holes. After complete assembly of the structure, the pit is filled with soil.

Requirements for installation of sewer structures

The installation is carried out in strict accordance with SNiP and is regulated by GOST No. 2080 90, which states that sharp turns of the system gasket should not be allowed. It is necessary to observe the angles of the inlet and outlet pipes.

- Working elements are made of fine-grained concrete in compliance with recommended standards.

- The tank must be equipped with reinforcing rods in order to evenly distribute the load and consist of reinforcing wire.

- Before installation, you need to prepare a working diagram and carry out preparatory work, which includes clearing the site and removing vegetation, including trees.

This is not a complete list of recommendations and working conditions, which are fully reflected in the relevant documents.

Plastic sewer inspection structures

Plastic products are becoming increasingly common. They are distinguished by ease of assembly and environmentally friendly materials used in the production of structures. Watch video It is important that plastic is a durable working material. The depth of a plastic sewer well can vary. Therefore, selecting the required design will not cause problems for the buyer. In addition, the cost of the complex is more attractive compared to a traditional concrete product.

Self-installation of viewing structures

Yes, this option is possible. But do-it-yourself installation is associated with certain costs and extensive preparatory work, which can hardly be completed on your own. Connecting the system to a private home may differ significantly from generally accepted principles. This may be due to the nature of the structure, the occurrence of groundwater and the structure of the work site. The principle of work is no different from industrial installation. There are many instructional videos on the Internet. There is enough technical literature. Therefore, there is no point in dwelling on this issue in detail.

Finally

To summarize, we can note the following. There are many designs of different types and purposes. The question of installation is based on the testimony of many services, and the optimal option is selected. Initially, paperwork will be completed: a drawing is created and the structure, which can be made from different materials, is installed according to it. Watch the video Note that in the private sector, ready-made options made from plastics. Self-installation of structures is allowed, subject to compliance with specifications and SNiP, taking into account existing GOSTs.

ORGANIZATION AND TECHNOLOGY OF WORK EXECUTION

1. Determine the location of the inspection well and prepare it for excavation work - clear the area, considering the access of equipment, if necessary.

2. Prepare a pit according to pre-made calculations.

3. Carry out waterproofing. To do this, gravel and crushed stone must be poured onto the bottom of the dug pit (Fig. 2), and a layer of bitumen must be poured on top.

Fig.2. Diagram of the inspection well

4. For a reinforced concrete inspection well, the bottom is filled with concrete (the tray is made using reinforcement). When the concrete dries (it will take about two weeks), you can install the rings.

5. Seal joints and gaps (Fig. 3).

Fig.3. Sealing joints and gaps

6. Insulate the pipe joints with the inspection well. Bitumen or concrete mortar is suitable for this.

7. Testing the well - temporarily filling it with water and leaving it for at least a day.

8. Fill the outside of the well with soil, compacting the soil tightly.

9. For the neck, you need to make a concrete blind area.

Ring prices

The pricing policy is determined by the market, and therefore in different regions the same product will cost differently, but everywhere its price is directly dependent on the size. And if for KS 7.3 you will have to pay from 700 rubles, then for KS 20.9 - already about 4.5 thousand rubles. Purchasing from the manufacturer provides savings of 5-15% compared to construction markets. But when drawing up an estimate, in addition to spending on rings, the customer must keep in mind other expenses:

- digging a foundation pit for a structure;

- for delivery of products;

- for installation work;

- construction of a well house (optional);

- for additional materials, for example, cement for sealing joints or pebbles for the filtration bottom of a well.

It makes sense to cooperate with one supplier. In many cases, this will bring additional benefits in the areas of service, delivery and information support.

What else do you need to buy?

In addition to the rings themselves, to install a water supply, sewerage or gas pipeline system, it is necessary to purchase additional elements, such as:

- bottom - the bottom slab will provide a solid foundation for the well;

- overlap - this element is designed to install a smaller ring on a larger one;

- additional product - it allows you to increase the height of the well with less weight.

Additional elements have a standard diameter, but smaller wall thickness, and can be used as upper components for a well, for example, a ring with a lid. Additional elements will help ensure the tightness of the structure and protect the pipes from freezing in the winter.